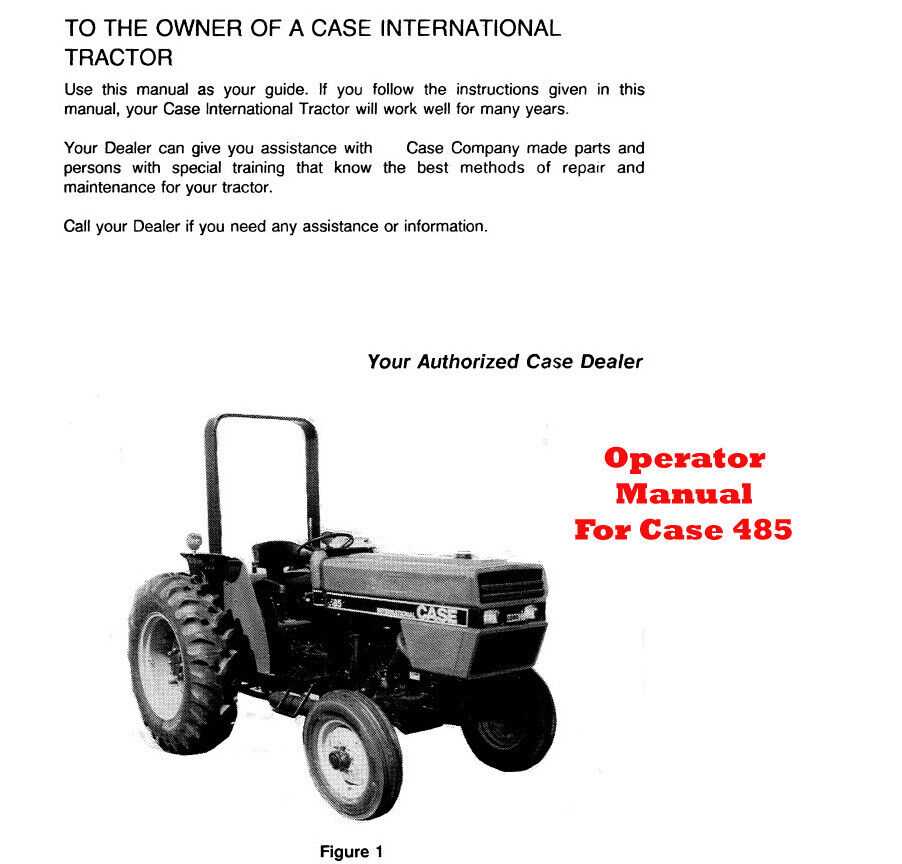

Understanding the Case 485 Parts Diagram for Efficient Maintenance

In the world of agricultural equipment, the intricate relationship between various components plays a crucial role in the overall functionality and efficiency of the machinery. An in-depth analysis of these elements can significantly enhance the understanding of maintenance, repair, and optimization processes.

Having a clear visual representation of how different sections interconnect allows operators and technicians to identify potential issues quickly. This knowledge not only facilitates timely interventions but also ensures that the machinery operates at its peak performance, minimizing downtime and maximizing productivity.

By examining these visual aids, one can appreciate the complexity of machinery and the importance of each component in contributing to the overall operation. Such insights are invaluable for anyone involved in the upkeep or utilization of these essential tools in the field.

Understanding Case 485 Components

This section explores the essential elements that make up a particular machinery model, highlighting their roles and interactions. Grasping these components is crucial for effective operation and maintenance.

- Engine: The powerhouse that drives the entire system.

- Transmission: Responsible for transferring power to the wheels.

- Hydraulic System: Facilitates movement and control of attachments.

- Electrical System: Provides energy for various functions and controls.

- Chassis: The framework that supports all other components.

Understanding each of these elements will ultimately lead to more efficient usage and troubleshooting.

