Comprehensive Guide to Bosch Miter Saw Parts Diagram

When working with complex machinery, having a clear understanding of its individual elements is crucial for optimal performance and maintenance. Every tool comprises various components, each playing a vital role in the overall functionality. Familiarity with these elements can enhance efficiency and prolong the lifespan of the equipment.

In this section, we delve into the intricate arrangement of essential components that contribute to the effective operation of your tool. By examining the layout and relationship between each part, users can gain valuable insights into the mechanics at play. This knowledge not only aids in troubleshooting but also empowers users to undertake necessary repairs or replacements with confidence.

Furthermore, recognizing how these elements interact can lead to improved safety practices. Understanding the role of each component helps prevent misuse and promotes a safer working environment. As we explore the detailed configuration of these critical features, you’ll be better equipped to maximize your tool’s capabilities.

Understanding Bosch Miter Saws

Power tools designed for precision cutting play a crucial role in woodworking and construction. They enable users to create accurate angles and clean finishes, essential for professional and DIY projects alike. Familiarity with their components enhances efficiency and ensures optimal performance.

Key Features

These machines typically offer adjustable angles and a sliding feature for wider materials. The motor’s power and blade type significantly influence cutting capabilities, making the selection of the right tool essential for specific tasks.

Maintenance Tips

Regular upkeep is vital to prolonging the lifespan of these tools. Ensuring blades are sharp, cleaning debris, and lubricating moving parts can greatly enhance functionality. Additionally, understanding each component’s role allows users to troubleshoot issues effectively.

