Understanding the Case 580SE Parts Diagram for Better Maintenance

In the world of construction and agriculture, the efficiency of equipment relies heavily on the intricate design and arrangement of its various elements. Each component plays a vital role in ensuring that the machine operates smoothly and effectively. To grasp the functionality of these machines, it is essential to have a clear view of how each piece interacts with others.

Mechanisms of heavy-duty machines are often complex, requiring a thorough understanding for both maintenance and repair. Familiarity with the specific layouts can enhance one’s ability to troubleshoot issues and perform upgrades. This knowledge ultimately leads to improved performance and longevity of the equipment.

Furthermore, exploring these intricate layouts allows operators and technicians to delve into the specifics of machinery, revealing the ultimate synergy among components. Recognizing how each part contributes to the overall operation not only facilitates better handling but also empowers users to make informed decisions regarding upgrades or replacements.

Understanding the Case 580SE

This section aims to explore the intricacies of a well-known machine, emphasizing its components and functionality. By delving into its design and mechanics, users can gain insights into its efficiency and versatility in various applications.

Key Features

- Robust construction for durability

- Advanced hydraulic system for enhanced performance

- Operator-friendly controls for ease of use

Maintenance Tips

- Regularly check fluid levels to ensure optimal operation.

- Inspect hoses and seals for wear and tear.

- Keep the machine clean to prevent corrosion.

