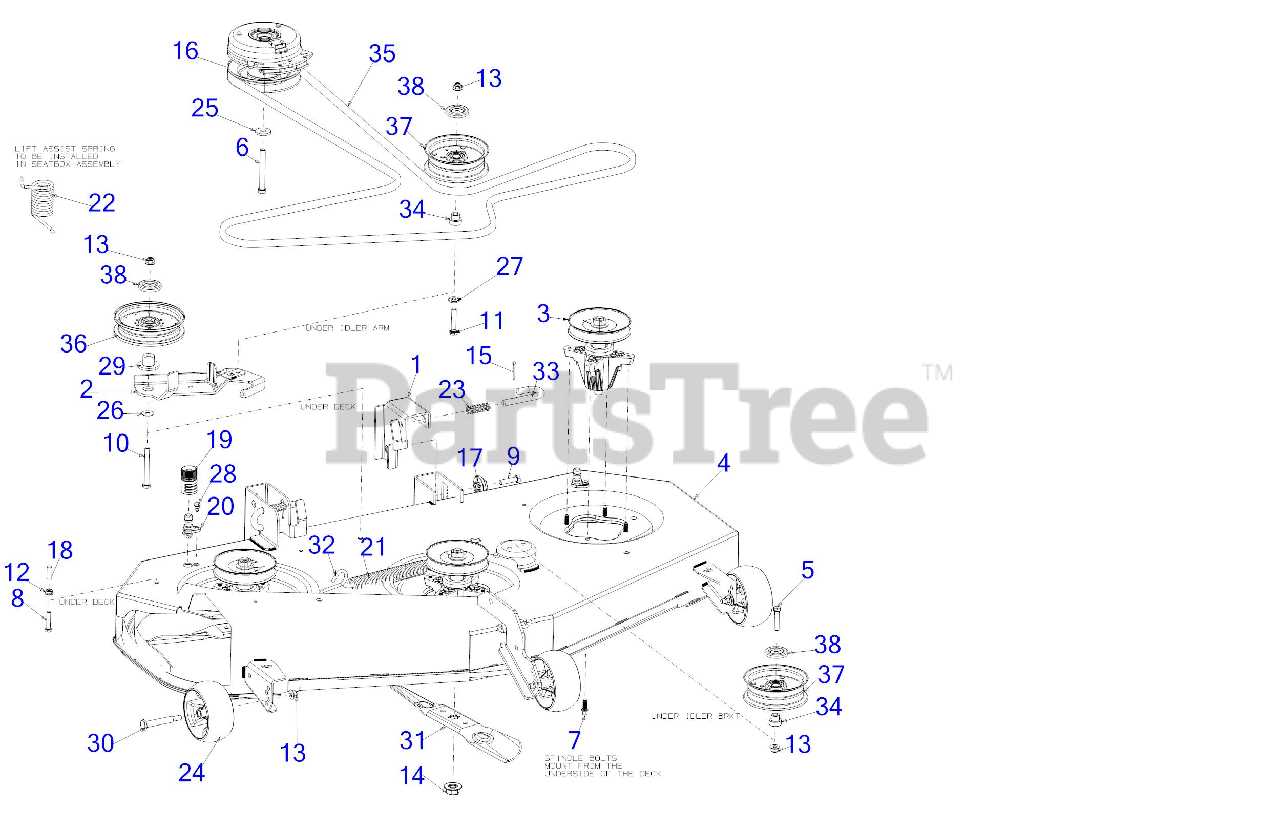

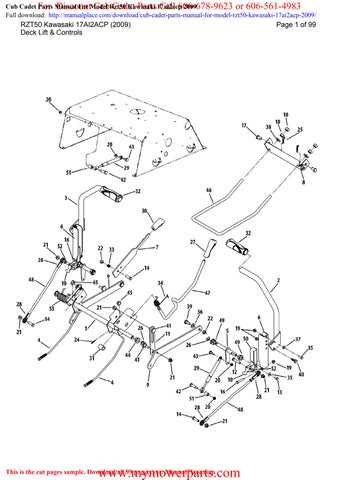

Complete Parts Diagram for Cub Cadet RZT 50

When it comes to maintaining your lawn care equipment, a clear visual representation of its various elements can be invaluable. This resource aims to provide insight into the intricate assembly of your machine, allowing for better understanding and efficient repairs. With a detailed look at the different sections, you can easily navigate the complexities of your mower’s configuration.

