Comprehensive Guide to Briggs Engine Parts Diagram

In the realm of small machinery, a comprehensive grasp of the individual elements that contribute to functionality is essential. Each component plays a pivotal role in the overall operation, ensuring seamless performance and reliability. Gaining insight into these essential elements can empower users to enhance maintenance practices and troubleshoot issues effectively.

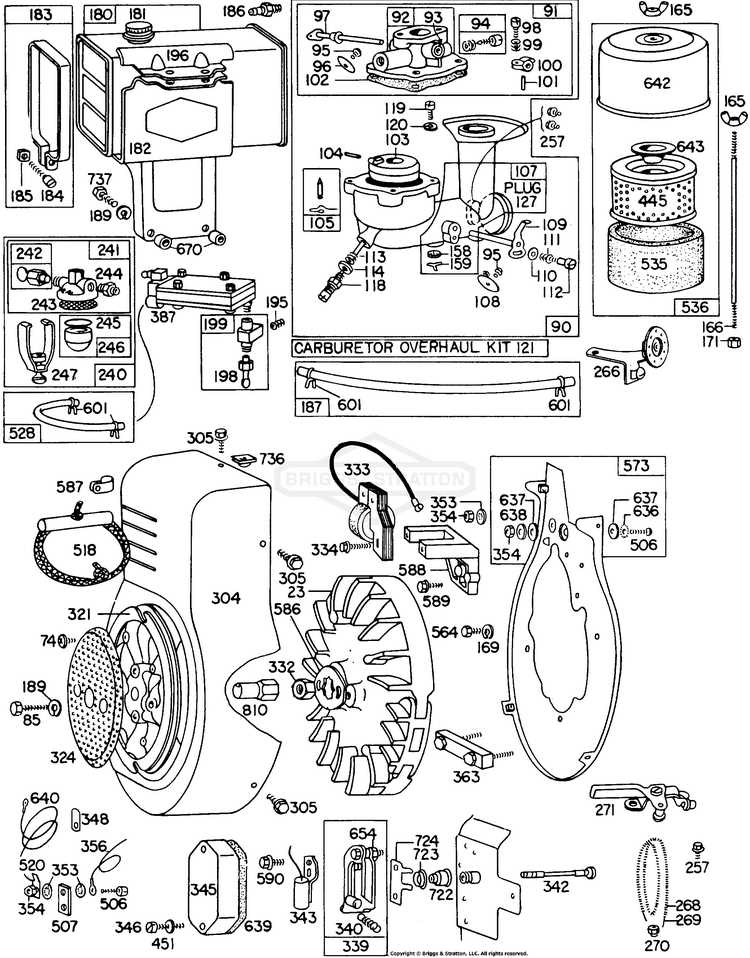

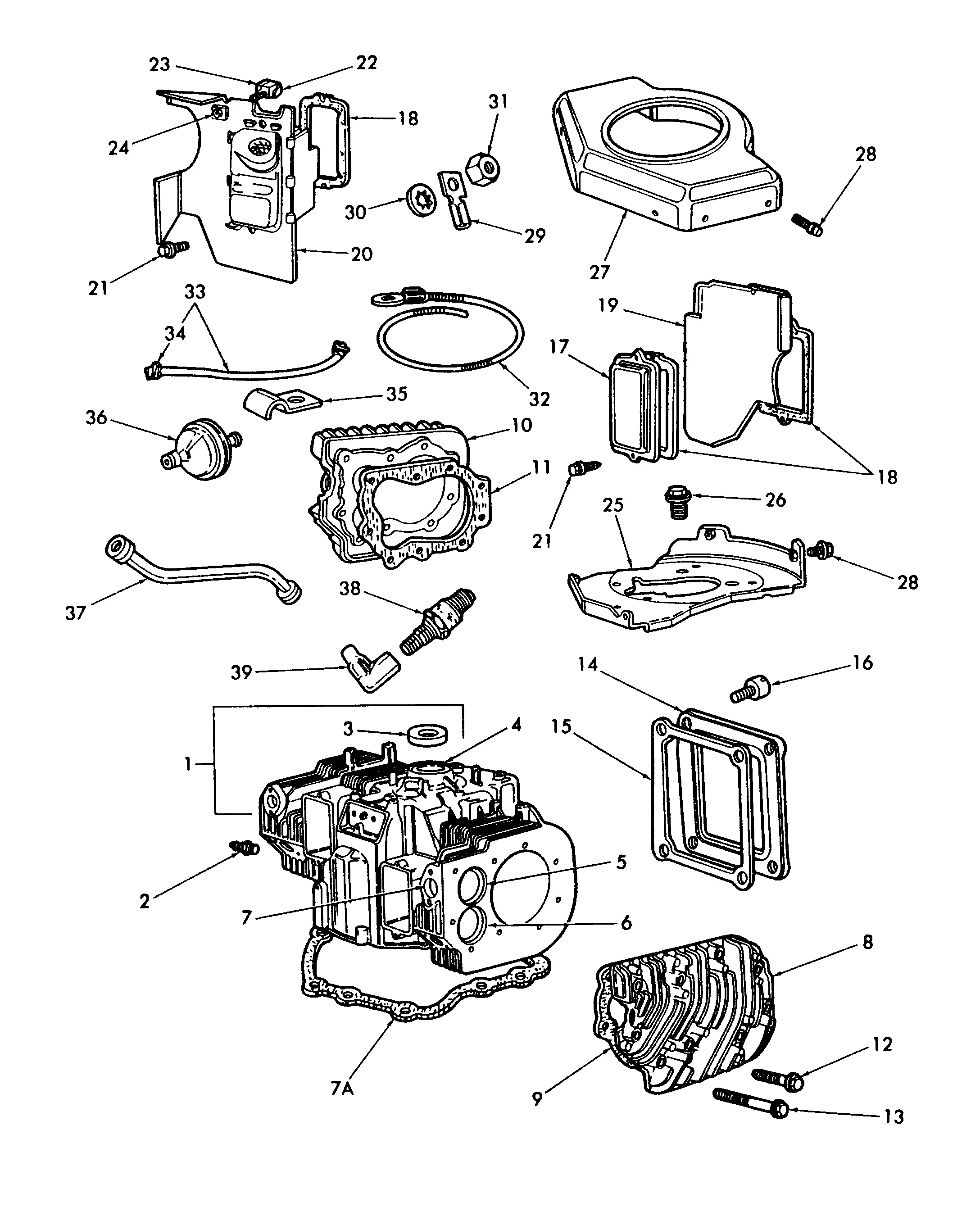

Visual representations serve as invaluable tools for identifying and understanding these various segments. By studying these illustrations, one can pinpoint the arrangement and interaction of each piece, facilitating a deeper appreciation for how they work together harmoniously. This knowledge not only aids in the repair process but also fosters a sense of confidence in handling equipment.

Furthermore, familiarity with these crucial segments paves the way for informed decisions regarding upgrades and replacements. Recognizing the specific roles and compatibility of each element allows for more strategic planning in enhancing machinery performance. Thus, a detailed exploration of these components is not just beneficial but essential for anyone involved in the operation and upkeep of small-scale devices.

Understanding Briggs Engine Parts

Gaining insight into the components of small machinery is essential for effective maintenance and troubleshooting. Each element plays a critical role in ensuring optimal functionality and performance. Familiarity with these components enhances the ability to identify issues and carry out repairs efficiently.

Central to these mechanisms are the various assemblies, including the fuel delivery system, ignition apparatus, and power transmission units. Recognizing how these elements interact can provide a clearer picture of the overall operation. Each component has a specific function, contributing to the seamless operation of the whole system.

Additionally, understanding the assembly’s layout can aid in diagnosing problems. By knowing where each part is located and its purpose, users can more easily determine what might be malfunctioning. This knowledge not only saves time but also fosters confidence in performing maintenance tasks.

In summary, a comprehensive grasp of the individual elements and their relationships is invaluable for anyone looking to maintain or repair small machinery effectively. This foundational knowledge empowers users to address issues proactively and ensure longevity in their equipment.

Diagram Overview and Importance

The visual representation of mechanical components plays a crucial role in understanding their interrelations and functions. Such illustrations provide clarity, helping both novices and experts navigate the complexities of various systems. By breaking down intricate assemblies into comprehensible segments, these graphics facilitate effective maintenance and troubleshooting.

Understanding the layout of each individual component enhances operational efficiency. With a clear overview, users can identify specific elements that require attention or replacement, thereby preventing potential issues before they escalate. This proactive approach not only extends the lifespan of the machinery but also promotes safety during operation.

In addition, these visual aids serve as educational tools, fostering a deeper comprehension of mechanics. They are invaluable for training purposes, enabling learners to visualize concepts that might otherwise be difficult to grasp. Overall, the significance of these representations cannot be overstated, as they bridge the gap between theory and practical application.