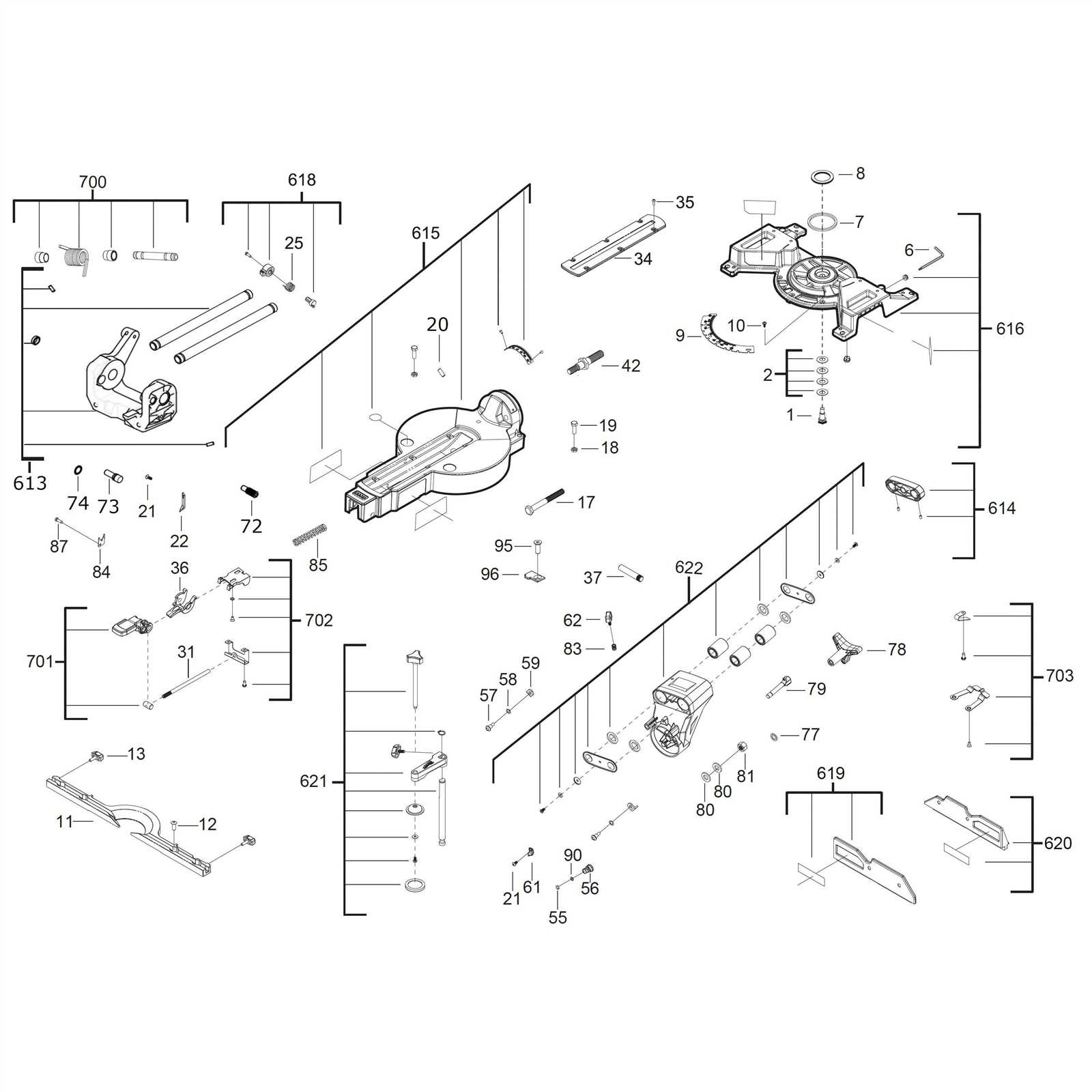

Key Components of Miter Saws

Understanding the essential elements of a cutting tool is crucial for effective usage and maintenance. Each component plays a significant role in ensuring precision and functionality, allowing users to achieve the desired results with ease.

| Component | Description |

|---|---|

| Base | Provides stability and support during operation, ensuring accurate cuts. |

| Blade | The primary cutting instrument, available in various types for different materials. |

| Fence | Helps guide the material being cut, ensuring straight and precise lines. |

| Pivot Arm | Allows the blade to be tilted for angled cuts, enhancing versatility. |

| Motor | Drives the blade, providing the necessary power for cutting tasks. |

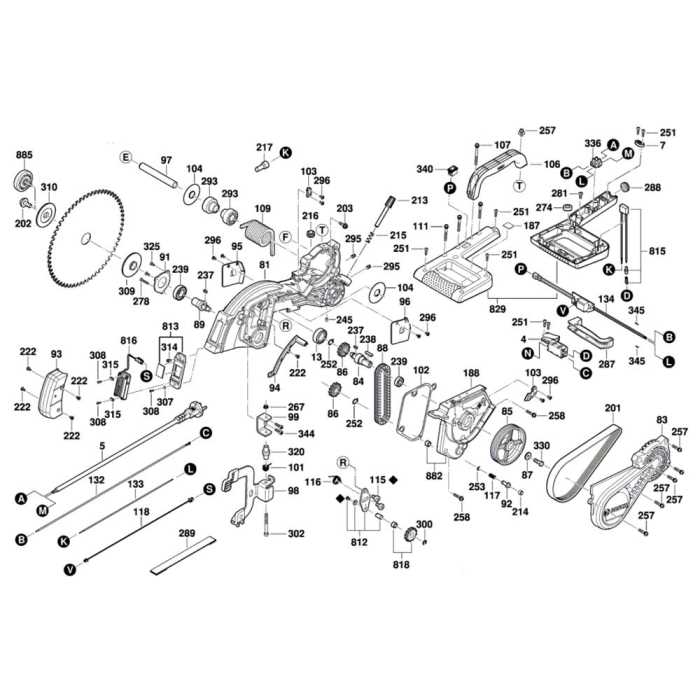

Importance of Accurate Diagrams

Having precise representations is crucial in ensuring the proper functionality of any tool or equipment. These visual aids serve as essential references for assembly, maintenance, and repair processes, ultimately enhancing user experience and safety.

Enhancing Understanding

Clear illustrations help users grasp complex structures and mechanics quickly. When components are depicted accurately, it minimizes confusion and allows for more efficient workflow, ensuring tasks are completed correctly.