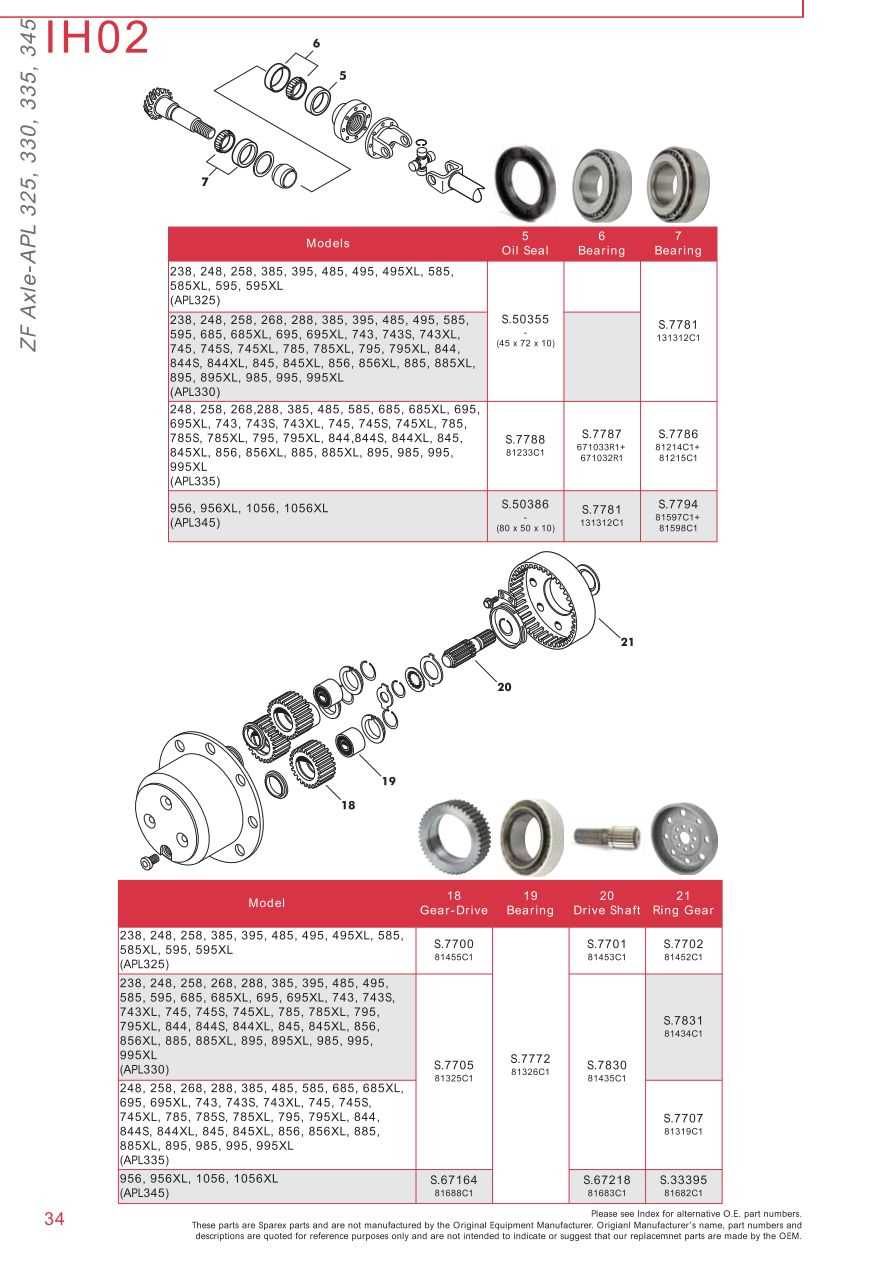

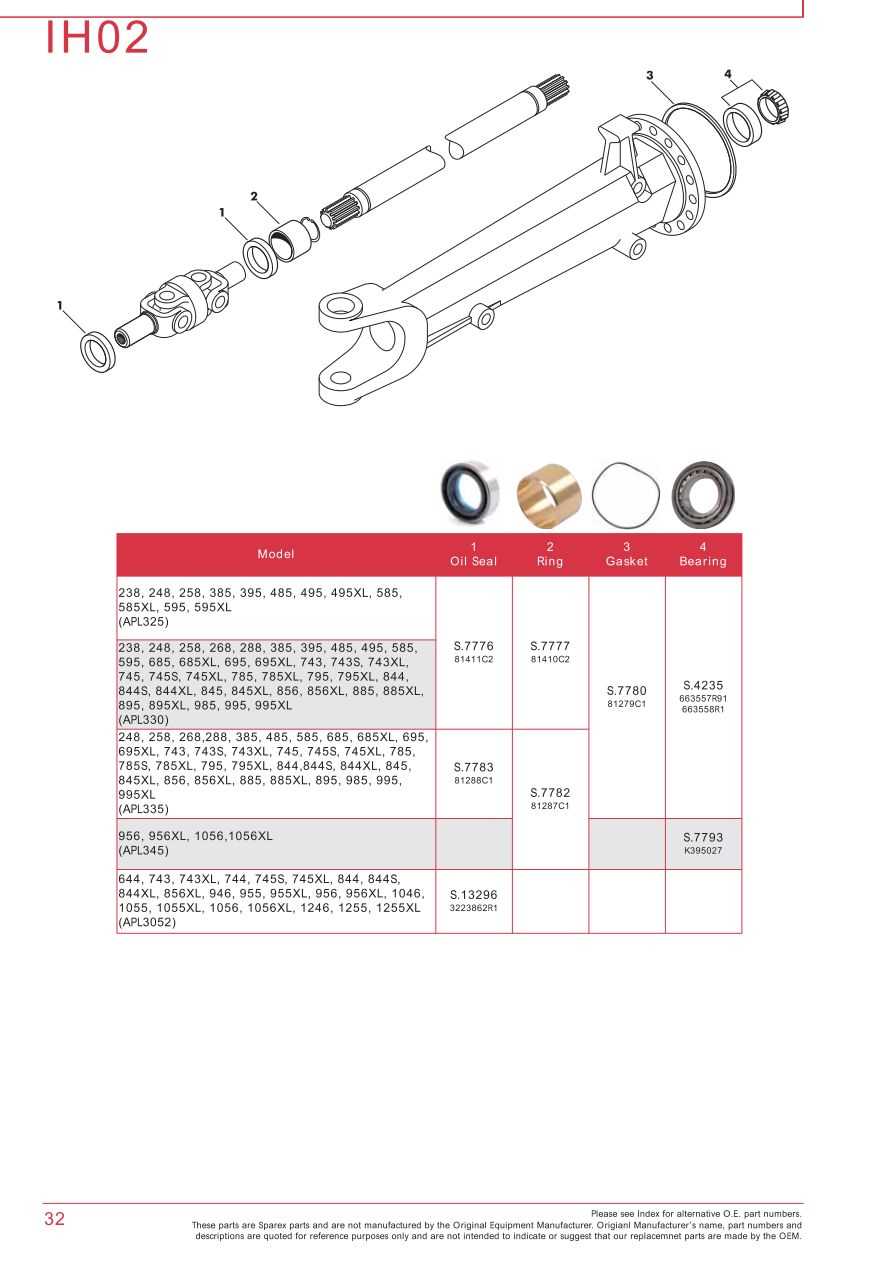

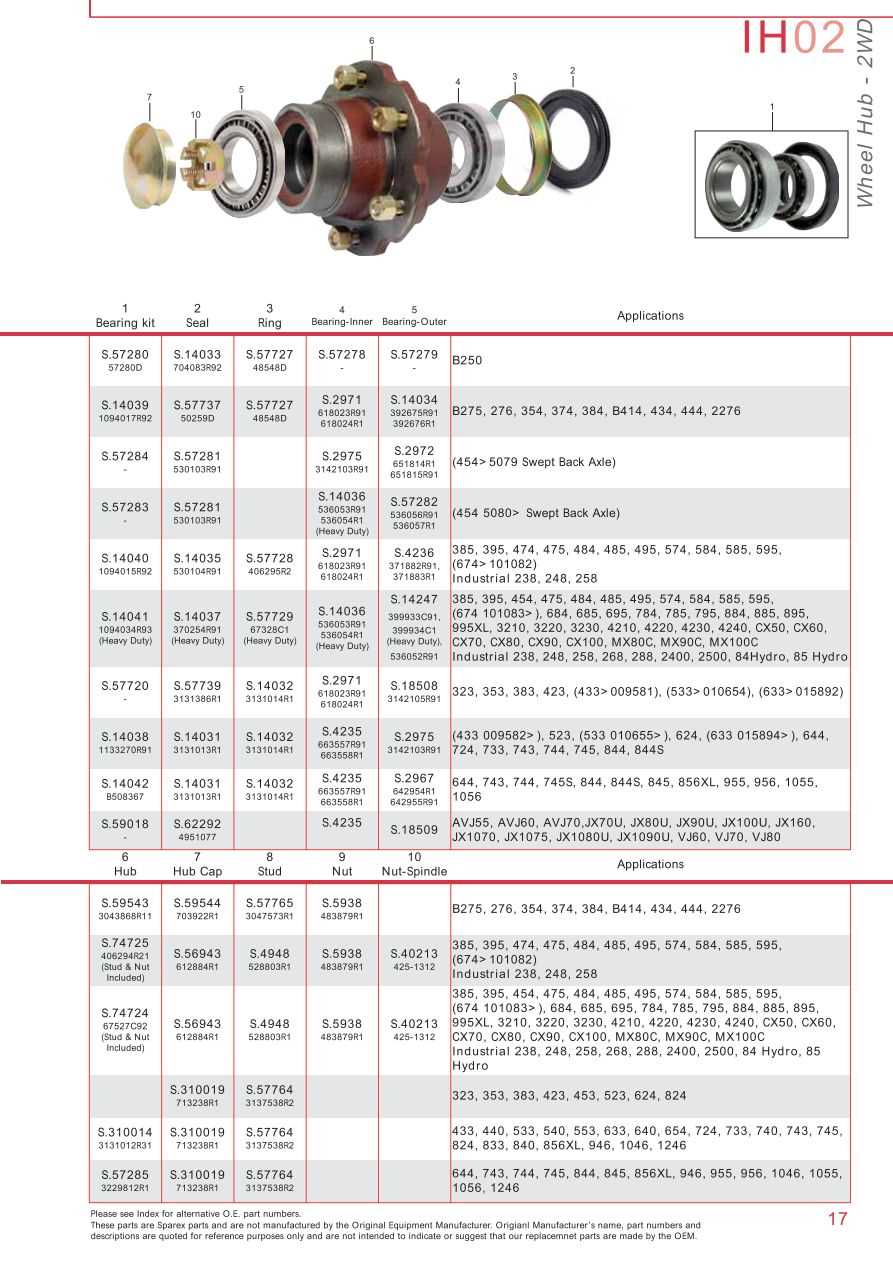

Importance of Parts Diagrams

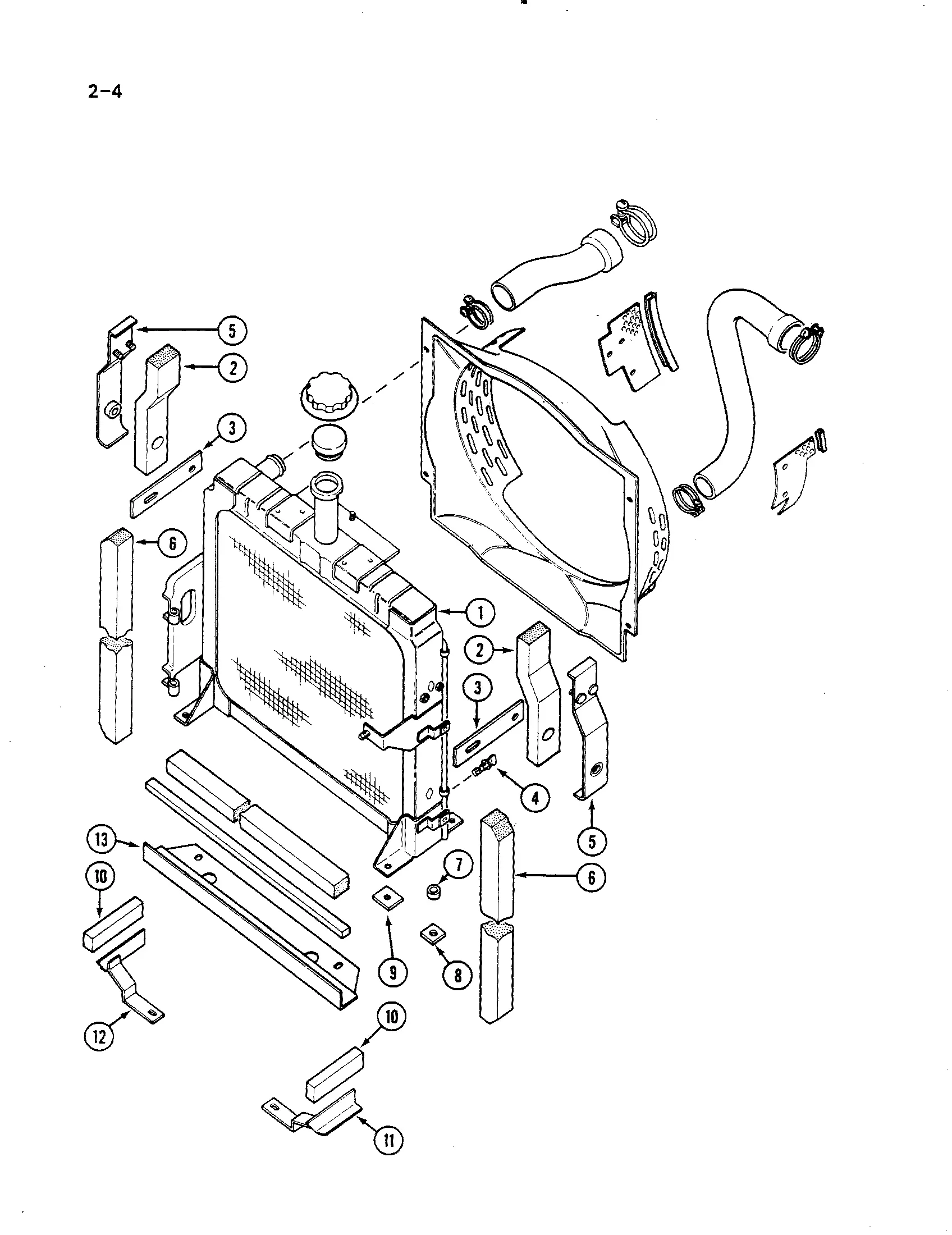

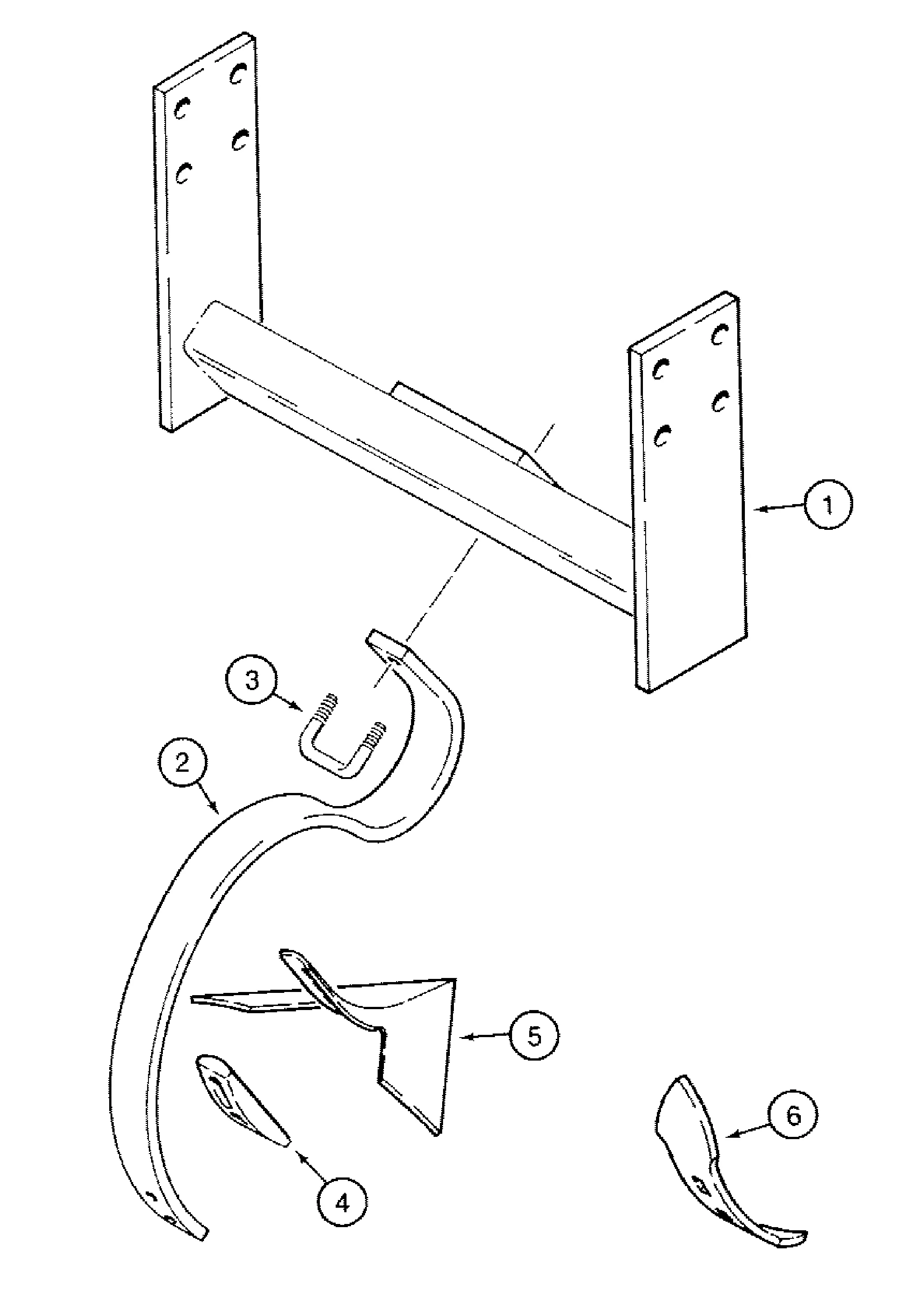

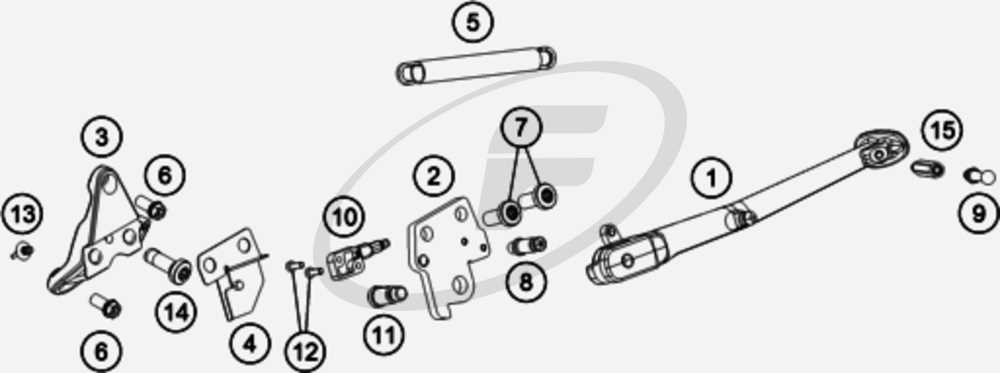

Visual representations of components play a crucial role in the maintenance and assembly of machinery. They provide a clear overview of how various elements fit together, ensuring that individuals can effectively identify and locate each piece. This clarity facilitates smoother repairs and enhances the understanding of complex systems.

Enhanced Understanding

Utilizing visual schematics allows users to grasp the relationships between different elements quickly. This understanding reduces the likelihood of errors during assembly or repairs, as it enables users to see the correct orientation and positioning of each component. Increased comprehension leads to greater efficiency and accuracy in handling equipment.

Streamlined Maintenance

When it comes to upkeep, having access to detailed illustrations simplifies the process of identifying worn or damaged items. Technicians can easily reference the visual aids to determine the necessary replacements. This streamlined approach not only saves time but also minimizes the risk of overlooking critical parts during maintenance activities.