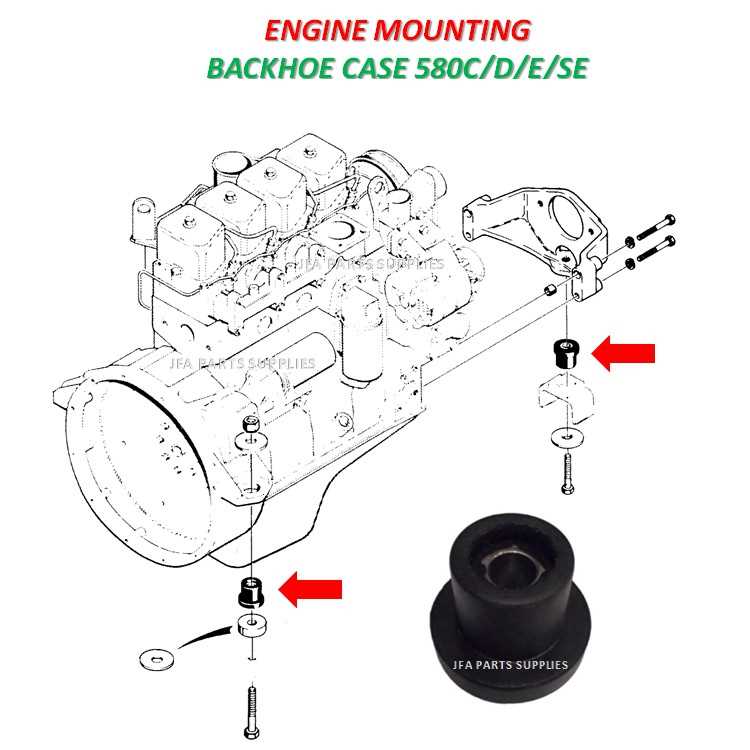

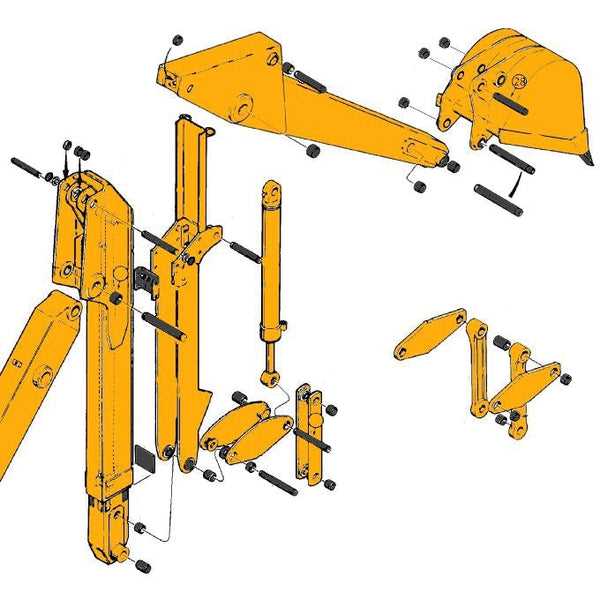

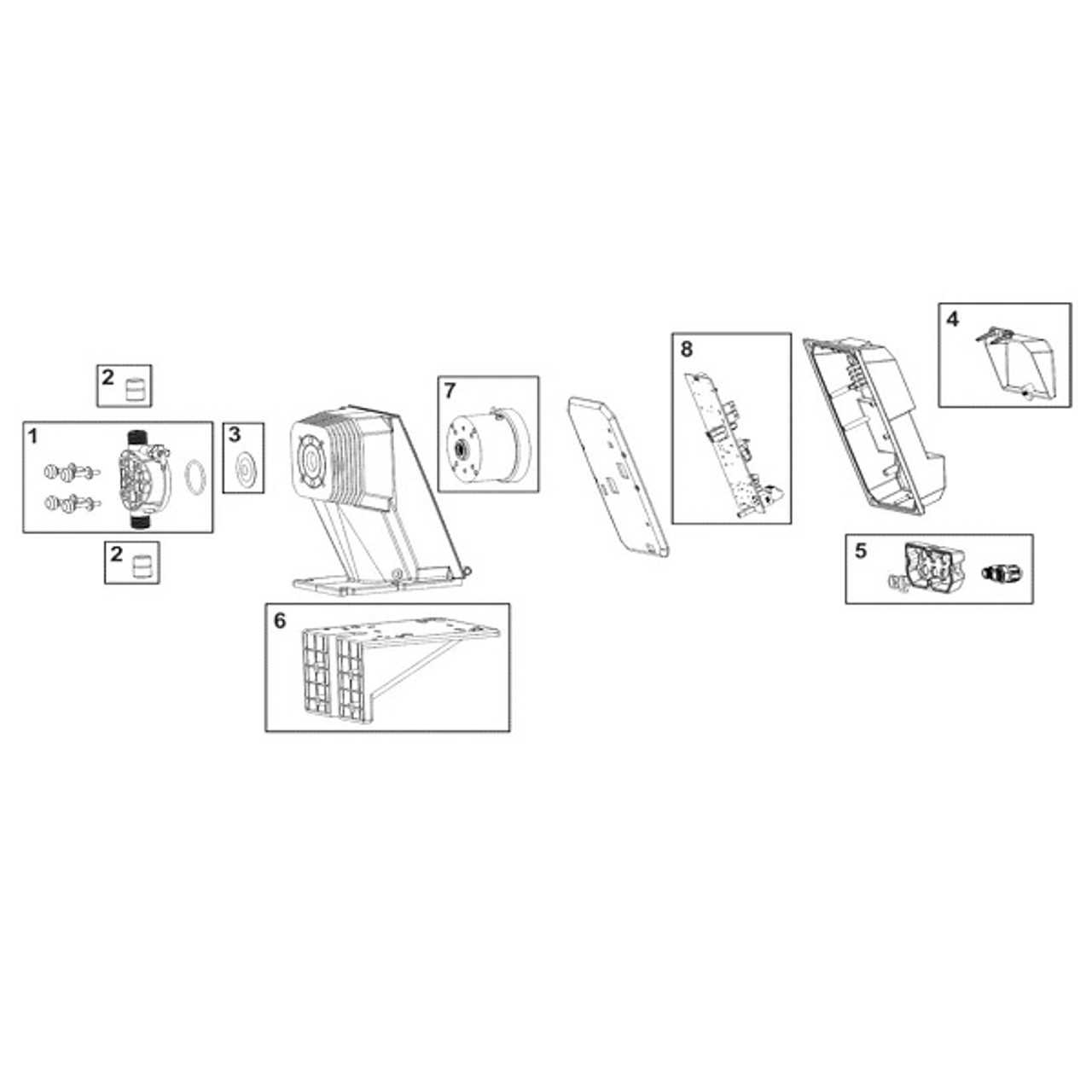

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is essential for effective maintenance and repair. Visual representations of components play a critical role in this process, providing clarity and enhancing workflow efficiency.

