Understanding the Brake Parts Diagram for Optimal Performance

In the realm of automotive engineering, the intricacies of vehicle stopping systems play a crucial role in ensuring safety and functionality. These mechanisms are designed to provide reliable control over speed and direction, enabling drivers to navigate various conditions with confidence. A comprehensive understanding of these systems is essential for both enthusiasts and professionals alike.

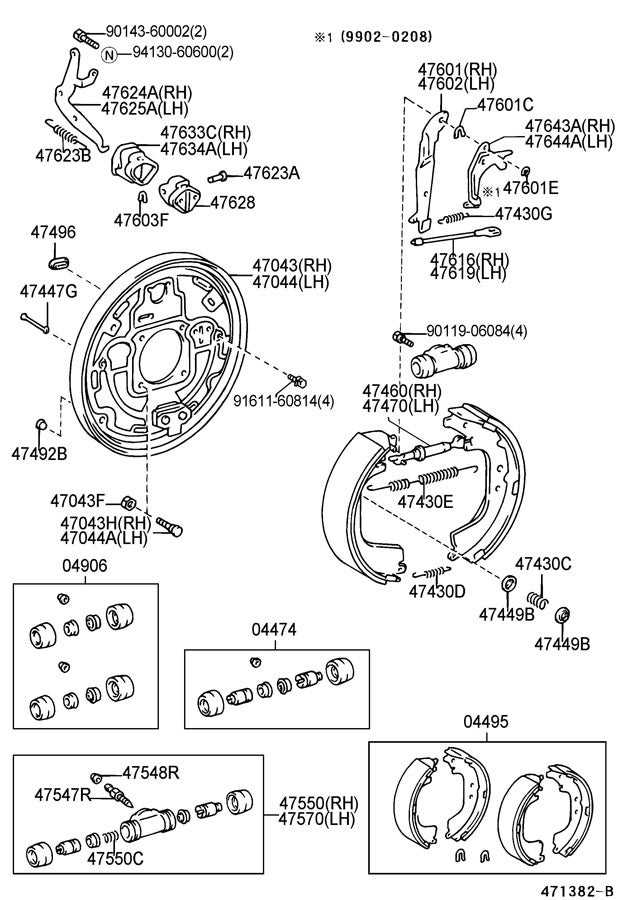

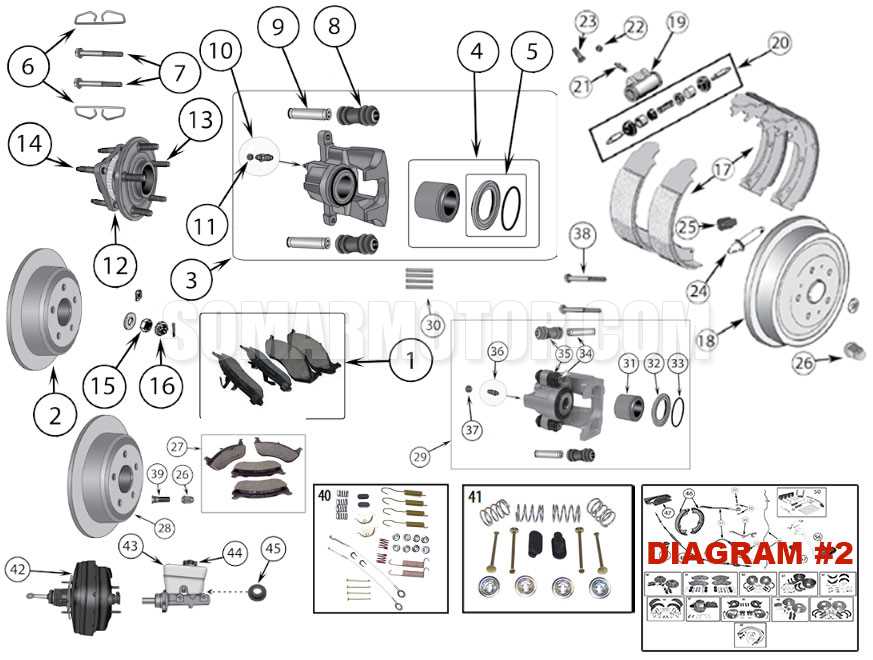

