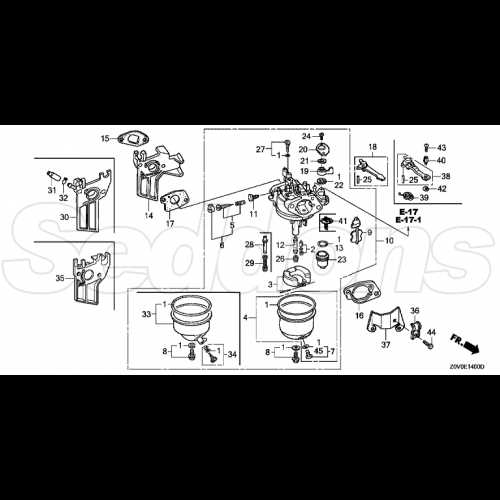

Honda GX340 Carburetor Parts Diagram Overview

When working with compact engines, it’s essential to have a clear understanding of how the various systems contribute to the overall function. One of the most critical assemblies plays a significant role in ensuring the engine runs efficiently by managing the flow of air and fuel. Mastering the structure and purpose of these elements can make a huge difference in maintenance and troubleshooting.

In this section, we will delve into the various elements that make up this crucial system, emphasizing the relationship between its individual parts. By exploring how these components are connected, you’ll gain a better understanding of how to maintain and repair these engines effectively. Whether you’re experienced or new to engine repair, this knowledge will help you keep things running smoothly.

Honda GX340 Carburetor Overview

The fuel-mixing component of an internal combustion engine plays a crucial role in ensuring optimal performance by controlling the blend of air and fuel. This mechanism is vital for regulating the engine’s efficiency, reliability, and overall functioning. Proper tuning of this system guarantees smooth operation and prevents various issues, such as stalling or rough idling.

Main Functions of the Fuel-Mixing Device

The primary task of this system is to deliver the right mixture of air and gasoline to the engine. It adjusts the fuel flow based on the engine’s needs, ensuring efficient combustion at different speeds. In doing so, it optimizes power output and fuel efficiency, while reducing emissions.

Importance of Maintenance and Cleaning

Regular upkeep of this component is essential to prevent clogs and ensure smooth operation. Over time, debris and residue can accumulate, affecting the flow and overall performance. A well-maintained system ensures longevity and reliable engine performance under various operating conditions.

Main Components of the Carburetor

The structure responsible for regulating the fuel and air mixture consists of several key sections, each playing a vital role in ensuring optimal engine performance. These components work in harmony to manage the flow of fuel and air, maintaining balance and efficiency.

- Float Chamber: This part holds fuel temporarily, allowing it to be released at the proper time and in the correct amount.

- Needle Valve: Controls the flow of liquid from the chamber, ensuring that the right amount enters the air stream.

- Throttle Plate: Adjusts the airflow entering the engine, influencing speed and power output.

- Choke Valve: Used to control the amount of air, particularly when starting a cold engine, helping enrich the mixture for easier ignition.

- Venturi: A narrowing in the airflow path that increases the velocity of air, creating a pressure drop to pull in fuel.

Fuel Intake System Explanation

The fuel intake mechanism is essential for delivering the right amount of fuel into the engine’s combustion chamber, ensuring efficient operation and power generation. This system involves several components that work together to regulate fuel flow, mix it with air, and ensure a controlled delivery for optimal performance.

Key Components of the Fuel Intake

- Fuel Line: Transfers fuel from the tank to the intake mechanism.

- Air Filter: Ensures clean air is mixed with fuel to prevent debris from entering the system.

- Throttle: Controls the air-fuel mixture by regulating airflow into the system.

How the System Operates

- The fuel travels through the fuel line, passing through a filtration system to remove impurities.

- A controlled amount of air enters through the air filter, ensuring a balanced air-fuel mixture.

- The throttle adjusts airflow, ensuring the right ratio of air to fuel for combustion, leading to smooth engine operation.

Airflow Path and Its Role

The movement of air through an engine’s intake system plays a critical role in ensuring optimal performance. Understanding how air flows, from the moment it enters the intake until it mixes with fuel, helps improve the overall efficiency of the engine. Proper air circulation ensures that the mixture is balanced, leading to smoother operation and better energy output.

Key Stages of Air Movement

- Entry: Air is drawn in through an opening where it is filtered to remove any debris.

- Channeling: The air is then directed through passageways that ensure a steady and controlled flow.

- Mixing: At this point, the air combines with fuel in a precise ratio to ensure efficient combustion.

Importance of Smooth Airflow

A well-maintained airflow system ensures that the engine receives the right amount of oxygen, which is essential for combustion. Disruptions or blockages in the air’s path can lead to inefficiencies, such as poor fuel combustion or irregular performance. Ensuring clean and unobstructed channels is essential for the engine’s longevity and functionality.

Throttle Mechanism and Adjustment

The throttle system plays a critical role in controlling engine speed and efficiency. Proper adjustment ensures optimal performance and smooth operation, making it essential to understand the key components and how they interact within the mechanism.

To adjust the throttle correctly, follow these general steps:

- Locate the linkage that connects the control lever to the speed control system.

- Inspect the springs and connections for any wear or slack that could affect movement.

- Adjust the tension of the spring to ensure smooth movement of the lever.

- Fine-tune the control arm position to allow full range of motion without obstruction.

After completing the adjustments, it’s important to test the setup by gradually increasing the speed. If there are any inconsistencies, revisit the settings and make the necessary corrections to achieve a responsive throttle system.

