Understanding the Craftsman 358 Chainsaw Parts Diagram

The effective functioning of any power tool relies on its intricate assembly of components. Each element plays a crucial role in ensuring optimal performance and reliability. Gaining insights into these individual pieces can empower users to maintain and troubleshoot their equipment more effectively.

In this section, we will explore the layout and organization of essential elements that contribute to the overall operation of the tool. Understanding how these components interact will not only enhance your knowledge but also assist in making informed decisions regarding repairs or upgrades.

Whether you are a novice or an experienced user, familiarizing yourself with the various sections of the tool’s anatomy will ultimately enhance your maintenance skills. Let’s delve into the specifics to uncover the functionality behind each critical part.

Understanding Craftsman 358 Chainsaw Parts

This section aims to provide a comprehensive overview of the various components that make up a specific type of power tool, emphasizing their functions and importance in ensuring optimal performance. A deep understanding of these elements can enhance maintenance practices and extend the lifespan of the equipment.

Key Components

- Engine: Powers the tool and drives the cutting mechanism.

- Guide Bar: Supports the cutting chain, allowing for smooth operation.

- Chain: The cutting element that performs the actual work of slicing through material.

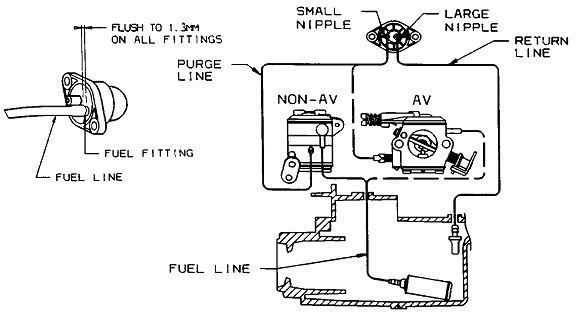

- Fuel System: Ensures the engine receives the necessary mixture for combustion.

- Air Filter: Protects the engine from dirt and debris, promoting efficient operation.

Maintenance Tips

- Regularly clean the air filter to ensure proper airflow.

- Inspect the cutting chain for wear and replace as necessary.

- Check the fuel mixture for optimal engine performance.

- Keep the guide bar lubricated to prevent excessive friction.

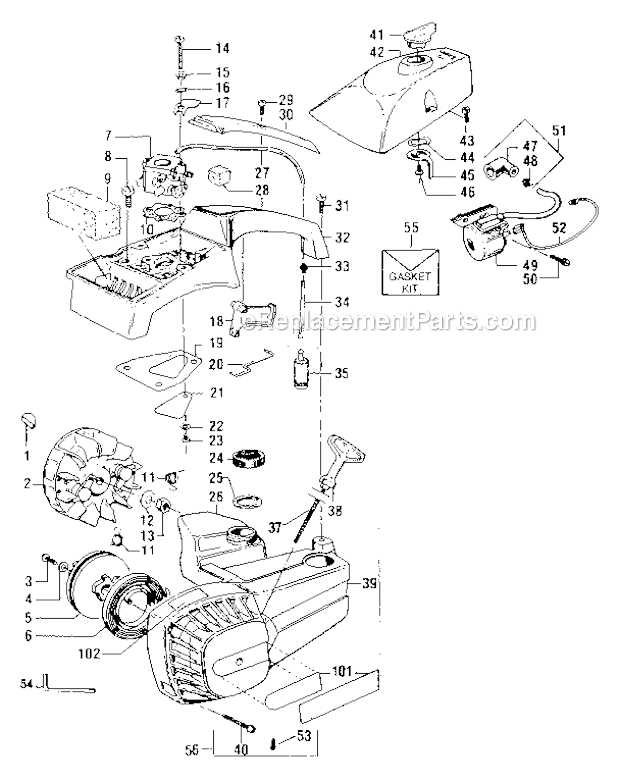

Overview of Craftsman 358 Model

This section provides a comprehensive look at a popular model known for its reliability and efficiency in various cutting tasks. It highlights key features and essential components that contribute to its performance, making it a favored choice among enthusiasts and professionals alike.

