Complete Guide to 2013 Ford F150 Front Bumper Parts Diagram

The assembly that shields the front section of a vehicle is crucial for both aesthetics and functionality. It serves as the first line of defense against external impacts and enhances the overall appearance of the automobile.

To gain insights into this assembly, one must explore its various elements and their interconnections. A comprehensive breakdown of these components allows for better maintenance and potential upgrades, ensuring optimal performance and safety.

By examining a detailed representation of this assembly, enthusiasts and mechanics alike can identify specific pieces, facilitating repairs and replacements. Understanding the configuration of these elements ultimately leads to a more informed approach to vehicle care.

Overview of 2013 Ford F150 Bumper

The front protection structure of a truck serves as a crucial component in both aesthetics and functionality. This assembly not only enhances the vehicle’s appearance but also plays a vital role in safeguarding essential elements during potential impacts. Understanding the intricacies of this component helps in making informed decisions regarding maintenance and upgrades.

Constructed from a variety of durable materials, the assembly is designed to absorb shocks while maintaining the structural integrity of the vehicle. It integrates seamlessly with other elements, contributing to the overall safety features. Regular inspection of this area can prevent costly repairs and ensure optimal performance on the road.

Replacement options vary, ranging from OEM selections to aftermarket alternatives, each offering distinct advantages. Customization possibilities allow owners to tailor their vehicles to personal preferences, whether for improved functionality or enhanced style. Knowing the available choices empowers truck enthusiasts to enhance their ride effectively.

Importance of Bumper Parts

The components that make up the protective front assembly of a vehicle play a crucial role in ensuring safety and functionality. These elements are designed not only to absorb impact during collisions but also to enhance the overall aesthetic appeal and structural integrity of the vehicle.

| Component | Function |

|---|---|

| Reinforcement | Provides structural support and impact resistance. |

| Cover | Enhances appearance while protecting inner components. |

| Grille | Facilitates airflow to the engine and protects against debris. |

| Fascia | Offers a sleek finish and houses various features like sensors. |

Understanding the significance of these components allows vehicle owners to maintain and upgrade their assemblies effectively, ensuring long-term performance and safety on the road.

