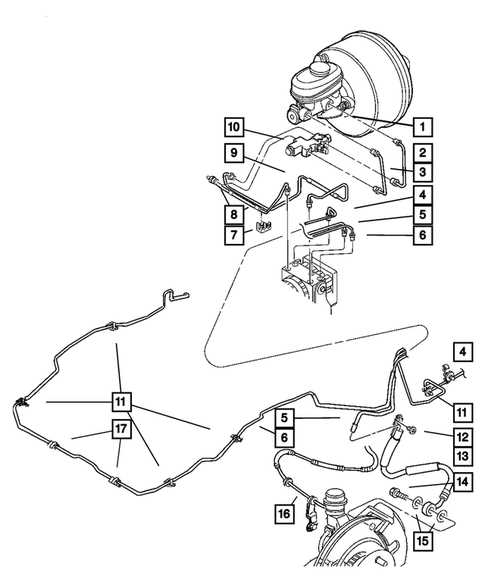

Understanding Jeep Brake Parts Diagram

In the world of automotive engineering, the components responsible for halting a vehicle’s motion are crucial for safety and performance. A clear grasp of how these elements work together can enhance both the maintenance and functionality of any automobile. This section delves into the various elements involved in the stopping process, providing insights into their interactions and significance.

By examining the intricate relationships among these mechanisms, readers will gain a better understanding of how each component contributes to overall efficacy. Identifying the role of each segment not only aids in troubleshooting potential issues but also fosters a deeper appreciation for engineering precision. In addition, this knowledge equips enthusiasts and professionals alike with the expertise necessary to make informed decisions regarding repairs and upgrades.

Maintaining the fluid responsible for hydraulic functions in a vehicle is crucial for ensuring optimal performance and safety. This liquid plays a vital role in the operation of various systems, transferring force and allowing components to function correctly. Understanding its significance and proper upkeep can greatly enhance overall vehicle reliability.

Importance of Quality Fluid

The quality of the hydraulic liquid affects several aspects of vehicle performance:

- Safety: High-quality fluid helps prevent system failures that could lead to dangerous situations.

- Efficiency: Properly maintained fluid ensures that all systems operate smoothly, improving responsiveness.

- Longevity: Regular checks and changes can extend the life of components by preventing wear and tear.

Maintenance Tips

To keep the hydraulic fluid in optimal condition, consider the following practices:

- Regular Checks: Monitor fluid levels frequently to ensure they remain within the recommended range.

- Fluid Changes: Replace the liquid according to the manufacturer’s guidelines, typically every 2 years or as recommended.

- Leak Inspection: Regularly inspect for leaks in the system, as any loss can compromise performance.

