Exploring the Homelite Chainsaw Parts Diagram for Ultimate Repair Insights

In the world of outdoor equipment, grasping the intricacies of machinery is essential for optimal performance. A comprehensive breakdown of individual elements not only enhances maintenance practices but also aids in troubleshooting potential issues. This knowledge empowers users to extend the lifespan of their tools.

Every mechanical unit consists of various interconnected segments that work in harmony. By exploring these elements, one can identify how each contributes to the overall functionality. Understanding these components allows users to make informed decisions when it comes to repairs or upgrades.

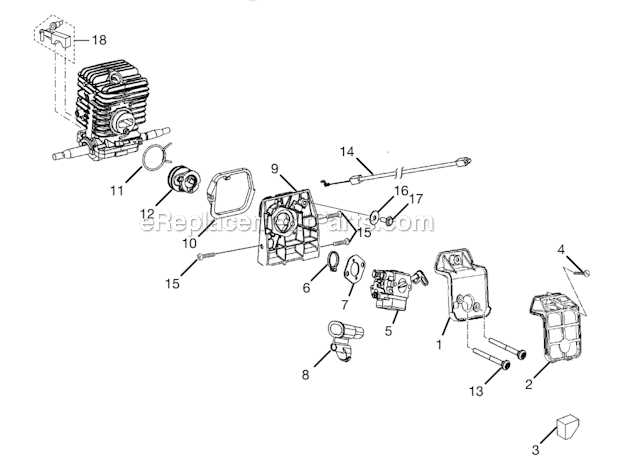

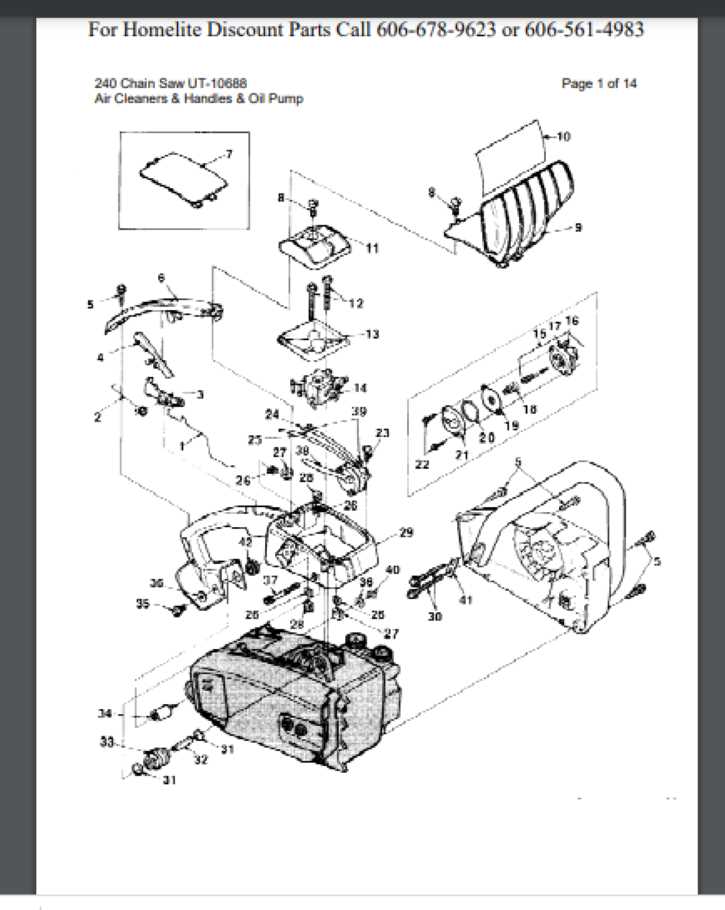

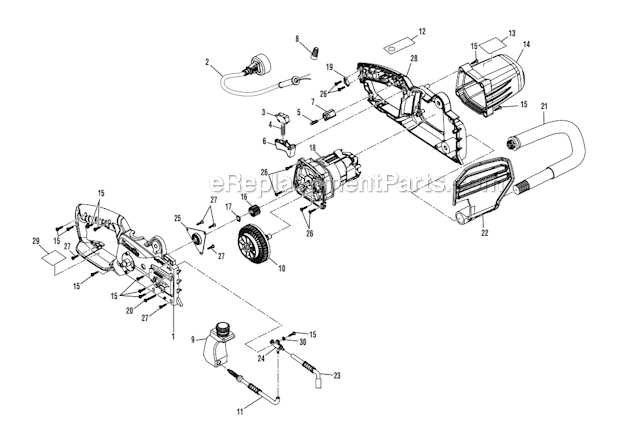

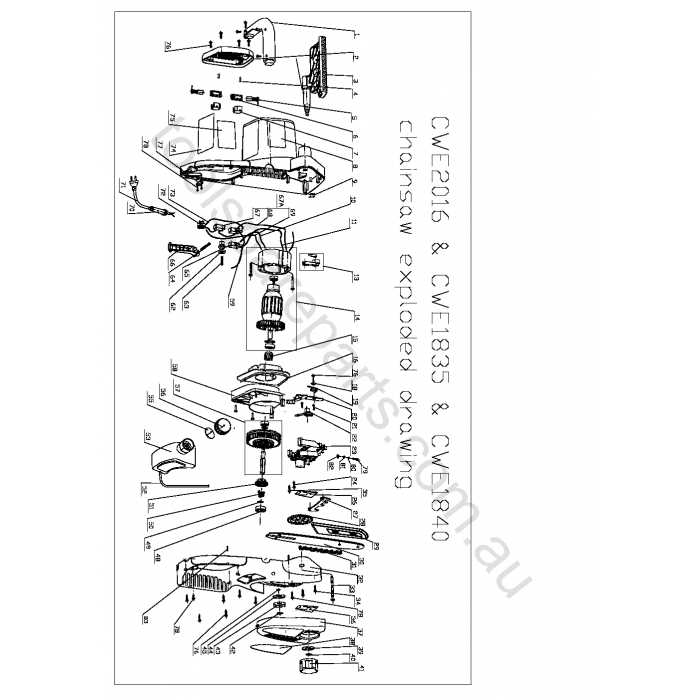

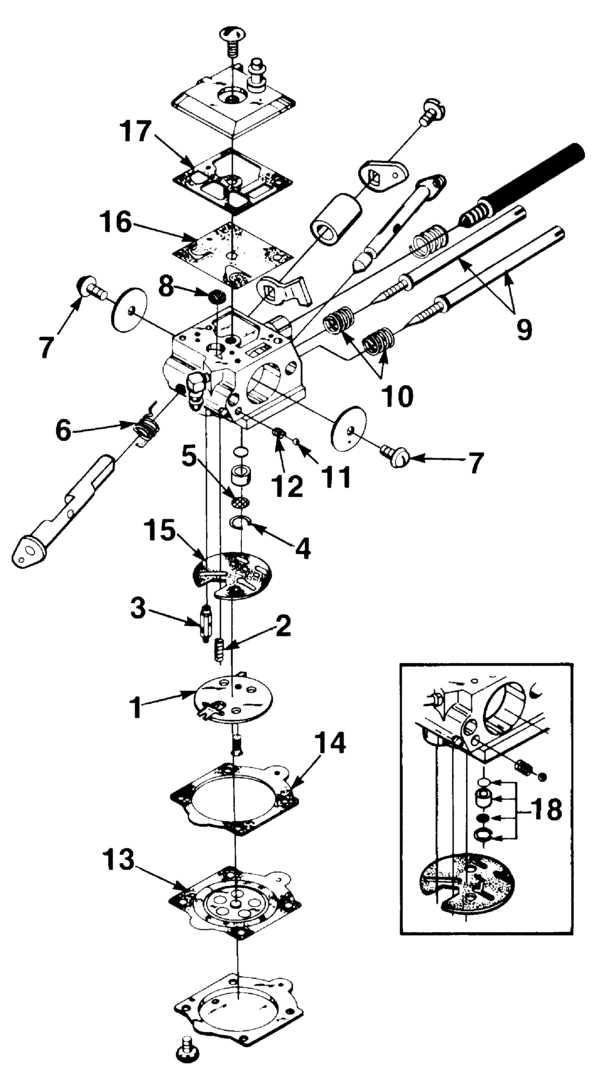

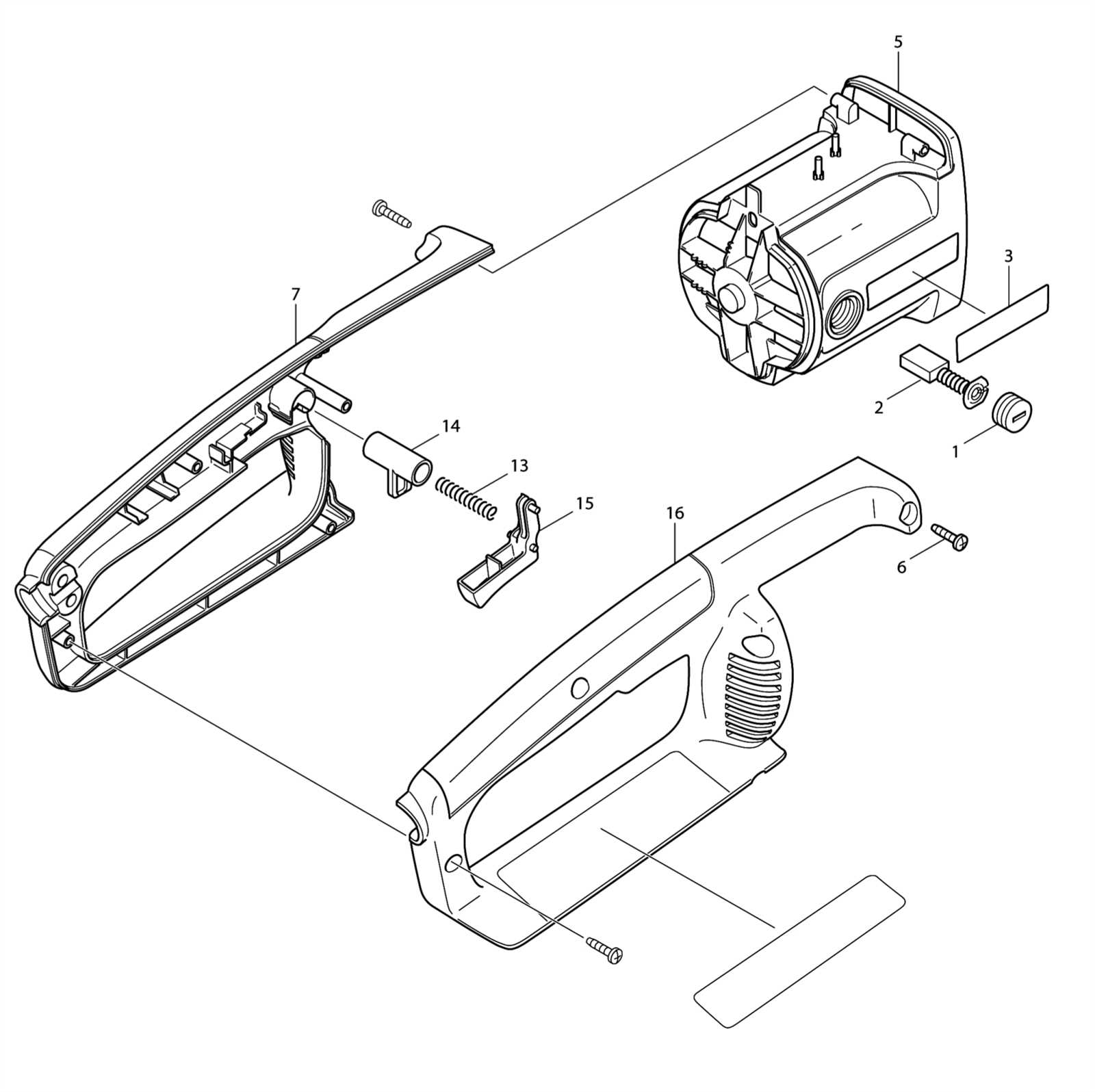

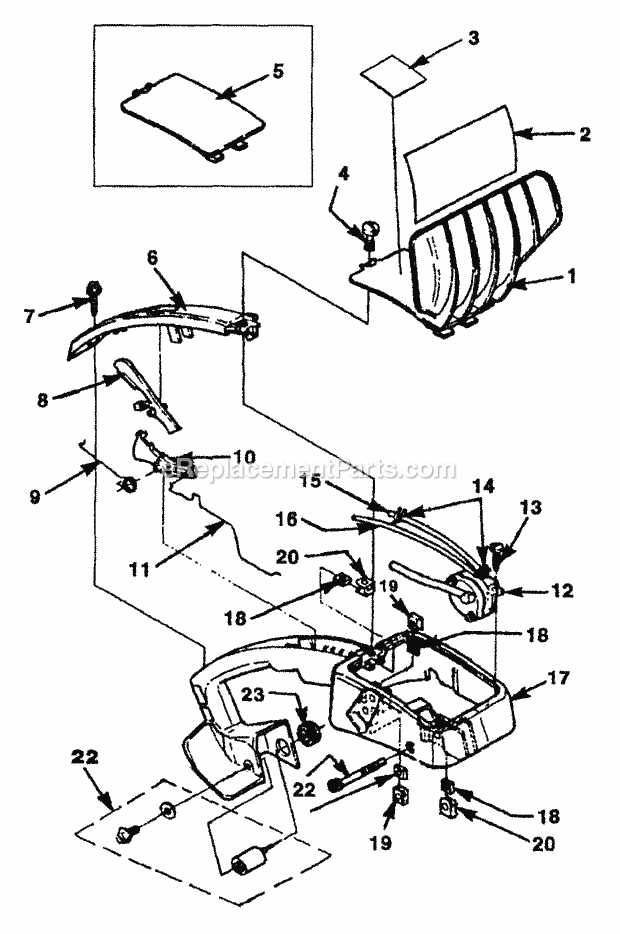

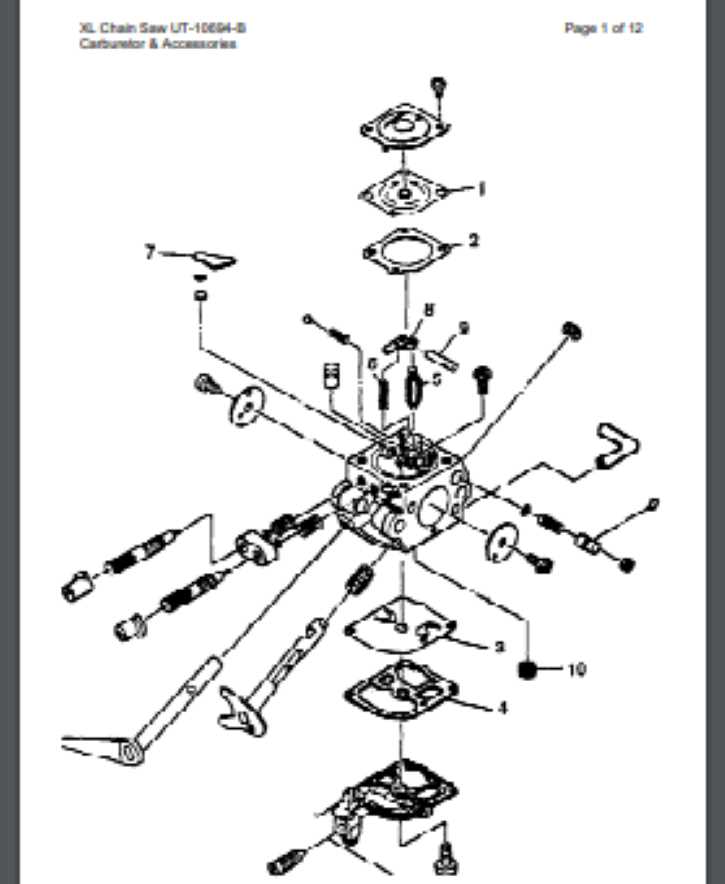

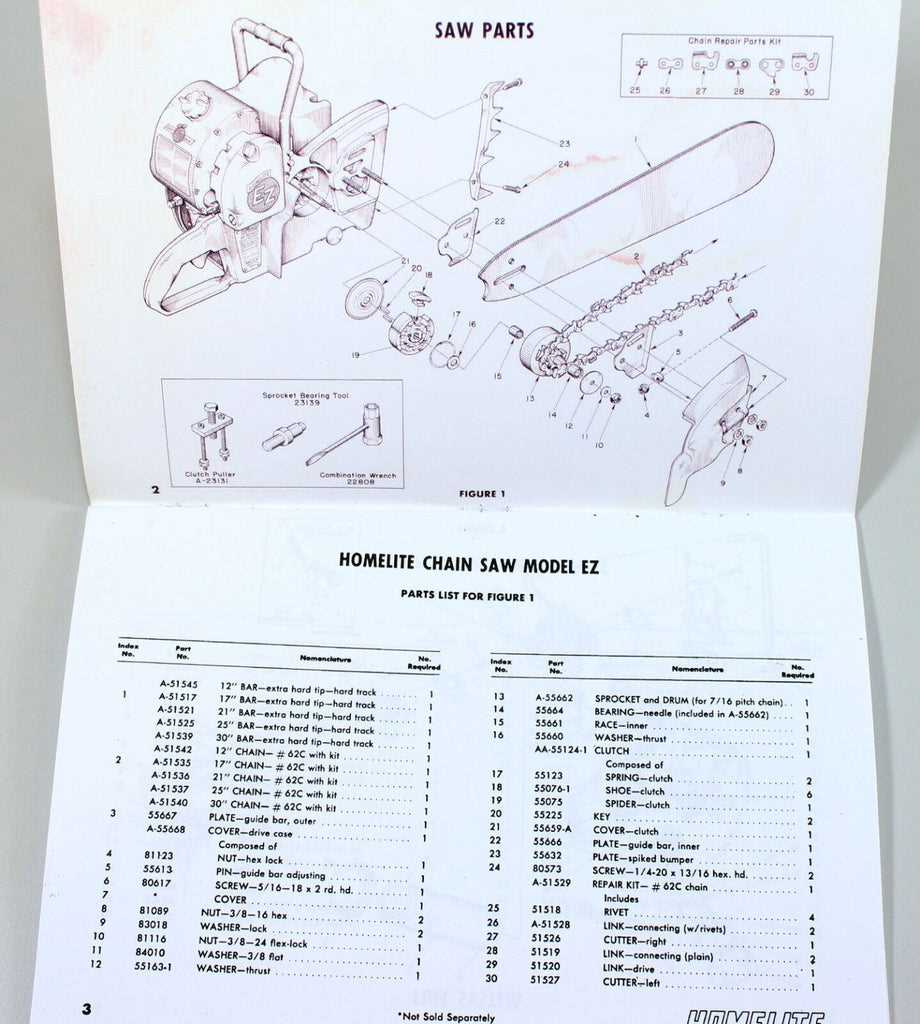

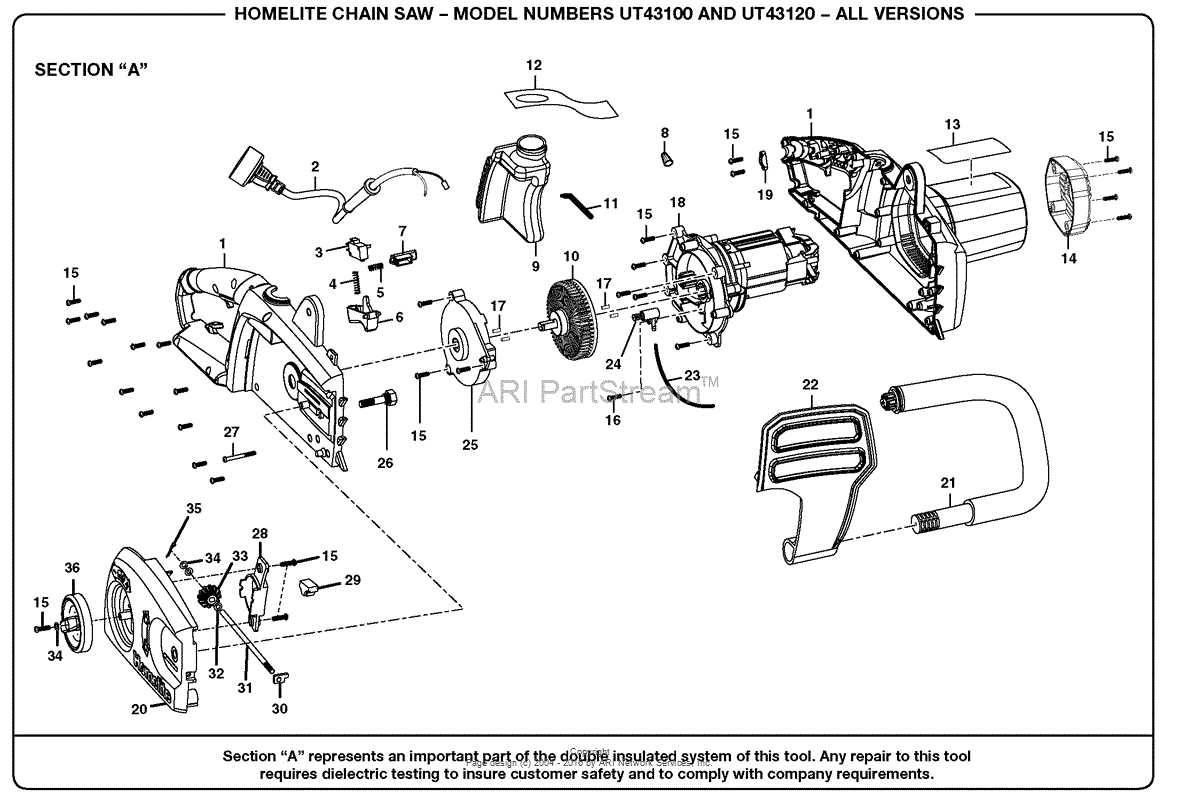

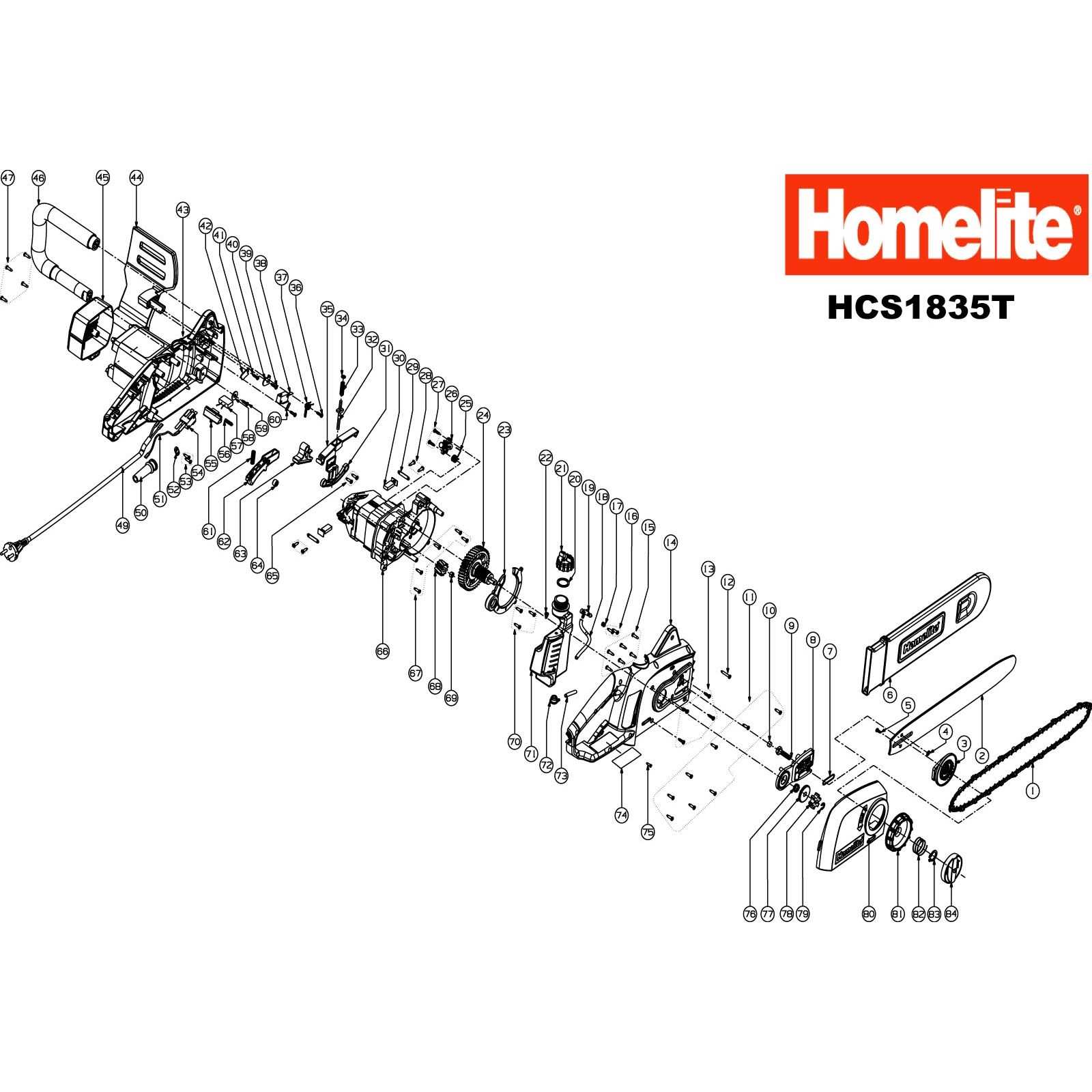

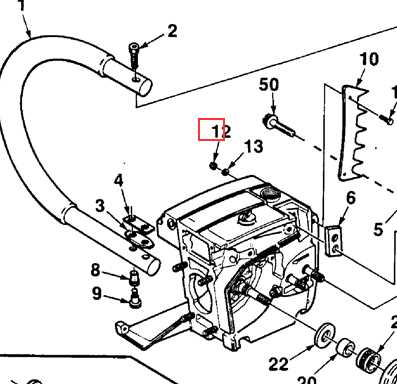

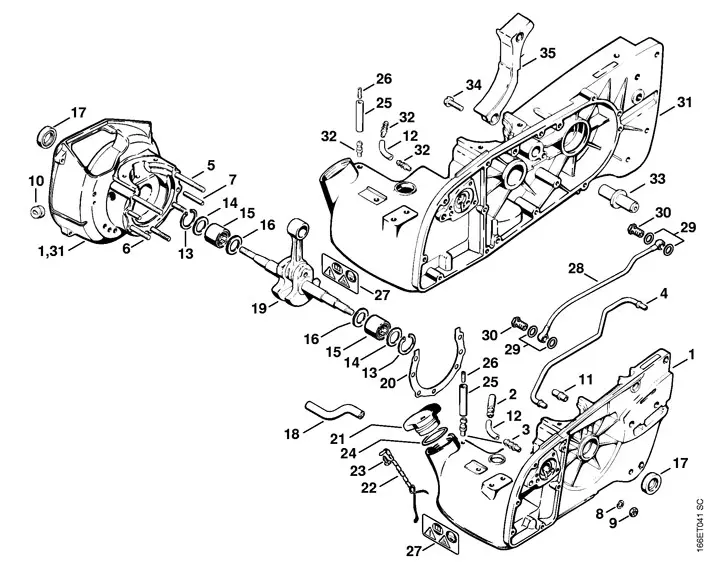

