Understanding the Fire Pump Parts Diagram for Optimal Performance

In the realm of safety and prevention, the efficiency of water delivery systems plays a crucial role in mitigating potential hazards. A comprehensive grasp of the various elements that contribute to this infrastructure can significantly enhance operational readiness and effectiveness during critical situations. Analyzing these key components reveals not only their individual functions but also how they collaborate to ensure optimal performance.

Recognizing the intricacies of these systems is vital for professionals in the field. Each component, from the primary mechanism to the auxiliary fixtures, serves a specific purpose that collectively supports the overall functionality. By dissecting the layout and interaction of these elements, one can appreciate the engineering behind reliable water distribution strategies.

Moreover, familiarity with the structural makeup allows for better maintenance practices and informed decision-making in emergency scenarios. Understanding how each section contributes to the whole empowers operators to respond swiftly and effectively, ensuring safety for all. This exploration aims to provide insights into the essential building blocks of these critical systems.

Understanding Fire Pump Components

In any system designed for water movement and pressure maintenance, a thorough comprehension of its various elements is essential. Each component plays a vital role in ensuring efficiency and reliability, contributing to the overall performance and safety of the installation.

Key Elements of the System

The essential units include mechanisms for suction, discharge, and control, all of which work in unison. Understanding these functions allows operators to diagnose issues quickly and maintain optimal operation.

Importance of Quality Components

Durability and reliability are critical attributes of these components. Utilizing high-quality materials and designs can significantly enhance the longevity and effectiveness of the entire assembly, ultimately leading to improved safety outcomes.

Key Functions of Fire Pumps

Understanding the essential roles of these systems is crucial for effective safety management in various environments. They serve to ensure that water is readily available and efficiently delivered during emergencies, safeguarding lives and property.

Water Supply Management

One primary function is to maintain an adequate supply of water under pressure. This is vital for immediate response during critical situations. By delivering a powerful stream, they enable quick access to necessary resources.

Pressure Regulation

Another important aspect is pressure control. These systems must adapt to fluctuating demands while ensuring a consistent flow. This adaptability is key to successful operations, especially in high-stress scenarios where every second counts.

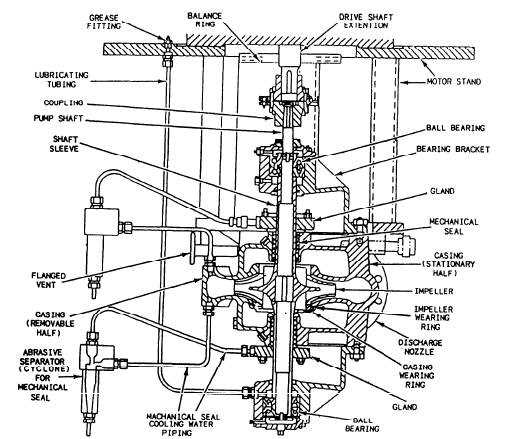

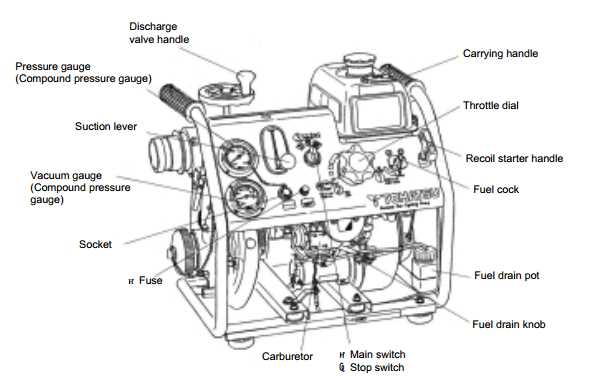

Essential Parts in Fire Pump Systems

The functionality of an effective suppression system relies on various critical components that work in harmony to ensure safety. Each element plays a pivotal role in maintaining performance and reliability during emergencies.