Comprehending each segment is essential for troubleshooting issues and performing routine maintenance. By familiarizing yourself with the various components, you’ll not only enhance the longevity of your equipment but also improve its overall performance. Having a structured overview enables you to identify specific areas that may require attention, making the upkeep process smoother and more efficient.

Additionally, this exploration serves as a guide for both novice and experienced users alike. Whether you are looking to replace a worn-out element or simply want to gain a deeper understanding of how everything fits together, having a comprehensive reference at your disposal is a significant advantage. It empowers you to tackle maintenance tasks with confidence and clarity.

Understanding the Cub Cadet RZT 50

This section aims to provide insight into a specific model of a lawn care machine, focusing on its design and functionality. These machines are engineered to enhance efficiency in maintaining outdoor spaces, combining innovative technology with user-friendly features. Understanding the components and their roles can significantly improve maintenance practices and operational efficiency.

Key Features

The highlighted model is recognized for its robust build and advanced capabilities. Users can expect a combination of power and precision, making it suitable for various landscaping tasks. Its unique design ensures ease of use, even for those new to lawn maintenance.

Maintenance Tips

| Component | Maintenance Task | Frequency |

|---|---|---|

| Blades | Sharpen and clean | Every 25 hours |

| Oil | Change | Every 50 hours |

| Air Filter | Inspect and replace | Every season |

| Belt | Check for wear | Monthly |

Understanding these aspects can empower users to maximize their equipment’s performance and longevity, ensuring a well-kept outdoor environment.

Key Components of the RZT 50

The efficient operation of any mowing machine relies on a variety of essential elements that work together seamlessly. Understanding these key components can enhance maintenance practices and improve overall performance.