Choke Valve Operation

The choke valve is a critical component that plays a significant role in controlling the air-fuel mixture in an engine during starting and cold conditions. By restricting airflow, it enriches the mixture, facilitating easier ignition and smoother operation when the engine is not yet warmed up. Understanding its function is essential for maintaining optimal performance.

Functionality of the Choke Valve

This mechanism typically operates through a simple yet effective design. When engaged, it partially closes the airflow path, which increases the fuel concentration in the mixture. This process is particularly beneficial in cooler temperatures, where fuel vaporization is less efficient. The choke valve usually features a lever or linkage connected to the throttle, allowing the operator to control its position easily.

Adjustment and Maintenance

Proper adjustment of the choke valve is crucial for effective engine performance. If the valve remains closed too long, it can lead to excessive fuel consumption and potential engine flooding. Conversely, if it opens too quickly, the engine may struggle to start. Regular maintenance, including cleaning and ensuring the mechanism operates smoothly, can help prevent these issues and promote efficient functioning.

Float Bowl and Fuel Regulation

The float bowl is a critical component in the fuel delivery system of small engines. Its primary function is to maintain a consistent level of fuel, ensuring that the engine receives the appropriate amount for optimal performance. This balance is essential for the effective operation of the entire fuel system.

Proper fuel regulation is achieved through a combination of mechanisms within the float bowl. Key elements include:

- Float Mechanism: This element rises and falls with the fuel level, controlling the flow of fuel into the bowl.

- Needle Valve: Positioned at the inlet, this valve opens and closes to regulate the fuel entering the bowl based on the float’s position.

- Vent System: Allows for air exchange, preventing vacuum formation and ensuring smooth fuel flow.

Maintaining the float bowl and its associated components is crucial for engine efficiency. Common issues include:

- Blockages in the fuel inlet, preventing adequate fuel flow.

- Wear or damage to the needle valve, leading to fuel leakage or inadequate supply.

- Incorrect float adjustment, causing fuel level fluctuations that affect engine performance.

Regular inspection and maintenance of the float bowl can significantly enhance engine reliability and longevity. Properly functioning components ensure that the engine operates smoothly, minimizing the risk of stalling or performance issues.

Gaskets and Seals Importance

In any machinery, the functionality and longevity heavily depend on the quality of sealing elements. These components play a crucial role in preventing leaks, ensuring optimal performance, and maintaining the integrity of the system. The effectiveness of these seals significantly impacts overall efficiency and reliability.

Effective sealing is essential to prevent the escape of fluids and gases, which can lead to operational issues and increased wear. When these elements are compromised, it may result in diminished performance, excessive emissions, and even catastrophic failures. Regular inspection and replacement of these components are vital to maintain operational standards.

Moreover, the selection of appropriate materials for gaskets and seals contributes to their durability and resistance against various environmental factors such as temperature fluctuations and chemical exposure. This ensures that the machinery can operate smoothly under different conditions, enhancing its overall lifespan and functionality.

Common Carburetor Issues

Many small engines experience challenges related to fuel delivery systems. These complications can hinder performance and lead to operational inefficiencies. Understanding these issues is crucial for effective maintenance and troubleshooting.

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| Fuel Leakage | Puddles of fuel under the engine | Worn gaskets or seals | Replace damaged gaskets and seals |

| Engine Stalling | Engine shuts off unexpectedly | Clogged jets or fuel lines | Clean jets and replace clogged lines |

| Rough Idling | Inconsistent engine speed at idle | Dirty passages or incorrect adjustments | Clean internal passages and adjust settings |

| Hard Starting | Difficulty starting the engine | Old fuel or incorrect mixture | Replace old fuel and verify mixture ratio |

Cleaning and Maintenance Tips

Regular upkeep and thorough cleaning are essential for optimal performance and longevity of your equipment. Neglecting these tasks can lead to inefficiency and costly repairs. Adopting a systematic approach to maintenance can help ensure that everything functions smoothly and reliably.

To maintain peak performance, consider the following essential practices:

| Task | Frequency | Description |

|---|---|---|

| Inspect Components | Monthly | Check all essential elements for wear and tear, ensuring everything is securely fastened and functioning properly. |

| Clean Surfaces | Weekly | Remove dust, debris, and residue from all surfaces to prevent buildup and ensure efficient operation. |

| Replace Filters | Every 3 months | Swap out old filters with new ones to ensure clean air and fuel flow, enhancing performance. |

| Check for Leaks | Monthly | Examine all connections for any signs of leakage and address issues promptly to prevent damage. |

| Lubricate Moving Parts | Every 6 months | Apply appropriate lubricants to moving components to reduce friction and wear. |

Following these guidelines will help you maintain your equipment in top condition, ensuring efficiency and reliability over time.

Parts Replacement and Compatibility

When it comes to maintaining outdoor power equipment, understanding the nuances of component interchangeability is essential. This section delves into the importance of selecting the right elements to ensure optimal performance and longevity of your machinery. Properly identifying compatible components not only enhances efficiency but also minimizes the risk of operational failures.

Identifying Compatible Components

Before proceeding with any replacements, it’s crucial to verify the specifications of the required elements. Different manufacturers may produce components with similar appearances but varying functionalities. Thus, referring to model numbers and manufacturer recommendations is advisable to avoid mismatches.

Replacement Options Overview

There are various avenues for sourcing replacement elements, ranging from original equipment to aftermarket alternatives. Each option presents its advantages and disadvantages, influencing both performance and cost. Below is a summary of these options:

| Type | Description | Pros | Cons |

|---|---|---|---|

| OEM | Original manufacturer components | Perfect fit, reliable quality | Higher cost |

| Aftermarket | Third-party replacements | Cost-effective, varied options | Quality may vary |

| Used | Pre-owned components | Lower prices, available | Potential wear and tear |