Engines serve as the powerhouse, driving the entire mechanism, while valves regulate the flow and pressure of the liquid, ensuring optimal delivery to the designated areas. The hoses act as conduits, transporting the fluid efficiently to where it’s needed most.

Controllers monitor and manage the operation, providing vital information and adjustments in real-time. Additionally, strainers and filters are essential for maintaining cleanliness, preventing debris from compromising the system’s integrity.

Understanding these elements allows for effective maintenance and enhances overall performance, ensuring readiness when the ultimate response is necessary.

Common Types of Fire Pumps

In the realm of emergency response systems, various types of equipment serve critical roles in safeguarding properties and lives. Understanding the distinctions among these systems is essential for effective planning and implementation in both residential and commercial settings.

| Type | Description |

|---|---|

| Electric Driven | Utilizes electricity for operation, ideal for stable environments with reliable power sources. |

| Diesel Driven | Operates on diesel fuel, often preferred for remote locations without direct electricity access. |

| Vertical Turbine | Designed for deep water sources, maximizing efficiency in extracting fluids. |

| Horizontal Split Case | Features a robust design, suitable for high-volume applications and easy maintenance. |

| End Suction | Compact and efficient, commonly used in smaller systems for quick response. |

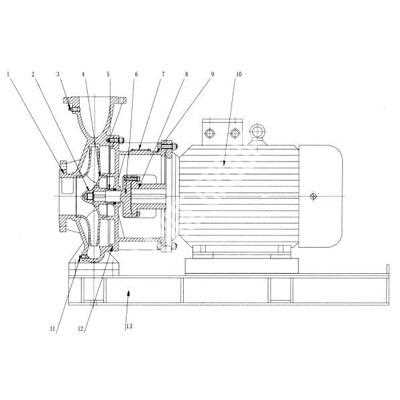

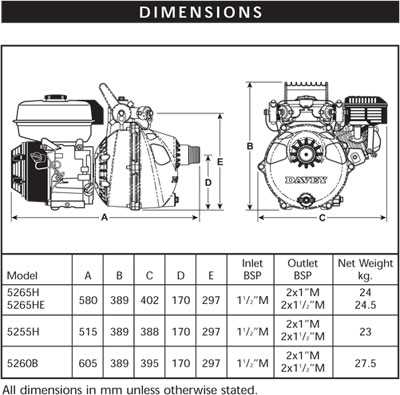

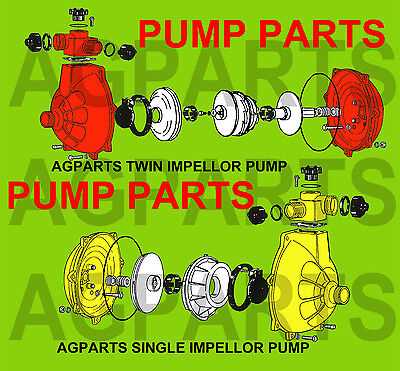

Components of a Fire Pump Diagram

This section provides a comprehensive overview of the essential elements that comprise a water delivery system used for emergency situations. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance when needed most.

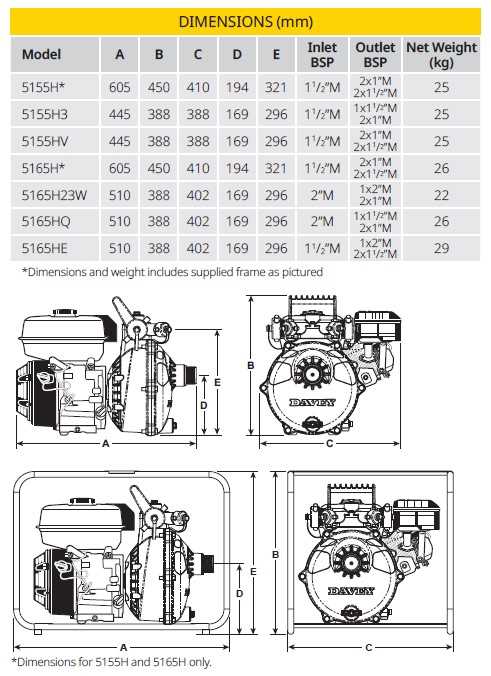

| Component | Description |

|---|---|

| Motor | The driving force that powers the mechanism, enabling fluid movement through the system. |