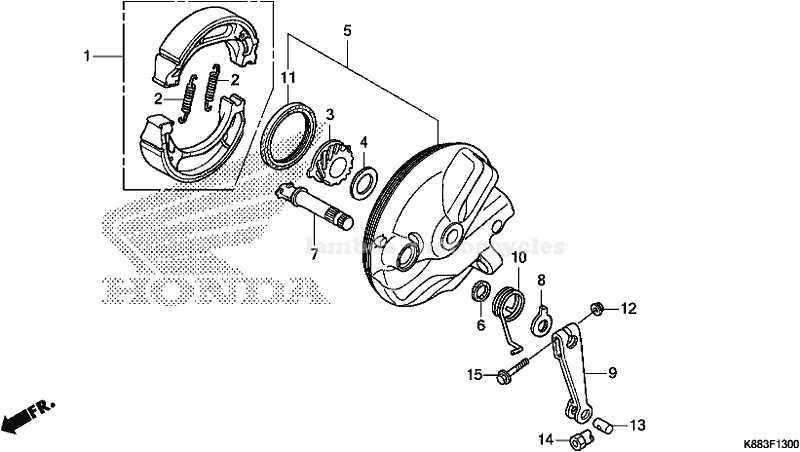

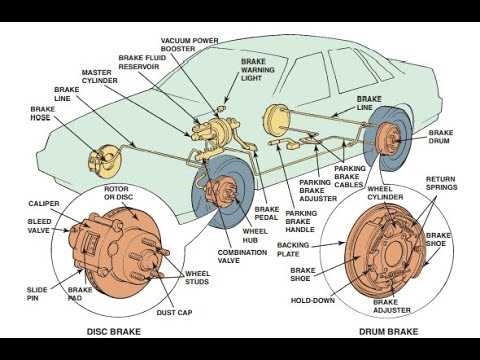

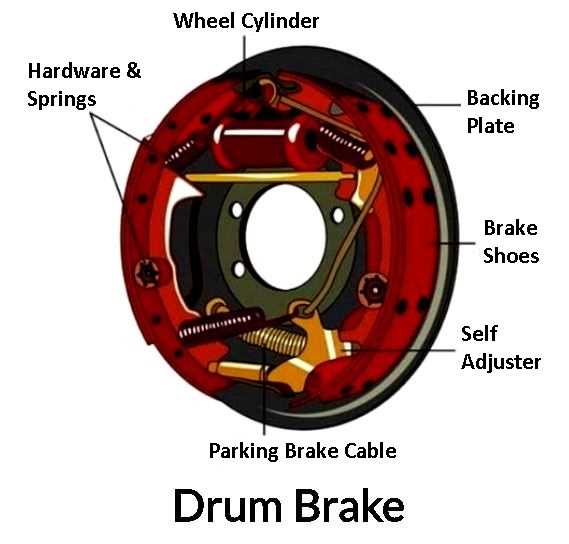

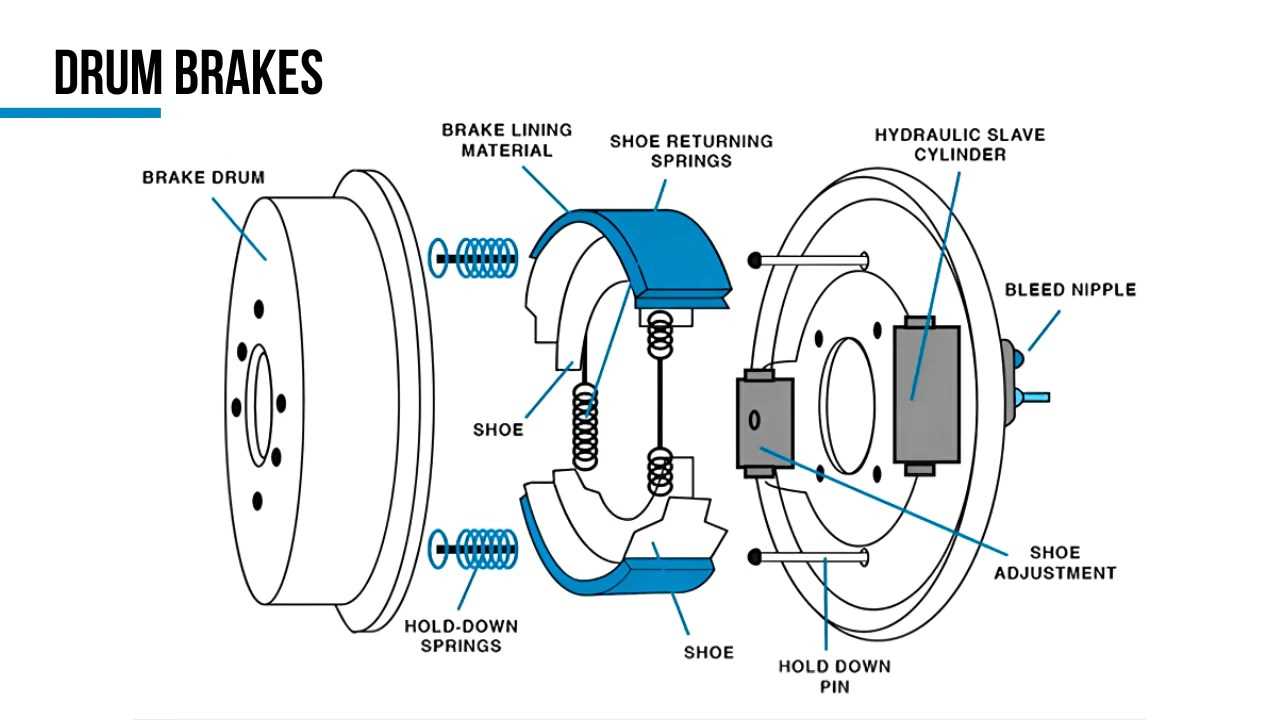

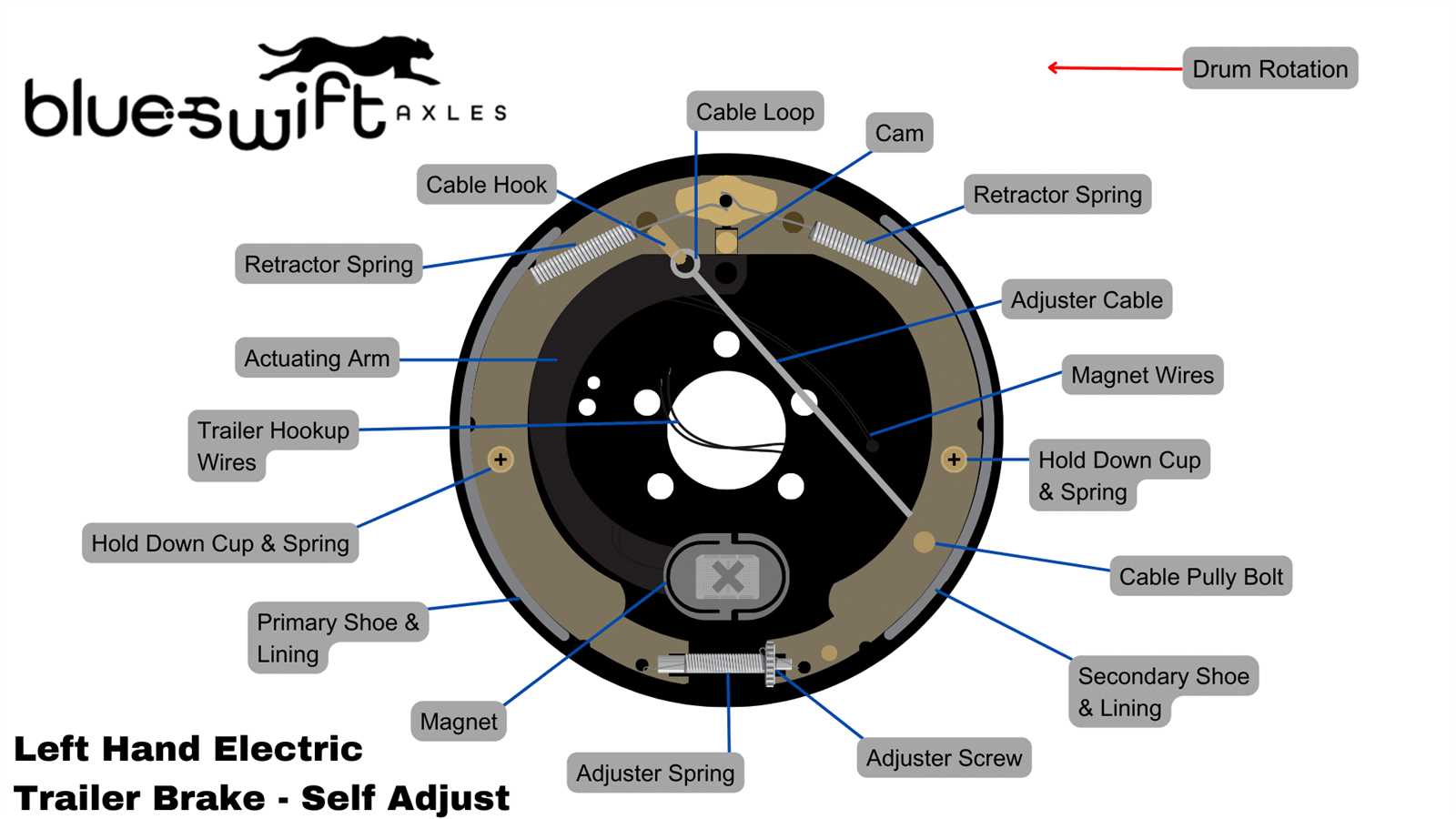

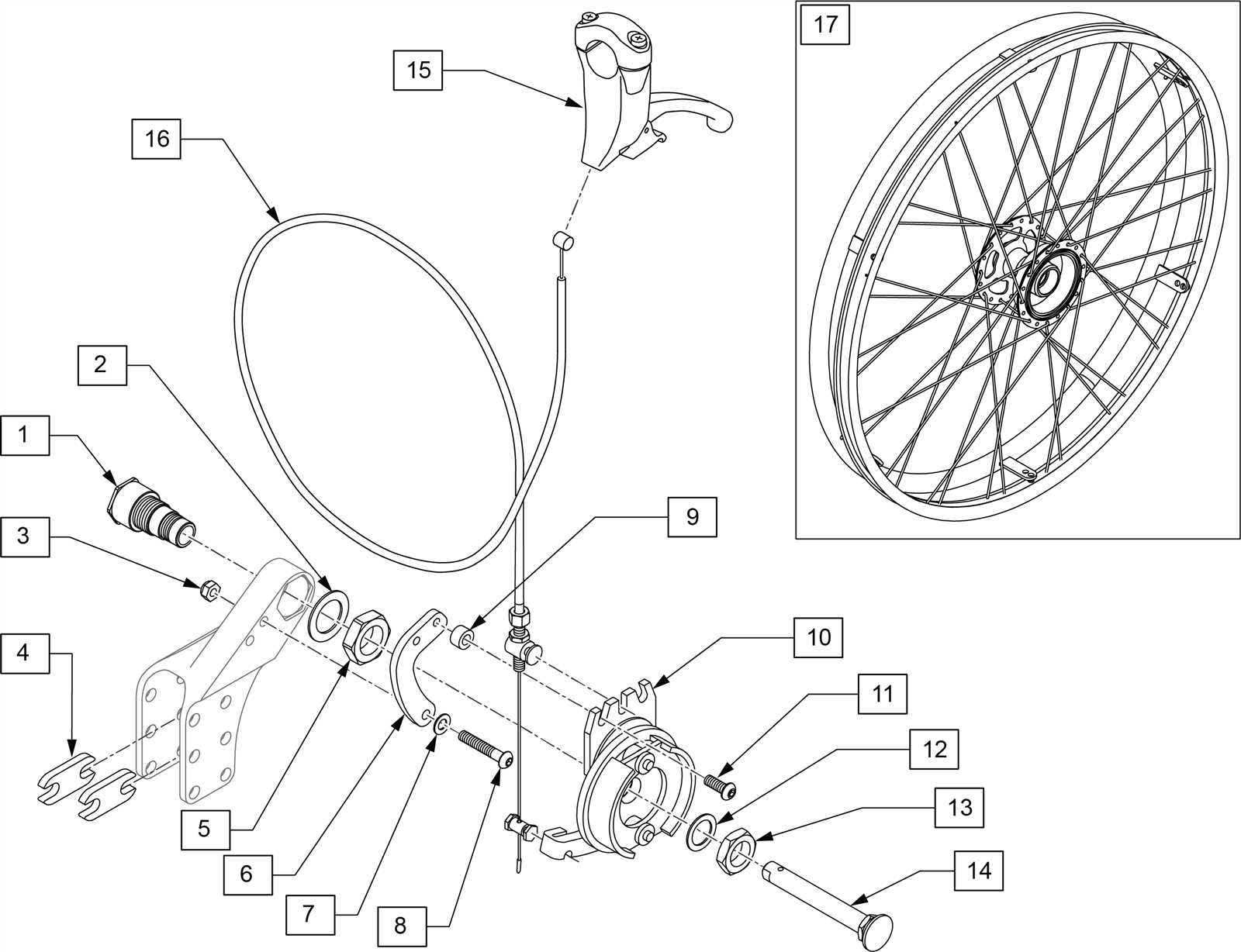

Visual representation of the components involved in these systems can greatly enhance our knowledge. Each element has a specific function that contributes to the overall efficiency and effectiveness of the stopping process. By breaking down these elements, we can gain insights into how they work together harmoniously.

