Understanding the Case 350 Dozer Parts Diagram

In the realm of heavy equipment, a comprehensive grasp of the individual elements that constitute a machine is essential for optimal performance and maintenance. Every component plays a pivotal role in the functionality and efficiency of the entire system. This knowledge is not just beneficial for operators; it also aids technicians and engineers in troubleshooting and repairs.

Visual representations of machinery components serve as invaluable tools for anyone looking to enhance their understanding of these complex systems. By examining schematics, one can identify the relationships and functions of various elements, leading to more informed decision-making during repairs and maintenance. Such insights can significantly prolong the lifespan of the equipment and improve overall productivity.

This discussion will delve into the intricacies of a particular model’s assembly, focusing on the various components and their specific functions. By exploring this information, readers will gain a clearer perspective on how to maintain and optimize their machinery, ensuring it operates at peak efficiency for years to come.

Understanding Case 350 Dozer Components

Grasping the essential elements of heavy machinery is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity. By familiarizing yourself with these parts, you can enhance both the efficiency and safety of your equipment.

Key Components Overview

- Engine: The powerhouse that drives all operations, providing the necessary force for movement and functionality.

- Transmission: This element transfers power from the engine to the tracks, allowing for smooth acceleration and deceleration.

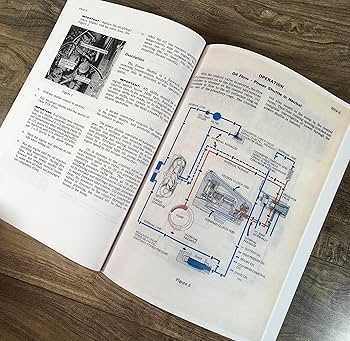

- Hydraulic System: Essential for powering various functions, including lifting and steering, making it a cornerstone of operational capability.

- Tracks: Providing traction and mobility, these components are designed to navigate various terrains effectively.

- Cabs: Protecting the operator, these enclosed spaces are designed for comfort and visibility during operation.

Maintenance Considerations

- Regularly inspect the hydraulic system for leaks and functionality.

- Check the engine oil and coolant levels frequently to ensure optimal performance.

- Examine tracks for wear and alignment to prevent operational issues.

- Clean the cab area regularly to maintain a safe and comfortable working environment.

Understanding these fundamental components and their maintenance requirements will lead to improved operational efficiency and reduced downtime, ultimately enhancing the lifespan of your machinery.

Overview of Dozer Functionality

Understanding the operational capabilities of heavy machinery used in construction and earthmoving is essential for efficient project execution. These robust machines are designed to perform a variety of tasks, primarily focusing on land grading, material handling, and site preparation. Their versatility and power make them indispensable in various applications.

Key functionalities include:

- Earth Moving: The primary function involves shifting large volumes of soil or debris from one location to another.

- Grading: They are equipped to create a level surface, which is crucial for building foundations and road construction.

- Site Preparation: Clearing and preparing land for development is a significant aspect of their operation.

- Material Spreading: These machines can distribute materials evenly across a designated area, aiding in the construction process.

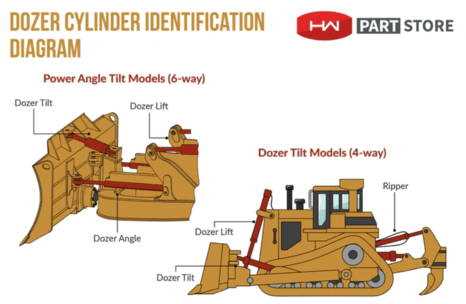

Additionally, the machinery is designed with various attachments that enhance its capabilities, such as:

- Blades: Used for cutting, leveling, and moving materials.

- Rippers: Designed to break up hard ground or compacted materials.

- Winches: Useful for pulling heavy objects, adding to the machine’s versatility.

In summary, the functionality of these powerful vehicles extends beyond mere transportation of materials, encompassing a wide array of construction-related tasks that streamline and enhance the efficiency of projects across diverse environments.