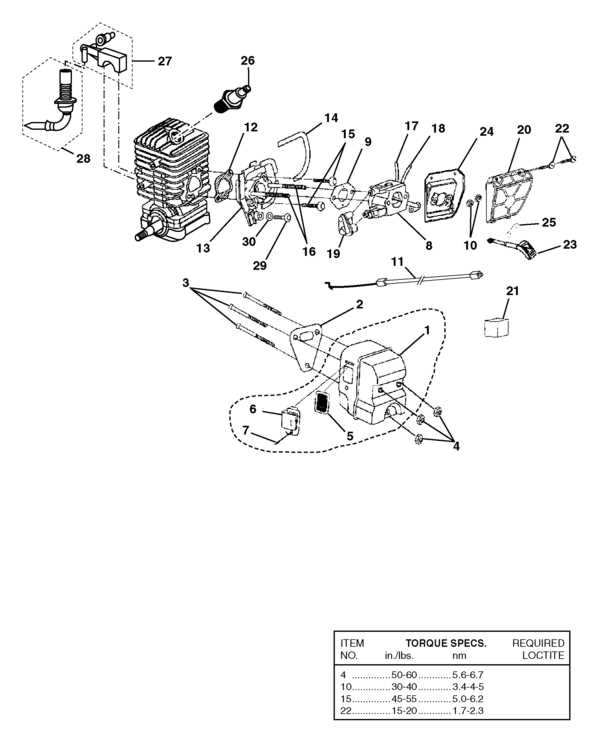

Additionally, having access to visual representations of these units can significantly simplify the process of assembly and disassembly. It serves as an ultimate guide for both novices and seasoned users alike, ensuring that anyone can confidently navigate the complexities of their machinery.

Understanding Homelite Chainsaw Components

Grasping the intricate elements of a cutting tool is essential for effective maintenance and optimal performance. Each component plays a pivotal role in ensuring the tool operates seamlessly, contributing to its overall functionality. This section will