These illustrations serve several vital purposes:

- Enhanced Clarity: Visual guides break down complex assemblies into manageable sections, making it easier to identify individual components.

- Improved Communication: They facilitate better discussions among technicians, ensuring everyone is on the same page regarding repairs or upgrades.

- Efficient Troubleshooting: Quick identification of malfunctioning parts can significantly reduce downtime, as technicians can focus on specific areas of concern.

- Streamlined Ordering: Clear visual aids allow for precise identification of required items when ordering replacements, minimizing the risk of errors.

In summary, these visual aids are indispensable tools that not only simplify the repair process but also enhance overall operational efficiency. Proper use of these resources can lead to significant time and cost savings, ultimately benefiting the entire maintenance workflow.

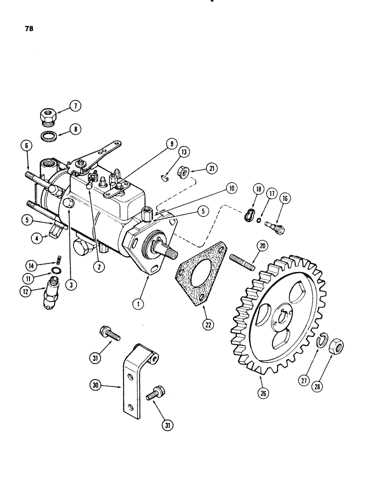

Key Components of the 580SE

This section explores the essential elements that contribute to the functionality and performance of a popular heavy machinery model. Understanding these components helps in appreciating the engineering behind its operation and maintenance.

Engine and Transmission

The powertrain includes a robust engine and a reliable transmission system. The engine provides the necessary power for various tasks, while the transmission ensures smooth gear shifting and efficient power delivery to the wheels.

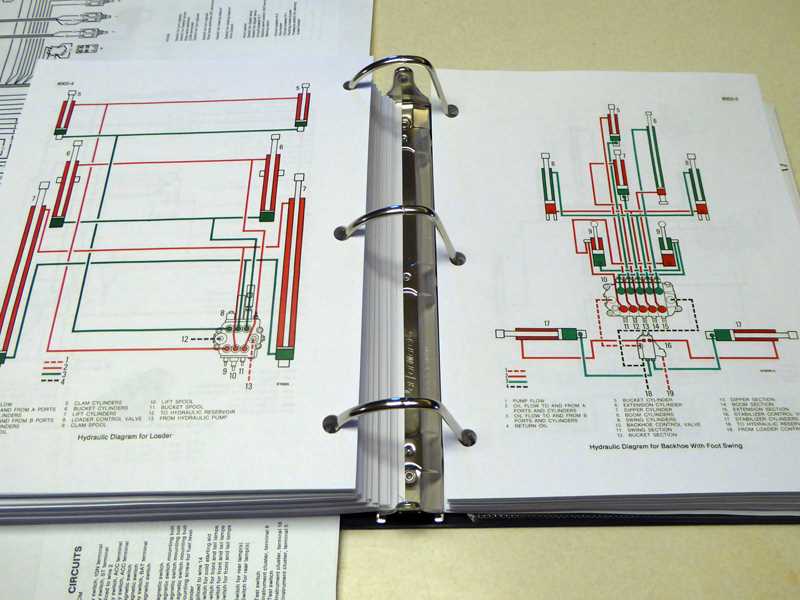

Hydraulic System

A well-designed hydraulic system is crucial for operating attachments and executing heavy lifting tasks. Key features include hydraulic cylinders and a pump that work together to enhance maneuverability and precision in various applications.

Benefits of Using Diagrams

Visual representations serve as powerful tools in various fields, enhancing understanding and communication. By translating complex information into an accessible format, they facilitate quicker comprehension and retention of concepts. This section explores the advantages of employing such illustrations in different contexts.

- Enhanced Clarity: Visual aids break down intricate processes into simpler components, making them easier to understand.

