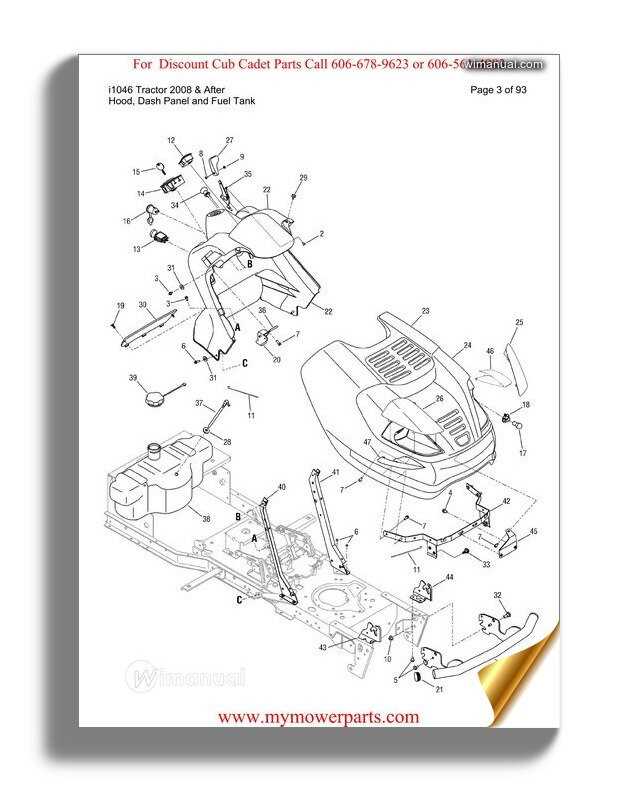

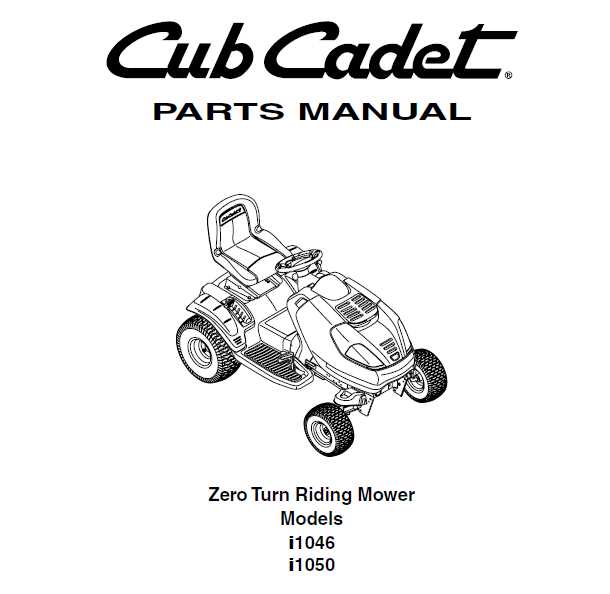

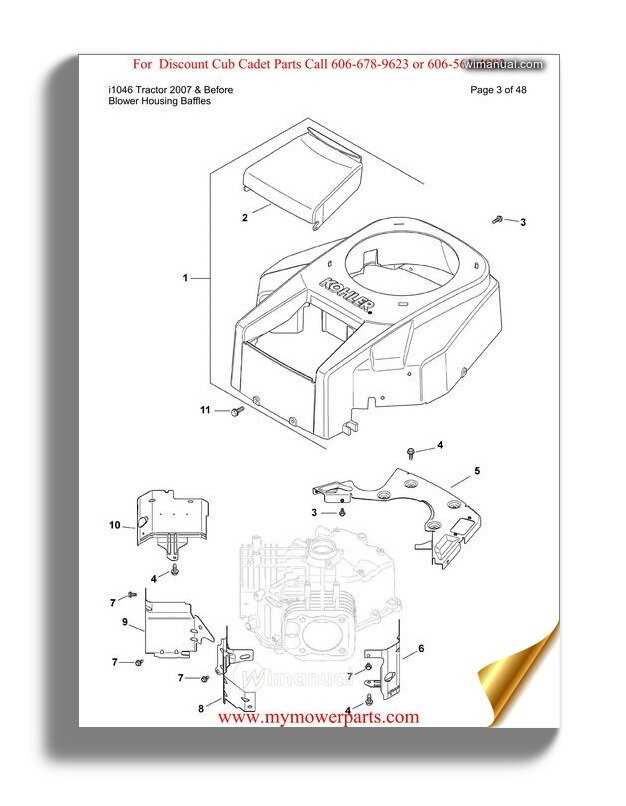

Cub Cadet 1046 Parts Diagram Explained

Understanding the key elements that power and maintain your lawn tractor is crucial for smooth operation and long-lasting performance. Each element of this machine plays a vital role in ensuring efficiency, and recognizing how they work together is the first step to maintaining optimal functionality.

