Dewalt 20V Chainsaw Parts Diagram Explained

In the world of power tools, having a comprehensive understanding of the individual elements that contribute to the overall functionality is essential for effective maintenance and repair. By exploring the intricate arrangements of these components, users can enhance their operational efficiency and prolong the life of their equipment.

Each tool consists of various sections that perform distinct roles, ranging from motor mechanisms to safety features. Grasping how these elements interact allows users to troubleshoot issues more effectively and make informed decisions about replacements and upgrades.

Furthermore, familiarizing oneself with the specific configurations can empower users to delve deeper into the mechanics, ultimately leading to a more rewarding experience. A thorough comprehension of these layouts is the ultimate key to mastering any tool in your collection.

Dewalt 20V Chainsaw Overview

This powerful tool represents a significant advancement in the world of outdoor equipment, designed for those who require both efficiency and reliability in their cutting tasks. Combining innovative technology with user-friendly features, it caters to a wide range of applications, from pruning branches to tackling larger projects.

Its lightweight design ensures easy handling, allowing users to operate it comfortably for extended periods. The robust motor delivers impressive performance, making quick work of various materials. Additionally, the battery system enhances convenience, providing the freedom to work without the constraints of cords, while also ensuring minimal noise and emissions compared to traditional models.

Safety features are thoughtfully integrated, offering peace of mind during operation. Ergonomic grips and adjustable settings further enhance the overall user experience, making this tool suitable for both professionals and hobbyists alike. With its blend of power, portability, and practicality, it stands out as an essential asset for anyone engaged in outdoor maintenance or landscaping tasks.

Key Features of Dewalt Chainsaw

This powerful cutting tool offers a range of innovative attributes designed to enhance performance and user experience. From advanced motor technology to ergonomic design, every aspect is tailored for efficiency and ease of use, making it an essential addition for any outdoor enthusiast or professional.

High Efficiency and Power

Equipped with a robust motor, this tool ensures quick and effective cutting. The combination of impressive battery life and energy management allows for extended usage without compromising on performance.

User-Friendly Design

The thoughtfully engineered structure promotes comfortable handling, reducing fatigue during extended tasks. Features such as tool-free chain tensioning and automatic lubrication enhance convenience, allowing users to focus on their work without interruption.

Understanding Chainsaw Parts Diagram

Grasping the layout of a cutting tool is essential for effective maintenance and operation. Recognizing each component and its function enables users to troubleshoot issues, perform repairs, and ensure optimal performance. Familiarity with the configuration enhances safety and efficiency, making the tool more user-friendly.

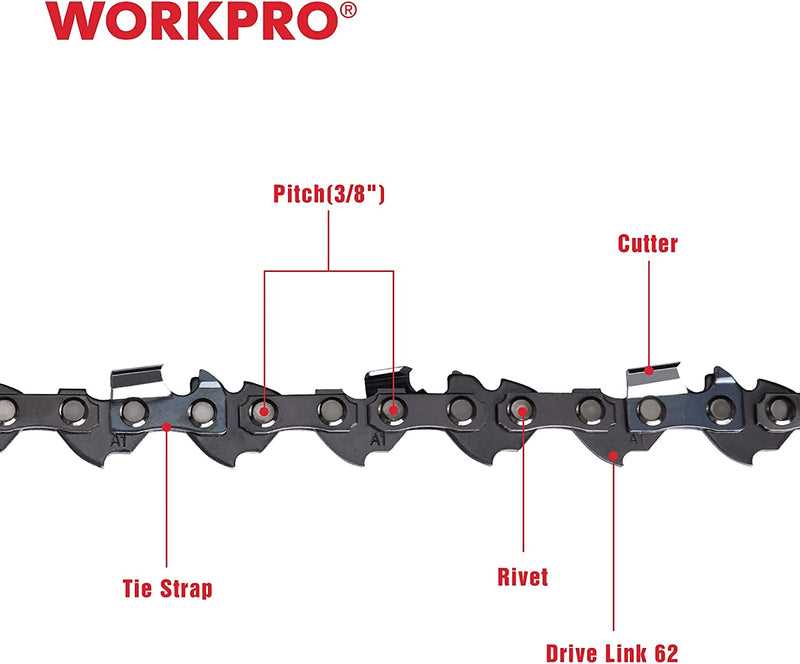

Key Components and Their Functions

Every cutting implement consists of several crucial elements that work together seamlessly. The motor serves as the powerhouse, providing the necessary energy for operation. The bar, which houses the blade, determines the tool’s reach and cutting capacity. Additionally, the chain is vital for achieving precision cuts, moving around the bar with remarkable speed.