Facilitating Repairs

When breakdowns occur, well-detailed visuals simplify the identification of issues. Users can quickly locate damaged or worn components, streamlining the repair process and reducing downtime significantly. Accurate visuals empower users to address problems swiftly and effectively.

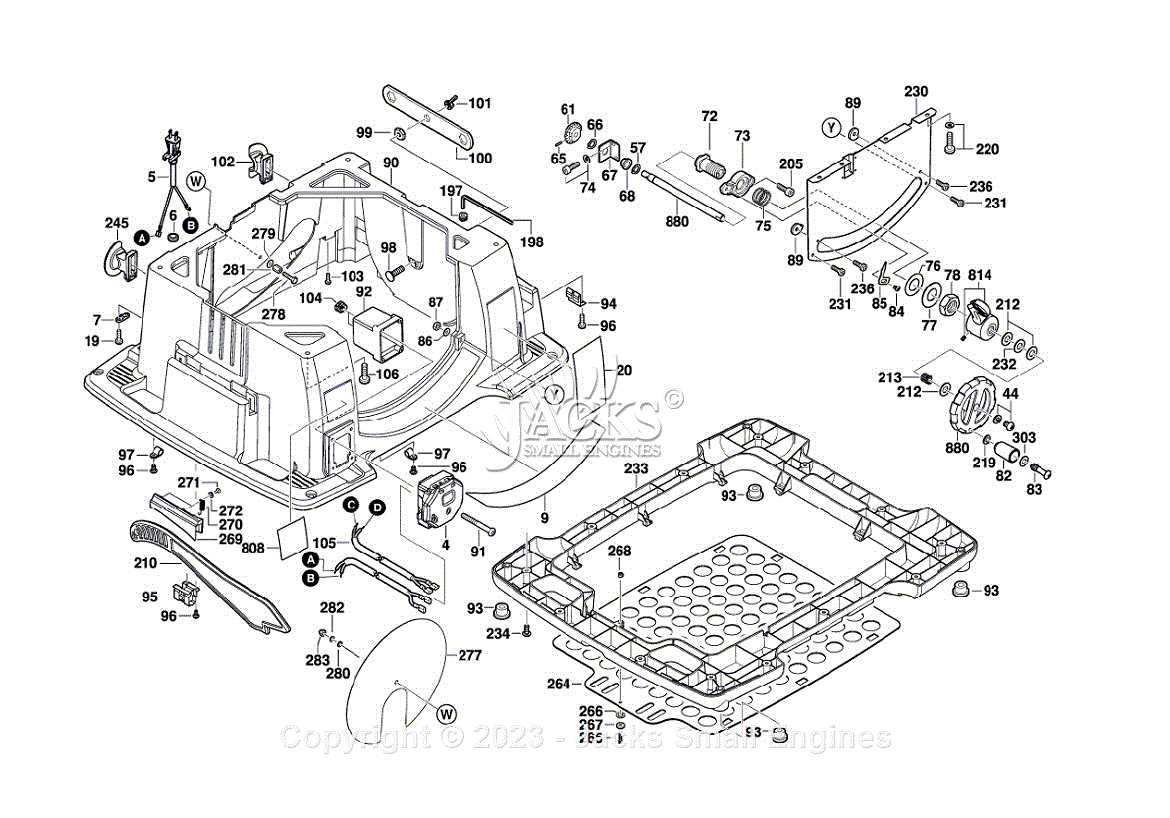

Common Parts in Bosch Models

This section focuses on the essential components found in various cutting tools produced by the brand, highlighting their functions and significance in overall performance.

- The primary element that performs the cutting action.

- Provides the necessary power for operation.

- Offers stability and support during use.

- Allows for the pivoting motion needed for angled cuts.

- Protects the user from accidental contact with the blade.

Understanding these key components can enhance the user experience and facilitate maintenance.