From the internal mechanisms responsible for movement to the external features that offer control, knowing how these components are structured and interact can make troubleshooting and repairs significantly easier. This guide offers a comprehensive look into the assembly, providing a clear understanding of the machinery’s core structure.

With a focus on practical application, this breakdown will help owners and operators ensure their equipment remains reliable and efficient. Clear insights into the configuration will make it easier to identify the location and function of key elements, assisting in regular upkeep or potential replacements.

This section provides a detailed breakdown of various elements that make up the mechanical structure of this model. The goal is to explore how individual components contribute to the machine’s overall function, helping users better understand the internal workings and maintenance needs. The content will guide through different segments of the equipment, focusing on their roles in operation and upkeep.

- Overview of major system elements

- Key functional modules and their interaction

- Identification of critical components for repair and maintenance

- Focus on frequently serviced elements

- Introduction to operational segments

- Understanding mechanical linkages

- Explaining structural and auxiliary elements

- Guiding through essential replacements

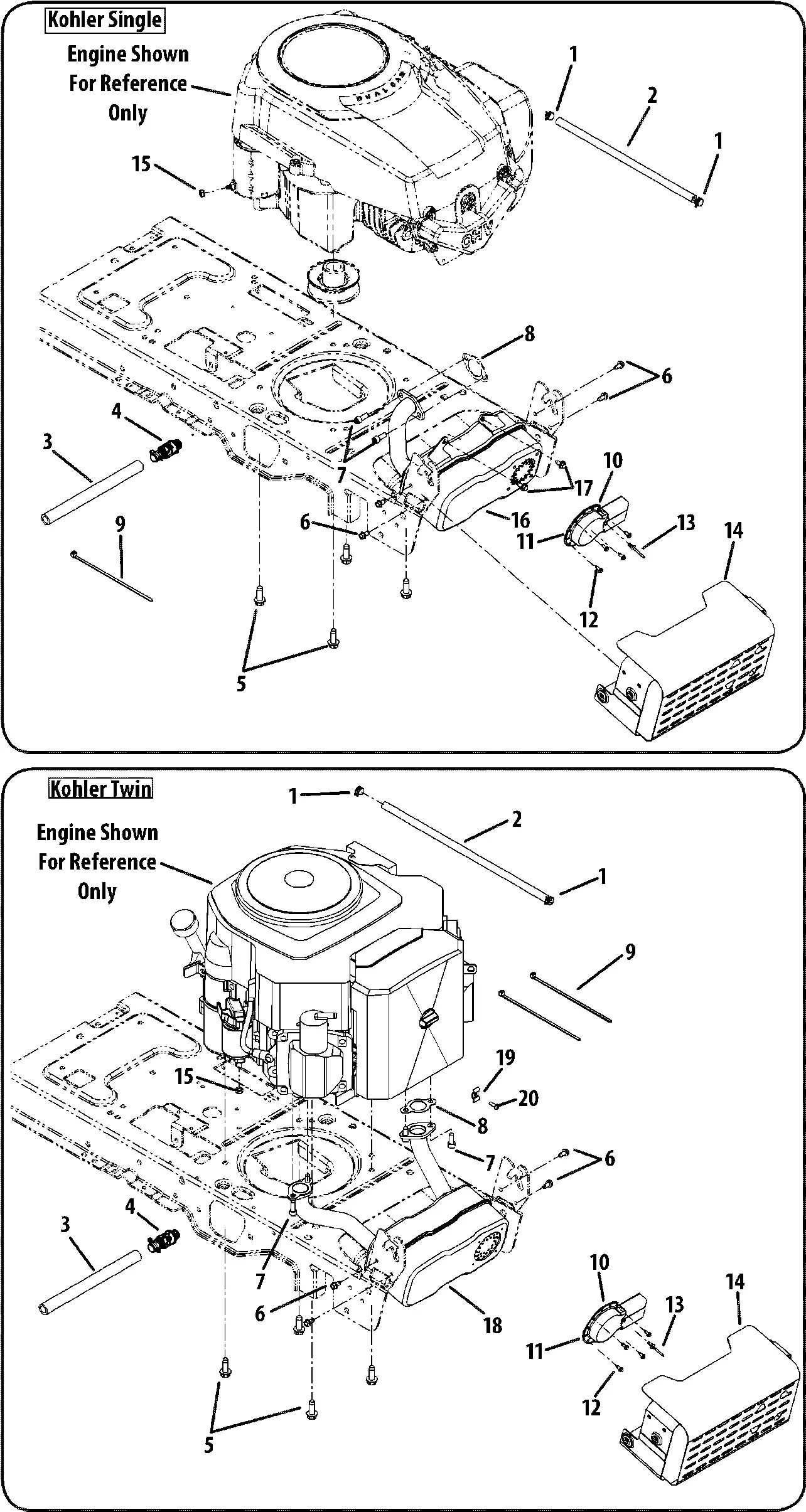

Key Components in the Engine System

The power unit relies on a variety of critical elements to ensure smooth operation and efficiency. Each part works in unison, playing a significant role in regulating performance and maintaining reliability. Understanding these components helps in troubleshooting and optimizing the overall function of the machine.