Key Components of Briggs Engines

Understanding the fundamental elements of small power units is essential for anyone looking to maintain or repair them. These components work together to ensure efficient operation and optimal performance, making knowledge of their functions critical for troubleshooting and enhancement.

Essential Elements

- Cylinder: The central chamber where combustion occurs, playing a crucial role in generating power.

- Piston: A movable component that translates combustion pressure into mechanical energy.

- Crankshaft: Converts the linear motion of the piston into rotational force, driving various mechanisms.

- Valves: Control the intake of fuel-air mixture and the expulsion of exhaust gases, ensuring proper airflow.

Supporting Mechanisms

- Ignition System: Responsible for initiating combustion, typically involving a spark plug and ignition coil.

- Fuel System: Manages the delivery of fuel to the combustion chamber, encompassing components like the carburetor or fuel injector.

- Cooling System: Maintains optimal operating temperatures to prevent overheating, utilizing fins or liquid coolant.

- Lubrication System: Reduces friction between moving parts, prolonging the lifespan of the unit.

Each of these components plays a vital role in the overall functionality of the system, and understanding their interactions can greatly aid in effective maintenance and repairs.

How to Read Engine Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance and repair. These visuals provide a comprehensive overview of components and their interrelationships, enabling users to grasp the overall structure and functionality of the system. Familiarity with these representations can significantly enhance your troubleshooting and assembly skills.

Start with the Legend: Most illustrations include a legend that explains symbols and notations used throughout. Familiarize yourself with these elements, as they are crucial for accurately interpreting the visual data presented.

Identify the Main Components: Look for the primary elements highlighted in the illustration. Often, these are displayed in a way that emphasizes their importance and relationship to one another. Understanding the roles of each part is key to comprehending the entire system.

Follow the Flow: Many visuals are designed to show the movement and interaction between components. Trace the flow of energy or materials through the system, noting how each part contributes to the overall operation.

Note the Connections: Pay attention to how different elements are connected. Lines or arrows often indicate pathways, which can clarify how systems work together. Recognizing these connections is vital for effective repairs or upgrades.

Consult Additional Resources: If a certain aspect is unclear, don’t hesitate to refer to manuals, online guides, or forums. Additional information can provide deeper insights into specific components or systems.

By mastering these techniques, you will enhance your ability to read technical illustrations effectively, leading to improved maintenance and understanding of complex machinery.

Common Issues with Engine Parts

When it comes to the mechanics of a machine, various components can encounter problems that affect overall performance. Identifying and addressing these issues early can prevent more significant damage and ensure smooth operation.

- Wear and Tear: Over time, frequent use can lead to degradation of materials, affecting efficiency.

- Corrosion: Exposure to moisture and chemicals can cause parts to rust, leading to structural weaknesses.

- Loose Connections: Vibration during operation can result in fasteners becoming loose, affecting stability.

Regular maintenance checks are essential to catch these problems before they escalate. Here are some common issues to monitor:

- Fuel leaks, which can create safety hazards.

- Overheating due to coolant deficiencies.

- Strange noises indicating potential mechanical failure.

By staying vigilant and proactive, operators can enhance the longevity and reliability of their machinery.

Replacement Parts and Upgrades

Maintaining optimal performance of your machinery often involves the timely replacement of components and thoughtful upgrades. Identifying the right alternatives can enhance efficiency and extend the lifespan of your equipment. This section will guide you through the options available for enhancing functionality and ensuring reliability.

Essential Components for Replacement

When considering replacements, it’s crucial to focus on high-quality options that match or exceed the specifications of the original components. Here are some common alternatives:

- Fuel systems: Upgrade to high-efficiency filters and pumps for improved fuel delivery.

- Ignition components: Consider premium spark plugs and ignition coils for better combustion.

- Cooling systems: Opt for high-performance fans and radiators to enhance cooling efficiency.

- Transmission elements: Replace worn belts and pulleys to ensure smooth operation.

Performance Enhancements

In addition to standard replacements, there are several enhancements that can significantly boost performance:

- Upgrade to a high-performance air intake system to increase airflow and power.

- Install advanced exhaust systems to improve gas flow and reduce back pressure.

- Utilize tuning kits that optimize fuel delivery and ignition timing.

- Consider lightweight components that reduce overall weight for better maneuverability.