Key Parts of the Case 350

Understanding the essential components of heavy machinery is crucial for effective operation and maintenance. Each element plays a significant role in ensuring optimal performance and longevity. Familiarity with these critical sections can aid operators and technicians in identifying issues and performing timely repairs.

Essential Components

- Engine Assembly

- Transmission System

- Hydraulic System

- Chassis and Frame

- Blade Mechanism

Supporting Elements

- Fuel System

- Electrical Components

- Cooling System

- Track and Undercarriage

- Cab and Operator Controls

Each of these components contributes to the overall functionality and reliability of the machine, making it essential for users to be knowledgeable about their characteristics and maintenance needs.

Maintenance Tips for Dozer Parts

Proper upkeep of heavy machinery components is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also minimizes costly repairs and downtime. This section outlines vital maintenance strategies to ensure the reliability of your equipment.

Regular Inspections

Frequent examinations of machinery components are crucial. Consider the following steps:

- Inspect hydraulic systems for leaks or wear.

- Check for any signs of corrosion on metallic surfaces.

- Examine tracks and undercarriage for alignment and damage.

Lubrication and Cleaning

Maintaining cleanliness and proper lubrication is vital for performance:

- Use appropriate lubricants for different components.

- Clean debris from all moving parts to prevent wear.

- Follow manufacturer guidelines for lubrication intervals.

By implementing these practices, you can extend the lifespan of your equipment and enhance its operational efficiency.

Common Issues with Case 350 Parts

When working with heavy machinery, various components can encounter issues that affect overall performance and reliability. Understanding these common challenges can help in identifying symptoms early and ensuring efficient operation.

- Wear and Tear: Continuous use can lead to significant degradation of critical components, necessitating regular inspections and timely replacements.

- Hydraulic Leaks: Fluid leaks are a frequent problem, often caused by worn seals or damaged hoses, which can impair functionality and lead to costly repairs.

- Electrical Failures: Malfunctions in wiring or sensors can disrupt operations, requiring thorough diagnostics to pinpoint and rectify the issue.

- Overheating: Insufficient cooling can lead to overheating, commonly due to clogged filters or malfunctioning fans, demanding immediate attention.

Addressing these issues proactively can enhance the longevity and efficiency of the machinery. Regular maintenance and a keen eye for potential problems are essential in minimizing downtime.

- Conduct routine inspections.

- Replace worn components as needed.

- Ensure proper fluid levels and quality.

- Keep electrical systems clean and functional.

By staying vigilant and addressing these common concerns, operators can maintain peak performance and avoid more extensive damage down the line.

Replacing Worn-Out Dozer Components

Maintaining the efficiency and longevity of heavy machinery requires regular attention to its critical components. As parts experience wear and tear over time, timely replacement becomes essential to ensure optimal performance and prevent costly breakdowns. This section focuses on the process of identifying and replacing these fatigued elements.

Identifying Worn Parts

Recognizing signs of wear is the first step toward effective maintenance. Common indicators include:

- Unusual noises during operation

- Reduced efficiency and power

- Visible damage or deformation

- Increased vibration levels

Regular inspections can help catch these issues early, ensuring that replacements are made before further damage occurs.