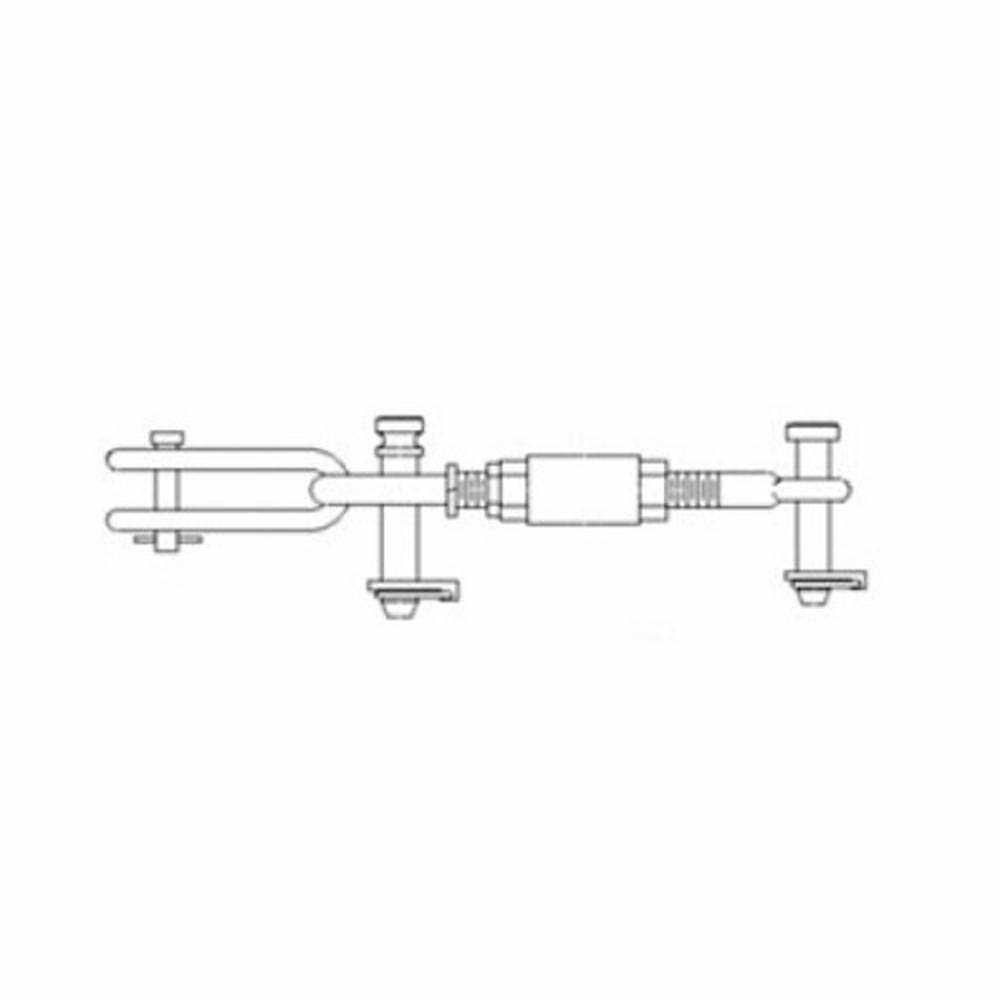

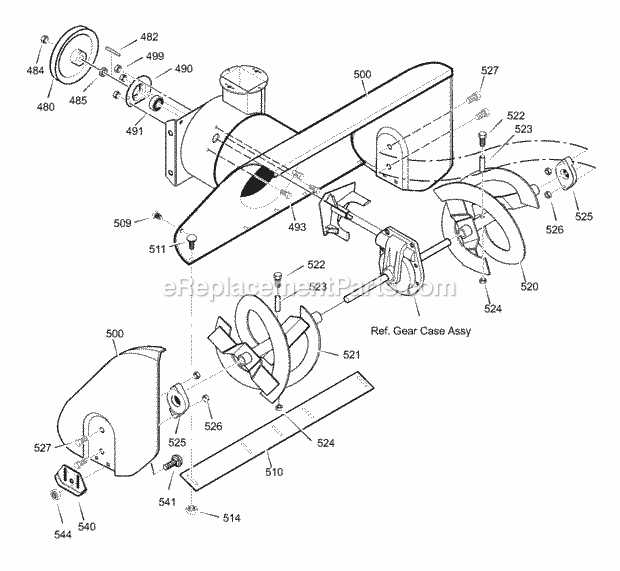

How to Read a Parts Diagram

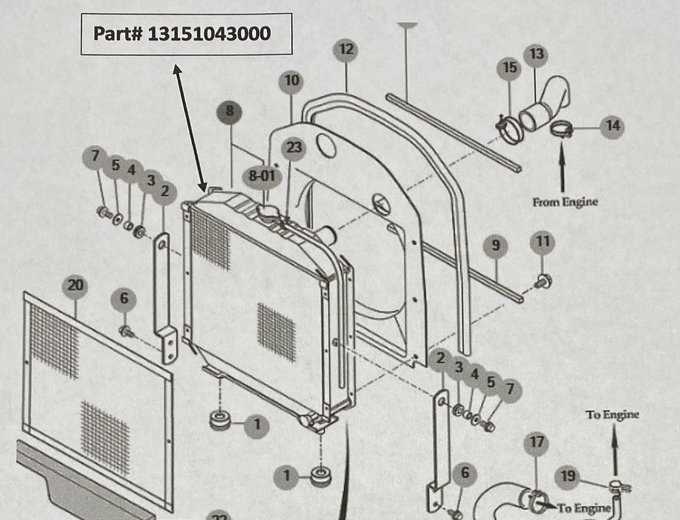

Understanding a visual representation of components is crucial for efficient maintenance and repair. This guide will help you navigate through the intricate symbols and labels often found in such illustrations, enabling you to identify individual elements and their functions seamlessly.

Familiarizing with Symbols

Each element in the illustration is typically represented by a specific symbol or shape. Recognizing these indicators is the first step in interpreting the visual. Common shapes may denote various types of components, while lines often indicate connections or relationships between them. Pay attention to any legends or keys provided, as they offer essential information on what each symbol represents.

Understanding Annotations

In addition to symbols, detailed notes and numbers are often included to provide further clarity. These annotations may include part numbers, descriptions, and specifications. Reviewing these details carefully will assist you in comprehending how each piece interacts with others. Look for any directional arrows or indicators, as they can indicate movement or orientation that is critical for assembly or disassembly.

With practice, interpreting these visual guides becomes more intuitive, leading to enhanced efficiency in your projects.

Common Issues with Case 485

In any machinery, certain challenges can arise that may affect performance and efficiency. Understanding these common problems can help operators troubleshoot and maintain equipment effectively. This section outlines frequent complications encountered in specific models, providing insights into their causes and potential solutions.

Mechanical Failures

One of the most prevalent issues involves mechanical breakdowns. Components such as the engine or transmission may experience wear and tear over time. Symptoms often include unusual noises, decreased power, or difficulty in operation. Regular maintenance, including oil changes and inspections, can mitigate these risks.