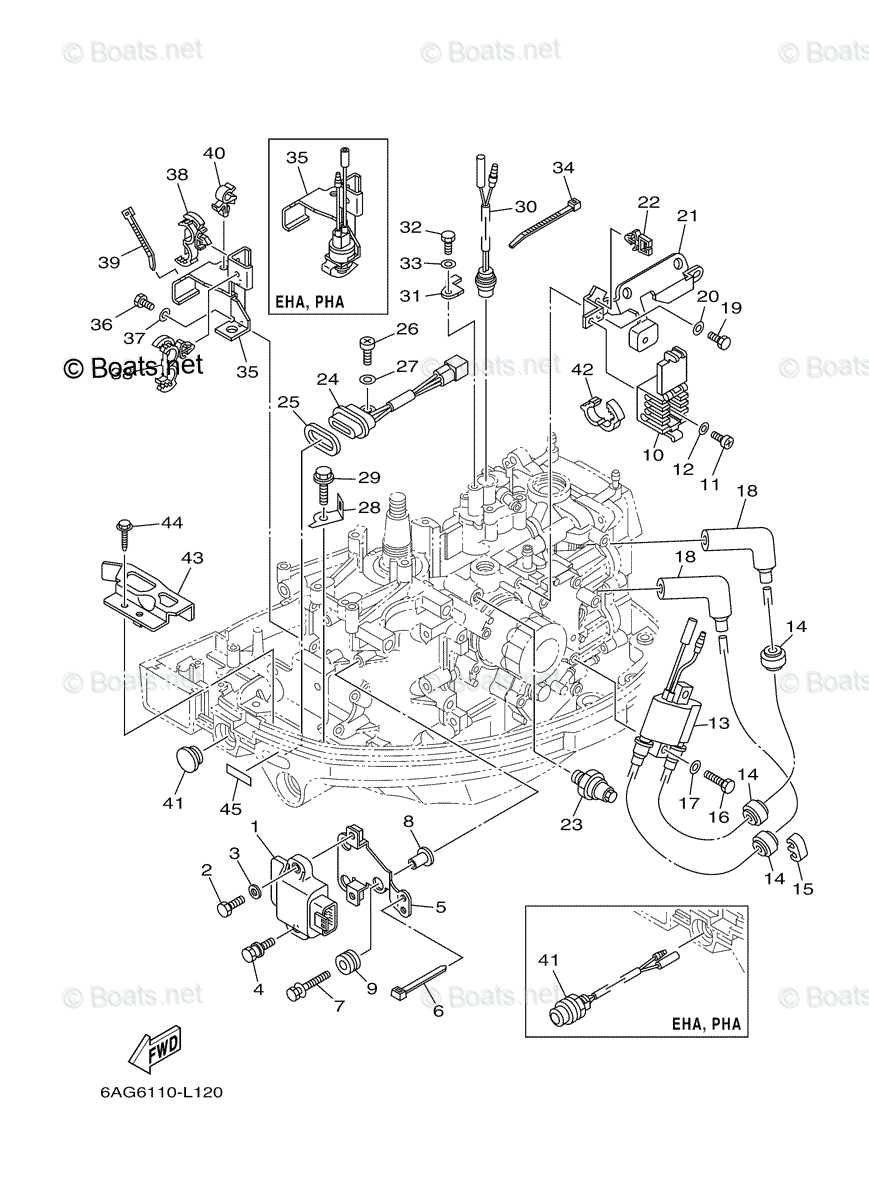

- Engine: The power source that drives the entire system, ensuring effective cutting and maneuverability.