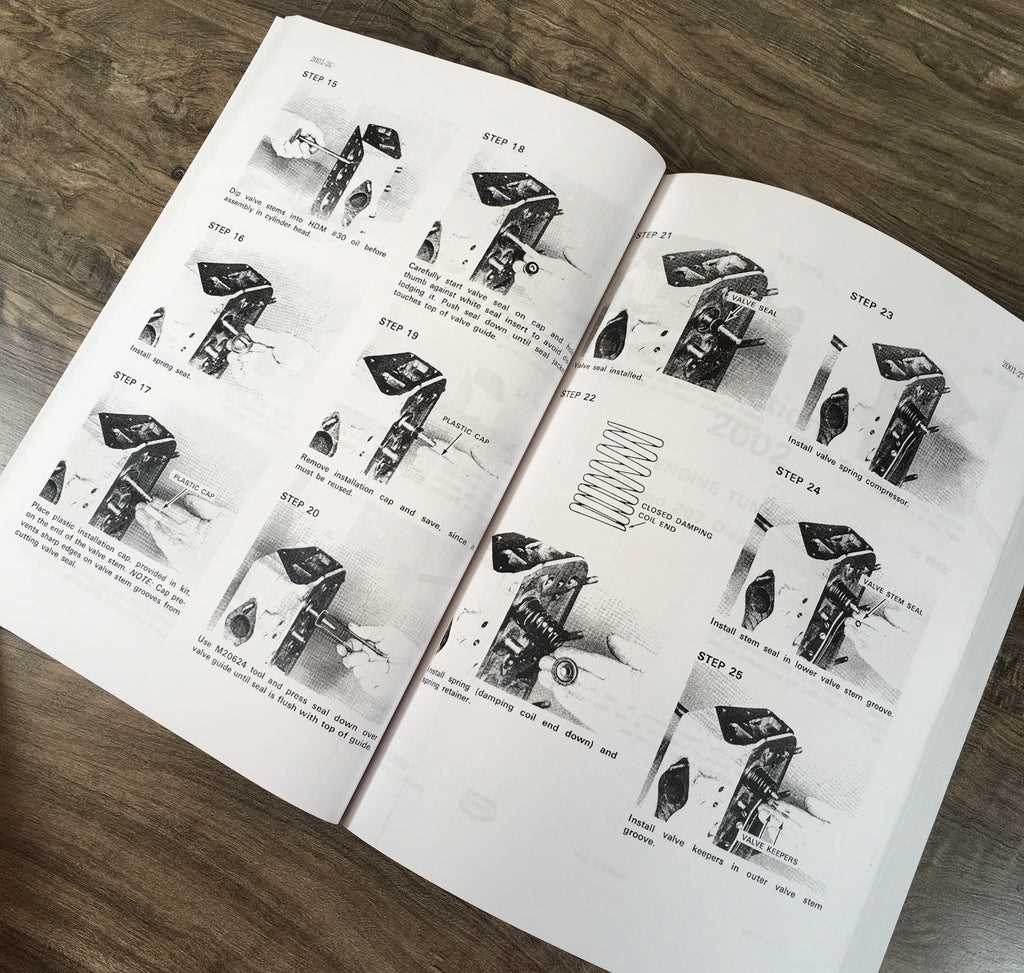

Replacement Process

Once worn components are identified, the replacement process typically involves the following steps:

- Gather necessary tools and new components.

- Shut down the machine and ensure it is safe to work on.

- Remove the old, damaged part carefully.

- Install the new component, ensuring proper alignment and secure fastening.

- Test the machine to confirm functionality.

By following these guidelines, operators can maintain the effectiveness of their machinery and avoid the pitfalls of neglecting worn parts.

Finding Genuine Case 350 Parts

Locating authentic components for your machinery is crucial for maintaining performance and longevity. Utilizing high-quality replacements ensures that your equipment operates efficiently and safely. Whether you’re in the field or in a workshop, sourcing the right elements can significantly impact your operations.

Research is key. Start by identifying reputable suppliers who specialize in original manufacturer products. Online marketplaces and dedicated machinery parts stores often provide comprehensive catalogs that make it easier to find what you need. Make sure to verify the credibility of the vendor by checking reviews and ratings.

Networking with industry professionals can also yield valuable insights. Engaging with forums and discussion groups allows you to tap into the experiences of others who have navigated similar challenges. Recommendations from fellow operators can guide you toward trustworthy sources and help avoid counterfeit items.

Finally, consider consulting with your machine’s manual or service guides. These resources often contain essential information about specifications and compatibility, ensuring that you acquire the correct replacements for your equipment. Staying informed will save you time and resources in the long run.