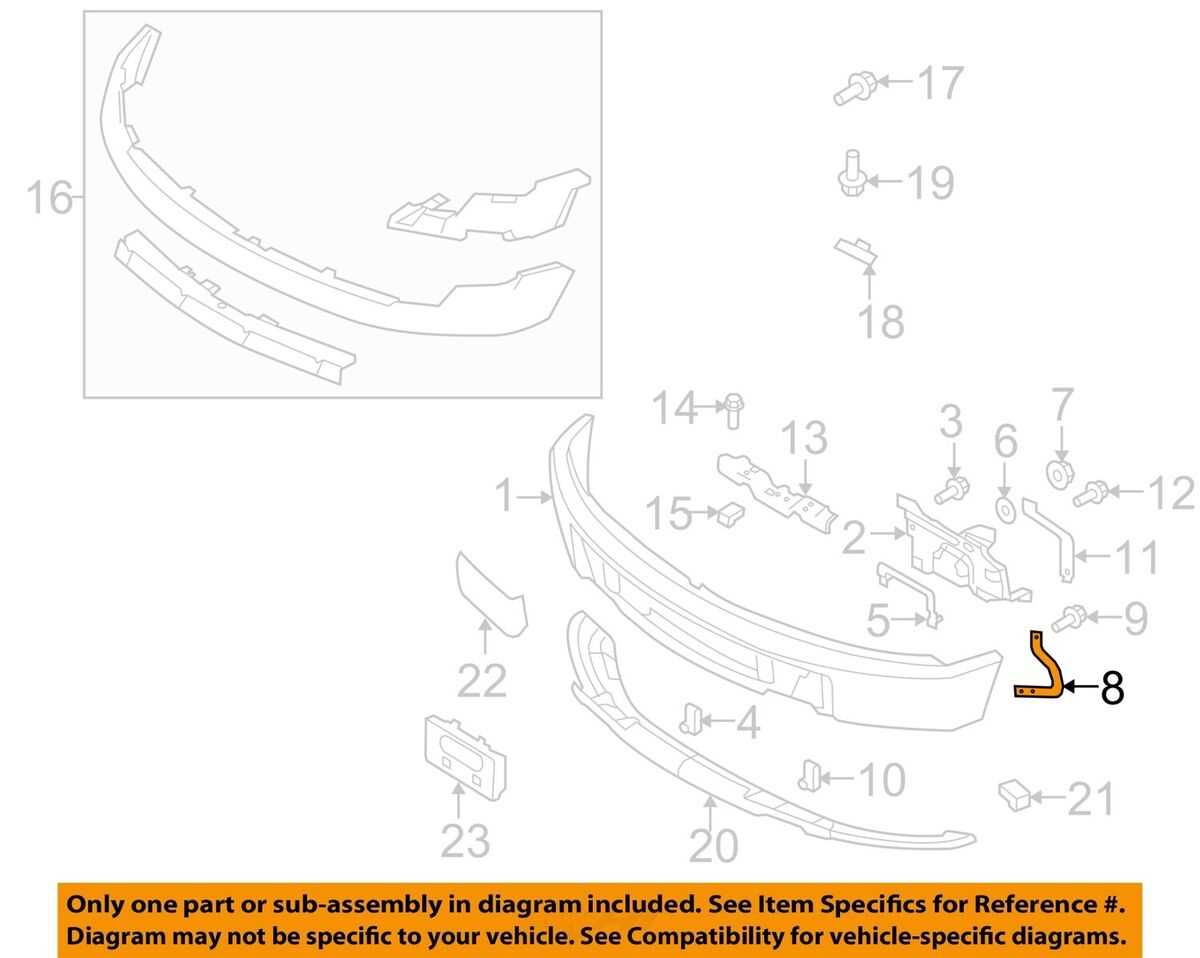

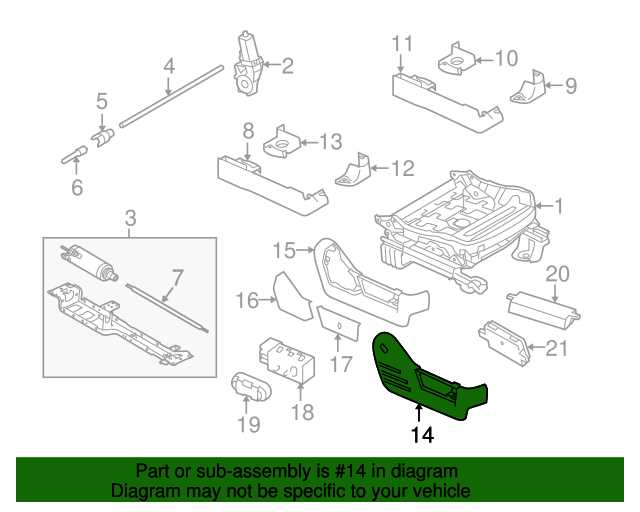

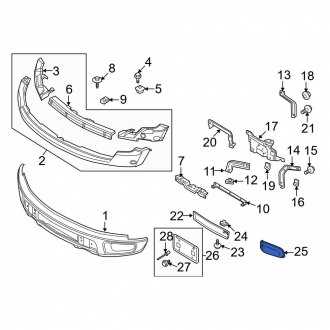

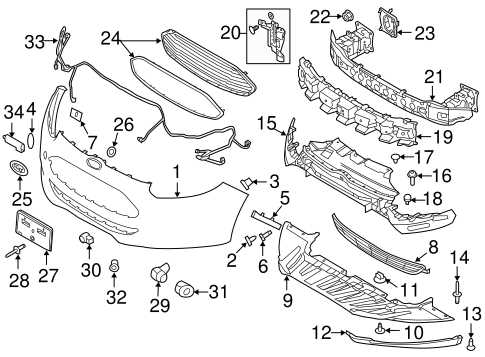

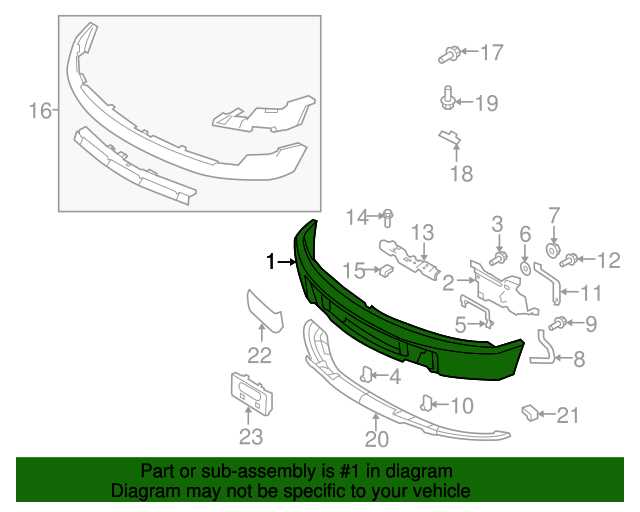

Key Components of the Front Bumper

The assembly at the vehicle’s forefront plays a crucial role in safety and aesthetics. Understanding its essential elements can enhance both functionality and appearance, ensuring optimal performance during everyday use and in challenging situations.

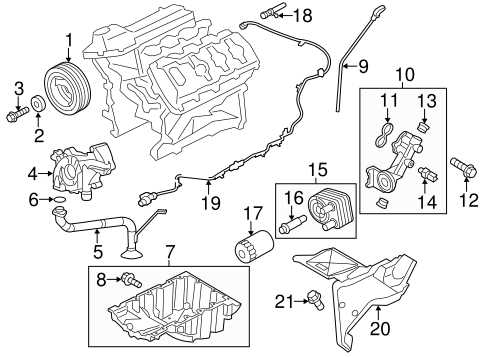