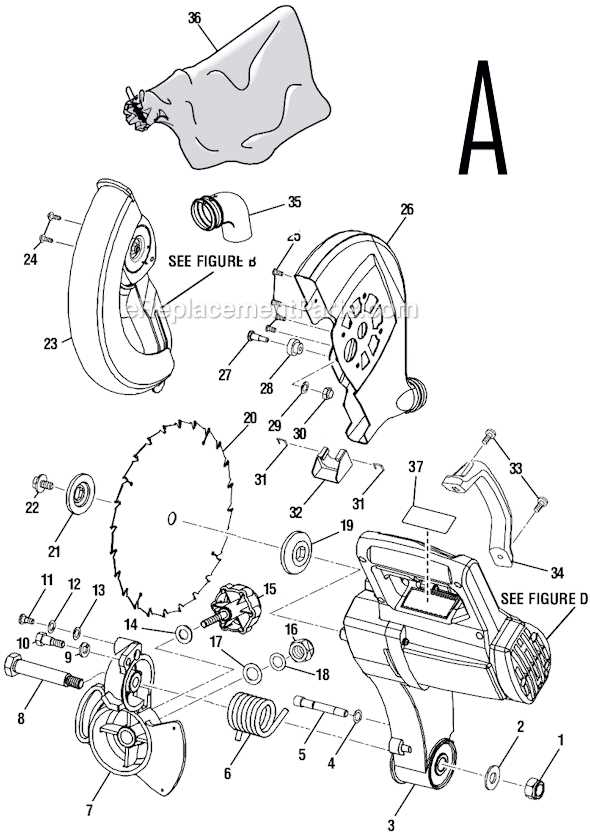

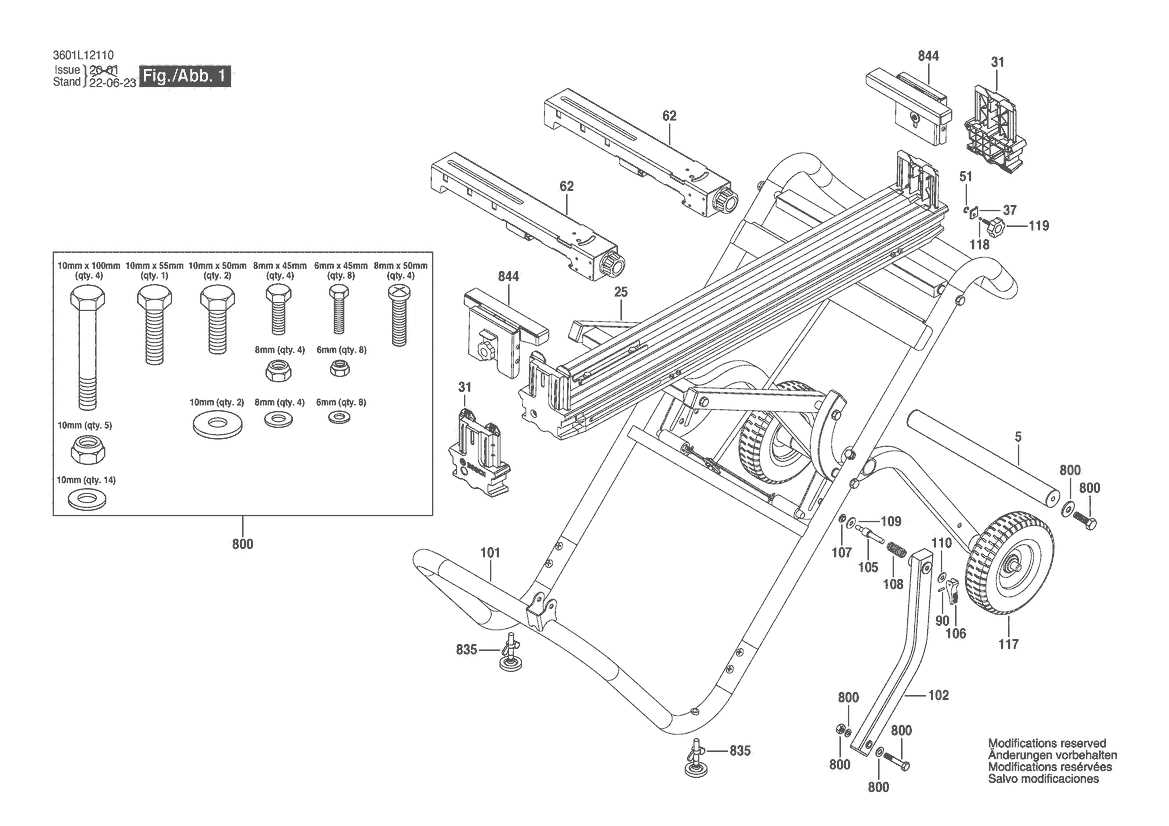

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide insights into the arrangement and relationships between different elements, making it easier to identify and replace necessary items.

Key Elements to Focus On

- Labels: Pay attention to the identifiers next to each component, which indicate specific parts.

- Legend: Refer to the legend for symbols that clarify the function of each part.

- Connection Lines: Observe how lines connect elements, revealing assembly and interaction points.

Steps to Effectively Interpret

- Start by familiarizing yourself with the layout of the illustration.

- Identify the components needed for your task.

- Cross-reference with manuals for detailed specifications.

- Note any potential variations in model versions.

Identifying Replacement Parts Easily

When working with power tools, understanding how to locate and identify necessary components is crucial for efficient maintenance and repair. Whether you’re looking to replace a worn-out piece or upgrade your equipment, having a clear approach can save time and enhance productivity.

To simplify the process of finding the right components, consider the following steps:

- Refer to User Manuals: Always consult the user guide that came with your equipment. It usually contains detailed information about individual components and their specifications.

- Online Resources: Utilize manufacturer websites and reputable online platforms. They often provide interactive schematics and lists of available components.

- Labeling and Organization: When disassembling any equipment, label each component as you remove it. This will help you keep track and ensure you replace the correct parts.

- Visual Identification: Familiarize yourself with common features and shapes of components. This knowledge will assist you in quickly recognizing them in diagrams or online listings.

- Seek Professional Help: If uncertain, don’t hesitate to consult a professional or reach out to customer support for guidance.

By following these steps, you can efficiently identify and obtain the components needed to keep your equipment in optimal condition.