- Improved Communication: They provide a common language that can bridge gaps between technical and non-technical individuals.

- Increased Retention: Information presented visually tends to be remembered more effectively, aiding in long-term learning.

- Efficient Problem-Solving: Visuals can quickly highlight areas of concern or focus, streamlining the decision-making process.

- Facilitation of Collaboration: Group discussions are often more productive when participants can refer to visual elements, ensuring everyone is aligned.

Incorporating illustrations into documentation not only clarifies content but also promotes engagement, making it an essential practice in effective communication.

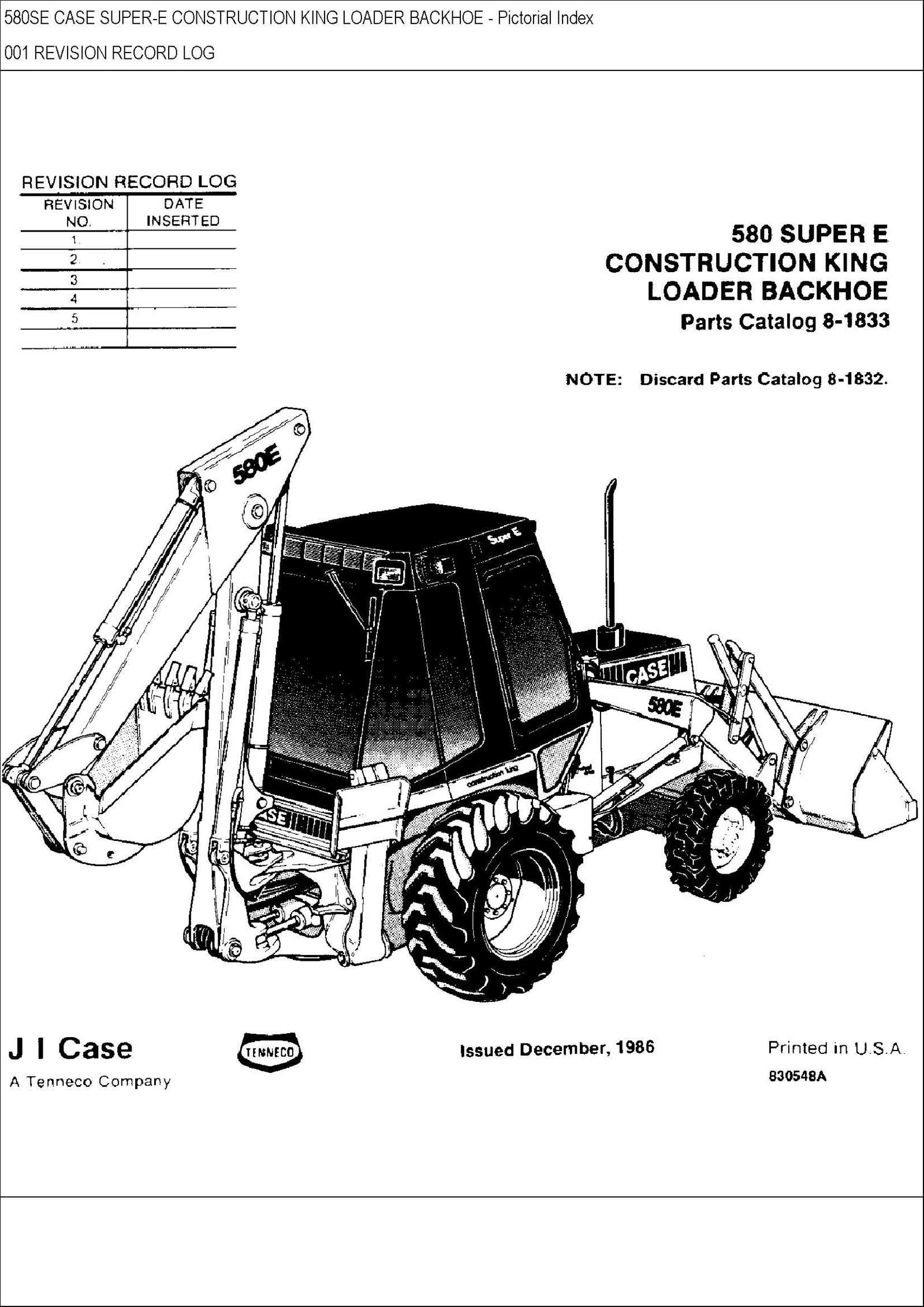

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visuals provide a clear representation of components, helping users identify and locate each element within a complex system. Mastering this skill can significantly enhance your efficiency when working on machinery.

