Understanding the Holley 4 Barrel Carburetor Parts Diagram

The intricacies of a four-chamber fuel delivery mechanism play a crucial role in optimizing engine performance. By examining its components, enthusiasts and mechanics can enhance both functionality and efficiency. A thorough comprehension of these elements is essential for effective maintenance and upgrades.

Within this system, each component serves a distinct purpose, contributing to the overall operation. Understanding how these elements interact can lead to improved tuning and greater reliability. As one delves deeper into each section, it becomes clear that attention to detail is paramount for achieving the ultimate performance.

This guide aims to provide a detailed overview, illustrating how each segment contributes to the entire assembly. By familiarizing yourself with these components, you can better appreciate their significance and explore ways to optimize your setup for enhanced results.

Understanding Holley 4 Barrel Carburetors

This section explores the intricacies of a specific type of fuel delivery system commonly used in performance vehicles. Its design is pivotal for enhancing engine efficiency and power output. By examining its structure and function, one can appreciate the engineering that contributes to optimal performance.

Key Components

Several essential elements work in harmony to ensure proper operation. Each component plays a distinct role in the overall functionality, contributing to effective fuel atomization and mixture delivery.

| Component | Function |

|---|---|

| Throttle Body | Controls airflow into the engine. |

| Fuel Bowl | Holds fuel, ensuring a steady supply. |

| Venturi | Creates a vacuum to draw in fuel. |

| Jets | Regulate fuel flow into the air stream. |

Performance Considerations

Understanding the interplay of these components allows for better tuning and adjustments, ultimately leading to enhanced engine response and efficiency. Proper maintenance and calibration can significantly influence performance outcomes.

Key Components of Holley Carburetors

Understanding the essential elements of a fuel delivery system is crucial for optimizing performance. Each component plays a significant role in ensuring proper air and fuel mixture, which directly impacts engine efficiency and responsiveness.

- Throttle Body: Controls airflow into the engine, adjusting for power demands.

- Fuel Inlet: Supplies fuel from the tank, ensuring a consistent flow to the mixing chamber.

- Venturi: Creates a vacuum that draws fuel into the airflow, mixing it for combustion.

- Choke: Regulates air intake during cold starts, improving engine performance.

- Float Chamber: Maintains a steady fuel level, preventing flooding or starvation.

- Jets: Control the amount of fuel delivered, fine-tuning the air-fuel mixture.

These components collectively ensure that the engine runs smoothly and efficiently, allowing for optimal power output.

How to Read Carburetor Diagrams

Understanding illustrations related to fuel delivery systems is essential for effective maintenance and tuning. These visuals can provide insight into the various components and their functions, helping enthusiasts and mechanics alike to identify issues and improve performance.

Key Components to Identify

- Fuel Inlet: Where the fuel enters the system.

- Throttle Plates: Control air and fuel mixture flow.

- Jets: Regulate the amount of fuel delivered to the engine.

- Float Chamber: Maintains a constant fuel level.

- Choke: Assists in starting the engine by enriching the mixture.

Steps to Interpret the Visuals

- Begin by familiarizing yourself with the legend or key, which explains symbols used.

- Identify each part and its location within the system.

- Follow the flow paths to understand how fuel moves through the assembly.

- Look for notes or annotations that provide additional details.

Common Issues with Holley Carburetors

When working with classic fuel delivery systems, enthusiasts often encounter a range of challenges that can impact performance. Understanding these issues is crucial for effective maintenance and troubleshooting. From fuel flow inconsistencies to airflow restrictions, identifying the root causes can significantly enhance the efficiency of your setup.

One frequent problem is fuel leakage, which can result from worn gaskets or improper assembly. This not only affects performance but also poses safety risks. Additionally, improper tuning can lead to rich or lean mixtures, causing engine misfires and reduced power output.

Another common concern is the buildup of deposits, which can obstruct passages and affect airflow. Regular cleaning and inspection can help mitigate this issue, ensuring optimal operation. Lastly, fluctuating idle speeds may indicate vacuum leaks or issues with the choke system, necessitating thorough checks to maintain reliable performance.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your fuel delivery system requires regular attention and care. By following a few essential practices, you can significantly enhance its lifespan and efficiency.

- Regular Cleaning: Periodic cleaning helps prevent buildup and ensures optimal operation. Use appropriate cleaners to remove deposits without damaging sensitive components.

- Inspect Gaskets and Seals: Check for wear and tear on gaskets and seals. Replacing them promptly can prevent leaks and maintain proper function.

- Check Fuel Quality: Always use high-quality fuel to minimize contaminants. Consider adding a fuel stabilizer to prevent deterioration.

- Adjust Tuning: Regularly assess and fine-tune the mixture and idle settings. This keeps the system running smoothly and efficiently.

- Monitor Performance: Pay attention to any changes in performance. Addressing issues early can prevent more significant problems down the line.

By implementing these practices, you can help ensure that your system remains reliable and efficient for years to come.