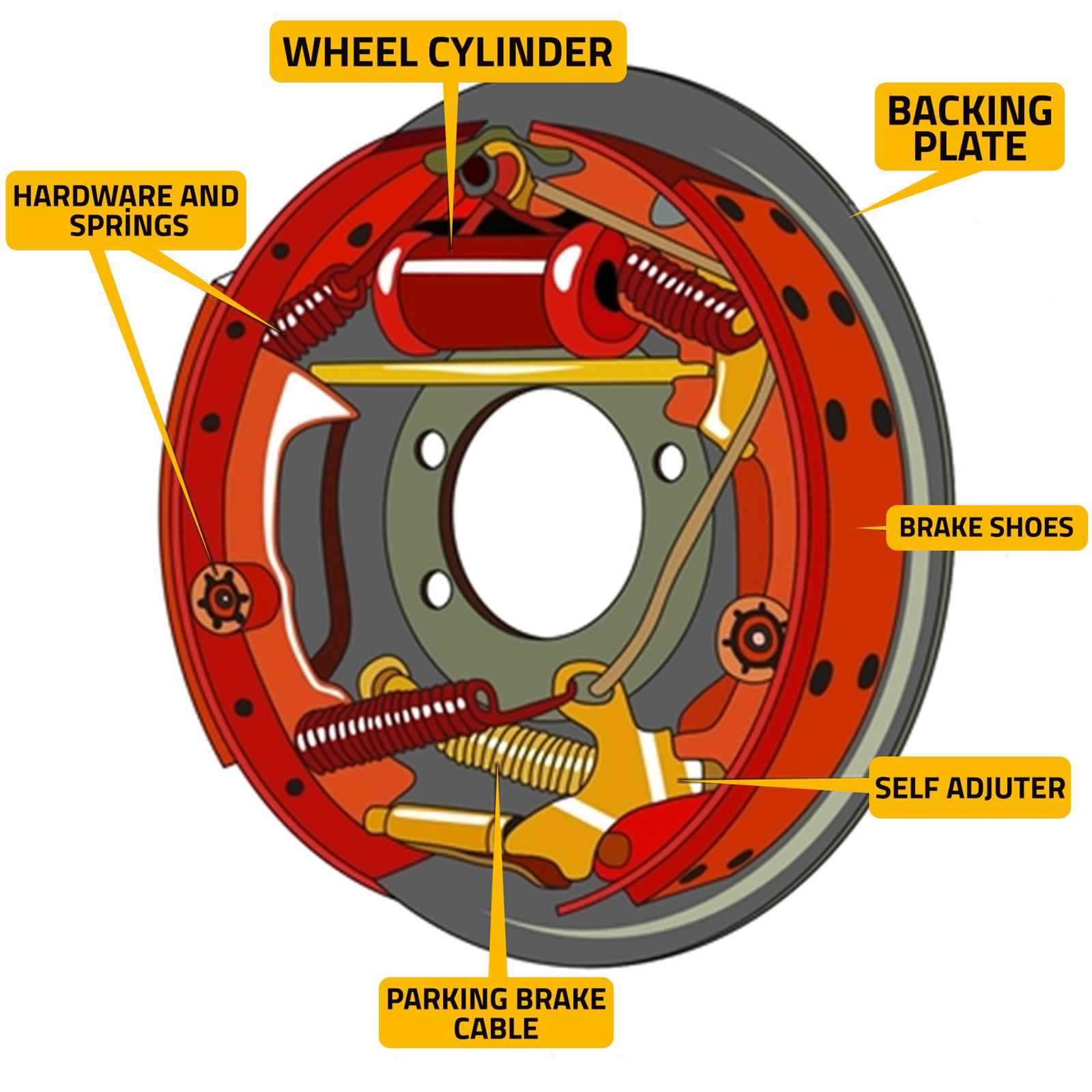

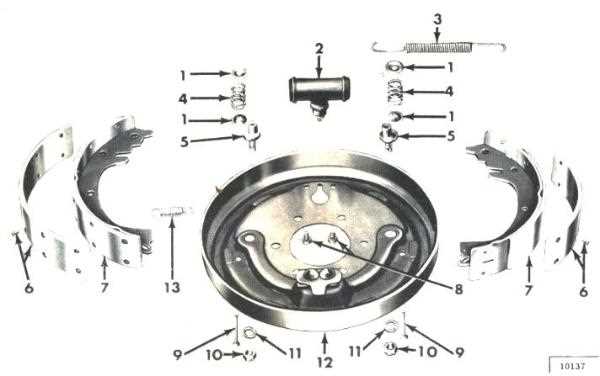

Signs of Worn Brake Parts

Understanding the indicators of deteriorated stopping components is crucial for maintaining vehicle safety. Regularly monitoring these signs can prevent severe issues and ensure optimal performance on the road.

Common Indicators

- Unusual noises during operation, such as squeaking or grinding sounds.

- Reduced responsiveness when applying the stopping mechanism.

- Vibrations or pulsations felt through the pedal.

- Visible wear or damage upon inspection of the components.

Visual and Sensory Cues

In addition to the audible signals, there are several visual and tactile signs to be aware of:

- Discoloration or uneven wear on the surface of the stopping mechanism.

- Excessive dust or debris accumulation around the components.

- Fluid leaks near the mechanism or associated systems.

- Burning odors during or after use, indicating overheating.