Firstly, familiarize yourself with the overall layout. Most illustrations categorize components based on their function and placement, which aids in quick reference. Secondly, pay attention to the numbering system or labeling; each item is usually assigned a unique identifier that corresponds to a detailed list, facilitating easy cross-referencing.

Additionally, notice the relationships between different elements. Arrows and lines often indicate connections or sequences, highlighting how various parts interact. By delving into these relationships, you can better understand the assembly and disassembly processes.

Finally, always consult the accompanying documentation for specifications and instructions. This comprehensive approach ensures that you grasp the ultimate functionality of each part, leading to successful repairs and maintenance.

Common Issues with Case 580SE

Every piece of heavy machinery faces its own set of challenges, and this particular model is no exception. Understanding the frequent problems encountered can aid in preventative maintenance and ensure optimal performance over time.

Hydraulic Problems: One of the most prevalent issues relates to the hydraulic system. Users often report leaks, which can stem from worn seals or damaged hoses. Maintaining proper fluid levels and regularly inspecting components can mitigate these concerns.

Engine Performance: Another common challenge involves engine efficiency. Operators may notice a decline in power or increased fuel consumption. This can often be attributed to clogged filters or issues with the fuel injection system. Routine checks and replacements can enhance overall functionality.

Electrical System Failures: Electrical problems can arise, affecting the starting system or various onboard instruments. Corroded connections and worn wiring are typical culprits. Regular inspections can prevent unexpected breakdowns and ensure reliability during operation.

Tire Wear: Uneven tire wear is also frequently reported, which can impact stability and handling. Proper alignment and regular tire maintenance are essential to prolong the lifespan of the tires and enhance safety.

By being aware of these common issues, operators can take proactive steps to address them, ensuring their machinery remains in excellent working condition.