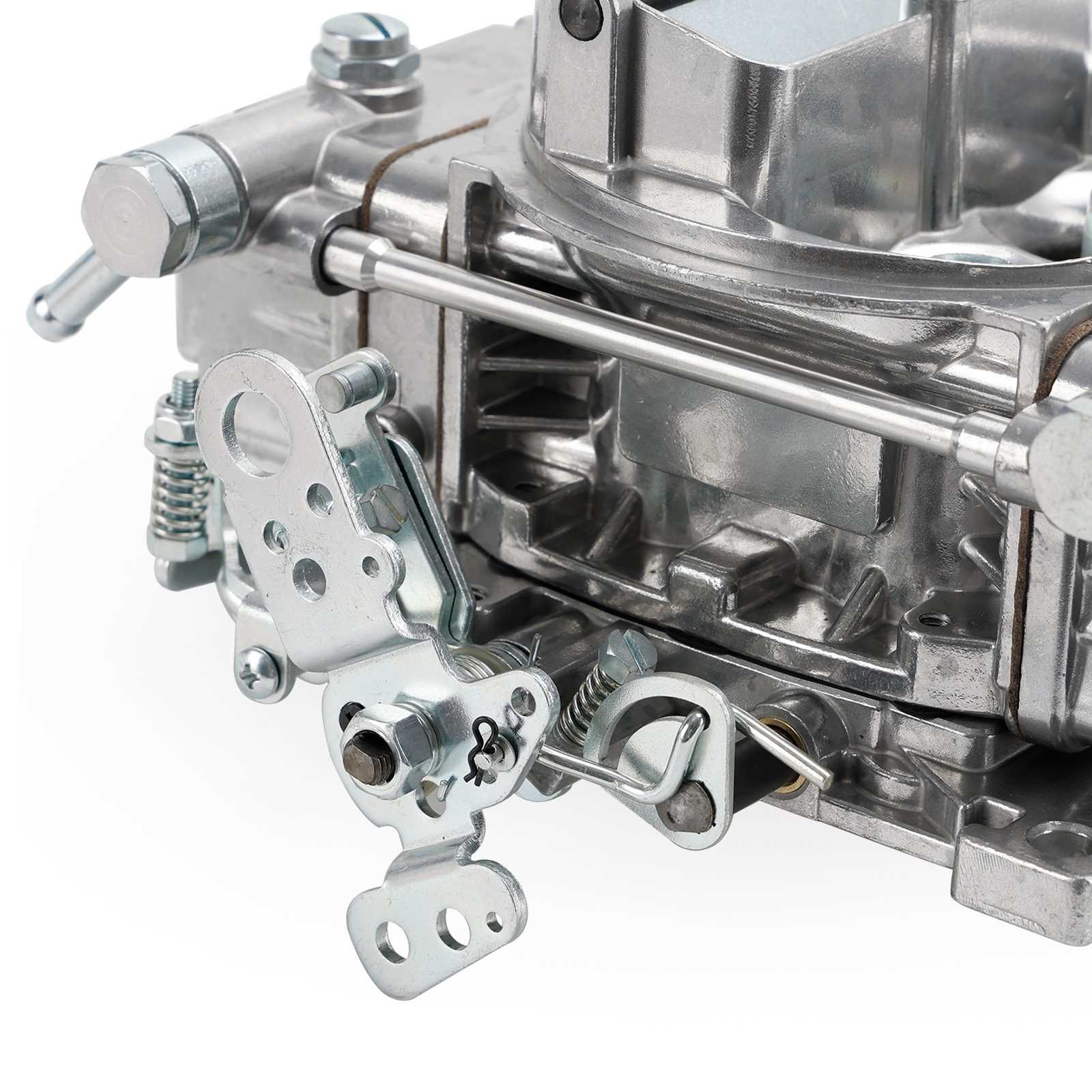

Identifying Parts in the Diagram

Understanding the various components illustrated in the schematic is crucial for effective maintenance and troubleshooting. Each element plays a specific role in the overall functionality, contributing to optimal performance. Recognizing these individual pieces allows enthusiasts and professionals alike to address issues more efficiently.

Key Components to Recognize

- Throttle Body: This element controls the airflow into the engine, directly impacting power and efficiency.

- Float Chamber: Responsible for maintaining a constant fuel level, ensuring proper fuel delivery.

- Venturi: A narrow passage that increases the speed of the air, creating a vacuum that draws in fuel.

- Jets: Tiny openings that regulate the flow of fuel into the airstream, critical for the air-fuel mixture.

- Accelerator Pump: Provides an extra burst of fuel during rapid throttle application, enhancing acceleration.

Steps for Identification

- Study the layout carefully, noting the positioning of each component.

- Refer to manufacturer specifications for detailed descriptions of each item.

- Use color coding or labels, if available, to differentiate between similar components.

- Cross-reference with online resources or manuals to verify your findings.

Upgrading Your Carburetor System

Enhancing your fuel delivery system can significantly boost performance and efficiency. By selecting the right components and making informed adjustments, you can achieve optimal results tailored to your needs.

- Evaluate your current setup to identify areas for improvement.

