Pella Casement Window Parts Diagram Guide

In today’s architectural designs, the functionality and longevity of openable structures in homes and buildings rely heavily on the interplay of various mechanisms. Understanding how each element contributes to smooth operation is essential for anyone looking to maintain or improve these systems.

The intricate design behind these structures involves several moving pieces, all working together to ensure ease of use and durability. Identifying the key components is crucial for repairs, replacements, or upgrades. In this guide, we’ll explore the primary elements, their roles, and how they fit within the broader framework.

Familiarizing yourself with these core elements will allow for more informed decisions when dealing with replacements or maintenance. By delving into the specific mechanisms, you’ll gain insights into how these components work in harmony to provide seamless functionality.

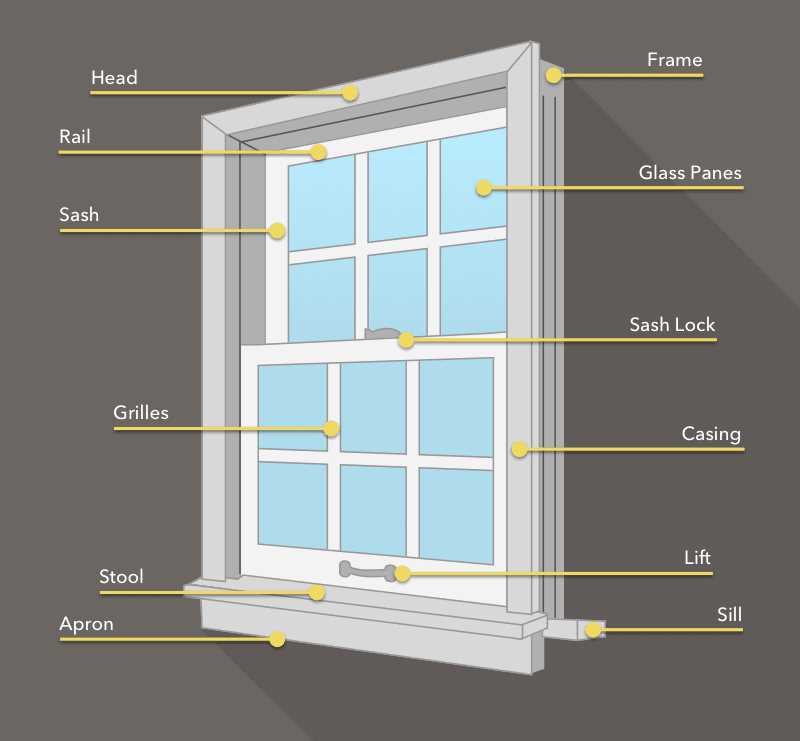

Pella Casement Window Parts Diagram Overview

Understanding the structure and components of this type of window system is essential for proper maintenance and repair. A clear diagram allows users to identify each piece and its function, ensuring smooth operation and longevity of the unit. By visualizing the elements involved, it becomes easier to assess any issues and plan for necessary adjustments or replacements.

Main Components Explanation

The assembly consists of several key elements that work together to provide both functionality and aesthetics. Each element plays a crucial role in the movement, sealing, and overall performance. Knowing how these pieces interconnect can help avoid common problems, like misalignment or draftiness.

Functional Insights

Each part has a specific purpose, from supporting the frame to enabling easy opening and closing. Understanding the role of each segment helps with troubleshooting and optimizing the performance of the system, ensuring smooth operation and energy efficiency over time.

Understanding the Components of Pella Windows

Modern residential openings consist of various interconnected elements that contribute to both functionality and aesthetic appeal. These structures combine mechanical precision with architectural design, allowing homeowners to enjoy natural light, ventilation, and insulation. Recognizing the role of each part is essential to ensure long-lasting performance and ease of use.

Frame Structure

The outer boundary of the opening plays a critical role in providing support and stability. This structural feature not only holds the entire assembly together but also serves as a barrier against external elements. Materials such as wood, vinyl, or aluminum are commonly used, each offering different benefits in terms of durability, energy efficiency, and maintenance.

Glass and Seals

The transparent panel is the most visible element, responsible for controlling the passage of light and heat. To enhance energy efficiency, multiple layers of glass are often employed, along with special coatings. Additionally, weather seals surrounding the edges ensure proper insulation, preventing drafts and moisture intrusion.

Common Issues with Hinged Ventilation Systems

Hinged ventilation systems are a popular choice for many homes, but over time, some components may experience wear and require attention. Understanding these common problems can help homeowners identify and address them early, preventing larger repairs or replacements in the future.

- Loose or stiff mechanisms: Over time, the hinges or handles can become loose, making it difficult to operate, or too tight, which may strain the hardware.

- Air leakage: Gaps in the seal can allow drafts, reducing energy efficiency and indoor comfort.

- Rust and corrosion: Exposure to moisture can cause metal parts to corrode, impacting smooth movement and overall function.

- Cracked seals: The rubber or foam seals around the frame may crack or break, leading to poor insulation and potential water intrusion.