- Fuel System: This includes the fuel tank, lines, and filters that deliver clean fuel to the combustion area.

- Air Intake: Air filters and intake valves ensure proper air flow, which is essential for effective combustion.

- Ignition System: Spark plugs and ignition coils create the necessary spark to ignite the air-fuel mixture, initiating the engine cycle.

- Cooling Mechanism: The fan and radiator prevent overheating by dissipating excess heat generated during operation.

- Lubrication System: Oil pumps and filters circulate lubricant to reduce friction between moving parts, enhancing longevity.

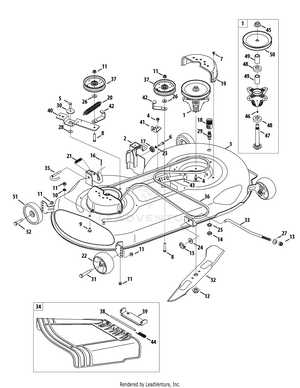

Understanding the Cutting Deck Assembly

The mowing platform is a key component in ensuring the efficient and precise trimming of grass. Understanding its layout and functionality helps in maintaining its performance over time. The platform’s components work together to deliver a smooth and even cut, which is essential for a well-kept lawn.

Several elements are involved in the operation of the cutting platform, from the rotating blades to the mechanical linkages that control height adjustment. Proper alignment and maintenance of these elements are crucial to avoiding uneven cuts or mechanical issues. Below is a breakdown of key components and their roles within the assembly:

| Component | Function |

|---|---|

| Blades | Responsible for cutting the grass evenly. |

| Deck Belt | Transfers power from the engine to the blades. |

| Spindles | Support the blades and allow them to rotate at high speeds. |

| Height Adjustment Lever | Controls the cutting height for different grass levels. |