Investing in quality replacements and upgrades not only improves performance but also enhances the durability of your machinery, ensuring it operates efficiently for years to come.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By following specific maintenance practices, you can significantly extend the lifespan and efficiency of your equipment. This section outlines essential tips that contribute to the reliable performance and longevity of your machinery.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and components free from debris and contaminants to prevent wear and corrosion. |

| Fluid Checks | Monitor and change lubricants and coolants as recommended to ensure optimal operation. |

| Inspect Filters | Replace air and fuel filters regularly to maintain efficiency and prevent clogs. |

| Tighten Fasteners | Periodically check and tighten bolts and screws to prevent vibrations from causing loose connections. |

| Scheduled Servicing | Follow a maintenance schedule that includes thorough inspections and professional servicing when necessary. |

| Monitor Performance | Pay attention to any changes in operation, such as unusual noises or vibrations, and address them promptly. |

Identifying Parts by Model Number

Understanding the specifics of machinery components can be crucial for maintenance and repairs. One effective method for locating the right components is through the model number. This unique identifier provides a straightforward way to ensure compatibility and quality when sourcing replacements.

Why Model Numbers Matter

Model numbers serve several important functions:

- They guarantee that the selected items fit correctly.

- They simplify the search process, making it easier to find specific items.

- They often indicate the manufacturing date, which can be important for compatibility.

How to Find Model Numbers

Locating the model number is essential for accurate identification:

- Check the product’s user manual, where model details are typically listed.

- Examine the machinery itself for labels or engravings.

- Visit the manufacturer’s website for online resources or support.

By following these steps, users can efficiently identify and procure the necessary components, ensuring the smooth operation of their equipment.

Tools Required for Engine Repair

Undertaking repairs on mechanical machinery necessitates a specific set of instruments to ensure efficiency and precision. Having the right tools not only facilitates the disassembly and assembly of components but also enhances the overall effectiveness of the maintenance process. This section highlights essential implements that every technician should have on hand for successful repairs.

Essential Hand Tools

Basic hand tools are indispensable in any repair workshop. Wrenches, pliers, screwdrivers, and hammers are fundamental for loosening, tightening, and adjusting various fittings. A quality socket set allows for the quick removal of bolts and nuts, while precision tools like torque wrenches ensure that fasteners are tightened to the correct specifications. Additionally, a sturdy toolbox is crucial for keeping these instruments organized and easily accessible.

Power Tools and Equipment

In addition to hand tools, power tools significantly expedite the repair process. Drills and impact wrenches can make quick work of tough fasteners, while grinders and sanders are useful for smoothing surfaces and preparing components for assembly. Safety gear, such as goggles and gloves, should always be used when operating power tools to prevent accidents and injuries. Investing in high-quality equipment will ultimately save time and enhance the quality of repairs.

Where to Find Genuine Parts

When it comes to maintaining the performance and longevity of your machinery, sourcing authentic components is essential. Genuine replacements ensure compatibility and reliability, which are crucial for optimal functionality. Knowing where to locate these quality items can significantly impact your repair and maintenance efforts.

Authorized dealers are among the best sources for original items, as they typically carry a comprehensive selection and can provide expert advice. Additionally, many manufacturers maintain online platforms where you can order components directly, often with detailed specifications to help you make informed choices.

Another option is specialty retailers that focus on specific brands or types of equipment. These shops often have knowledgeable staff who can assist you in identifying the right components for your needs. Online marketplaces can also be useful; however, it’s important to verify the seller’s reputation to ensure you’re purchasing authentic goods.

Finally, local repair shops may offer original items or can help you track down the necessary components. Building relationships with these professionals can lead to better insights into where to find the most reliable supplies.

Exploring Aftermarket Options

When it comes to enhancing performance and reliability, exploring alternative solutions can open up a world of possibilities. Many enthusiasts and professionals look beyond original components to find superior quality and tailored features that better meet their needs. This section will delve into various aftermarket choices available in the market.

Aftermarket products often provide advantages such as improved durability, enhanced efficiency, and greater customization. Here are some key considerations when exploring these options:

- Quality Assurance: Look for reputable brands that offer warranties and customer support.

- Performance Enhancements: Many alternatives are designed to boost functionality and performance.

- Cost-Effectiveness: Assess whether the initial investment translates to long-term savings and benefits.

- Compatibility: Ensure that the chosen alternatives are compatible with existing setups.

In addition to these factors, it is crucial to research user reviews and expert recommendations to make informed decisions. Here are some popular categories to consider:

- Filters and Air Intakes

- Fuel Systems

- Ignition Components

- Exhaust Systems

By carefully evaluating these aftermarket selections, users can enhance their overall experience and achieve the desired performance outcomes.