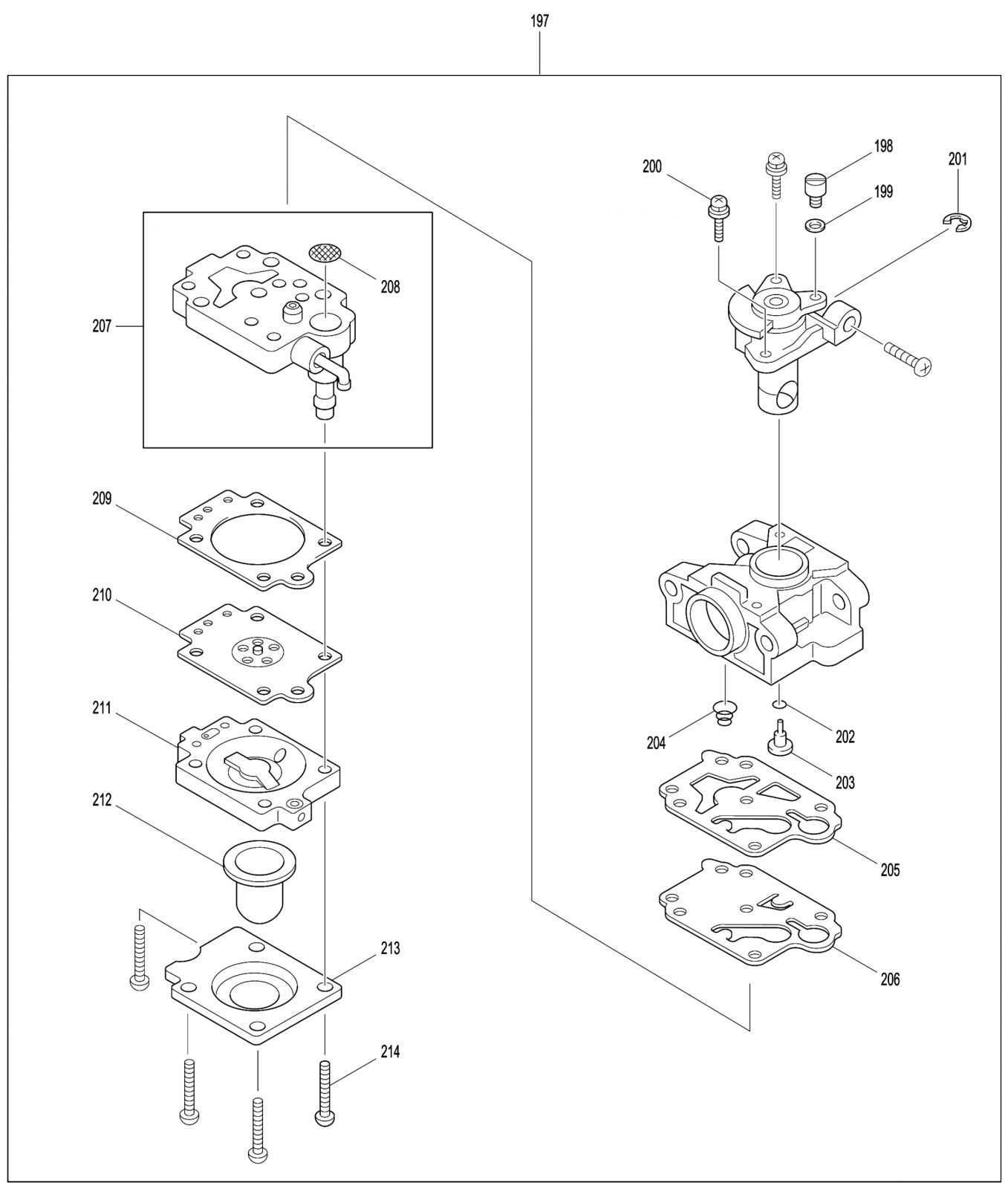

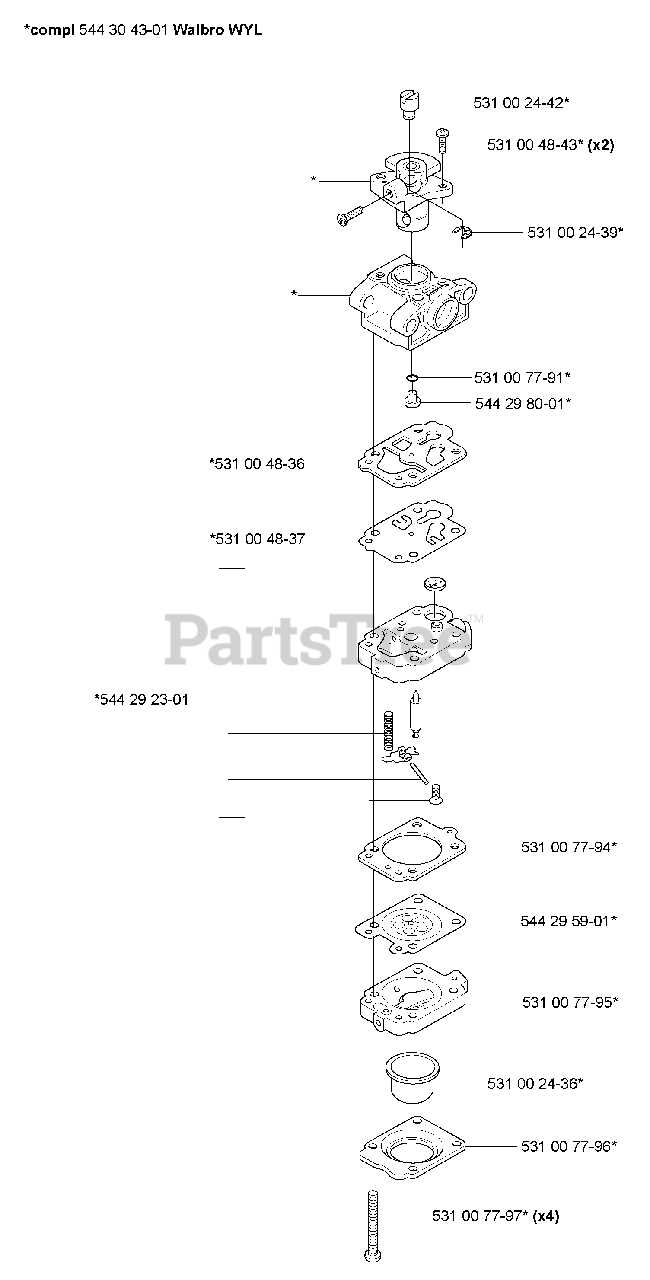

Understanding the Walbro WYL Carburetor Parts Diagram

The efficient operation of small engines hinges on a complex assembly that regulates the air-fuel mixture essential for combustion. Grasping the intricacies of these components can greatly enhance maintenance and repair efforts. Enthusiasts and technicians alike benefit from a detailed understanding of how each element contributes to the overall functionality.

To effectively troubleshoot or upgrade any engine, one must first familiarize themselves with the specific arrangement of the internal mechanisms. A comprehensive visual representation serves as a vital tool for both learning and executing repairs. This ensures that users can accurately identify each section, facilitating smoother adjustments and replacements.

By delving into the structure of these assemblies, one can uncover the ultimate secrets to optimizing engine performance. Mastery of these components not only improves reliability but also prolongs the lifespan of the machinery in question. Understanding the layout is key to achieving optimal results in both routine maintenance and specialized interventions.

Understanding Walbro WYL Carburetors

Gaining insight into fuel delivery mechanisms is crucial for enhancing engine performance. These systems play a vital role in managing air and fuel mixtures, ensuring optimal combustion and efficiency. A deep understanding of their components can significantly improve maintenance and repair tasks.

Components of these mechanisms include essential elements such as the float chamber, which regulates the fuel level, and the needle valve, responsible for controlling fuel flow. Additionally, the throttle plate plays a key role in managing airflow, impacting acceleration and overall engine response.