Reinforcement Structure: This foundational element provides stability and strength, protecting the vehicle’s framework during impacts. It is designed to absorb shock and minimize damage to critical components.

Covering Shell: The outer layer contributes to the overall design while shielding the underlying mechanisms. Often crafted from durable materials, it resists wear and environmental factors.

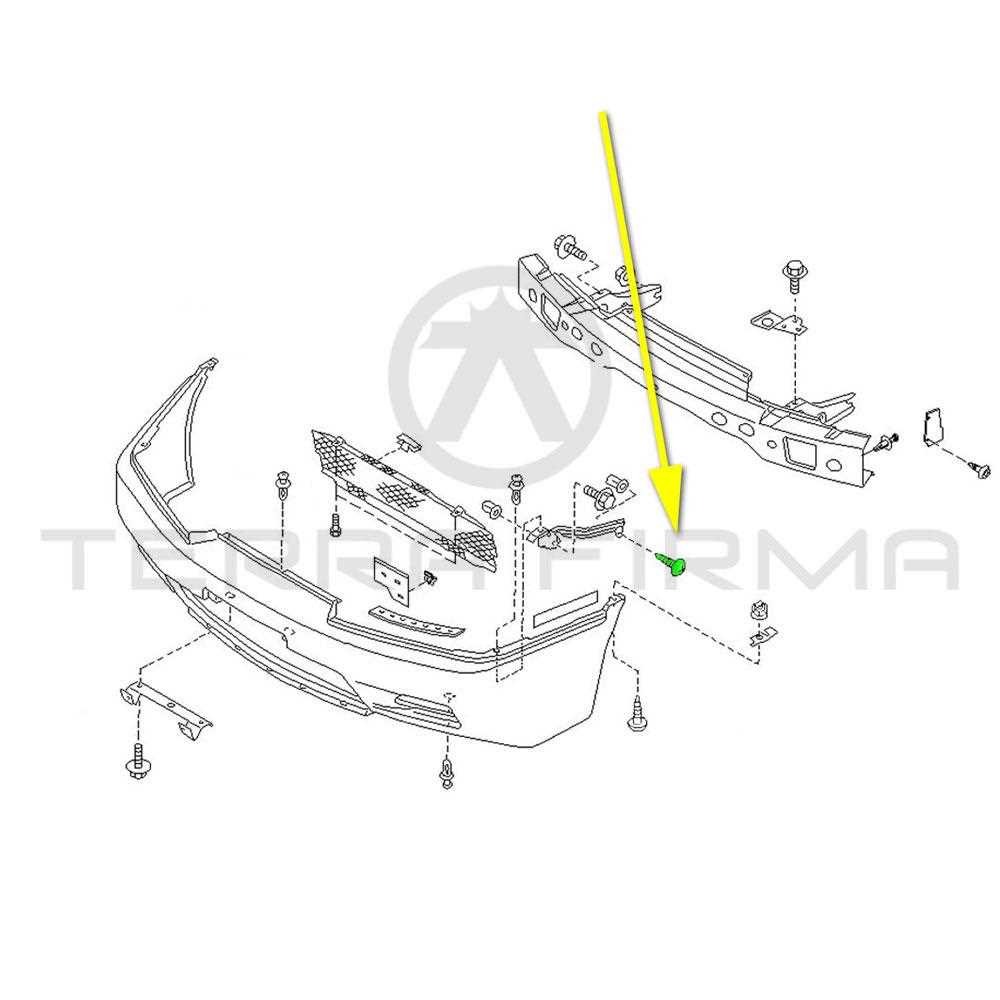

Mounting Brackets: These connectors secure the assembly to the vehicle’s chassis, ensuring proper alignment and durability. Their design is essential for maintaining structural integrity under various conditions.