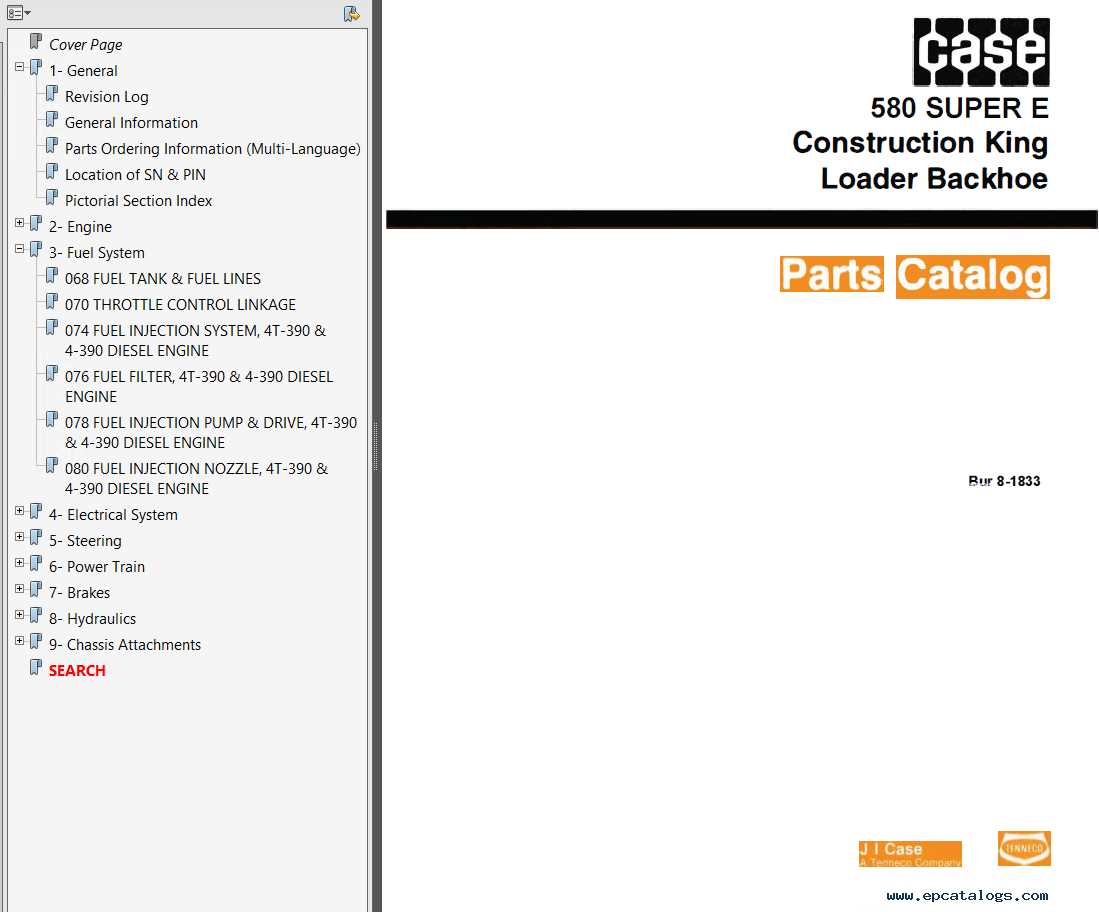

Where to Find Diagrams

Locating visual representations for machinery components can significantly enhance your understanding and maintenance capabilities. Various resources are available to help enthusiasts and professionals alike access detailed illustrations that break down complex assemblies and systems.

Online Resources: Numerous websites cater to equipment enthusiasts, offering comprehensive visual aids. Manufacturer sites often have downloadable resources that provide accurate and up-to-date visuals. Additionally, forums and community websites can be excellent places to find shared diagrams, as users frequently upload useful materials.

Technical Manuals: Printed manuals and guides often contain essential illustrations. These documents are designed to assist users in troubleshooting and repairs, making them invaluable tools for anyone looking to grasp the intricacies of their machinery.

Local Dealerships: Engaging with local equipment dealers can yield beneficial results. They often have access to proprietary resources and can provide specific illustrations or direct you to where you can find them.

Library and Archives: Public libraries and technical archives may house historical documents, manuals, and diagrams. Exploring these resources can uncover valuable information that might not be readily available online.

By exploring these avenues, individuals can gain the necessary insights to better understand the machinery they work with, ultimately improving efficiency and effectiveness in their tasks.

Maintaining Your Equipment

- Schedule routine inspections to identify potential issues early.

- Keep all components clean and free from debris.

- Lubricate moving parts as per manufacturer recommendations.

- Replace worn-out components promptly to avoid further damage.

By implementing a consistent maintenance routine, you can ultimately improve the reliability and effectiveness of your equipment.

Identifying Replacement Parts

When it comes to maintaining heavy machinery, recognizing the necessary components for repairs and upgrades is crucial. Understanding how to pinpoint these elements can greatly enhance the efficiency and longevity of equipment. This section will provide guidance on how to accurately identify and source essential components for your machinery.

Key Considerations

Before you begin searching for components, consider the following factors:

- Model Specifications: Ensure you know the exact model of your machinery, as variations may exist within similar units.

- Usage History: Review any previous repairs or modifications that might affect the parts needed.

- Manufacturer Guidelines: Consult the manufacturer’s recommendations for replacements to ensure compatibility and performance.

Steps to Identify Components

Follow these steps to effectively identify the components required for your machine:

- Consult the Manual: The user manual often contains detailed information about each component and its specifications.

- Visual Inspection: Examine the machinery closely to locate any worn or damaged items that require replacement.

- Utilize Online Resources: Access online platforms or forums where experts share insights and diagrams related to your machinery.

- Contact Suppliers: Reach out to authorized dealers or suppliers who can assist in identifying and sourcing the correct components.

By following these guidelines, you can ensure that you accurately identify the necessary components, leading to effective maintenance and repairs of your machinery.