- Broken locking mechanisms: The locks can wear out or break, compromising security and ease of use.

Regular maintenance, such as lubric

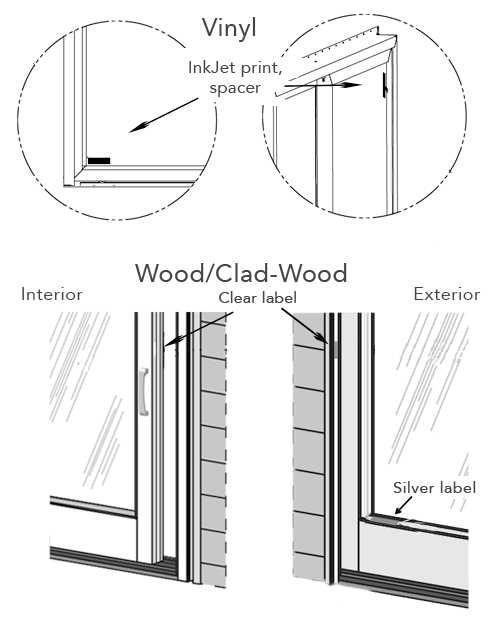

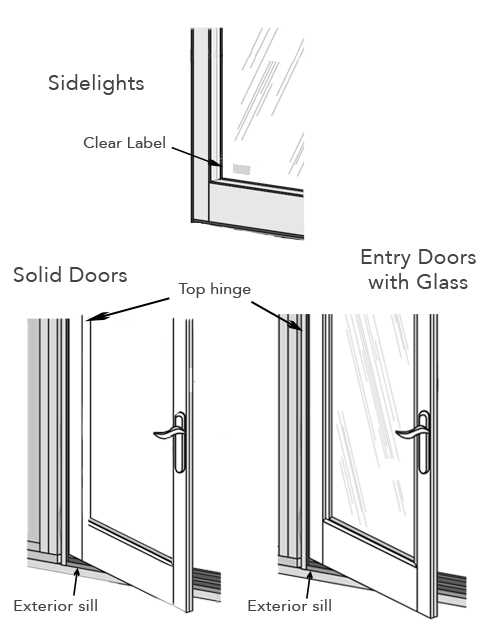

How to Identify Worn Out Parts

Over time, many components in your structure may begin to show signs of wear and tear. Recognizing these early signs can prevent further damage and ensure efficient performance. It’s essential to understand the common symptoms that indicate a need for replacement or repair.

Visual Clues

One of the most apparent indicators of aging elements is visible deterioration. Cracks, discoloration, or deformation in materials may signal that the item is no longer functioning properly. Regular inspections help detect these issues before they escalate.

Functional Symptoms

When mechanisms become difficult to operate or lose their smoothness, it’s often a sign of underlying wear. Stiffness, unusual noises, or inconsistent movement suggest that internal components have degraded and may need attention.

Replacement Process for Pella Window Hardware

Upgrading or fixing components of your home’s openings can enhance both functionality and appearance. Ensuring that the mechanisms responsible for smooth operation are properly maintained or replaced can prevent future issues and prolong the lifespan of your system.

Step 1: Assess the Condition of the Mechanism

Before starting, carefully inspect the current setup. Look for signs of wear, rust, or damage in the moving elements. Ensure that all handles, locks, and support structures are secure and functioning correctly. If any part shows deterioration, it may need to be replaced.

Step 2: Removal and Installation

After identifying the necessary components, carefully remove the old mechanisms. Unscrew or unclip the fittings, making sure to preserve any reusable screws or brackets. When installing the new parts, follow the reverse process, ensuring all elements are aligned and fastened properly to restore full operation.

Step-by-Step Guide to Replacing Components

Replacing elements of a frame system can seem daunting, but with the right tools and instructions, it becomes a manageable task. This guide will walk you through the essential steps for ensuring proper installation and functionality when swapping out worn or broken components. By following these directions closely, you can restore the efficiency and security of your setup.

Preparation and Safety

Before beginning the replacement process, gather the necessary tools and ensure you have all the components you need. A few common tools for this task include:

- Screwdriver

- Pliers

- Measuring tape

- Replacement elements

It’s also important to wear protective gear such as gloves and safety glasses to avoid injury during the installation process.

Step-by-Step Process

- Remove the Existing Components: Start by carefully detaching the old parts. Use a screwdriver to remove any screws holding them in place.

- Inspect the Frame: Once the damaged parts are removed, inspect the frame for any signs of damage or wear. Make sure the surface is clean before placing new parts.

- Install New Elements: Align the new components with the existing framework. Secure them in place with screws, ensuring everything fits tightly and securely.

- Test Functionality: After installation, test the functionality of the new parts to ensure everything is working correctly. Check for smooth movement and proper alignment.

By following these steps, you can easily replace components and maintain the integrity of your system. Regular maintenance and timely replacements will extend the life of your setup while ensuring it functions at its best.