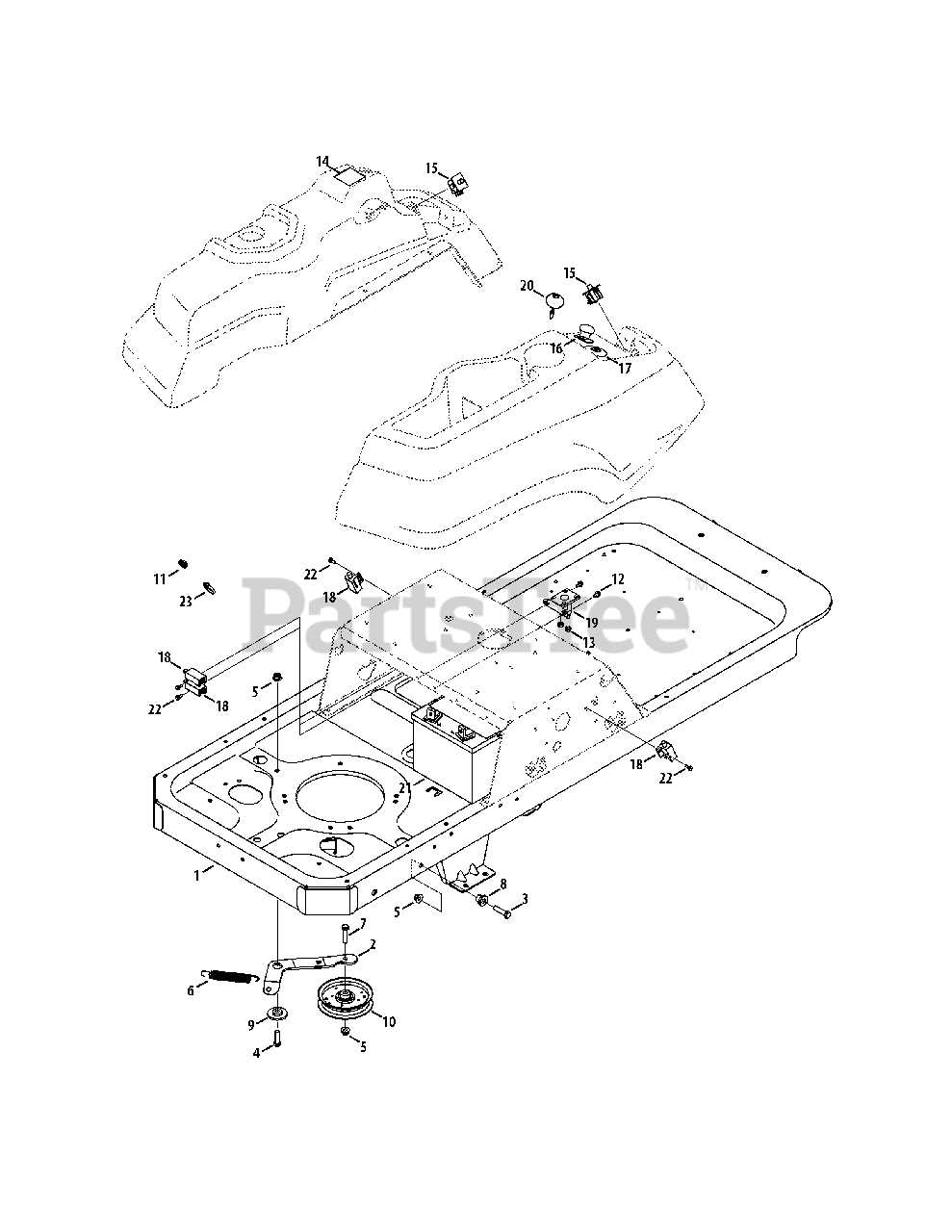

- Transmission: This element transfers power from the engine to the wheels, allowing for smooth movement and speed control.

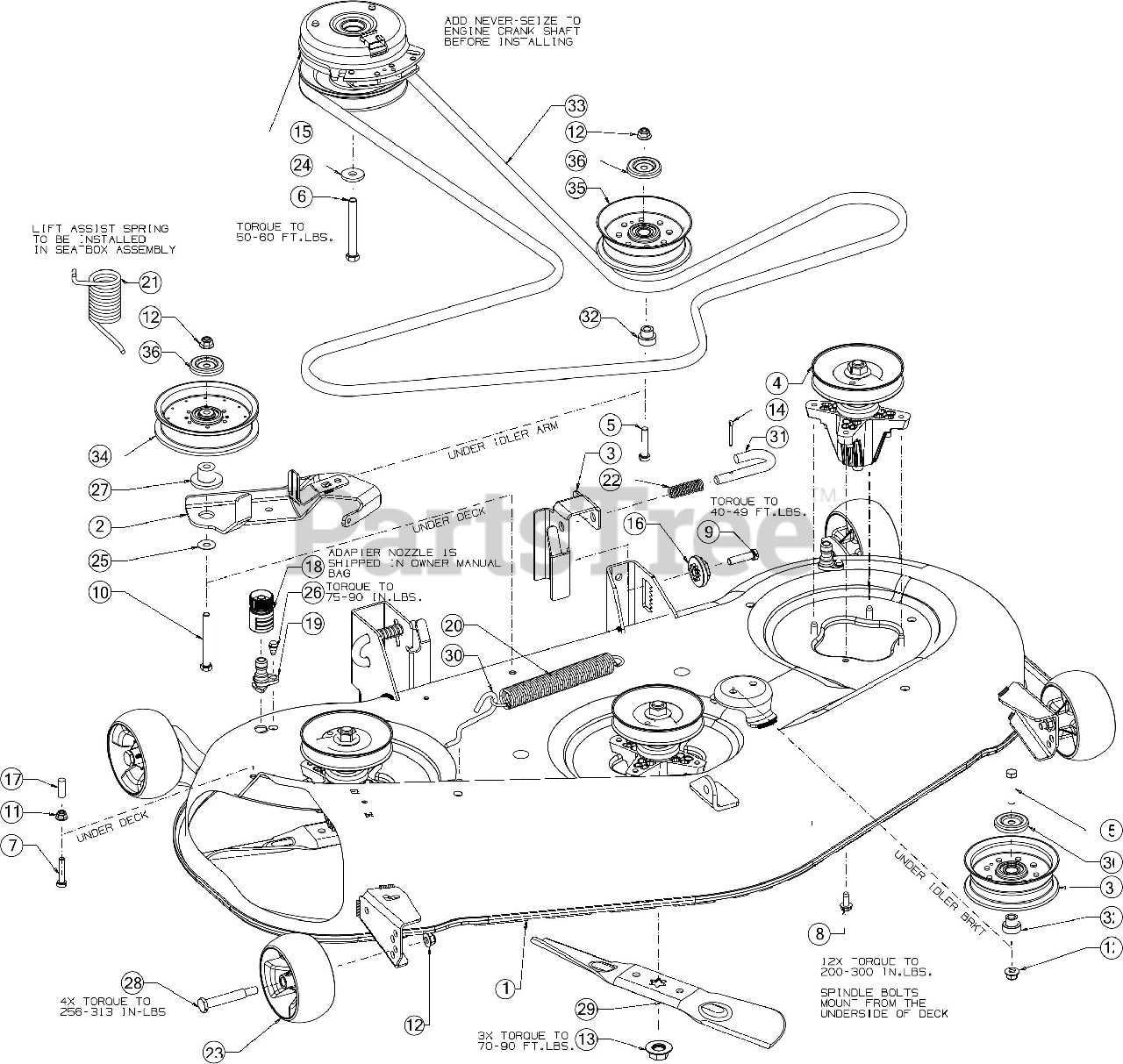

- Deck: The cutting assembly that houses the blades, designed for optimal grass cutting and discharge.