Moreover, familiarity with these essential elements empowers vehicle owners to recognize signs of wear and potential issues, facilitating timely maintenance and repairs. This not only prolongs the lifespan of the mechanisms but also enhances safety on the road. A clear grasp of these interconnected components can make a significant difference in automotive care.

Understanding Brake System Components

Effective stopping power is crucial for vehicle safety, relying on a complex arrangement of elements that work in harmony. Each component plays a vital role in ensuring reliable deceleration and control during operation.

Key Elements of the System

- Hydraulic Mechanism

- Friction Material

- Calipers

- Rotors

- Master Cylinder

Functionality Overview

- The hydraulic mechanism amplifies force applied by the driver.

- Friction material generates the necessary grip against moving surfaces.

- Calipers house the friction components and facilitate their movement.

- Rotors provide a surface for friction to act upon, enabling deceleration.

- The master cylinder controls the hydraulic fluid flow throughout the system.

Types of Brake Parts Explained

This section explores the various components essential for halting a vehicle effectively. Understanding these elements can enhance your awareness of their functions and maintenance needs, ultimately leading to safer driving experiences.

Key Components

The primary elements include the friction materials, which create the necessary grip on the wheels, and hydraulic systems that facilitate smooth operation. Each component plays a crucial role in ensuring the vehicle responds promptly to the driver’s commands.

Additional Elements

Supporting components like the calipers and rotors also contribute significantly to the overall efficiency. Regular inspection of these parts can prevent wear and ensure optimal performance during everyday use.

Function of Each Brake Component

Understanding the role of each element within the stopping system is crucial for optimal performance and safety. Each component works in harmony to ensure effective deceleration, offering reliability and control during operation.

Key Elements and Their Functions

| Component | Function |

|---|---|

| Caliper | Houses the friction material and applies pressure to the discs to create stopping force. |

| Disc | Provides a surface for the friction material to grip, converting kinetic energy into heat. |

| Pads | Friction materials that engage with the disc, generating the necessary force to slow the vehicle. |

| Master Cylinder | Converts the force from the pedal into hydraulic pressure, activating the calipers. |

Conclusion

Each element contributes uniquely to the overall efficiency of the system, ensuring safe and effective halting. Regular maintenance of these components is essential for long-lasting performance.

Brake Diagram Overview for Beginners

This section provides an introduction to the essential components involved in slowing down or stopping a vehicle. Understanding these elements is crucial for anyone looking to enhance their knowledge about automotive systems.

Key Components Explained

The system consists of various elements that work together to ensure safety and efficiency. Among these, you’ll find mechanisms that create friction, hydraulic systems that amplify force, and sensors that monitor performance. Each component plays a vital role in the overall functionality.

Importance of Familiarity

Being knowledgeable about these systems can lead to better maintenance practices and informed decision-making during repairs. Ultimately, this understanding contributes to safer driving experiences and longevity of the vehicle.

Common Brake System Issues

Understanding the frequent problems that can arise in a stopping mechanism is crucial for maintaining vehicle safety and performance. Issues can manifest in various ways, affecting the overall functionality and reliability of the system.

| Issue | Description |

|---|---|

| Noise | Unusual sounds can indicate wear or misalignment, often leading to decreased effectiveness. |

| Vibration | Shaking during operation may suggest uneven wear or damaged components, requiring inspection. |

| Pulling | When a vehicle drifts to one side, it could indicate an imbalance in the stopping mechanism. |

| Fluid Leaks | Leaks can compromise the system’s pressure, leading to reduced performance and potential hazards. |

| Fading | Loss of responsiveness under heavy use can signal overheating, requiring immediate attention. |

Importance of Regular Brake Maintenance

Ensuring the reliability of your vehicle’s stopping mechanism is crucial for safety on the road. Consistent upkeep not only enhances performance but also prolongs the lifespan of essential components. Neglecting this responsibility can lead to severe consequences, including compromised safety and costly repairs.