Key Features

The model boasts a powerful engine, ensuring optimal cutting speed and durability. Its ergonomic design enhances user comfort, while safety mechanisms protect against potential hazards during operation.

Essential Components

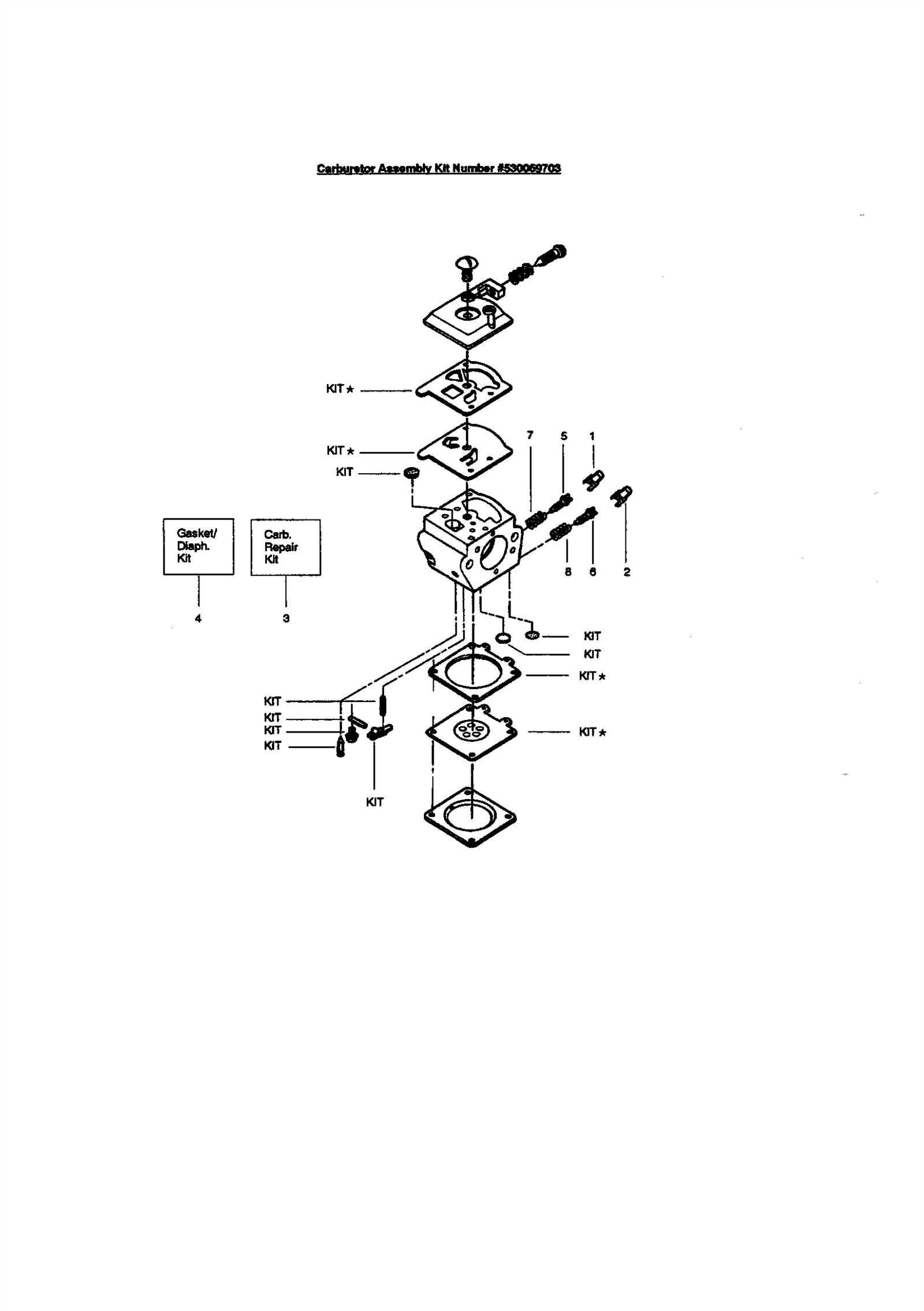

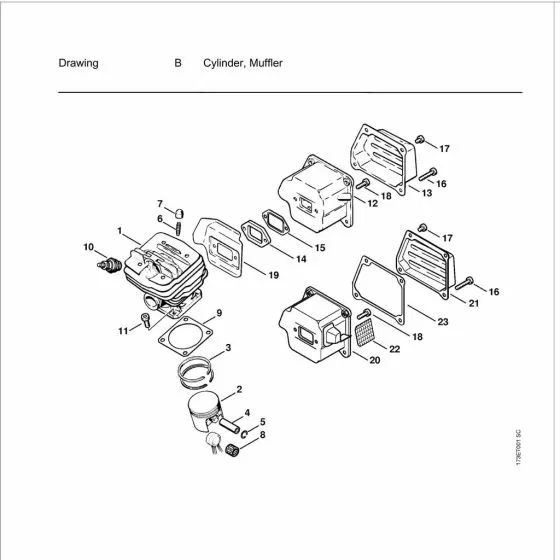

Understanding the crucial elements of this tool is vital for maintenance and performance. Key assemblies include the fuel system, bar and chain assembly, and starter mechanism, each playing a significant role in the overall functionality.

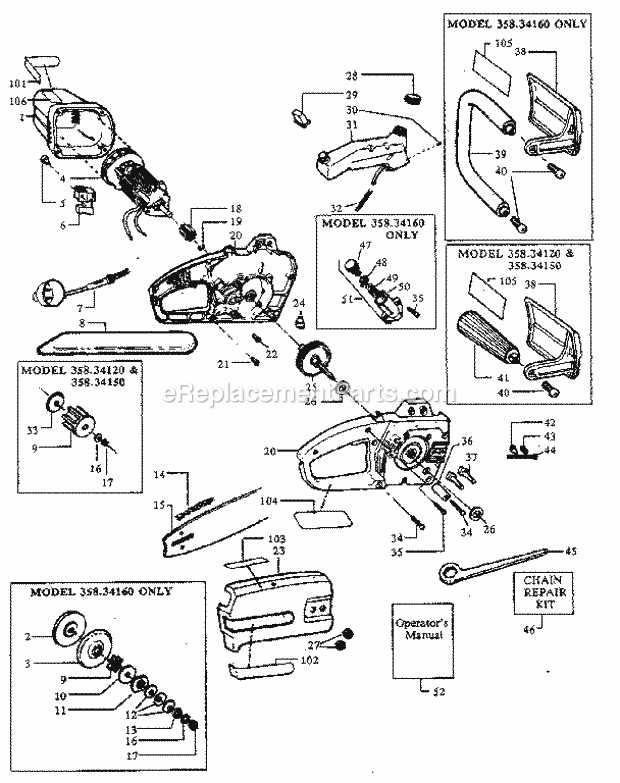

Importance of Parts Diagrams

Understanding the components of a tool is crucial for effective maintenance and repair. Visual representations serve as invaluable resources, guiding users through the intricate assembly and functionality of each element. This knowledge not only enhances the lifespan of the equipment but also ensures safe operation.

Enhancing Maintenance Efficiency

With detailed visuals, users can quickly identify specific elements that require attention. This streamlines the maintenance process, allowing for quicker repairs and replacements. When every piece is clearly labeled, troubleshooting becomes significantly less daunting, leading to a more efficient workflow.