Importance of Understanding the Layout

Being familiar with the configuration of the implement aids in recognizing wear and tear. Identifying specific parts can facilitate timely replacements, ultimately extending the life of the tool. Moreover, understanding the setup fosters better safety practices, minimizing the risk of accidents during operation.

Common Issues with Dewalt Chainsaws

Power tools can experience various problems that hinder their performance. Understanding these common complications is essential for maintaining efficiency and ensuring longevity. Identifying and addressing these issues promptly can prevent further damage and enhance the overall user experience.

Frequent Problems

Some of the typical challenges faced with electric cutting tools include battery malfunctions, motor failures, and chain tension issues. Below is a table summarizing these common problems and potential solutions.

| Issue | Description | Solution |

|---|---|---|

| Battery Drain | Rapid depletion of power during use. | Check for proper charging, inspect connections, and consider battery replacement. |

| Motor Overheating | Tool becomes excessively hot during operation. | Allow the tool to cool down, clean air vents, and avoid prolonged use without breaks. |

| Chain Slippage | Chain comes off the guide bar during operation. | Adjust the tension according to the manufacturer’s guidelines and inspect for damage. |

| Poor Cutting Performance | Difficulty cutting through materials. | Sharpen the chain, ensure proper tension, and check for any obstructions. |

Maintenance Tips

Regular maintenance can significantly reduce the occurrence of these issues. Cleaning components, checking battery health, and ensuring proper lubrication can enhance performance and extend the lifespan of the tool.

Essential Maintenance Tips for Longevity

Regular upkeep is crucial for ensuring the optimal performance and lifespan of your power tool. By adhering to a few simple practices, you can enhance its efficiency and reduce the likelihood of unexpected breakdowns. These measures not only preserve functionality but also contribute to your overall safety while using the equipment.

Routine Inspections

Conduct frequent checks on your equipment to identify any wear and tear. Look for signs of damage, such as frayed cords or loose components, and address these issues promptly. Keeping everything in working order will prevent minor problems from escalating into major repairs.

Proper Cleaning Techniques

After each use, ensure that all debris and residues are removed. Utilize appropriate cleaning tools to maintain the surfaces and mechanisms. Regular cleaning not only improves performance but also minimizes the risk of corrosion and other long-term damage.

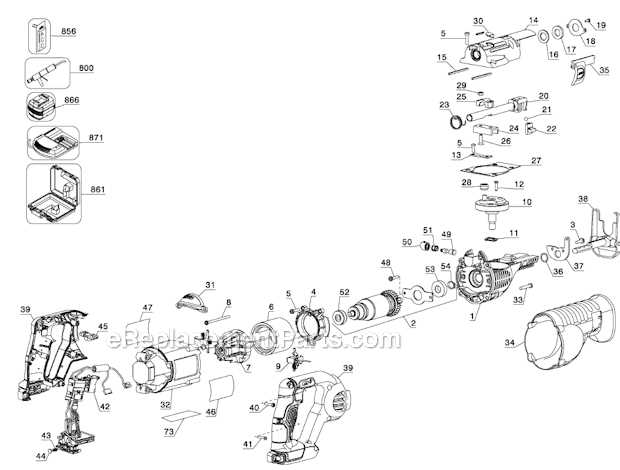

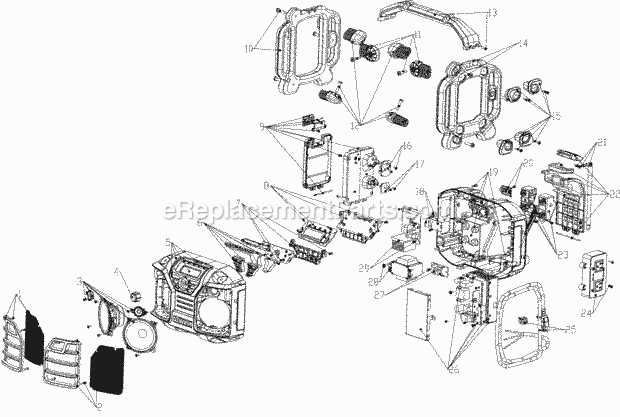

How to Identify Replacement Parts

When maintaining your equipment, recognizing the right components for replacement is crucial for optimal performance. Proper identification ensures that you select the most suitable items that match your tool’s specifications, leading to improved functionality and longevity.