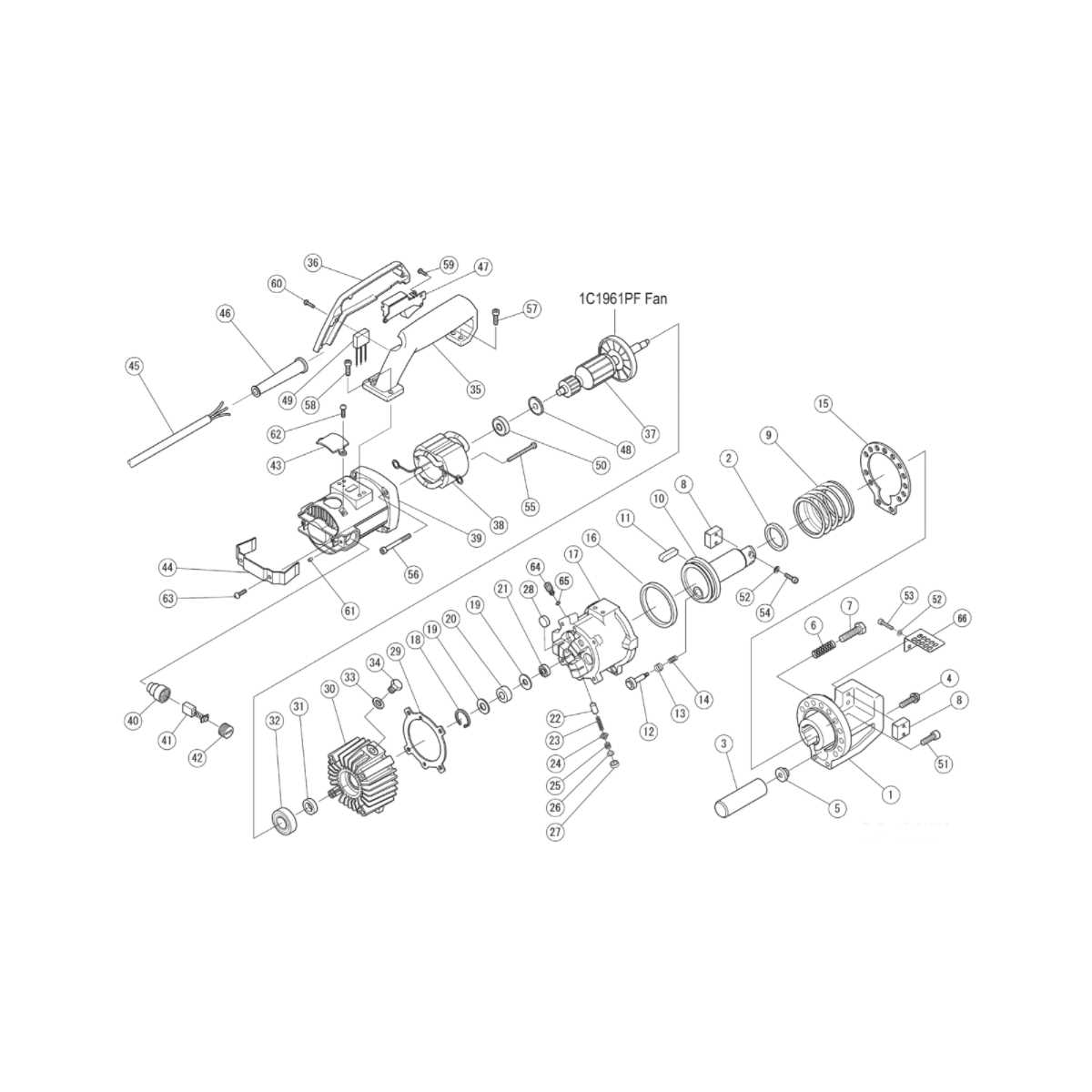

Drive System and Transmission Parts

The drive mechanism and gear system play a crucial role in ensuring the efficient movement and power transfer within the equipment. These components work together to deliver the necessary torque and speed adjustments, allowing for smooth operation across varying terrains.

Key Components of the Drive Mechanism

The primary elements involved in the system include belts, pulleys, and gear assemblies. The belts are responsible for transferring energy from the motor, while the pulleys guide the movement of these belts. Gears ensure that the power is delivered effectively, maintaining a balance between speed and control.

Transmission and Gear Functionality

The transmission is the heart of the movement system, responsible for adjusting speed and torque. It shifts between gears based on load requirements, ensuring the machine operates efficiently. A well-maintained transmission ensures longevity and optimal performance.

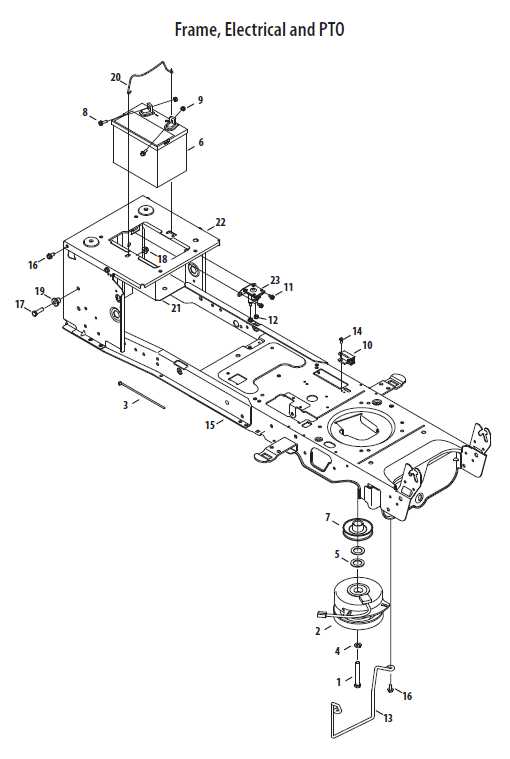

Electrical Wiring and Key Connections

Understanding the structure and layout of electrical systems is crucial for maintaining and optimizing the functionality of various machines. The arrangement of wires and connectors ensures that each component receives the necessary power to operate efficiently. Paying close attention to the connections and pathways within the system can help avoid malfunctions and ensure long-lasting performance.