Exploring Aftermarket Part Options

When maintaining heavy machinery, considering alternative components can be a practical choice. Aftermarket offerings often provide cost-effective solutions without compromising quality. These options enable operators to customize their equipment, enhancing performance and longevity while potentially reducing downtime.

Several factors should be taken into account when exploring these alternatives, such as compatibility, durability, and warranty coverage. Understanding these elements can aid in making informed decisions that benefit both operational efficiency and budget management.

| Factor | Considerations |

|---|---|

| Compatibility | Ensure the part matches specifications for seamless integration. |

| Durability | Assess material quality and expected lifespan under typical conditions. |

| Warranty | Evaluate the warranty terms to protect your investment. |

| Cost | Compare prices against original components to find the best value. |

By thoroughly researching and selecting suitable aftermarket components, operators can optimize their machinery’s performance while also achieving significant savings in maintenance costs.

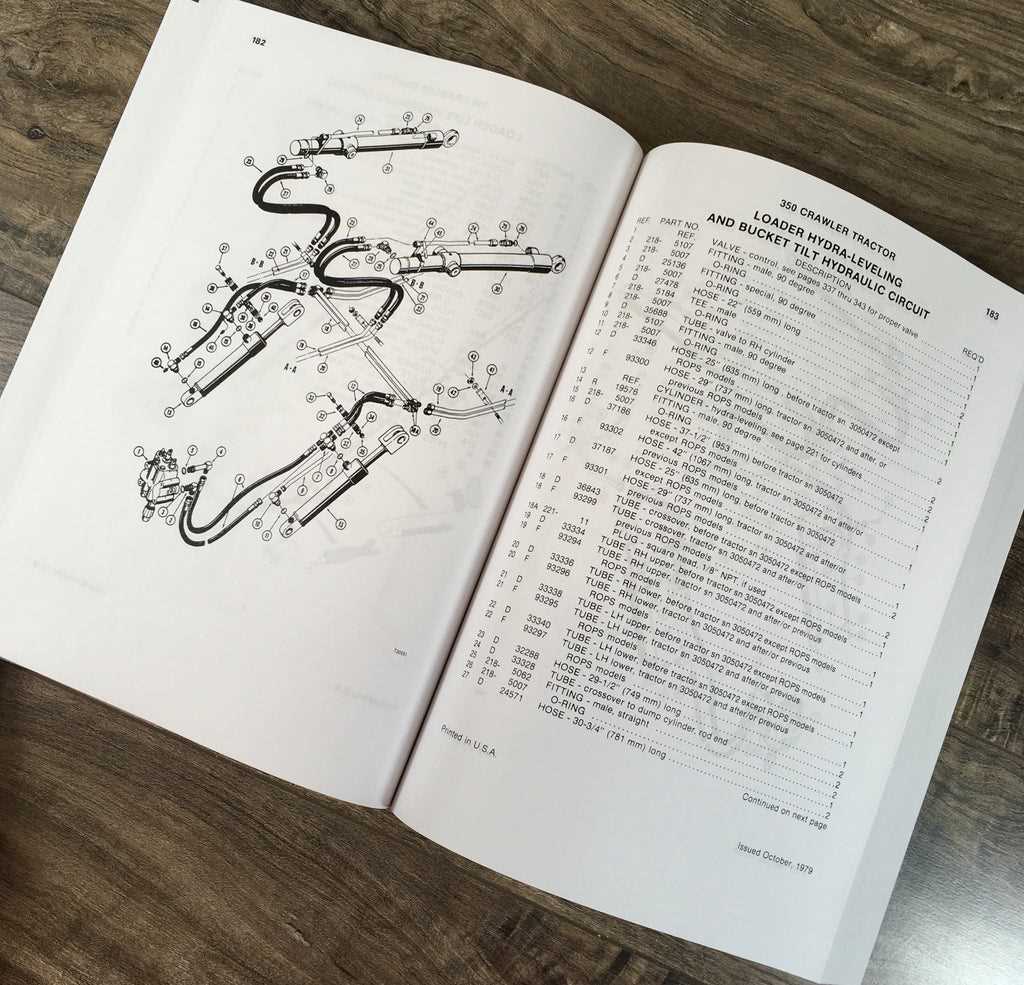

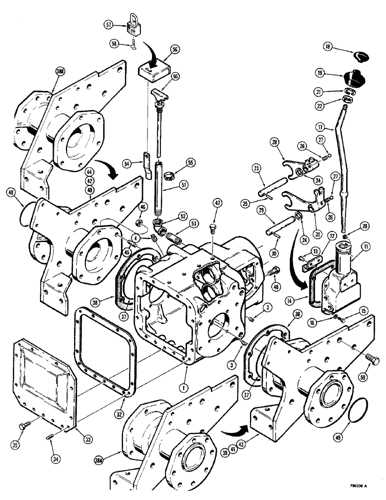

Diagram Explanation for Easy Reference

This section aims to provide a clear and concise overview of the visual representation of components, facilitating a better understanding of their arrangement and functionality. By breaking down complex systems into easily digestible elements, users can quickly identify various parts and their relationships within the machinery.

Understanding the Layout

The illustration typically showcases an organized arrangement of components, each labeled for quick identification. This layout allows for efficient navigation, enabling users to pinpoint specific elements without confusion. Understanding the positioning and connectivity of these items can significantly enhance maintenance and repair efforts.

Utilizing the Visual Guide

Referencing this visual guide can greatly simplify troubleshooting and replacement processes. When familiar with the layout, individuals can more effectively communicate issues or locate necessary items, streamlining both repair and maintenance tasks. Regular consultation of this resource can promote a deeper familiarity with the machinery, leading to more efficient operation.

How to Read Equipment Diagrams