- Blades: Sharp instruments responsible for cutting grass at the desired height, crucial for maintaining lawn health.

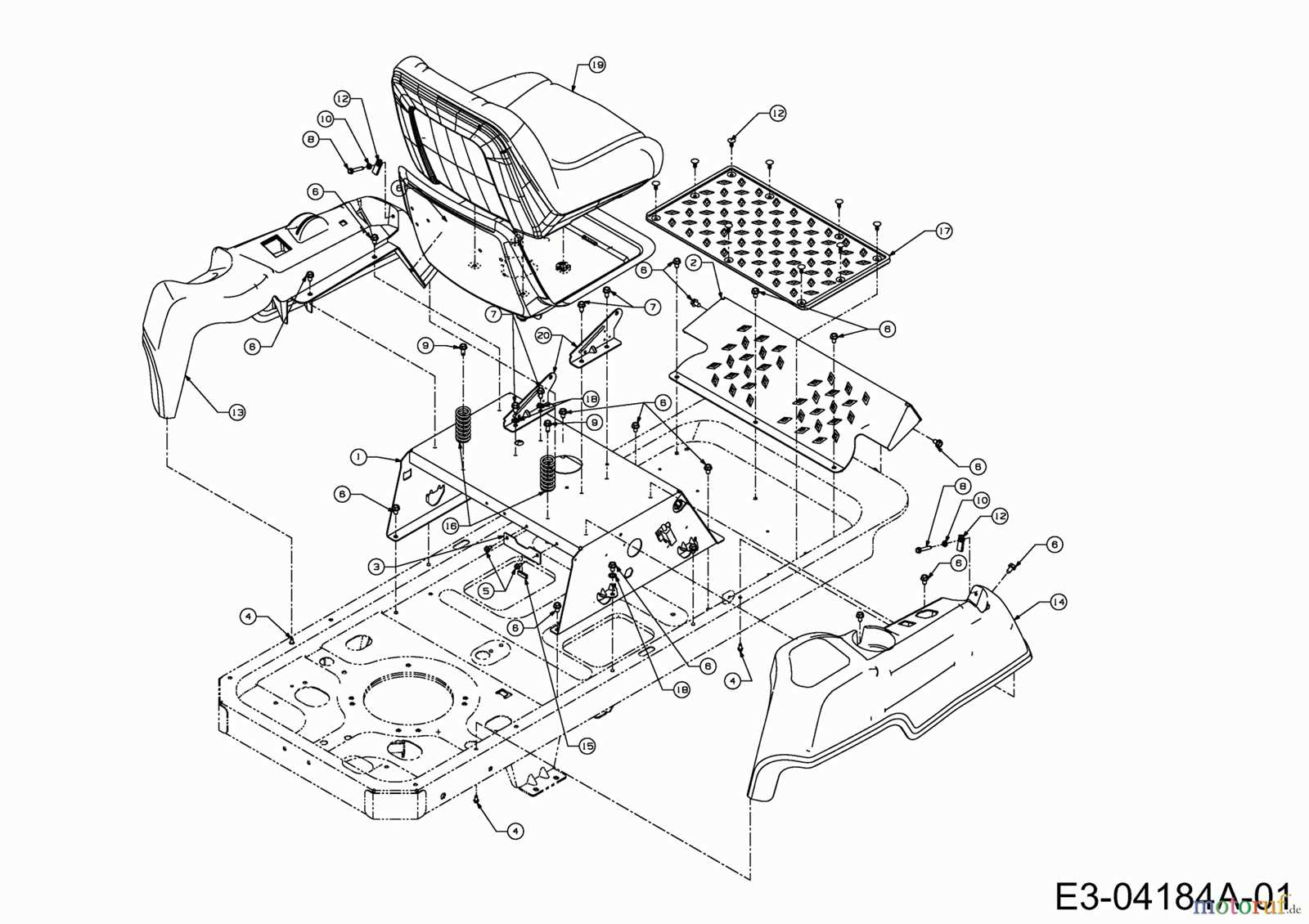

- Chassis: The frame that supports all components, providing stability and durability during operation.