Facilitating Accurate Repairs

When attempting to replace or fix components, having a visual reference helps ensure that the correct items are sourced and fitted. Clarity in these illustrations minimizes the risk of errors, preventing potential damage and ensuring that everything operates as intended. Proper understanding fosters confidence in users, ultimately improving overall performance.

Identifying Key Components

Understanding the essential elements of a cutting tool is crucial for efficient operation and maintenance. Each component plays a significant role in the overall functionality and performance, making it important to recognize their individual purposes and interconnections. This knowledge not only aids in troubleshooting but also enhances user safety and longevity of the equipment.

Major Parts Overview

The primary components of this equipment include the power unit, cutting mechanism, and various controls. The power unit, typically comprising the engine or motor, provides the necessary force. The cutting mechanism, which includes the blade and guide, is responsible for executing the intended cuts. Controls allow the operator to manage speed and power output, ensuring precise operation.

Supporting Elements

In addition to the main parts, several supporting elements contribute to overall performance. These include the housing that protects internal mechanisms, vibration dampeners for user comfort, and safety features designed to prevent accidents. Recognizing these auxiliary components can significantly enhance the user experience and operational efficiency.

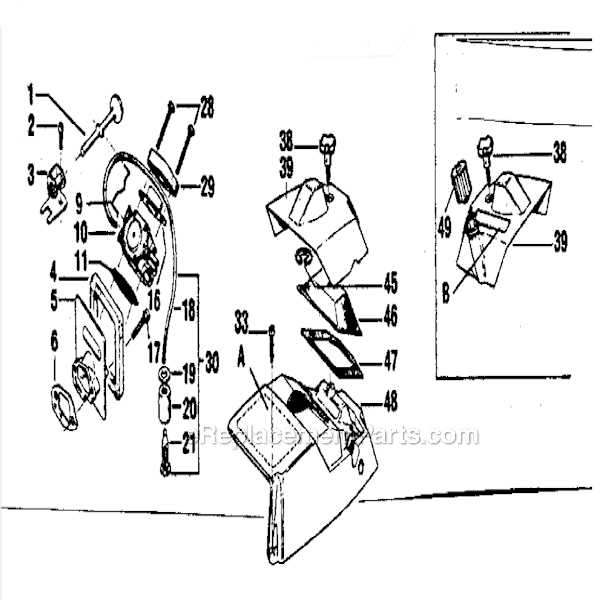

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair of various machines. Such illustrations provide a comprehensive view of how different elements fit together and function. By familiarizing yourself with the structure of these representations, you can streamline the process of identifying and ordering the necessary items for restoration or enhancement tasks.

Begin by observing the overall layout, which typically categorizes elements into distinct sections. Each segment often represents a specific function or area within the equipment. Pay attention to labels, as they denote the names or numbers assigned to each item, helping you to locate and refer to them easily.

Next, take note of the connections indicated in the illustration. Arrows or lines frequently illustrate how components interact with one another, providing insight into the assembly sequence. Understanding these relationships is crucial for troubleshooting or during reassembly after repairs.

Additionally, familiarize yourself with the accompanying legend or key, which can clarify symbols and notations used throughout the visual guide. This reference can significantly enhance your ability to interpret the information accurately.

Lastly, practice by comparing the illustration with the actual components. This hands-on approach will reinforce your understanding and improve your ability to work with the machinery effectively. The more you engage with these visuals, the more proficient you will become at deciphering their intricate details.