Understanding technical illustrations is crucial for anyone involved in machinery maintenance and repair. These visual representations serve as guides, helping users navigate complex systems and identify components. Mastering the art of interpreting these visuals can enhance efficiency and prevent costly mistakes during maintenance tasks.

Key Elements to Focus On

When examining technical illustrations, pay attention to the following aspects:

| Element | Description |

|---|---|

| Symbols | Each symbol represents a specific component or function. Familiarize yourself with the legend provided to decode these icons. |

| Lines and Arrows | Lines indicate connections or pathways, while arrows show the direction of flow or movement, guiding the reader through the system. |

| Labels | Clear labels help identify parts and specifications. Ensure to cross-reference these with the accompanying text for clarification. |

| Scale | Understanding the scale is essential for visualizing the actual size and dimensions of components. |

Practical Tips for Effective Interpretation

To enhance your understanding of technical visuals, consider these strategies:

- Start with the legend to decode symbols.

- Follow the flow of lines and arrows to grasp how components interact.

- Refer to the manual for additional context on specific elements.

- Practice by analyzing various illustrations to build familiarity.

Benefits of Understanding Parts Layout

Grasping the arrangement of components in machinery can significantly enhance efficiency and maintenance practices. A clear understanding of how elements fit together not only facilitates quicker repairs but also promotes optimal performance.

Enhanced Maintenance: Knowing the configuration of various elements allows operators to identify potential issues before they escalate. Regular checks can be performed more effectively when one is aware of where critical components are located.

Increased Efficiency: Familiarity with the layout aids in troubleshooting and repair processes. This knowledge reduces downtime, as technicians can quickly locate and address faults, minimizing interruptions in workflow.

Improved Safety: Recognizing the placement of essential parts contributes to safer operation. Understanding how components interact helps prevent accidents that could arise from misinterpretation of machine functionality.

Cost Savings: By reducing the time spent on repairs and minimizing errors, a solid comprehension of the assembly can lead to significant financial savings. Efficient use of resources is directly tied to the ability to navigate and understand the layout effectively.