Understanding the Parts Diagram of the Craftsman 18 Inch 42cc Chainsaw

In the world of outdoor maintenance, a reliable power cutting tool is essential for efficiency and precision. Knowing the various elements that constitute this equipment can significantly enhance its performance and longevity. This guide aims to unravel the intricate layout of the device, enabling users to understand how each segment contributes to its overall functionality.

Each component plays a critical role in the operation of the tool, from the engine that powers it to the blade that executes the cutting. Recognizing the relationship between these elements not only facilitates better usage but also aids in troubleshooting and maintenance. Understanding these intricacies empowers users to make informed decisions regarding repairs and upgrades.

Moreover, familiarity with the internal structure enhances safety, allowing operators to handle the equipment with greater confidence. By delving into the specifics of each section, users can optimize their experience and ensure the tool remains in peak condition, ready to tackle any task that arises.

Understanding Chainsaw Components

To effectively operate and maintain a cutting tool, it’s essential to grasp the various elements that comprise it. Each component plays a crucial role in the functionality and performance of the equipment, influencing everything from efficiency to safety.

The Engine is the powerhouse, providing the necessary energy for operation. It converts fuel into mechanical energy, driving the entire system. Understanding how this element interacts with others is vital for optimal performance.

The Bar is the elongated metal piece where the cutting occurs. Its length and design affect the tool’s capability to navigate through different materials, making it an important factor in choosing the right equipment.

The Chain wraps around the bar, featuring sharp teeth that do the actual cutting. Its tension and sharpness directly impact the efficiency and precision of the task at hand.

The Handle provides the user with control and comfort during operation. A well-designed handle enhances maneuverability, reducing fatigue and improving safety.

The Safety Features, including chain brakes and anti-vibration systems, are critical for protecting the operator. Understanding these elements ensures safer usage and minimizes the risk of accidents.

By delving into the functions and interrelations of these components, one can achieve a deeper understanding of the tool’s capabilities, leading to better maintenance practices and improved performance.

Importance of Diagram for Repairs

Understanding the intricacies of a mechanical device is crucial for effective maintenance and troubleshooting. Visual representations serve as invaluable tools that facilitate the identification and assembly of various components. By providing clarity on how elements fit together, these illustrations enhance the repair process, ensuring that users can efficiently locate issues and replace faulty parts.

Moreover, having a detailed visual guide can significantly reduce the risk of errors during repairs. Technicians can follow step-by-step instructions, making it easier to understand the sequence of disassembly and reassembly. This not only saves time but also minimizes the chances of damaging delicate components.

Additionally, such visuals are beneficial for both seasoned professionals and novice users. For those new to repair tasks, a clear graphic can demystify complex mechanisms, making the learning curve less daunting. This accessibility fosters a sense of confidence, empowering individuals to tackle repairs that they might otherwise shy away from.

In summary, having a comprehensive visual reference is essential for successful repairs. It enhances understanding, reduces mistakes, and builds confidence, ultimately leading to a more efficient and satisfying maintenance experience.

Common Issues with Chainsaw Parts

Understanding the frequent challenges associated with cutting tools can enhance maintenance and longevity. Issues often arise from wear and tear, improper usage, or lack of regular upkeep, leading to decreased performance and potential safety hazards.

Fuel System Problems: Blockages or leaks in the fuel delivery system can hinder operation. Ensuring clean lines and a proper fuel mixture is essential.

Chain Tension Issues: Incorrect tension can lead to inefficient cutting or damage. Regularly checking and adjusting the tension ensures optimal functionality.

Bar Wear: Over time, the guide bar can develop grooves or become uneven, affecting performance. Periodic inspection and replacement are necessary for maintaining effectiveness.

Air Filter Clogging: A dirty air filter restricts airflow, resulting in poor engine performance. Routine cleaning or replacement can significantly improve efficiency.

Starter Mechanism Failure: Difficulty in starting may indicate issues with the recoil starter. Regular inspection can help identify problems early on.

Identifying Essential Replacement Parts

Understanding the fundamental components of your equipment is crucial for maintaining its performance and longevity. Recognizing which elements may require attention can ensure optimal functionality and prevent unexpected failures.

Key Components to Monitor

- Engine Assembly

- Guide Bar

- Chain

- Air Filter

- Fuel System

Signs of Wear and Tear

- Difficulty in starting

- Excessive vibration during operation

- Uneven cutting performance

- Fuel leaks

- Visible damage to the chain or bar

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor power tool requires regular upkeep and attention. By implementing simple yet effective practices, you can significantly extend the lifespan and performance of your equipment.