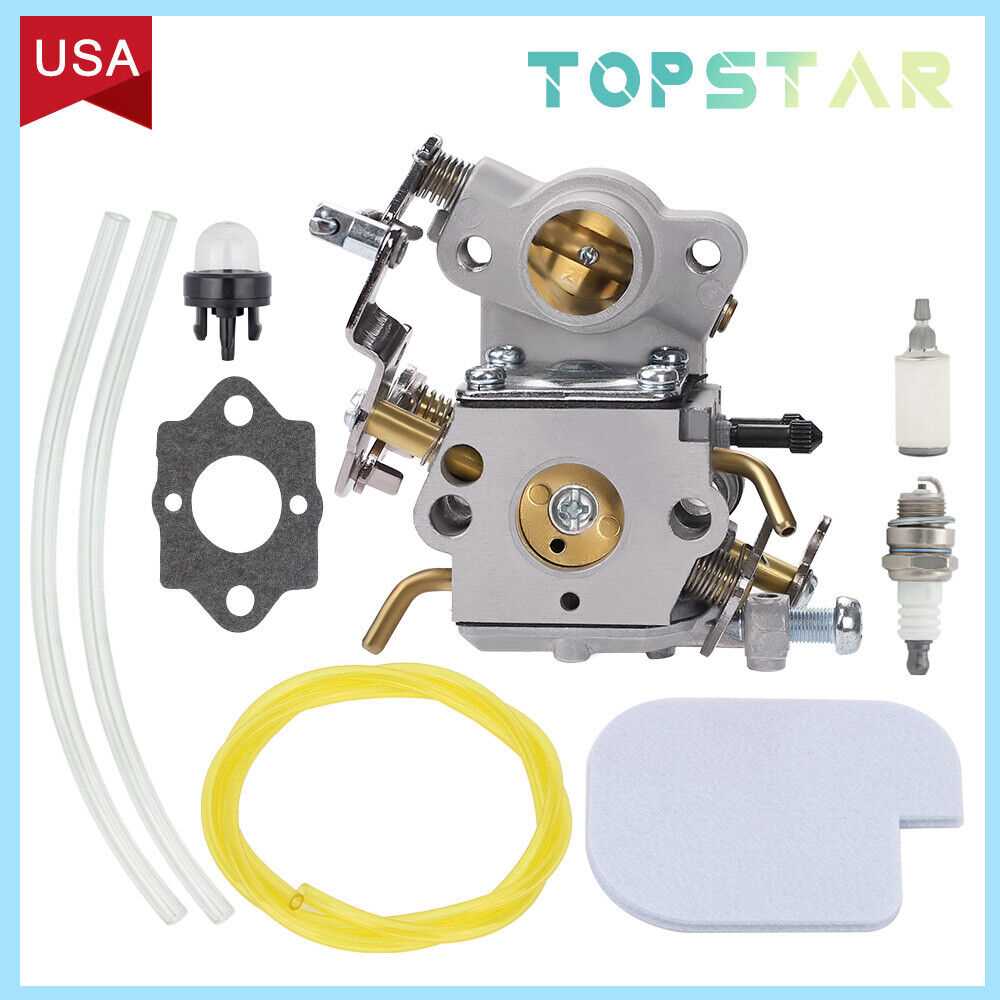

Common Replacement Parts Needed

Regular maintenance often requires the replacement of certain components to ensure optimal performance and longevity of your tool. Identifying these essential elements is crucial for effective upkeep and functionality.

Key Components to Consider

- Fuel Filter

- Air Filter

- Starter Rope

- Bar and Chain Assembly

Maintenance Accessories

- Sprocket

- Drive Links

- Oiler Pump

- Gasket Set

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your power tool. Regular maintenance not only enhances performance but also ensures safety during operation. By following a few key practices, you can significantly reduce wear and tear and keep your equipment in optimal condition.

Begin with routine cleaning after each use to remove debris and residue that can lead to rust or mechanical issues. Inspect the machine regularly for any signs of damage or wear, and replace any worn components promptly. Additionally, ensure that lubrication is applied where necessary, as this reduces friction and promotes smooth functioning.

Keep the air filters clean to maintain efficient airflow, and check fuel quality to prevent operational hiccups. Finally, storing the equipment in a dry and safe place protects it from environmental factors that could cause deterioration. By incorporating these practices into your maintenance routine, you can ensure your tool remains reliable and effective for years to come.