| Impeller | A rotating component that transfers energy to the liquid, increasing its velocity and pressure. |

| Volute | A casing that guides the fluid from the impeller to the discharge outlet, converting kinetic energy into pressure. |

| Inlet Strainer | A filtration device that prevents debris from entering the system, protecting internal components from damage. |

| Discharge Outlet | The exit point where the liquid is released into the system, directing flow to hoses or other delivery mechanisms. |

| Control Panel | The interface for monitoring and managing the operation of the entire system, ensuring safety and efficiency. |

Familiarity with these elements enhances the ability to troubleshoot and optimize the functionality of the entire system, thereby ensuring readiness for any emergency situation.

Importance of Maintenance in Fire Pumps

Regular upkeep is crucial for ensuring optimal performance and reliability of essential equipment. Neglecting this aspect can lead to severe consequences, particularly in emergency situations.

Here are key reasons why maintenance should not be overlooked:

- Safety Assurance: Consistent checks help prevent malfunctions, ensuring safety during critical times.

- Operational Efficiency: Well-maintained systems operate more effectively, reducing the risk of failure.

- Cost Savings: Preventive measures can avoid expensive repairs and replacements down the line.

- Compliance: Regular inspections help meet industry standards and regulations.

Investing time and resources into maintenance ultimately enhances the longevity and reliability of the equipment, safeguarding both lives and property.