Impact Absorbers: Strategically placed within the assembly, these components help dissipate energy during collisions, reducing the risk of injury to occupants and damage to the vehicle.

Grille and Lighting Fixtures: Often integrated into the assembly, these elements enhance visibility and airflow while contributing to the vehicle’s overall aesthetic appeal. They are vital for both functionality and style.

Understanding these critical components helps in maintaining and upgrading the vehicle’s front assembly, ensuring it meets safety standards and enhances driving experience.

Common Issues with F150 Bumpers

Understanding the typical problems associated with vehicle front-end components is crucial for maintenance and safety. These elements can encounter various challenges that affect both functionality and aesthetics.

Common Problems

- Cracks and Breaks

- Paint Fading and Chipping

- Misalignment

- Corrosion from Weather Exposure

- Loose Attachments

Impact of Damage

Damage can compromise safety and the overall appearance of the vehicle. Regular inspections and timely repairs are essential to prevent further issues.

Replacement Parts Availability

The availability of essential components for vehicle restoration is crucial for maintaining optimal performance and aesthetics. Access to quality replacements ensures that enthusiasts and owners can efficiently manage repairs and enhancements, minimizing downtime and maximizing utility.

Sources for Quality Components

Numerous suppliers provide a vast selection of high-quality replacements, ranging from original equipment manufacturers to aftermarket vendors. Engaging with reputable retailers can guarantee that the materials meet or exceed industry standards, enhancing durability and reliability.

Considerations for Selection

When sourcing components, it is vital to consider factors such as compatibility, warranty options, and pricing. Evaluating these aspects will enable consumers to make informed decisions that align with their specific needs and budget.