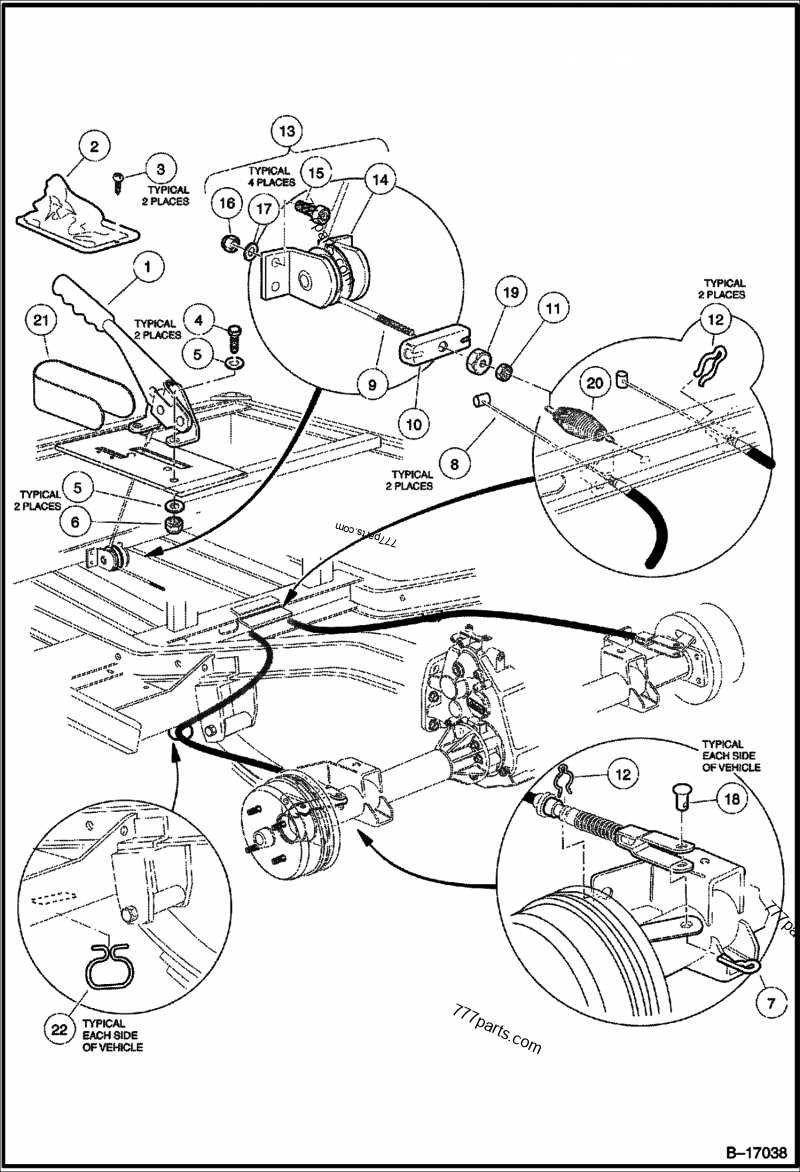

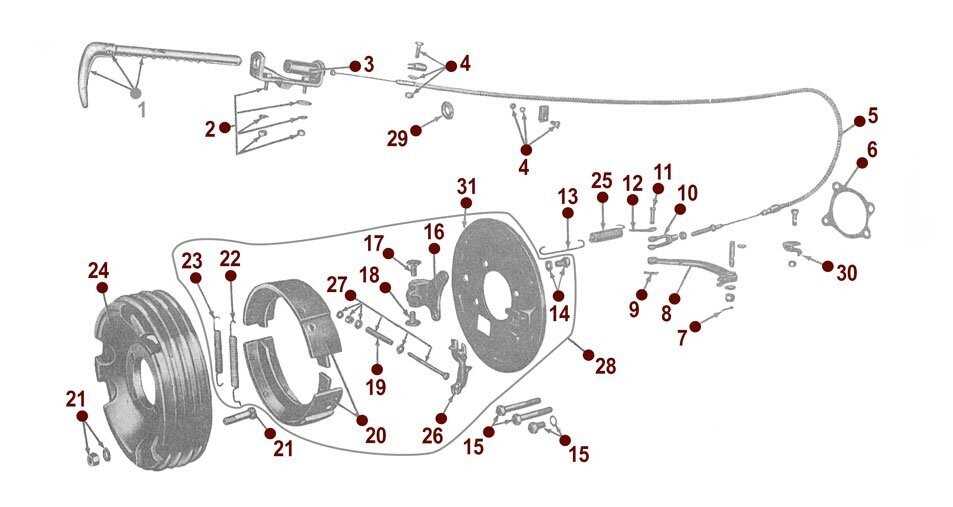

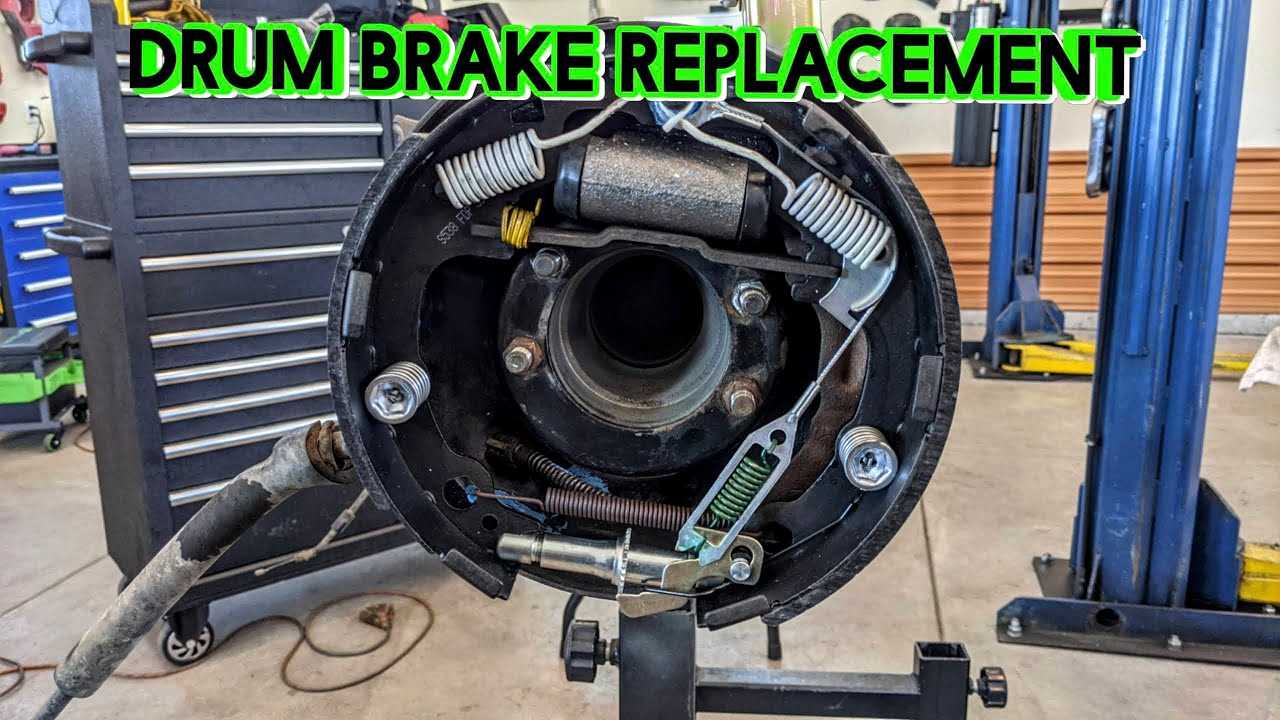

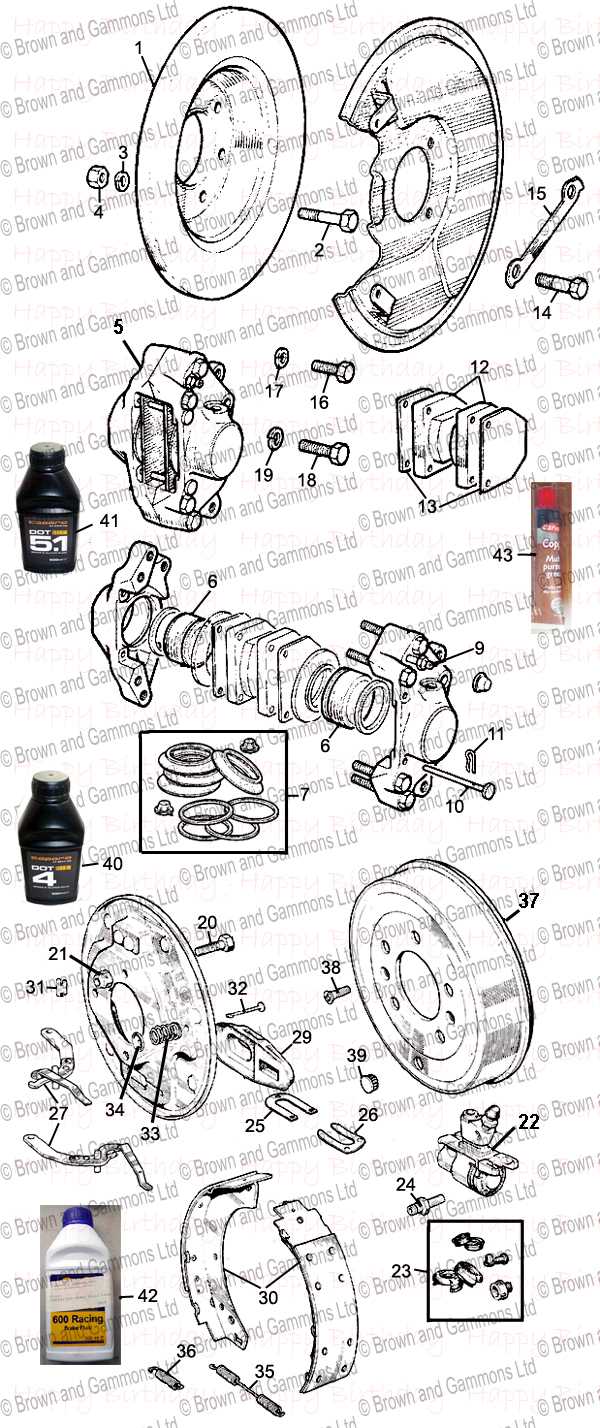

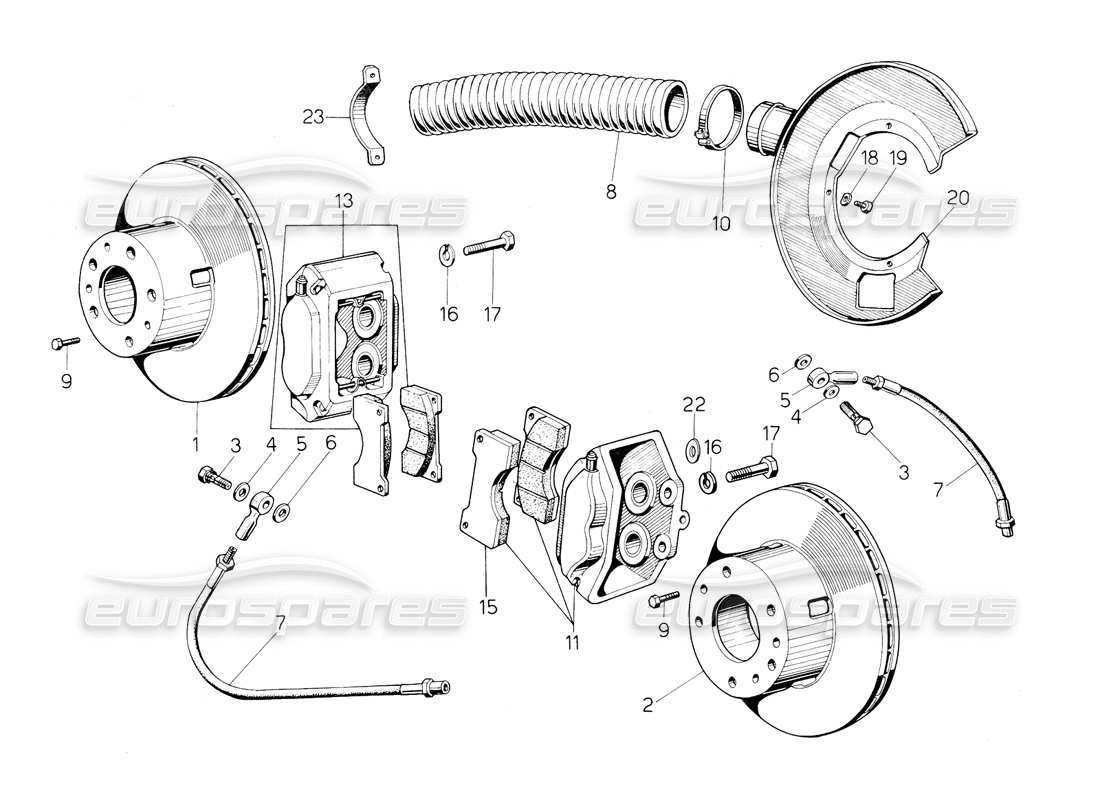

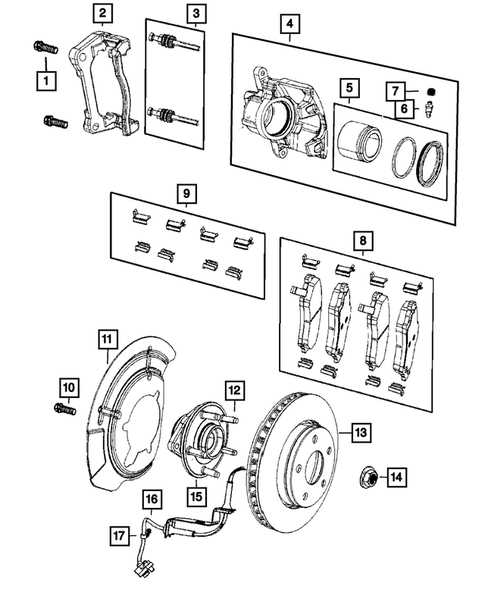

Replacing Brake Components: A Guide

When it comes to maintaining your vehicle’s safety, understanding the process of replacing key elements in the stopping system is essential. This guide provides a clear overview of the necessary steps and considerations for successfully changing these vital components, ensuring reliable performance on the road.

Preparation Before Replacement

Before embarking on the replacement journey, it is crucial to gather the right tools and materials. Here’s what you will need:

- Socket set

- Torque wrench

- Brake cleaner

- Replacement components

- Safety goggles

- Gloves

Additionally, make sure to consult your vehicle’s manual for any specific instructions related to the system being serviced.

Steps to Follow for Replacement

- Park the vehicle on a flat surface and engage the parking brake.

- Loosen the lug nuts on the wheels where replacement will occur.

- Raise the vehicle using a jack and secure it with jack stands.

- Remove the wheel to access the components in question.

- Carefully detach the existing elements, noting how they are installed for reference.

- Clean the mounting surfaces with brake cleaner to ensure a good fit for the new components.

- Install the new components, making sure to follow the original configuration.

- Reattach the wheel and tighten the lug nuts to the specified torque settings.

- Lower the vehicle and perform a test to ensure everything is functioning properly.

Following these steps will help you maintain the efficacy of your vehicle’s stopping mechanism, providing peace of mind while driving.

Tools Needed for Brake Repair

Repairing the stopping mechanism of a vehicle requires specific instruments to ensure safety and functionality. Having the right tools not only simplifies the process but also guarantees that each component is installed correctly. Below is a list of essential tools that will aid in successfully completing the repair task.

Essential Hand Tools

Basic hand tools are vital for any repair job. A set of wrenches and sockets is crucial for loosening and tightening fasteners. Additionally, pliers and screwdrivers will assist in removing and securing various components. It’s advisable to have both metric and standard sizes available to accommodate different fittings.

Specialized Equipment

In addition to standard tools, specialized equipment can make the job more efficient. A torque wrench is essential for applying the correct tension to fasteners, preventing over-tightening. Furthermore, a brake bleeder kit is important for removing air from the hydraulic system, ensuring optimal performance. Having a jack and jack stands is also necessary for safely lifting the vehicle during repairs.