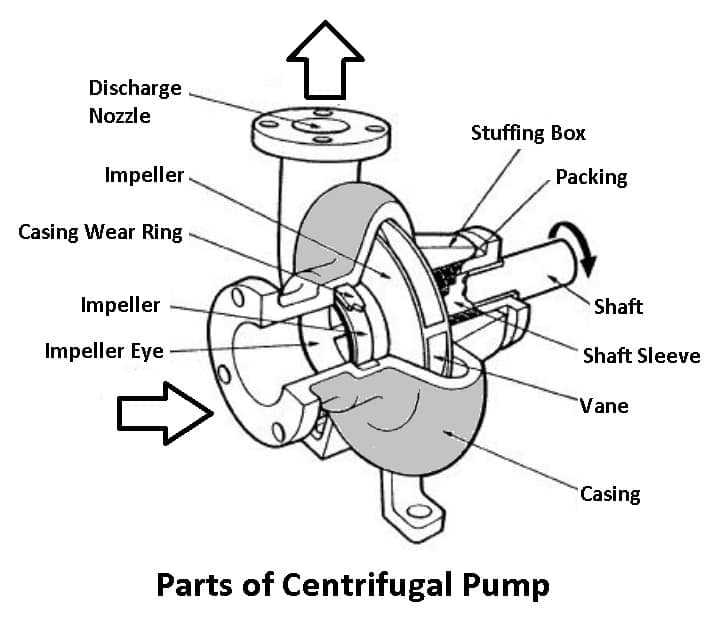

Fire Pump Operation Principles Explained

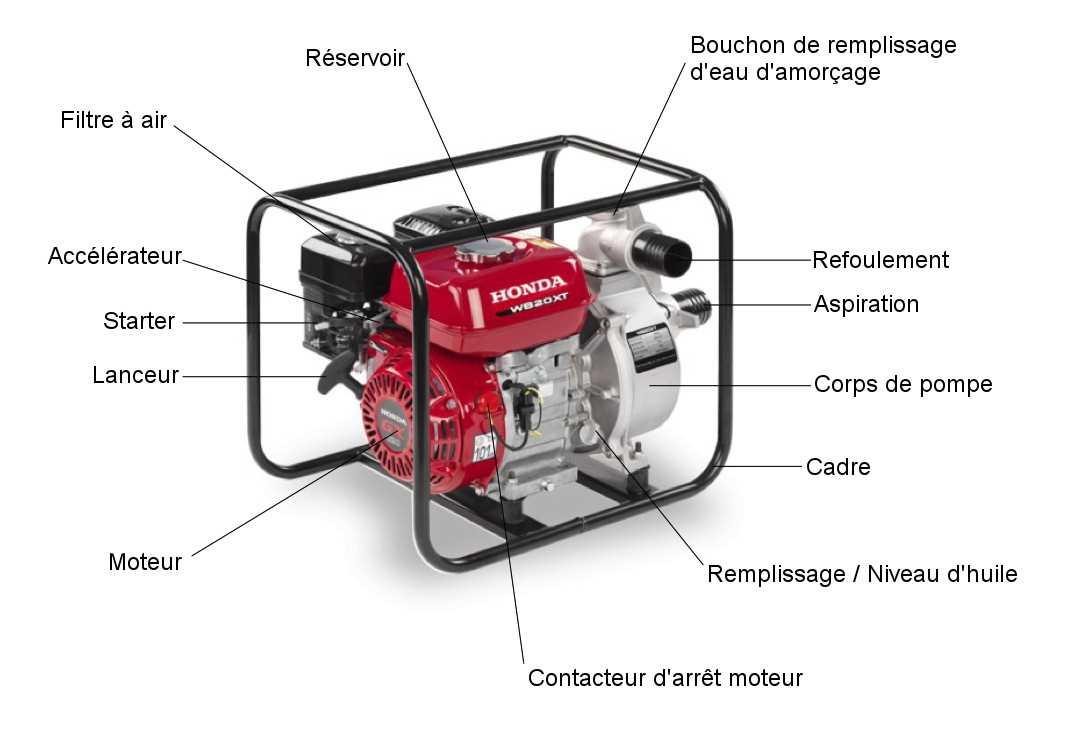

Understanding the mechanisms behind water propulsion systems is essential for effective application in emergency scenarios. These systems utilize principles of hydraulics and mechanics to ensure a steady and reliable flow under pressure, crucial for extinguishing flames and protecting property. By exploring how these devices function, we can appreciate their design and operational efficiency.

At the core of these systems lies the conversion of mechanical energy into hydraulic energy. This transformation occurs through a rotating element, which imparts kinetic energy to the water. As the fluid moves through various components, it is pressurized, enabling it to reach considerable heights and distances. This dynamic process is critical for effective distribution in firefighting efforts.

The configuration of the internal elements significantly influences the overall effectiveness. Key components, such as the impeller and casing, work in unison to maximize flow and minimize energy loss. Proper maintenance and understanding of these components ensure optimal performance, which is vital during emergencies when every second counts.

Moreover, the system’s ability to adapt to different scenarios highlights its versatility. Adjustments in flow rate and pressure can be made based on the specific requirements of the situation, allowing for tailored responses to various challenges encountered in the field. This adaptability underscores the importance of comprehensive training and knowledge for personnel operating these vital systems.

In summary, the successful operation of water delivery systems relies on a harmonious interplay of mechanical principles, component design, and adaptability. A deeper understanding of these fundamentals not only enhances operational efficiency but also ensures preparedness for any eventuality, ultimately contributing to effective emergency management.

Choosing the Right Fire Pump Parts

Selecting the appropriate components for your system is crucial for ensuring optimal performance and safety. A thorough understanding of the available options and their functionalities can significantly impact efficiency and longevity.

Considerations such as the environment in which the equipment will operate, the specific demands of your application, and the compatibility of different elements are essential. Research on various materials and designs will help you make informed decisions.

Moreover, consulting with professionals or referencing reliable sources can provide valuable insights into the ultimate choices that best suit your needs. Ensuring that each selection aligns with industry standards will contribute to the reliability of your overall system.