Tuning these devices is equally important. Adjustments to the mixture can lead to better fuel economy and reduced emissions. Understanding how to modify these settings allows for tailored performance according to specific needs or environmental conditions.

Familiarity with the assembly and disassembly process is beneficial for troubleshooting common issues. This knowledge empowers users to diagnose problems accurately and perform necessary repairs efficiently, minimizing downtime and costs.

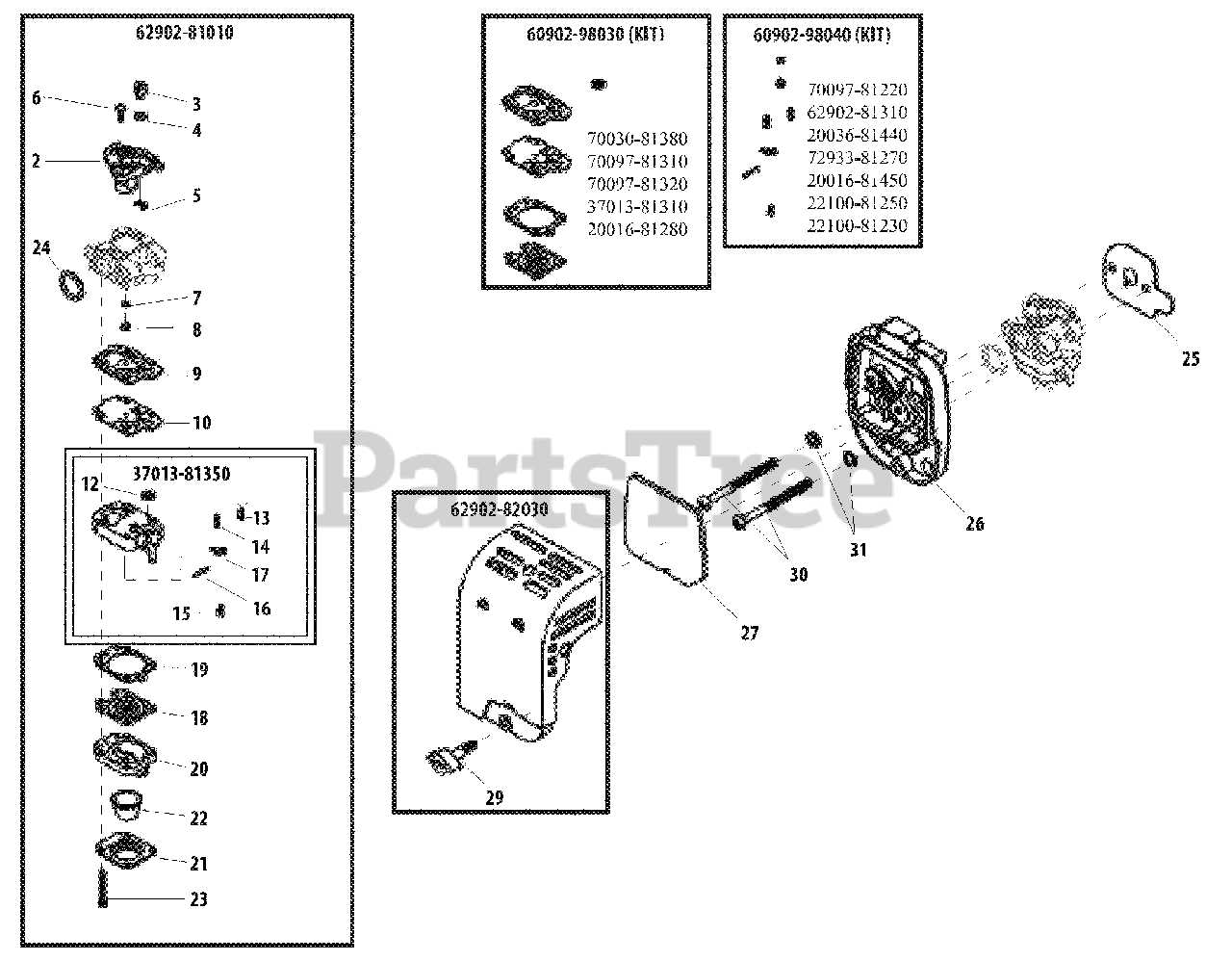

Components of the Walbro WYL

This section delves into the various elements that constitute a specific type of fuel delivery system. Understanding each component’s function is essential for effective maintenance and performance optimization. These elements work in unison to ensure proper fuel flow and air mixing, critical for the efficient operation of an engine.