- Consider upgrading to high-flow mechanisms for increased air and fuel mixture.

- Investigate the benefits of modern tuning tools for precise adjustments.

- Ensure compatibility with existing engine configurations to avoid conflicts.

Implementing these upgrades can lead to enhanced throttle response and overall engine power, allowing you to fully enjoy your driving experience.

Fuel Mixture Adjustments Explained

Properly balancing the fuel and air mixture is crucial for optimal engine performance. This adjustment ensures that the combustion process is efficient, leading to better power output and reduced emissions. Understanding how to modify this ratio can significantly impact the vehicle’s overall functionality.

The Importance of Fuel Mixture

Getting the mixture right affects several aspects of engine performance:

- Power Output: An optimal mix provides maximum power.

- Fuel Efficiency: Correct adjustments can enhance mileage.

- Engine Longevity: Proper combustion reduces wear and tear.

- Emissions Control: A balanced mixture minimizes harmful emissions.

How to Adjust the Mixture

Adjusting the mixture typically involves a few key steps:

- Identify the adjustment screws: Usually located on the side of the unit.

- Start with factory settings: Refer to the manufacturer’s specifications.

- Make incremental adjustments: Turn the screws gradually, usually a quarter turn at a time.

- Test the engine: Observe how the engine responds to the adjustments.

- Fine-tune as necessary: Continue to adjust based on performance feedback.

Monitoring engine behavior during and after adjustments is essential for achieving the desired results.

Compatibility with Various Engines

When considering the performance enhancement of your vehicle, understanding the compatibility of specific fuel delivery systems with different engine types is crucial. This ensures optimal functioning and efficiency, allowing for smoother operation and improved horsepower. Each engine has unique characteristics that dictate which system is most suitable.

Understanding Engine Types

Engines come in various configurations, including V8, inline, and flat designs, each with distinct requirements. The compatibility of a fuel delivery system can significantly impact the overall performance and responsiveness of the engine. For instance, certain systems are better suited for high-performance applications, while others excel in fuel efficiency for everyday driving.

Key Factors for Compatibility

Several factors determine whether a particular fuel delivery mechanism will work effectively with an engine. Engine size, airflow characteristics, and intended use are paramount. Additionally, modifications such as increased displacement or enhanced airflow may necessitate specific configurations to maximize potential. Ensuring compatibility not only enhances performance but also maintains reliability and longevity.

In conclusion, selecting the right fuel delivery system involves careful consideration of the engine’s specific needs and characteristics. This alignment is vital for achieving desired performance outcomes and ensuring a reliable driving experience.

Tools Needed for Installation

Proper installation requires a variety of tools to ensure a smooth and efficient process. Having the right equipment on hand not only saves time but also minimizes the risk of errors during assembly.

- Socket set

- Wrench set

- Screwdriver set

- Torque wrench

- Gasket scraper

- Cleaning supplies

Additionally, consider these optional tools for enhanced convenience:

- Impact wrench

- Pliers

- Multimeter

- Inspection mirror

Gathering these tools in advance will streamline the installation process and lead to a successful outcome.

Best Practices for Tuning Performance

Tuning for optimal performance involves a series of careful adjustments and considerations to ensure your engine operates efficiently and responsively. By focusing on specific components and their interactions, you can enhance power output and fuel efficiency while reducing emissions. This section outlines key strategies to achieve the best results in your tuning endeavors.

| Practice | Description |

|---|---|

| Start with the Basics | Ensure that your engine is in good condition. Check spark plugs, ignition timing, and air filters before making any adjustments. |

| Utilize Proper Tools | Invest in quality tuning tools such as a wideband O2 sensor and a vacuum gauge to obtain accurate readings during adjustments. |

| Incremental Changes | Make small adjustments one at a time and test after each change. This allows you to isolate the effects of each modification. |

| Monitor A/F Ratios | Maintain the ideal air-fuel mixture for optimal combustion. This is crucial for maximizing performance and efficiency. |

| Adjust for Conditions | Consider environmental factors such as altitude and temperature. These can significantly affect engine performance and may require tuning adjustments. |

| Regular Maintenance | Stay on top of regular maintenance to prevent issues that can hinder performance. A well-maintained engine responds better to tuning. |

Resources for Further Learning

Expanding your knowledge on engine components and their functionalities can significantly enhance your skills in automotive maintenance and performance tuning. This section provides valuable resources that can help you dive deeper into understanding the intricate workings of these vital mechanisms.

Books and Manuals

Numerous publications offer detailed insights into the mechanics and tuning of fuel delivery systems. Consider exploring specialized manuals that cover everything from basic principles to advanced tuning techniques. These resources often include illustrations and step-by-step guides to help you grasp complex concepts effectively.

Online Courses and Tutorials

The internet is a treasure trove of educational content. Platforms like YouTube and dedicated automotive websites provide a wealth of video tutorials and courses that walk you through various aspects of fuel system management. Engaging with these materials can enhance your practical skills and theoretical understanding, making it easier to troubleshoot and optimize performance.