Essential Circuits and Their Role

Several critical circuits form the backbone of any electrical system. These circuits include power lines that feed into key components, as well as control pathways that regulate various operations. Ensuring these circuits are correctly wired and properly insulated is vital for overall system efficiency.

Main Connectors and Their Placement

The positioning of connectors plays an important role in both ease of maintenance and stability. Properly placed connectors allow for smooth transitions between components and reduce the likelihood of disconnects or short circuits. Regular inspection of these junctions is recommended to maintain operational integrity.

| Connection Type | Purpose |

|---|---|

| Power Connector | Supplies power to key components |

| Control Connector | Regulates operation of electrical systems |

| Grounding Wire | Prevents electrical overloads |

Essential Parts for Steering Mechanism

Maintaining proper control and maneuverability is key to ensuring smooth operation of any vehicle. The steering assembly plays a critical role in allowing the operator to guide and direct movements effectively. Understanding the crucial elements involved in this system helps in ensuring long-lasting performance and reliability.

- Steering Wheel: This is the interface through which the operator inputs control. It transmits motion down to the rest of the steering components.

- Steering Column: A vital link that connects the wheel to the mechanical elements responsible for turning the vehicle’s wheels.

- Steering Shaft: The shaft transfers rotational force from the steering wheel to the key components within the steering assembly.

- Drag Link: This element ensures the smooth transmission of movement from the steering gear to the wheels, helping to adjust the vehicle’s direction.

- Spindle: The spindle is a part that supports the wheel and rotates to enable directional changes in response to the operator’s input.

- Tie Rods: Connecting the steering mechanism to the wheels, tie rods play a critical role in adjusting the wheel alignment and maintaining steady steering control.

Maintenance Tips for Mower Blades

Proper care and upkeep of the cutting components are essential for ensuring a smooth and efficient mowing experience. Routine maintenance not only prolongs the life of these components but also enhances the overall performance of your equipment.

Inspecting for Wear and Damage

Regularly examine the sharp edges for signs of dullness, cracks, or bends. Dull blades can cause uneven cuts, while damaged ones may harm the machine or affect its efficiency.

- Look for nicks, dents, and cracks along the edge.

- Ensure there are no bent areas affecting the balance.

- Replace any damaged pieces immediately to prevent further issues.

Sharpening and Balancing

Sharpening ensures a clean cut, while balancing prevents unnecessary strain on the engine. Both processes are essential to maintaining optimal performance.

- Use a file or sharpening tool to restore the cutting edge.

- Check the balance using a balancing tool to ensure even weight distribution.

- Reinstall the components carefully, ensuring all bolts are properly tightened.

Hydraulic System Components and Functions

In any mechanical system where fluid power is utilized, understanding the structure and purpose of the hydraulic elements is essential. These elements work together to ensure smooth operation, transferring energy through liquid pressure. Each component within the system has a specific role that contributes to overall efficiency.

Main Elements of the Hydraulic System

- Pump: Responsible for moving fluid through the system, creating pressure needed to perform work.

- Valves: Control the flow and direction of fluid, ensuring it reaches the correct parts of the mechanism.

- Cylinders: Convert hydraulic energy into mechanical force, often used for lifting or moving heavy components.

- Reservoir: Stores the hydraulic fluid and helps dissipate heat generated during operation.

Supporting Components

- Filters: Remove contaminants from the fluid to maintain system health and prevent blockages.

- Piping and Hoses: Transport hydraulic fluid between different sections of the system, ensuring a continuous flow of energy.

- Fittings and Seals: Ensure tight connections between components, preventing leaks and maintaining pressure.