- Wheels: Essential for mobility, these elements come in various sizes to suit different terrains and maneuverability needs.

- Control System: The interface that allows the operator to manage speed, direction, and cutting height with precision.

- Fuel System: Responsible for storing and delivering fuel to the engine, crucial for uninterrupted operation.

By familiarizing oneself with these fundamental parts, operators can ensure their equipment runs smoothly and efficiently, leading to a well-maintained lawn and extended lifespan of the machine.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify each element’s role and interconnection within the system. Such clarity enhances the ability to troubleshoot issues, ensuring that repairs are executed efficiently and accurately.

Furthermore, these illustrations facilitate easier ordering of replacements, preventing delays in restoration. By providing a comprehensive overview, they support both novice and experienced users in navigating complex assemblies with confidence. Ultimately, leveraging these visual aids can lead to improved performance and longevity of equipment.

Where to Find Official Diagrams

Accessing reliable schematics for outdoor equipment is crucial for maintenance and repairs. These visual aids help users identify components and understand assembly, ensuring efficient upkeep.

- Manufacturer’s Website: Start by visiting the official site of the equipment brand. They often provide downloadable resources.

- User Manuals: Check the manuals that came with the machine, as they frequently contain detailed illustrations.

- Authorized Dealers: Local dealers can offer printed materials or assist in locating digital versions.

- Online Forums: Communities focused on outdoor machinery often share resources and links to official documentation.

Utilizing these sources will enhance your ability to maintain and operate your equipment effectively.

Common Replacement Parts for RZT 50

Maintaining your mower is essential for ensuring its longevity and optimal performance. Over time, certain components may wear out or require replacement due to regular use. Understanding which elements are commonly replaced can help you keep your machine running smoothly and efficiently.

Key Components for Replacement

One of the most frequently changed items is the blades. Dull or damaged blades can result in uneven cutting and can stress the engine. Regularly replacing them can improve the quality of your lawn care.

Another important aspect is the belts. These components transmit power from the engine to the blades. If they become frayed or worn, they can affect the mower’s performance significantly. Keeping an eye on their condition is crucial.

Additional Essentials

In addition to blades and belts, filters are vital for maintaining engine efficiency. Regularly replacing air and fuel filters ensures that your engine receives clean airflow and fuel, which is essential for optimal operation.

Lastly, pay attention to the batteries and electrical connections. A reliable power source is critical for starting the mower and ensuring all electrical systems function correctly. Routine checks can help you avoid unexpected failures.

How to Read Parts Diagrams

Understanding visual representations of mechanical components is crucial for effective maintenance and repairs. These illustrations provide a clear view of each element’s placement and interconnection, aiding in identifying necessary items and their functions.

Key Elements to Focus On

- Labels: Ensure to check for clear labels indicating each component.

- Numbers: Reference numbers often correspond to a list detailing specifications.

- Sections: Identify different sections to grasp how parts fit within the larger system.

Steps to Interpret the Visuals

- Begin by familiarizing yourself with the layout.

- Locate the part you need and match it with the corresponding label.

- Consult the accompanying list for detailed descriptions.

- Note any specific installation or maintenance instructions provided.

Maintenance Tips for Longevity

To ensure the extended life and optimal performance of your equipment, regular upkeep is essential. Adopting a consistent maintenance routine not only enhances functionality but also prevents costly repairs in the long run.

1. Regular Cleaning: Keeping the machinery free from debris and dirt can significantly reduce wear and tear. Clean components after each use to prevent buildup that can affect performance.

2. Oil Changes: Frequent oil changes are crucial for lubricating moving parts and preventing engine damage. Follow the manufacturer’s recommendations for intervals and type of oil.

3. Check Belts and Cables: Inspecting and adjusting belts and cables regularly can help prevent failures during operation. Replace any worn or frayed components promptly.