Tools for Repair and Maintenance

Effective upkeep of heavy machinery relies heavily on a range of specialized instruments. These tools not only enhance the efficiency of repair tasks but also ensure the longevity of the equipment. Understanding which instruments to utilize can significantly improve the overall maintenance process.

Essential Instruments

Various tools are critical for performing both routine maintenance and complex repairs. Here are some of the most important ones:

| Tool Type | Purpose |

|---|---|

| Wrenches | Tightening and loosening bolts and nuts |

| Screwdrivers | Fastening screws in various applications |

| Socket Sets | Providing greater torque for nuts and bolts |

| Pliers | Gripping and bending components |

| Hydraulic Jacks | Lifting heavy parts for access and replacement |

Advanced Equipment

In addition to basic tools, advanced equipment plays a crucial role in ensuring thorough repairs. Utilizing the right technology can enhance precision and speed during maintenance tasks:

| Equipment Type | Function |

|---|---|

| Diagnostic Tools | Identifying faults and performance issues |

| Pressure Washers | Cleaning components effectively |

| Torque Wrenches | Ensuring proper tightness on fasteners |

| Bench Vises | Holding components securely during work |

| Heat Guns | Softening materials for easier manipulation |

Case 580SE Specifications Overview

This section provides a comprehensive examination of the features and characteristics of a specific construction machine, highlighting its capabilities and technical details that make it suitable for various applications.

- Engine Type: Diesel engine with robust performance.

- Power Output: Approximately 80 horsepower.

- Operating Weight: Around 8,000 pounds.

- Loader Capacity: Maximum load capacity of about 2,500 pounds.

- Dig Depth: Capable of reaching depths up to 14 feet.

- Transmission: Smooth-shifting hydrostatic transmission.

Understanding these specifications is crucial for operators seeking efficiency and reliability in their machinery, ensuring optimal performance in various construction tasks.

Upgrading and Modifying Your Machine

Enhancing the functionality and performance of your equipment can significantly improve its efficiency and extend its lifespan. This section explores various approaches to upgrading and modifying your machinery, ensuring you get the most out of your investment.

Benefits of Upgrades

- Improved Performance: Upgrading components can lead to better speed and power output.

- Increased Efficiency: Modern parts often consume less fuel and operate more smoothly.

- Enhanced Durability: High-quality replacements can reduce wear and tear, prolonging the life of your machine.

- Customization: Tailoring your equipment to specific tasks can enhance productivity and comfort.

Common Modifications

- Engine Upgrades: Consider installing a more powerful engine or performance chip for better output.

- Hydraulic Enhancements: Upgrading the hydraulic system can improve lifting capacity and responsiveness.

- Cab Improvements: Adding ergonomic seats and advanced controls can enhance operator comfort and control.

- Attachment Options: Explore various attachments designed for specialized tasks to increase versatility.

By understanding the potential upgrades and modifications available, you can make informed decisions that will lead to a more efficient and capable machine.

Resources for Further Learning

Expanding your knowledge about machinery and its components can greatly enhance your understanding and maintenance skills. Numerous resources are available to help enthusiasts and professionals alike deepen their expertise in this area. Below are various types of materials and platforms that can aid in your learning journey.

- Online Courses:

- Explore platforms like Coursera and Udemy for courses on equipment mechanics and repair.

- Look for specialized programs focusing on heavy machinery and automotive technology.

- Books and Manuals:

- Consult technical manuals that provide in-depth information about machinery functions.

- Read textbooks covering topics such as mechanical engineering and systems maintenance.

- Forums and Online Communities:

- Join discussion groups on platforms like Reddit and specialized forums to connect with fellow enthusiasts.

- Participate in Q&A sessions to gain insights from experienced professionals.

- YouTube Channels:

- Follow channels dedicated to machinery repair and maintenance for visual tutorials.

- Watch videos that demonstrate troubleshooting techniques and equipment usage.

- Trade Shows and Workshops:

- Attend industry events to network with experts and learn about the latest technologies.

- Participate in hands-on workshops to apply your knowledge in practical settings.

Utilizing these resources can significantly improve your proficiency and confidence when working with various types of machinery.