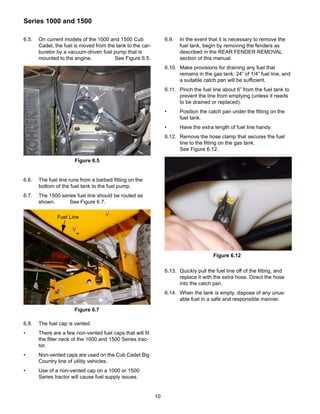

Fuel System Parts and Their Roles

The fuel mechanism is a critical aspect of any machinery, ensuring efficient energy delivery to the engine. Various components work in unison to facilitate the proper flow and management of fuel, ultimately affecting performance and reliability. Understanding each element’s function within this system can help in maintaining and troubleshooting any issues that arise.

- Fuel Tank: This reservoir stores the fuel, keeping it safe until it is needed by the engine.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine, it ensures the correct pressure is maintained for optimal performance.

- Fuel Filter: This component removes impurities from the fuel, preventing damage to the engine and ensuring smooth operation.

- Fuel Lines: These conduits transport fuel from the tank to the engine, requiring regular inspection to avoid leaks.

- Carburetor or Fuel Injector: These elements mix air and fuel in the right ratio for combustion, crucial for engine efficiency and power.

By recognizing the individual roles of these components, operators can better understand the overall functionality of the fuel mechanism and address any maintenance needs effectively.

Common Wear and Tear Parts

In any mechanical system, certain components are more prone to degradation over time due to regular use and environmental factors. Understanding these elements is crucial for effective maintenance and longevity of the equipment. This section highlights the frequently replaced components that contribute to optimal performance and efficiency.

Frequently Affected Components

- Belts: These are vital for transferring power within the machinery. Over time, they can stretch, crack, or fray, requiring periodic inspection and replacement.

- Blades: Cutting edges endure significant wear, leading to dullness or damage. Regular sharpening or replacement ensures efficient operation.

- Filters: Air and fuel filters accumulate debris and contaminants, impacting performance. Routine changes are necessary to maintain clean operation.

- Battery: Batteries have a limited lifespan and may require replacement as they lose their ability to hold a charge effectively.

Maintenance Tips

- Inspect components regularly for signs of wear.

- Replace worn items promptly to avoid further damage.

- Follow manufacturer guidelines for maintenance schedules.

- Store equipment in a controlled environment to minimize deterioration.

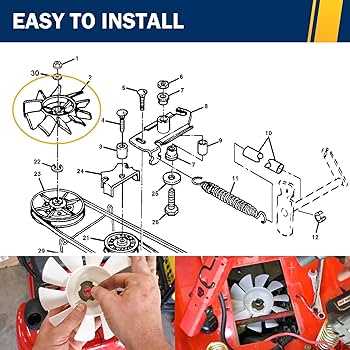

Adjusting and Replacing the Belt System

Maintaining the efficiency of a lawn mower often requires attention to its drive mechanism, particularly the belt system. Proper adjustment and timely replacement of these components are essential to ensure optimal performance and prevent potential damage. Understanding the mechanics involved can help in achieving a smoother operation and prolonging the lifespan of the equipment.

Understanding the Belt Configuration

The belt configuration in any mower is designed to transfer power effectively from the engine to the cutting deck. Over time, wear and tear can affect its tension and alignment. Regular inspection is crucial to identify any signs of fraying or loosening. Adjustment is typically done by altering the tensioning mechanism, ensuring that the belt maintains adequate grip without excessive slack.

Replacing Worn-Out Components

When the belt shows significant wear, replacing it becomes necessary. Begin by disconnecting the power source to ensure safety. Follow the manufacturer’s guidelines to remove the old belt, paying attention to the routing path. Installing the new belt requires careful alignment to avoid any operational issues. After installation, recheck the tension to confirm it meets the required specifications.

Finding Genuine Replacement Parts

When maintaining or repairing equipment, sourcing authentic components is essential for ensuring optimal performance and longevity. Using high-quality replacements not only enhances functionality but also minimizes the risk of further issues arising from substandard alternatives.

To secure reliable components, consider the following approaches:

- Authorized Dealers: Purchasing from certified vendors guarantees that the items meet the necessary specifications and standards.

- Online Retailers: Reputable e-commerce platforms often provide a wide selection of authentic components. Always check reviews and seller ratings before making a purchase.

- Manufacturer’s Website: Visiting the official site can lead to finding the correct items directly from the source, ensuring quality and compatibility.

It is advisable to keep the model information handy when searching for specific components. This practice helps in confirming that the replacements will fit seamlessly and function as intended.

Furthermore, consult community forums or user groups dedicated to your equipment type. Experienced users often share their insights on sourcing reliable replacements, helping newcomers avoid common pitfalls.