Key components include the diaphragm, which regulates fuel flow based on engine demand, and the needle valve, responsible for controlling the fuel entry into the mixing chamber. The jet plays a vital role in atomizing the fuel, allowing for a better air-fuel mixture. Additionally, gaskets and seals ensure that the system remains airtight, preventing any loss of pressure that could hinder performance.

Other noteworthy elements are the adjusting screws, which allow for fine-tuning of the mixture, and the throttle body, which regulates airflow into the engine. Each of these parts contributes to the overall functionality, and a thorough understanding can aid in troubleshooting and enhancing engine efficiency.

Functionality of Each Part

This section explores the roles and interactions of various components within a fuel delivery system, emphasizing their importance in achieving optimal performance. Each element contributes uniquely to the overall functionality, ensuring efficient fuel mixing and delivery to the engine.

Key Components

The primary elements include the metering mechanism, which regulates fuel flow; the idle circuit, responsible for low-speed operation; and the adjustment screws that fine-tune air and fuel mixtures. Understanding these components allows for better troubleshooting and maintenance.

Impact on Performance

Each section plays a vital role in maintaining engine efficiency and responsiveness. Proper calibration of the mixing and delivery systems ensures that the engine operates smoothly under varying conditions, enhancing overall power and reducing emissions.

Common Issues with Walbro WYL

In the realm of fuel delivery systems, certain challenges frequently arise, impacting performance and efficiency. Recognizing these common problems can help in timely maintenance and repairs, ensuring optimal functioning.

| Issue | Description |

|---|---|

| Clogged Filters | Debris accumulation can hinder fuel flow, leading to performance issues. |

| Air Leaks | Inadequate sealing may allow air to enter the system, disrupting the fuel-air mixture. |

| Fuel Inconsistency | Poor-quality or old fuel can cause irregular engine behavior and decreased efficiency. |

| Incorrect Adjustments | Improper tuning can lead to poor acceleration and reduced power output. |

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your engine components. Regular maintenance not only improves performance but also prevents costly repairs down the line. Following a systematic approach will ensure that each element operates efficiently and effectively.

Here are some key practices to consider for optimal longevity:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Fuel Filter | Every 25 hours | Replace if clogged or damaged. |

| Clean Air Intake | Every 50 hours | Ensure unobstructed airflow for efficiency. |

| Check Gaskets and Seals | Every season | Replace worn or cracked components. |

| Monitor Fuel Quality | Regularly | Use fresh fuel to avoid residue buildup. |

| Adjust Mixture Settings | As needed | Ensure optimal performance and efficiency. |

Incorporating these practices into your routine will not only enhance performance but also extend the life of your engine elements, ensuring reliability for many uses to come.

How to Identify Genuine Parts

Recognizing authentic components is crucial for ensuring optimal performance and longevity of your equipment. Imitations may appear similar but often lack the quality and reliability required for efficient operation. Understanding key characteristics can help you discern the difference.

| Feature | Genuine Item | Counterfeit |

|---|---|---|

| Brand Markings | Clear and precise | Faded or incorrect |

| Material Quality | Durable and robust | Thin or brittle |

| Packaging | Professional with branding | Generic or no branding |

| Pricing | Consistent with market | Unusually low |

| Seller Reputation | Authorized dealer | Unknown or unverified |

Tools Needed for Repair

When undertaking maintenance or restoration tasks, having the right tools is essential for achieving optimal results. Proper equipment ensures efficiency and minimizes the risk of damage during the process. Below is a list of tools that are typically required for successful repairs.