Signs of Wear in Fire Pump Components

Recognizing deterioration in essential equipment is crucial for maintaining operational efficiency and safety. Over time, various components may exhibit signs that indicate they are no longer functioning optimally. These indications can help in timely interventions and prevent significant failures.

Common symptoms of wear include unusual noises during operation, vibrations, or leaks around joints. Additionally, visible corrosion, discoloration, or surface degradation can signal that specific elements are approaching the end of their useful life. Monitoring performance metrics can also reveal deviations from normal operating conditions, suggesting potential issues that require attention.

Regular inspections play a vital role in identifying these signs early. Establishing a maintenance schedule ensures that wear is detected promptly, allowing for repairs or replacements before they lead to catastrophic failures. Ultimately, proactive measures can significantly enhance the longevity and reliability of the equipment.

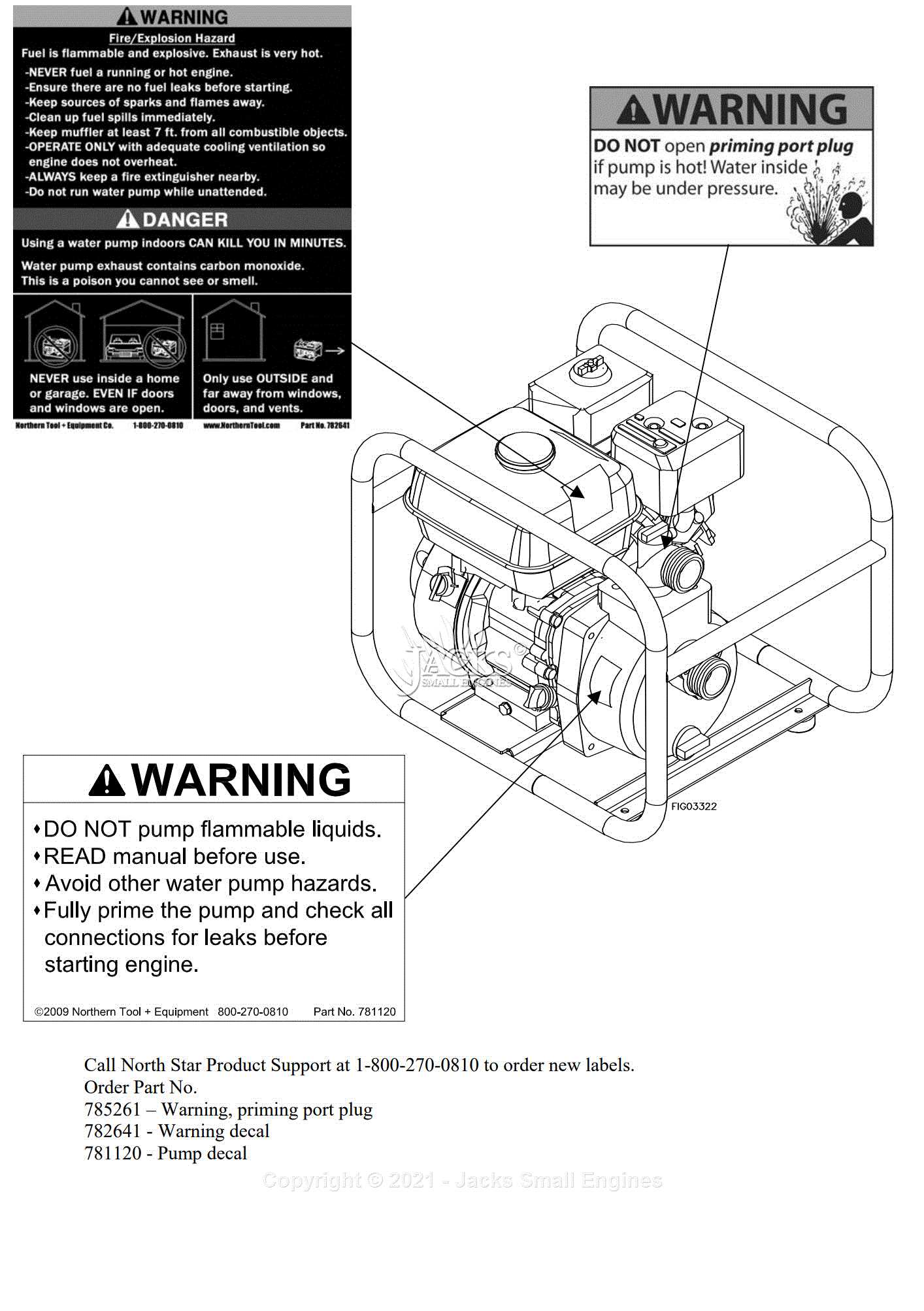

Safety Features in Fire Pump Design

Ensuring the highest level of protection in emergency situations requires a meticulous approach to design and engineering. Incorporating robust safety elements not only enhances operational reliability but also safeguards lives and property. This section delves into critical components that contribute to a secure and efficient response mechanism.

Redundant Systems: Integrating backup mechanisms is essential. In the event of a primary system failure, these alternatives ensure continuous functionality, thereby minimizing risk during critical operations.

Automated Monitoring: Modern technology enables real-time assessment of performance metrics. Continuous monitoring of pressure levels and system integrity allows for prompt identification of issues, facilitating immediate corrective actions.

Durable Materials: The choice of construction materials plays a vital role in longevity and resilience. Using high-quality, corrosion-resistant substances ensures that equipment withstands harsh environments and prolonged exposure.

Accessibility Features: Designing for ease of access is crucial. Ensuring that vital components are reachable for maintenance or emergency operations enhances overall safety and functionality.

Implementing these elements forms a comprehensive strategy that not only meets regulatory standards but also elevates the preparedness of response teams in critical situations.