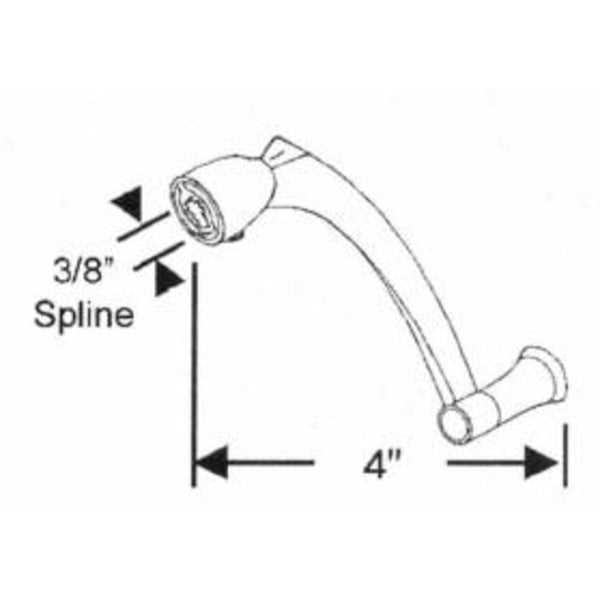

Choosing the Right Pella Window Parts

When it comes to selecting the right components for your installation, making the correct choice is essential for both functionality and longevity. Understanding how each element contributes to the overall structure ensures smooth operation and minimizes the need for future repairs. It’s important to consider material durability, ease of use, and compatibility with your existing framework.

To begin, focus on the key features that impact performance:

- Material Quality: The choice of materials directly influences strength and longevity. Opt for corrosion-resistant materials to enhance durability.

- Functionality: Ensure all moving parts operate smoothly to guarantee efficiency and avoid operational issues.

- Compatibility: Choose components that are specifically designed for your model to ensure perfect alignment and proper functioning.

Moreover, understanding the installation requirements and the tools needed can help streamline the process. If you’re unsure about specific pieces, consult a professional or refer to the manufacturer’s guidelines for expert recommendations.

Factors to Consider for Replacement Parts

When it comes to updating or restoring elements of your home’s structure, selecting the right components is crucial. These replacements not only need to fit perfectly but also function efficiently for long-term use. Considerations range from material durability to compatibility with existing setups, ensuring that the new items meet both aesthetic and practical demands.

Compatibility with Existing Mechanisms

One of the first factors to evaluate is how well the replacement integrates with your current system. This involves ensuring that the new items match in size, function, and overall design. Mismatched components can lead to poor performance or even damage over time, so it’s important to carefully verify compatibility before making a purchase.

Material and Durability

The material quality of the replacement is essential for longevity and maintenance. Look for items made from robust materials that are resistant to wear, weather, and other environmental factors. High-quality replacements will not only last longer but also offer better protection and energy efficiency, saving you costs in the future.

Maintaining Pella Casement Window Components

Proper care of your home’s fixtures is essential for their longevity and efficient operation. Regular upkeep ensures that moving parts, seals, and structural elements function seamlessly, preventing unnecessary wear and enhancing performance. Maintaining these components helps avoid costly repairs and replacements while preserving the comfort of your living space.

There are several key areas to focus on when caring for these home fixtures. Below is an overview of the critical components, their maintenance needs, and recommended intervals for inspection and repair.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Seals | Inspect for cracks or wear and apply weatherproofing agents if necessary. | Annually |

| Hinges | Lubricate moving parts to ensure smooth operation and check for rust. | Every 6 months |

| Frames | Clean with a mild detergent and check for signs of water damage or structural issues. | Every 3 months |

| Hardware | Tighten screws and bolts; replace any damaged or worn-out parts. | Annually |

| Glass | Clean the glass with non-abrasive cleaners to maintain clarity and inspect for cracks. | Every 2 months |

By regularly maintaining these components, you can extend their service life and ensure that your home remains safe, energy-efficient, and comfortable.

Best Practices for Long-Lasting Window Parts

Ensuring the durability and smooth operation of your home’s fixtures is essential for long-term satisfaction. To achieve this, it’s important to focus on proper care and maintenance, which can significantly extend the lifespan of key components. Whether you’re installing new systems or maintaining existing ones, following specific guidelines will help prevent premature wear and tear and improve overall performance.

Regular Cleaning and Maintenance

One of the most effective ways to extend the life of your home’s features is regular cleaning. Dust, dirt, and debris can accumulate and hinder the smooth function of various elements. To prevent this, it’s recommended to:

- Clean surfaces and moving parts periodically with a soft cloth and mild detergent.

- Ensure that track mechanisms and hinges are free from obstructions and grime.

- Lubricate moving elements with suitable oils or greases to avoid rust and stiffness.

Proper Installation and Adjustments

Correct installation plays a vital role in the longevity of these elements. Misalignment or improper fitting can cause unnecessary strain and reduce functionality. Consider the following when installing or adjusting fixtures:

- Ensure that all components are aligned according to the manufacturer’s specifications.

- Double-check that all fastenings and seals are tight and secure.

- Perform periodic adjustments to maintain optimal movement and fit.