| Tool | Description |

|---|---|

| Screwdriver Set | Essential for loosening and tightening various fasteners. |

| Wrench Set | Used for gripping and turning nuts and bolts securely. |

| Socket Set | Provides versatility for various sizes of fasteners, enhancing torque application. |

| Pliers | Useful for gripping, bending, and cutting materials as needed. |

| Cleaning Brush | Helps remove debris and build-up from components for better performance. |

| Fuel Line Pliers | Specialized for handling fuel lines safely and effectively. |

Step-by-Step Assembly Guide

This section provides a clear process for putting together essential components of a fuel delivery system. Following these steps will ensure proper functionality and longevity of the assembly, making it crucial for optimal performance.

Gather Your Tools

Before beginning, collect all necessary tools and components. A screwdriver, pliers, and a clean workspace are essential for a smooth assembly process. Ensure you have all pieces ready for a streamlined approach.

Assembly Process

Start by carefully positioning the base component. Next, align each element as per the provided instructions. Ensure all connections are snug but not overly tight to avoid damage. Final checks should include examining seals and fittings for a secure fit.

Aftermarket vs. OEM Parts

The choice between alternative components and original manufacturer offerings can significantly impact performance, reliability, and cost. Understanding the differences between these two options is essential for making informed decisions regarding maintenance and repairs.

Advantages of OEM Components

- Designed specifically for the intended application, ensuring perfect fit and function.

- Often backed by warranties, providing peace of mind for users.

- Manufactured to meet strict quality standards, ensuring durability and reliability.

Benefits of Aftermarket Components

- Generally more affordable, offering potential savings on repairs and maintenance.

- A wider variety of options available, allowing customization to meet specific needs.

- Some alternatives may provide enhanced performance compared to original offerings.

Ultimately, the decision between alternative and original offerings should consider factors such as budget, desired performance, and long-term maintenance goals.

WYL Carburetor Performance Enhancements

Improving engine efficiency and overall performance involves optimizing fuel delivery systems. This section explores various modifications that can elevate the functionality of these vital components, ensuring they meet the demands of high-performance applications. By understanding how each enhancement interacts with the engine, users can achieve significant gains in power and responsiveness.

| Enhancement | Description | Benefits |

|---|---|---|

| Jetting Adjustments | Tweaking fuel jets to match engine specifications. | Improved fuel atomization and power output. |

| Throttle Response Upgrade | Modifying the throttle linkage for quicker actuation. | Faster acceleration and enhanced drivability. |

| Intake Modifications | Altering the intake design to improve airflow. | Better engine breathing and higher RPM range. |

| Float Level Adjustment | Setting the float to optimal levels for consistent fuel supply. | Stability in performance under various conditions. |

| Upgrade to High-Performance Components | Replacing standard components with higher quality alternatives. | Increased durability and efficiency during operation. |

Implementing these enhancements can lead to noticeable improvements in vehicle performance. Careful consideration of each aspect will result in a more responsive and powerful setup, tailored to individual needs and preferences.

Resources for Further Learning

For those looking to deepen their understanding of fuel delivery systems and their components, a variety of materials and platforms are available. Exploring these resources can enhance your knowledge and improve your skills in maintenance and repair.

- Online Tutorials:

- Video tutorials on platforms like YouTube provide step-by-step guides.

- Specialized websites offer in-depth articles and tips from experts.

- Books and Manuals:

- Reference books covering general engine mechanics can be invaluable.

- Manufacturer manuals often include detailed assembly and troubleshooting sections.

- Forums and Community Groups:

- Online forums allow for discussions with fellow enthusiasts and professionals.

- Local clubs or meetups can provide hands-on experience and knowledge sharing.

- Workshops and Courses:

- Community colleges often offer courses in small engine repair.

- Workshops hosted by industry professionals can provide practical insights.

Engaging with these resources will not only broaden your understanding but also help you stay updated on the latest techniques and best practices in the field.