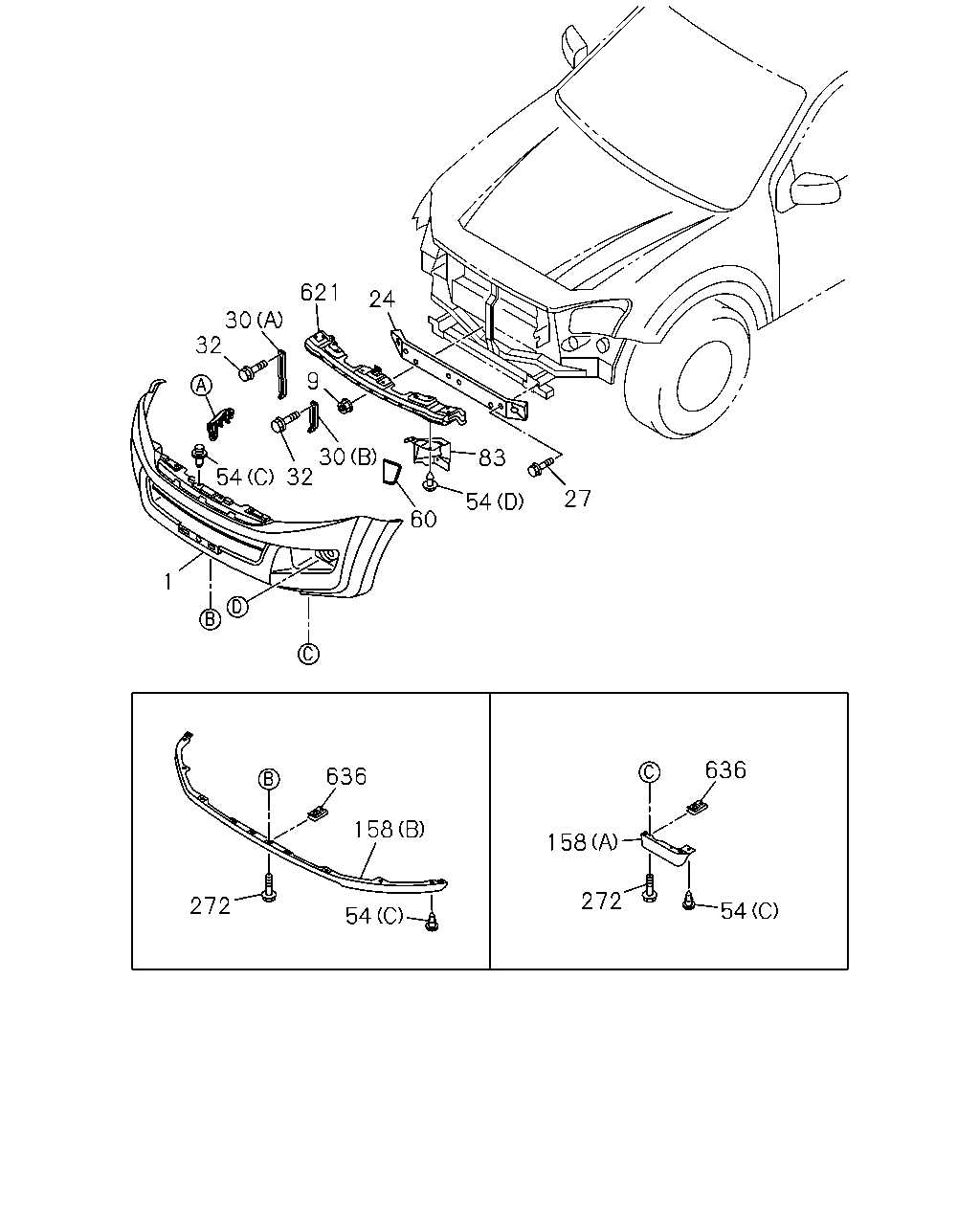

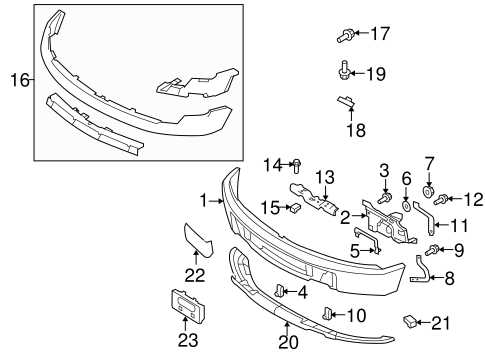

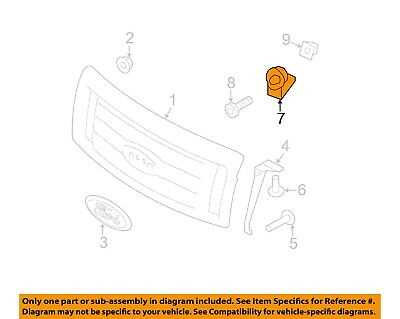

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in assembly or repair tasks. These visual representations simplify complex structures, providing clarity on how components fit together. By learning to interpret these images, you can enhance your efficiency and accuracy in various projects.

Start by identifying the key elements within the illustration. Each item will usually be labeled with numbers or letters, corresponding to a list of components. This reference list is crucial for finding the correct pieces quickly.

Next, pay attention to the layout. The arrangement of the components can indicate how they connect or interact. Observe any directional arrows or connecting lines that might suggest movement or assembly order.

Finally, take note of any additional information provided, such as specifications or part numbers. This data can be invaluable when sourcing replacements or understanding compatibility with other elements.

Aftermarket vs OEM Components

When it comes to vehicle repairs and enhancements, choosing the right components can significantly impact performance and longevity. The decision often lies between original manufacturer products and alternatives produced by third parties. Each option presents distinct advantages and drawbacks that can influence your purchasing decision.

OEM components are produced by the original manufacturer and are designed to fit and function precisely as the original parts. They are often favored for their reliability and compatibility. However, they typically come with a higher price tag.

On the other hand, aftermarket options can provide cost-effective alternatives that may offer enhanced features or improved performance. These products often appeal to those looking for customization or specific enhancements that OEM components may not provide.