Maintenance Tips for Miter Saws

Regular upkeep of your cutting tool is essential for optimal performance and longevity. By following a few straightforward guidelines, you can ensure that your equipment remains in excellent condition, providing precise cuts every time. This section outlines effective strategies for maintaining your tool and avoiding common issues.

Cleaning and Lubrication

Keep your equipment clean by removing dust and debris after each use. Use a soft brush or compressed air to eliminate particles from the motor and moving parts. Additionally, lubricate the pivot points and sliding mechanisms periodically with a suitable oil to reduce friction and wear. Remember that clean and well-lubricated components enhance performance and prevent damage over time.

Inspection and Adjustment

Regularly check the alignment and condition of the blade. Ensure it is sharp and free from nicks or damage, as this affects cutting accuracy. If you notice any wobbling or misalignment, adjust the settings according to the manufacturer’s guidelines. Taking the time to inspect your tool can prevent costly repairs and ensure consistent results.

Popular Bosch Miter Saw Models

When it comes to precision cutting tools, several renowned models stand out in the marketplace. These machines are designed to provide excellent performance, versatility, and durability, catering to both professional craftsmen and DIY enthusiasts. Understanding the key features of these popular options can help users select the right tool for their specific needs.

One of the most favored models is designed with an emphasis on compactness and portability, making it ideal for job sites and home projects alike. Its powerful motor and adjustable angles enable users to tackle a variety of tasks with ease.

Another noteworthy model is celebrated for its advanced laser guide system, which enhances accuracy during cuts. This feature significantly reduces the chances of errors, ensuring a clean finish every time.

For those seeking greater cutting capacity, a larger model offers extended versatility, capable of handling wider materials. This option is particularly advantageous for larger projects where precision is crucial.