Hydraulic System Troubles

Another area of concern is the hydraulic system, which is crucial for the equipment’s functionality. Leaks or loss of pressure can lead to inefficient performance. Operators should regularly check for fluid levels and inspect hoses for any signs of damage. Prompt repairs are essential to avoid further complications.

Identifying Key Components

Understanding the essential elements of machinery is crucial for effective maintenance and operation. Recognizing these components aids in troubleshooting and enhances performance.

- Engine: The heart of the machine, responsible for power generation.

- Transmission: This system transfers energy from the engine to the wheels.

- Hydraulic System: Utilizes fluid power to perform various functions.

- Cooling System: Prevents overheating by regulating temperature.

- Electrical System: Powers all electronic components and controls.

Each part plays a vital role, and familiarity with them is the ultimate key to optimizing functionality and longevity.

Maintenance Tips for Case 485

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Following a structured maintenance plan can prevent unexpected breakdowns and costly repairs. Below are some effective strategies to keep your equipment in top shape.

Routine Inspections

- Check fluid levels frequently, including engine oil, coolant, and hydraulic fluid.

- Inspect belts and hoses for wear and tear, replacing them as necessary.

- Examine the electrical system for loose connections and corrosion.

Cleaning and Lubrication

- Regularly clean the exterior to prevent dirt accumulation that can lead to overheating.

- Lubricate moving parts according to the manufacturer’s guidelines to reduce friction and wear.

- Keep air filters clean and replace them as needed to maintain airflow efficiency.

By adhering to these maintenance tips, you can enhance the reliability and efficiency of your machinery, ensuring it performs well for years to come.

Where to Find Diagrams Online

Locating visual representations of machinery can be essential for effective maintenance and repairs. Fortunately, a variety of online resources cater to those seeking detailed illustrations of components and systems. From manufacturer websites to dedicated forums, there are numerous platforms where one can access this valuable information.

Official Manufacturer Websites: Many manufacturers provide downloadable resources that include technical illustrations. These sites often host extensive archives of manuals and schematics.

Online Forums and Communities: Engaging with specialized communities can yield insights and shared resources. Users frequently post helpful links or even their own diagrams, enriching the collective knowledge.

Document Sharing Platforms: Websites like Scribd or SlideShare may feature user-uploaded technical documents, which can include the visual guides you need.

Social Media Groups: Platforms like Facebook or Reddit have groups dedicated to specific equipment where members share resources, including valuable visuals.

By exploring these avenues, enthusiasts and professionals alike can delve into a wealth of information to assist in their projects.

Ordering Replacement Parts Efficiently

Acquiring components for machinery can often feel overwhelming, but with a streamlined approach, the process becomes significantly more manageable. By understanding the key steps involved, individuals can enhance their efficiency and minimize downtime.

Research and Identification

Begin by conducting thorough research to identify the necessary components. Utilize online resources and manuals to gather detailed specifications. This foundational step ensures that you order the correct items, avoiding costly mistakes.

Choosing the Right Supplier

After pinpointing the required components, selecting a reliable vendor is crucial. Look for suppliers who offer competitive pricing, prompt shipping, and quality assurance. Establishing a strong relationship with your provider can also lead to better deals and faster service in the future.

Tools Needed for Repairs

Proper maintenance and restoration of machinery require a specific set of instruments to ensure efficiency and safety. Having the right tools on hand can significantly streamline the repair process, enabling technicians to perform their tasks effectively.

Essential Instruments

Before starting any repair work, it is crucial to gather the following tools:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | For driving screws and fastening components. |

| Pliers | For gripping and manipulating small parts. |

| Torque Wrench | For applying specific torque settings to fasteners. |

| Multimeter | For measuring electrical parameters. |

Safety Gear

In addition to the tools, it’s essential to have safety equipment, such as gloves, goggles, and ear protection, to ensure a secure working environment.

Assembly Instructions for Case 485

This section provides detailed guidance for assembling components in a specific model. Following these instructions will ensure a smooth and efficient setup, leading to optimal functionality and performance. Proper organization and attention to detail are crucial throughout the process.

Preparation Steps

Before starting the assembly, gather all necessary components and tools. Ensure that your workspace is clean and well-lit to facilitate easy access to parts. Reviewing the instructions thoroughly will help in understanding the sequence of operations.

Assembly Process

Begin by aligning the primary units according to the specified orientation. Secure each component with appropriate fasteners, making sure they are tightened to the recommended torque specifications. It is essential to check for any misalignments at each stage to avoid complications later. Once all parts are assembled, perform a final inspection to confirm that everything is in place and functioning as intended.

Note: Always refer to the specific manual for detailed illustrations and any additional recommendations during the assembly process.