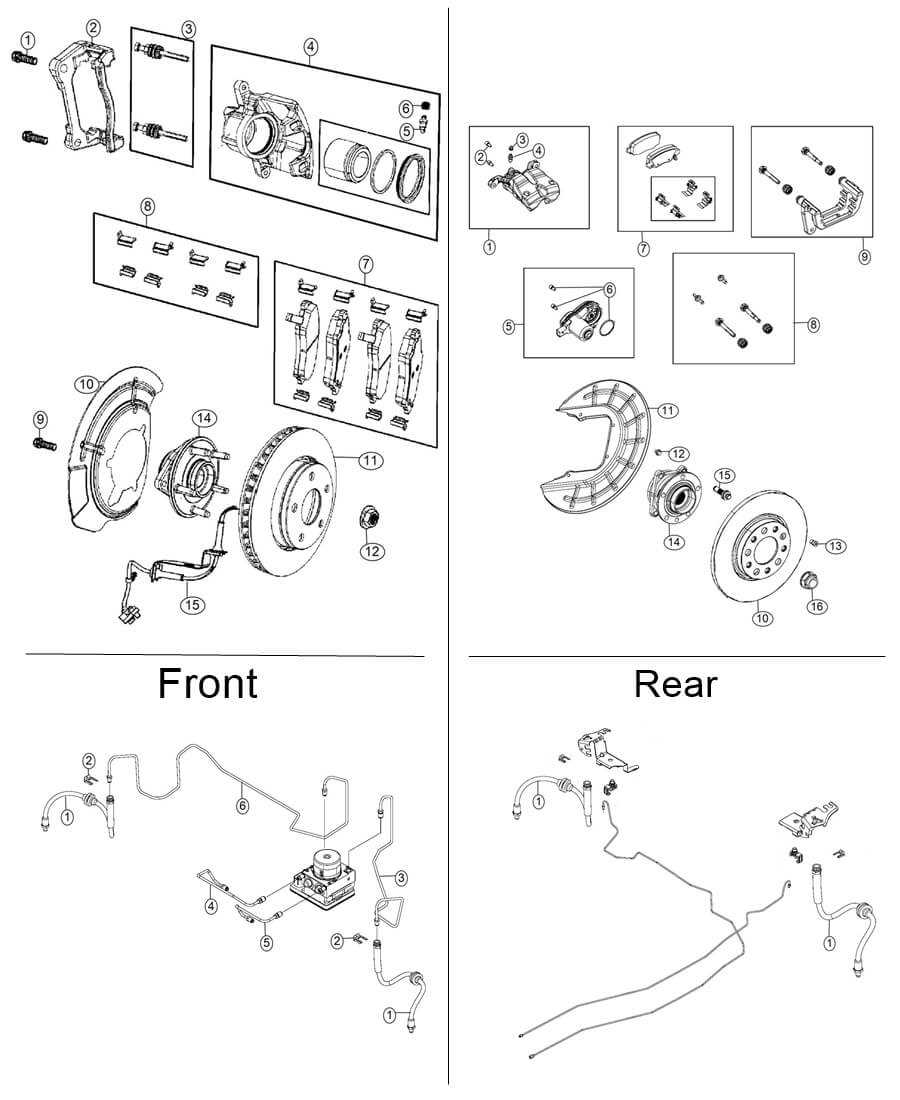

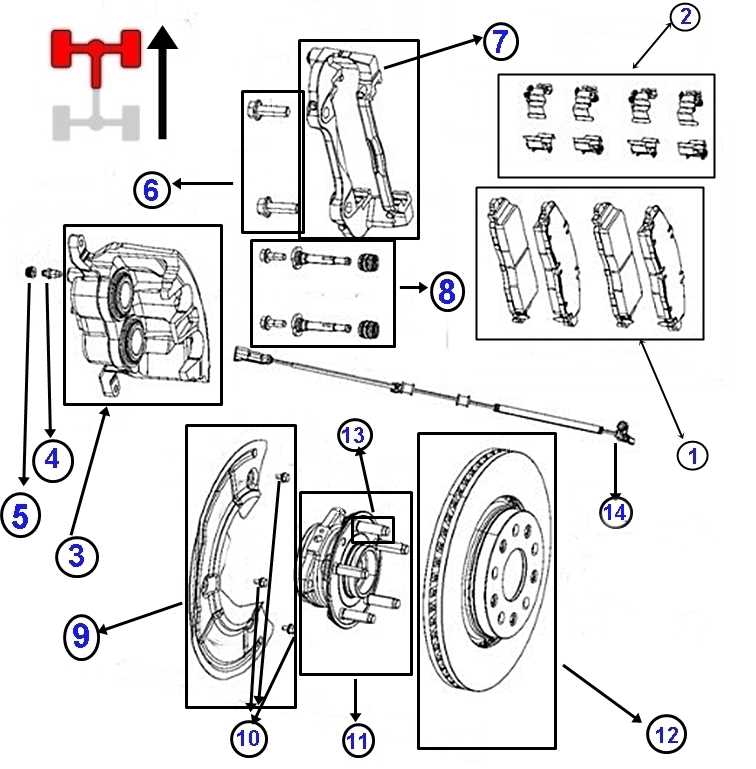

Upgrading Your Jeep Brake System

Enhancing the stopping mechanism of your vehicle can significantly improve its overall performance and safety. A well-functioning stopping system is crucial for ensuring quick and responsive halting power, especially in challenging conditions. This section will guide you through essential upgrades that can elevate your vehicle’s control and handling capabilities.

Key Upgrades for Enhanced Performance

There are several modifications you can make to optimize your vehicle’s stopping efficiency. Each upgrade contributes to improved stability and reaction time, ensuring a safer driving experience.

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Performance Rotors | These components provide better heat dissipation and increased durability. | Reduced fade and enhanced stopping power. |

| Premium Friction Material | Advanced compounds offer improved grip and longevity. | Consistent performance under various conditions. |

| Stainless Steel Brake Lines | Upgrading to stainless steel helps maintain pressure and reduces swelling. | Improved pedal feel and response time. |

Considerations Before Upgrading

Before making any enhancements, it’s essential to assess your current system and identify specific needs. Consider factors such as driving habits, environmental conditions, and the intended use of the vehicle. Proper research and planning will ensure that you select the most suitable upgrades for your requirements.

Safety Tips for Brake Maintenance

Proper upkeep of stopping mechanisms is essential for ensuring vehicle safety and reliability. Regular inspections and timely interventions can prevent unforeseen failures and enhance overall performance. Below are several key recommendations to follow when handling maintenance tasks related to these crucial components.

Regular Inspections

Consistent examinations of stopping systems are vital. Look for signs of wear, such as unusual sounds or reduced responsiveness. Addressing minor issues promptly can save time and resources in the long run. It is also beneficial to consult professional mechanics for comprehensive assessments.

Use Quality Components

When replacing any essential elements, always opt for high-quality materials. Choosing reputable brands can significantly affect durability and functionality. Additionally, ensure that all installations are performed accurately to avoid potential hazards during operation.