Each of these tools has unique attributes that make them suitable for different applications, ensuring that users can find the perfect fit for their cutting requirements.

Tools Needed for Repairs

When it comes to maintenance and fixing your cutting apparatus, having the right tools is essential for ensuring efficiency and safety. Proper equipment not only streamlines the repair process but also enhances the longevity and performance of your device.

First and foremost, a reliable set of screwdrivers is crucial for loosening and tightening various components. A combination of Phillips and flathead types will cover most needs. Additionally, pliers and adjustable wrenches are valuable for gripping and turning hardware securely.

A good quality torque wrench is also important, as it allows you to apply the correct amount of force to fasteners, preventing damage. Furthermore, having a pair of safety goggles is indispensable for protecting your eyes from debris during repairs.

Finally, an organized toolbox will help keep your tools accessible and in good condition, making your repair tasks more efficient. With the right equipment at hand, you can confidently tackle any maintenance job that arises.

Where to Buy Replacement Parts

Finding components for your tools can enhance their longevity and performance. It’s essential to know reliable sources to ensure you get quality replacements.

Online Retailers

- Amazon: A vast selection with user reviews.

- eBay: Great for finding both new and used items.

- Manufacturer’s Website: Often offers original replacements.

Local Stores

- Hardware Stores: Check for specialized tool sections.

- Home Improvement Centers: Usually stock common replacements.

- Specialty Tool Shops: Ideal for hard-to-find items.

Comparing Bosch to Other Brands

When evaluating the tools available on the market, it is essential to examine various manufacturers and their offerings. Each brand brings its unique strengths and weaknesses, which can significantly influence performance, durability, and user experience. This comparison will highlight some key factors that set one brand apart from others, allowing users to make informed decisions based on their specific needs.

Quality and Performance

One of the most critical aspects of any power tool is its reliability. Tools from different manufacturers may vary in construction quality, leading to differences in longevity and effectiveness. While some brands prioritize cost-efficiency, others focus on innovative technology and superior materials, resulting in a more robust performance. Users should consider how these factors align with their project requirements.

Customer Support and Warranty

After-sales service can significantly impact user satisfaction. Brands that offer comprehensive support, including accessible customer service and generous warranty policies, often foster stronger relationships with their customers. This aspect can be a deciding factor for many users, particularly for those who invest in high-end equipment. A brand that stands behind its products can provide peace of mind and assurance of quality.

DIY Repairs vs. Professional Help

When it comes to fixing equipment, individuals often face the decision of tackling the repairs themselves or seeking assistance from an expert. This choice can significantly impact both the outcome of the repair and the time and resources involved.

Here are some key considerations to keep in mind when weighing your options:

- Skill Level: Assess your own abilities. Do you have experience with similar repairs?

- Complexity of the Issue: Some problems may require specialized knowledge or tools that the average person may not possess.

- Cost Implications: DIY repairs can save money, but consider potential costs if something goes wrong.

- Time Commitment: Evaluate how much time you can dedicate to the repair. Will it disrupt your schedule?

- Long-term Reliability: Professional repairs often come with guarantees, ensuring the work is done correctly.

Ultimately, the choice between doing it yourself and hiring a professional will depend on your comfort level, the nature of the problem, and the value you place on your time and resources.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their functions within the tool. Understanding these elements can enhance your experience and help you maintain optimal performance.

What should I do if a component breaks? It is essential to identify the specific piece that has failed and consult the manufacturer’s guidelines for replacement options.

How can I ensure I’m ordering the correct replacement? Always refer to the model number and specifications provided in the user manual to match the replacement item accurately.

Are there aftermarket options available? Yes, many manufacturers offer compatible alternatives, but be cautious and verify their quality and compatibility with your equipment.

How often should I inspect the components? Regular inspections are recommended, especially if the tool is used frequently. Look for signs of wear and tear to ensure safe operation.

Can I perform repairs myself? If you have the necessary skills and tools, many users choose to handle minor repairs. However, for complex issues, professional assistance is advisable.