Regular Cleaning

Keeping your tool clean is essential. Remove debris and buildup after each use to prevent wear and tear. Use a soft brush and mild detergent for a thorough clean, paying special attention to air filters and cooling fins.

Routine Inspections

Conducting regular checks on all components can help identify potential issues before they become serious. Inspect the cutting mechanism, fuel lines, and safety features, and replace any worn parts promptly to maintain optimal operation.

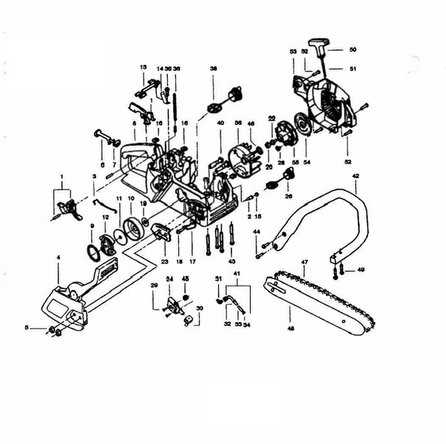

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial insights into the structure and functionality of various items, helping users identify each piece and its role in the overall system.

Key Elements of the Illustrations

- Labels: Each part is usually marked with a unique identifier, aiding in quick reference.

- Numbering: Components are often numbered sequentially, correlating with a list for clarity.

- Connections: Arrows may indicate how different elements interact or fit together.

Tips for Effective Interpretation

- Familiarize yourself with common symbols and notations used in these visuals.

- Cross-reference the illustration with an accompanying parts list for accuracy.

- Take your time to study each section to grasp the complete assembly process.

Safety Precautions While Repairing

Ensuring safety during repairs is crucial for preventing accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the repair experience.

- Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Work in a well-lit and clutter-free environment to avoid trips and falls.

- Keep all tools organized and within reach to minimize distractions.

- Disconnect the power source before starting any maintenance tasks.

Being mindful of your surroundings and adhering to safety protocols will lead to a more efficient and secure repair process.

Tools Required for Assembly

When undertaking the assembly process, having the right tools is essential for ensuring efficiency and accuracy. Each component plays a crucial role, and utilizing the appropriate instruments can significantly enhance the overall experience.

Essential Instruments

Begin with a sturdy screwdriver set, as they are vital for securing various parts together. Additionally, a reliable wrench will assist in adjusting nuts and bolts with precision, ensuring that everything fits snugly.

Safety Gear

Don’t forget to equip yourself with protective eyewear and gloves. These items are indispensable for safeguarding against potential hazards during the assembly process.

Comparing Different Chainsaw Models

When it comes to selecting a cutting tool for various tasks, understanding the differences among various models is essential. Each tool offers unique features that cater to specific needs, making it crucial to evaluate them based on performance, usability, and suitability for intended applications.

- Power and Performance:

- Engine size and type can greatly affect cutting efficiency.

- Consider the torque and speed for optimal operation.

- Weight and Balance:

- Lighter models are often easier to handle for extended periods.

- Balance plays a significant role in reducing user fatigue.

- Features and Technology:

- Look for advancements like anti-vibration systems and automatic oiling.

- Ergonomic designs can enhance comfort and control.

- Cost and Maintenance:

- Evaluate the initial purchase price versus long-term maintenance costs.

- Availability of spare parts can impact overall value.

By carefully considering these aspects, one can make an informed decision that aligns with their specific requirements, whether for professional use or personal projects.

Where to Find Quality Replacement Parts

Finding reliable components for your outdoor power equipment is essential for maintaining performance and longevity. High-quality replacements ensure that your tools operate efficiently, allowing you to tackle any task with confidence. There are several avenues to explore when searching for the best options available in the market.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers provide genuine components that meet manufacturer standards, ensuring compatibility and durability. |

| Online Marketplaces | Websites like eBay or Amazon offer a wide selection, often including user reviews to guide your purchase decisions. |

| Local Repair Shops | Local technicians often stock high-quality replacements and can provide advice based on their experience. |

| Specialty Stores | Dedicated outdoor equipment retailers frequently carry a range of components and can assist with specific needs. |

| Manufacturer’s Website | Visiting the official site can lead you to the most accurate and up-to-date options for your machinery. |

Exploring these various sources can help you find the components you need, ensuring your equipment remains in optimal working condition.