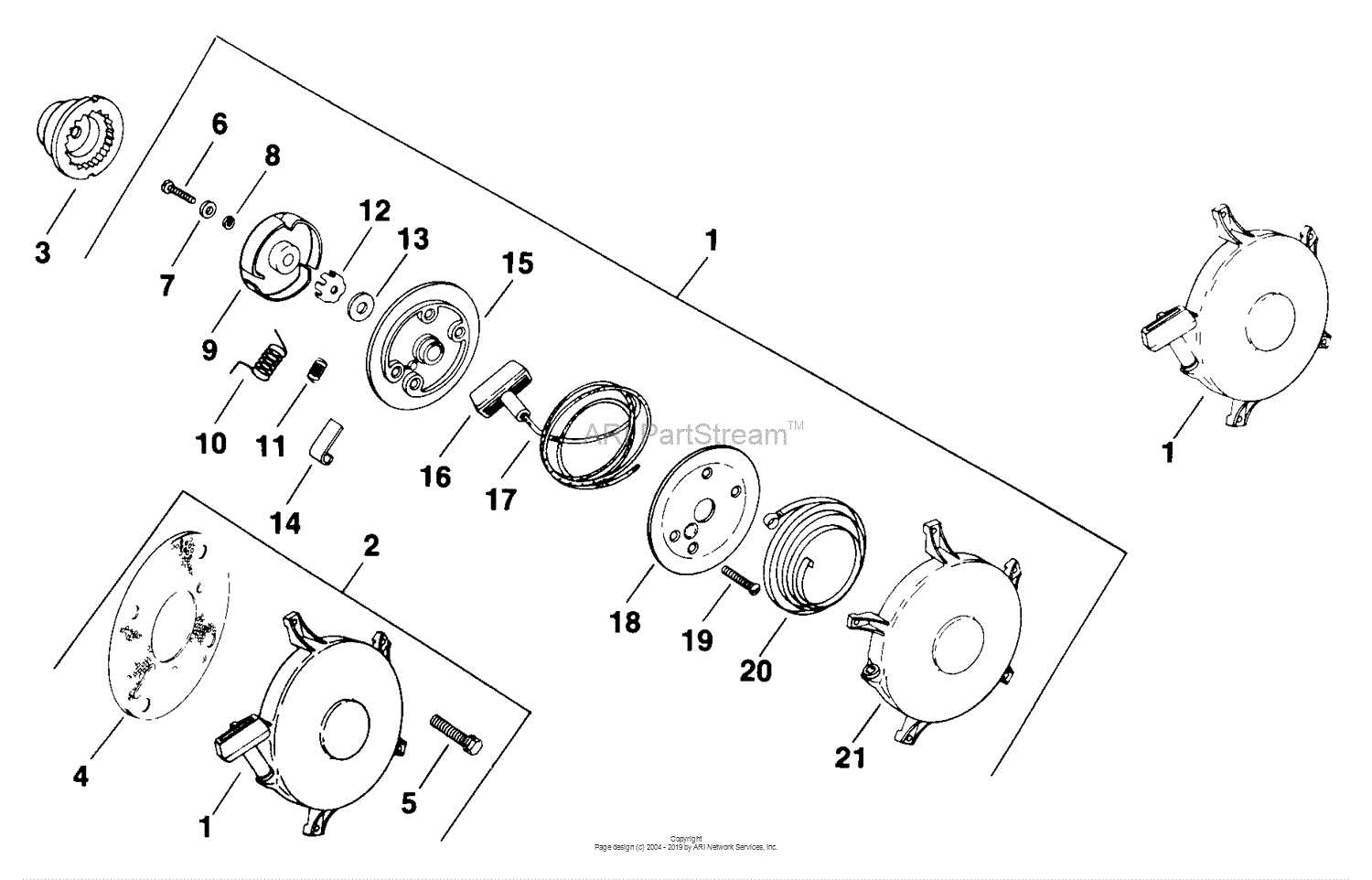

How to Read Fire Pump Diagrams

Understanding the layout of essential components is crucial for effective operation and maintenance. This section will guide you through the fundamental aspects of interpreting these technical illustrations.

- Familiarize with Symbols: Each representation has specific symbols. Learning these is the first step to comprehension.

- Identify Key Components: Locate the main elements such as valves, gauges, and connections. Recognizing their placements helps in understanding the overall system.

- Follow Flow Directions: Arrows indicate the direction of movement. This knowledge is vital for diagnosing issues.

- Refer to Legends: Most illustrations include a legend. Utilize it to clarify any unfamiliar symbols or terminology.

By mastering these aspects, you will enhance your ability to navigate and utilize technical visuals effectively.

Innovations in Fire Pump Technology

The evolution of equipment designed for emergency response has led to remarkable advancements, enhancing efficiency and reliability. Innovations in design, materials, and technology have significantly improved performance, enabling quicker and more effective responses during critical situations.

Smart Technology Integration

Recent developments include the incorporation of smart technology, allowing for real-time monitoring and diagnostics. These systems provide essential data, enabling operators to make informed decisions and optimize response strategies. Artificial intelligence and data analytics are increasingly utilized to predict needs and streamline operations.

Enhanced Durability and Sustainability

Innovations in materials have also led to greater durability and environmental sustainability. Advanced composites and eco-friendly components minimize maintenance needs while ensuring longevity. This shift not only enhances performance but also aligns with modern standards for sustainability.

Best Practices for Fire Pump Installation

Ensuring the effectiveness of water supply systems requires meticulous attention during setup. Adopting optimal methods can significantly enhance performance, reliability, and safety. This section explores essential strategies to facilitate successful installation and operation of these critical systems.

Site Assessment

Conducting a thorough evaluation of the installation site is paramount. Analyze environmental conditions, accessibility, and proximity to water sources. Proper positioning minimizes challenges and enhances operational efficiency.

Quality Components

Utilizing high-quality materials and components is vital for longevity and reliability. Investing in durable equipment ensures sustained performance and reduces maintenance needs over time.