- Advantages of OEM:

- Perfect fit and compatibility

- Assured quality and reliability

- Warranty coverage

- Disadvantages of OEM:

- Higher costs

- Limited options for customization

- Advantages of Aftermarket:

- Cost savings

- Variety of choices and features

- Potential for improved performance

- Disadvantages of Aftermarket:

- Variable quality and reliability

- Possible compatibility issues

- Limited warranty options

Ultimately, the choice between aftermarket and OEM components hinges on individual priorities, including budget, desired performance, and long-term vehicle goals. Careful consideration of both options can lead to an informed decision that best suits your needs.

Installation Tips for Bumper Parts

Ensuring a seamless integration of components requires careful attention to detail and technique. Proper installation not only enhances the vehicle’s aesthetics but also guarantees safety and functionality. Here are some key tips to keep in mind during the assembly process.

Preparation Steps

Before starting the installation, gather all necessary tools and components. Verify that each item is compatible with your vehicle’s specifications. Reviewing the manufacturer’s guidelines can provide valuable insights on the correct assembly procedures.

Installation Process

When proceeding with the installation, follow these essential steps:

| Step | Description |

|---|---|

| 1 | Remove any existing components carefully to avoid damage. |

| 2 | Align new components properly for a perfect fit. |

| 3 | Tighten all fasteners securely, ensuring stability. |

| 4 | Test the installation by applying light pressure to check for movement. |

Tools Required for Installation

Successfully completing the installation of the necessary components for your vehicle’s exterior requires specific tools. Having the right equipment not only streamlines the process but also ensures that the task is performed safely and effectively. Below is a list of essential tools you will need to accomplish this project.

Essential Tools

- Socket Set

- Wrench Set

- Screwdriver Set (flathead and Phillips)

- Torque Wrench

- Pry Bar

- Utility Knife

- Ratchet Strap (optional)

Additional Supplies

- Protective Gloves

- Safety Glasses

- Flashlight

- Cleaning Cloths

- Lubricant Spray

Having these tools and supplies on hand will make your installation process more efficient and help ensure a successful outcome.

Maintenance Tips for Bumpers

Ensuring the longevity and functionality of your vehicle’s exterior components is essential for both aesthetics and safety. Regular upkeep can prevent wear and tear, enhancing the overall performance of your ride.

Routine Inspections

- Check for cracks or dents regularly.

- Inspect attachment points for looseness.

- Look for signs of rust or corrosion.

Cleaning Techniques

- Wash with mild soap and water to remove debris.

- Avoid harsh chemicals that can damage the surface.

- Use a soft cloth to prevent scratching.

By incorporating these practices, you can delve into the ultimate care routine for your vehicle’s protective elements, ensuring they remain in optimal condition for years to come.

Cost Analysis of Replacement Parts

Understanding the financial implications of component replacements is crucial for vehicle maintenance. Evaluating expenses associated with various elements can aid in budget planning and decision-making.

| Component | Average Cost | Factors Influencing Price |

|---|---|---|

| Outer Shield | $250 | Material, brand, and condition |

| Support Bracket | $75 | Design complexity and manufacturing |

| Fastening Hardware | $30 | Quantity and material type |

| Grille Section | $120 | Market demand and availability |

Assessing these costs provides insight into the ultimate expenditure involved in restoring functionality, ensuring that owners make informed choices regarding repairs.

Comparing Bumper Styles and Designs

When evaluating the various styles and designs of protective front-end components, it’s essential to understand how their construction influences both functionality and aesthetic appeal. Each design serves unique purposes, catering to different preferences and needs.

Key Design Features

- Material Composition

- Shape and Profile

- Integration with Vehicle Features

- Weight and Aerodynamics

Popular Styles

- Classic Design: Timeless and functional.

- Off-Road Style: Enhanced durability for rugged terrains.

- Aerodynamic Models: Improved fuel efficiency and streamlined look.

Ultimately, selecting the right style requires a careful balance between appearance and performance, allowing vehicle owners to customize their rides effectively.

Frequently Asked Questions about Bumpers

This section addresses common inquiries related to protective front structures. Understanding these components is essential for maintenance and repair, ensuring safety and functionality.

What materials are typically used in bumper construction?

Most protective structures are crafted from materials like steel, aluminum, and various types of plastics. Each material offers distinct advantages in terms of durability, weight, and cost-effectiveness.

How do I know if my vehicle’s protective structure needs replacement?

Signs that indicate a need for replacement include visible damage, rust, or if it fails to align correctly with other components. Regular inspections can help identify these issues early, ensuring safety on the road.