Start by consulting the user manual, which typically contains detailed information about the various components and their respective model numbers. This document is an invaluable resource that outlines compatibility and provides insights into maintenance schedules.

Next, examine the existing elements closely. Look for serial numbers or labels that can provide further clues about the specific versions you need. Each item may have unique identifiers that simplify the search for replacements.

Utilizing online resources can also enhance your understanding. Many websites offer comprehensive databases where you can input your tool’s model to find corresponding components. Additionally, engaging with online forums or communities can yield recommendations and advice from experienced users.

Lastly, consider reaching out to authorized retailers or service centers. They possess expert knowledge and can assist in locating the correct replacements, ensuring that you acquire high-quality items tailored to your equipment.

Benefits of Using Genuine Parts

When maintaining and repairing tools, the choice of components can significantly impact performance and longevity. Opting for authentic replacements ensures compatibility and reliability, fostering an environment where equipment operates at its best. This decision not only enhances functionality but also promotes safety during usage.

Enhanced Performance

Using original components guarantees optimal efficiency. These elements are engineered to meet the exact specifications required by the machinery, leading to improved operational capabilities. Authentic parts work harmoniously with existing systems, reducing the risk of malfunctions and ensuring consistent results.

Increased Durability

Investing in genuine replacements typically leads to longer lifespan for your equipment. These components are crafted from high-quality materials, designed to withstand rigorous conditions. By choosing original parts, users can avoid frequent breakdowns and the need for premature replacements, ultimately saving time and money.

Step-by-Step Assembly Guide

This section provides a detailed approach to assembling your tool, ensuring every component fits seamlessly for optimal performance. Following these steps will help you navigate the process effectively and enhance your understanding of how each piece works together.

Gathering Necessary Components

Begin by collecting all the essential elements required for the assembly. Make sure to have your manual on hand for reference, as it will guide you through the specifics of each part and its function within the overall structure.

Assembly Instructions

Start by securing the base and connecting it with the designated elements, following the sequence outlined in your manual. Carefully attach each component, ensuring that all screws and fasteners are tightened properly to prevent any issues during operation. Once assembled, conduct a thorough inspection to confirm everything is in place.

Comparison with Other Brands

When evaluating power tools, it’s essential to consider various options on the market. Different manufacturers offer a range of features, performance levels, and pricing structures. This section highlights how one brand measures up against its competitors in terms of quality, functionality, and user satisfaction.

Performance and Reliability

Users often prioritize performance and reliability when selecting equipment. Here’s how this brand stacks up against others:

- Typically, it delivers consistent power and efficiency during operation.

- Some competitors may have models that excel in specific tasks but lack overall versatility.

- Customer reviews frequently cite durability as a strong point for this manufacturer.

Cost and Value

Pricing is a critical factor in decision-making. Consider the following aspects:

- Initial investment is often competitive compared to similar offerings.

- Many users find that the long-term value justifies the upfront cost.

- Alternatives may present lower prices, but quality and longevity can be compromised.

Safety Precautions When Using Chainsaw

Utilizing power tools requires an understanding of potential hazards and necessary precautions to ensure a secure experience. Awareness of safety measures is crucial for preventing accidents and injuries while working with cutting equipment.

Essential Safety Measures

- Always wear appropriate protective gear, including gloves, goggles, and hearing protection.

- Inspect the equipment before use, checking for damage or wear.

- Ensure a clear work area, free of obstacles and debris.

- Maintain a firm grip and a balanced stance during operation.

Operational Guidelines

- Start the tool on stable ground, never while holding it in your hands.

- Keep bystanders at a safe distance, especially children and pets.

- Be aware of your surroundings, including overhead hazards.

- Use proper cutting techniques to avoid kickback and loss of control.

Customer Reviews and Feedback

This section explores the opinions and experiences shared by users regarding their recent purchases. Insightful feedback helps potential buyers make informed decisions and highlights the strengths and weaknesses of the product.

| Rating | Review | Pros | Cons |

|---|---|---|---|

| 5/5 | Excellent performance and easy to handle! | Lightweight, powerful | Battery life could be improved |

| 4/5 | Very reliable for small jobs. | Good balance, affordable | Limited cutting capacity |

| 3/5 | Decent tool, but had some issues. | Easy to maintain | Frequent need for repairs |