4. Tire Maintenance: Ensure tires are properly inflated and inspect them for damage. Correct tire pressure improves handling and prolongs tire life.

5. Battery Care: Keep terminals clean and check the battery charge regularly. A well-maintained battery can avoid unexpected breakdowns.

6. Seasonal Storage: Prepare your equipment for off-season storage by draining fuel, cleaning surfaces, and covering it to protect against the elements.

Implementing these practices will ultimately help you maintain your machinery in peak condition, allowing you to enjoy efficient operation for years to come.

Identifying Wear and Tear

Recognizing signs of deterioration in machinery is essential for maintaining performance and prolonging lifespan. Regular inspection helps identify components that may need attention before they lead to more significant issues. Understanding common indicators of wear can assist in taking timely action and ensuring optimal operation.

Common Signs of Deterioration

Several indicators can help pinpoint parts that require maintenance. Observing changes in performance, unusual noises, or physical damage can signal the need for further investigation. Below is a table summarizing key signs to watch for:

| Indicator | Description |

|---|---|

| Excessive Vibration | Indicates imbalance or wear in moving components. |

| Strange Noises | Can suggest loose or damaged parts affecting operation. |

| Leaks | Fluid leaks may point to failing seals or gaskets. |

| Uneven Cutting | May indicate dull blades or misalignment in cutting elements. |

Importance of Regular Checks

Conducting routine examinations not only helps in identifying wear but also aids in avoiding costly repairs. Addressing minor issues promptly can lead to more efficient performance and a safer operating environment. Developing a maintenance schedule is beneficial for keeping machinery in top condition.

Ordering Parts Online Effectively

Purchasing components online can be a seamless experience if approached with the right strategies. Understanding how to navigate various platforms and ensuring accurate selection is crucial for a successful transaction.

Research and Verify

Before making any purchases, conduct thorough research. Check for reviews, ratings, and the reliability of the seller. Cross-reference information to confirm that you are getting genuine items that meet your specific requirements.

Compare and Contrast

Take the time to compare prices and shipping options from different vendors. Look for any potential discounts or bundled offers that can enhance your savings. This effort can lead to the ultimate deal while ensuring you receive quality products.

DIY Repair vs. Professional Help

When faced with the need for repairs on outdoor equipment, individuals often weigh the benefits of tackling the issue themselves versus seeking the expertise of a professional. Each approach carries its own set of advantages and challenges, and understanding these can aid in making an informed decision.

Advantages of DIY Repair

Opting for a do-it-yourself approach can foster a sense of accomplishment and provide valuable learning experiences. It often leads to cost savings, as you avoid labor fees and can purchase parts directly. Additionally, this method allows for greater flexibility in terms of timing, enabling repairs to be conducted at your convenience.

Benefits of Professional Assistance

Conversely, enlisting the help of a skilled technician ensures that the work is performed to a high standard. Professionals bring experience and specialized knowledge that can prevent future issues and ensure safety. This option often results in quicker resolutions, allowing you to return to using your equipment without prolonged downtime.

| Criteria | DIY Repair | Professional Help |

|---|---|---|

| Cost | Lower (no labor fees) | Higher (labor costs included) |

| Time | Variable (depends on skill level) | Usually quicker (experienced technicians) |

| Skill Development | Enhances skills | Minimal learning opportunity |

| Quality of Work | Varies (depends on experience) | Generally high (trained professionals) |

| Convenience | Flexible scheduling | Dependent on technician availability |

Customer Reviews on RZT 50 Parts

This section explores user feedback regarding components for a specific lawn maintenance machine. Reviews highlight experiences that can guide potential buyers in making informed decisions.

Key aspects users frequently discuss include:

- Quality and durability of the components

- Ease of installation and compatibility

- Customer service and support experiences

- Value for money and overall performance

Many customers appreciate:

- The longevity of the items, noting they withstand heavy use.

- The straightforward installation process, making it accessible for DIY enthusiasts.

- The responsiveness of customer support, aiding in troubleshooting and advice.

However, some users have pointed out:

- Inconsistent quality in certain batches.

- Delayed shipping times affecting overall satisfaction.

- Occasional difficulty in finding specific items at local retailers.

Ultimately, customer reviews serve as a valuable resource for anyone considering these components, helping to shed light on both the positives and potential drawbacks.