Regular inspections and servicing can provide numerous benefits:

- Enhanced Safety: A well-maintained system reduces the risk of accidents caused by failure.

- Improved Performance: Properly functioning mechanisms ensure effective stopping power.

- Cost Savings: Preventative care minimizes the likelihood of expensive repairs in the future.

- Increased Longevity: Routine maintenance helps extend the life of crucial components.

- Better Fuel Efficiency: Optimized performance can lead to improved fuel consumption.

Incorporating regular checks into your vehicle’s maintenance routine can make a significant difference in safety and performance. It is advisable to consult professionals for thorough assessments and necessary adjustments.

How to Interpret Brake Diagrams

Understanding schematics related to stopping systems is essential for maintenance and repair tasks. These visual representations provide crucial information about the components and their functions within the overall system. By mastering the art of reading these visuals, one can enhance their mechanical skills and ensure optimal performance.

Begin by familiarizing yourself with the symbols used, as they represent different elements. Each symbol has a specific meaning, which can vary by manufacturer. Pay attention to the legends or keys accompanying the visuals, as they provide context and clarity regarding the components and their relationships.

Next, identify the flow of operation. Understanding how energy transfers through the system helps in diagnosing issues. Trace the lines connecting the components; these indicate how they interact and function together. Note any directional arrows that signify movement or flow, as they can be critical for troubleshooting.

Finally, compare the schematic with the physical setup. This hands-on approach allows for a deeper comprehension of how theoretical knowledge applies in real-world scenarios. By continually practicing this skill, one can ultimately achieve greater proficiency and confidence in maintaining stopping mechanisms.

Comparing Disc and Drum Brakes

Understanding the differences between two common types of stopping mechanisms is crucial for vehicle performance and safety. Each design has its unique characteristics, advantages, and limitations that can affect their functionality under various conditions.

- Design:

- Disc systems feature a flat, circular component that rotates with the wheel, while drum systems consist of a cylindrical housing that encloses the mechanism.

- Heat Dissipation:

- Disc models typically manage heat more effectively due to their exposed design, reducing the risk of fading.

- Drum types can retain heat, leading to potential performance issues during extended use.

- Performance:

- Disc systems generally provide better stopping power, especially in wet conditions.

- Drum systems can offer adequate performance for lighter vehicles but may struggle under heavy loads.

- Maintenance:

- Disc configurations are easier to inspect and replace, contributing to lower long-term upkeep costs.

- Drum setups can be more complex to service, potentially leading to higher maintenance expenses.

Ultimately, the choice between these two designs depends on the specific needs of the vehicle and its intended use, making it essential to consider their respective strengths and weaknesses.

Tools Needed for Brake Repairs

To effectively perform maintenance on your vehicle’s stopping mechanism, having the right instruments at your disposal is crucial. A well-equipped workspace ensures that you can address issues safely and efficiently, leading to better performance and reliability on the road.

Essential Tools

- Socket set

- Wrenches

- Torque wrench

- Jack and jack stands

- Brake cleaner

- Anti-seize lubricant

- Grommet puller

Optional Tools

- Caliper tool

- Rubber mallet

- Pliers

- Brake line wrench

- Digital caliper

Having these tools at hand will simplify the task, making it more manageable for both beginners and experienced mechanics alike.

Safety Tips for Brake Work

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions can enhance your experience and protect your well-being.

- Always wear protective gear, including gloves and safety goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Use the correct tools for the job to minimize the risk of injury.

- Ensure the vehicle is securely elevated with jack stands before starting any work.

- Disconnect the battery to prevent electrical issues.

Following these guidelines can lead to a safer and more efficient workflow, allowing you to focus on the task at hand.

Upgrading Your Brake Components

Enhancing your vehicle’s stopping system can significantly improve its overall performance and safety. By selecting high-quality alternatives, you not only boost responsiveness but also extend the lifespan of crucial elements.

Benefits of Upgrading

- Improved stopping power

- Enhanced durability

- Better heat dissipation

- Reduced noise and vibration

Components to Consider

- Calipers: Opt for lightweight materials for better efficiency.

- Rotors: Choose slotted or drilled options for enhanced cooling.

- Lines: Upgrade to stainless steel for improved fluid response.

- Pads: Select high-friction materials for superior grip.