Tools Required for Repairs

When undertaking maintenance tasks, having the right tools on hand is essential for ensuring efficiency and accuracy. A well-equipped workspace not only facilitates smoother operations but also enhances safety during repairs. Below is a list of essential instruments that will aid in effectively addressing various repair needs.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening or tightening screws on various components. |

| Wrench Set | Essential for securing nuts and bolts, ensuring all parts are firmly attached. |

| Socket Set | Provides the versatility needed for different sizes of fasteners. |

| Pliers | Useful for gripping, bending, and cutting wire or other materials. |

| Chain Lubricant | Critical for maintaining smooth operation and preventing wear. |

| Safety Goggles | Protects eyes from debris and chemicals during maintenance activities. |

Additional Accessories

In addition to the basic tools, consider including various accessories such as cleaning brushes, replacement parts, and protective gloves. These items can further streamline the repair process, ensuring that you are fully prepared for any task that arises.

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. There are several avenues to explore when seeking these essential elements, ensuring you have access to quality replacements.

Online retailers offer a vast selection, often providing detailed descriptions to help identify the correct items. Additionally, local hardware stores may stock commonly needed components, allowing for immediate access. For those seeking specific or hard-to-find items, specialized suppliers can be invaluable resources.

Moreover, forums and community groups dedicated to maintenance and repair can offer advice and recommendations on the best sources. Utilizing multiple channels can lead you to the ultimate solution for your needs.

Safety Precautions When Repairing

Ensuring safety during maintenance and repair tasks is essential to prevent injuries and ensure effective functioning of equipment. Proper precautions can help avoid accidents and create a secure working environment.

First and foremost, always wear appropriate protective gear such as gloves, goggles, and sturdy footwear. These items safeguard against sharp components and debris that may be present.

Before starting any work, disconnect the power source to eliminate the risk of accidental activation. This simple step can prevent serious injuries.

Maintain a clean workspace free from clutter, as this minimizes the risk of slips and falls. Keeping tools organized also aids in quick and efficient repairs.

Lastly, familiarize yourself with the equipment’s manual and follow all instructions carefully. Understanding the mechanisms involved will enhance both safety and effectiveness in your repair tasks.

FAQs About Craftsman 358 Chainsaw

This section addresses common inquiries regarding the operation, maintenance, and troubleshooting of a popular power tool used for cutting tasks. It aims to provide clear answers to enhance user experience and ensure optimal performance.

Common Questions

| Question | Answer |

|---|---|

| What type of fuel should I use? | Use a mixture of gasoline and oil as specified in the user manual for best performance. |

| How often should I sharpen the blade? | Sharpen the blade after every 5-10 hours of use, or when you notice reduced cutting efficiency. |

Troubleshooting Tips

| Issue | Solution |

|---|---|

| Tool won’t start | Check fuel levels, inspect the spark plug, and ensure safety features are disengaged. |

| Excessive vibrations | Examine the chain tension and ensure all screws are tightened securely. |

Additional Resources for DIY Repairs

For those looking to undertake repairs on their equipment, having access to the right information and tools is crucial. Various resources can provide guidance, from detailed manuals to online forums, ensuring that every repair task is approached with confidence and clarity. Utilizing these resources not only enhances the repair process but also empowers individuals to gain a deeper understanding of their devices.

Online Communities

Engaging with online forums and social media groups can be immensely beneficial. These platforms allow users to share experiences, ask questions, and receive advice from seasoned enthusiasts. Participating in discussions can help troubleshoot common issues and uncover innovative solutions.

Instructional Videos and Guides

Visual learners may find instructional videos particularly useful. Numerous channels and websites offer step-by-step tutorials that cover everything from basic maintenance to complex repairs. These resources can demystify the process and provide a clearer picture of what is required for successful outcomes. Additionally, downloadable manuals often contain vital information about specifications and assembly, making them invaluable tools for any DIY enthusiast.