Understanding Anti-lock Brake Systems

The concept of anti-lock technology is essential for enhancing vehicle safety during deceleration. This system works by preventing wheel lockup, which can lead to loss of control. By modulating the force applied to each wheel, it ensures optimal traction even under challenging conditions.

How It Operates

The functionality of this system involves sensors that monitor the speed of each wheel. When the sensors detect that a wheel is about to stop spinning, the system momentarily reduces pressure on the brakes. This rapid adjustment occurs several times per second, allowing the driver to maintain steering control while effectively slowing down.

Benefits of Anti-lock Technology

One of the primary advantages of this system is its ability to improve stopping distances on slippery surfaces. Additionally, it enhances vehicle stability, providing drivers with greater confidence, especially in adverse weather conditions. Overall, this technology represents a significant advancement in automotive safety features.

FAQs About Jeep Braking Systems

The braking mechanism is crucial for vehicle safety, and understanding its components can help owners maintain their vehicles effectively. Below are common inquiries regarding the functionality and maintenance of these essential systems.

What are the signs that my stopping system needs attention?

Look for indicators such as unusual noises, decreased responsiveness, or a warning light on the dashboard. These may suggest that your stopping system requires inspection or repairs.

How often should I check the components?

It is advisable to inspect the various components regularly, typically every 10,000 to 15,000 miles, or as recommended in your vehicle’s manual. This helps ensure everything is functioning properly.

Can I replace elements of the stopping system myself?

While some individuals may have the skills to replace certain components, it is often recommended to seek professional assistance, especially for critical parts that require precise installation.

What maintenance tasks should I perform?

Regular maintenance tasks include checking fluid levels, inspecting the condition of the components, and replacing worn items as needed to ensure optimal functionality.

Are there specific materials used in these systems?

Yes, various materials are utilized, including metal, rubber, and composite materials. Each serves a unique purpose in enhancing durability and performance.