explore the various parts that make up this essential equipment, highlighting their significance.

Main Elements

- Engine: Powers the entire mechanism.

- Guide Bar: Directs the cutting motion.

- Chain: The primary tool for cutting through materials.

- Handle: Provides control and stability.

Additional Components

- Fuel System: Supplies necessary energy.

- Ignition: Initiates the combustion process.

- Safety Features: Ensures user protection during operation.

- Maintenance Parts: Include filters and spark plugs for longevity.

Importance of Parts Diagrams

Understanding the intricate components of any mechanical device is crucial for effective maintenance and repair. Visual representations of these elements serve as invaluable resources, allowing users to identify and address issues with precision. Such illustrations enhance comprehension, making the assembly and disassembly processes more manageable for both novice and experienced individuals.

Enhancing Clarity and Accessibility

Visual guides break down complex machinery into easily digestible sections. This clarity aids in troubleshooting and ensures that users can locate specific components without confusion. The accessibility of these resources empowers individuals to take on repairs confidently, reducing reliance on professional services.

Facilitating Efficient Repairs

When issues arise, knowing where to look is essential for timely resolutions. These visual tools not only save time but also minimize the risk of further damage during repairs. By following a structured approach outlined in these illustrations, users can systematically address problems, ensuring a smoother restoration process.

| Benefits | Description |

|---|---|

| Visual Learning | Helps individuals understand components better through illustrations. |

| Time-Saving | Reduces time spent searching for parts and instructions. |

| Increased Confidence | Empowers users to undertake repairs without professional help. |

Common Issues with Chainsaw Parts

In the world of power tools, mechanical failures can significantly hinder performance. Understanding frequent malfunctions can help users maintain their equipment effectively and enhance its longevity. Addressing these challenges promptly is crucial to ensure smooth operation and prevent further complications.

Fuel System Problems

A common challenge arises from the fuel system, where blockages or leaks can lead to inefficiency. Users often encounter issues with fuel lines, filters, and carburetors that may require regular inspection and cleaning. Contaminated fuel can also create starting difficulties and reduce overall power output.

Bar and Chain Wear

The cutting assembly is another area prone to wear and tear. Dull or damaged blades can compromise cutting performance, while improper tension can lead to accidents or further damage. Regular maintenance, including sharpening and lubrication, is essential to ensure optimal functionality.

Identifying Homelite Chainsaw Models

Understanding various models of outdoor power tools can greatly enhance the experience of users seeking replacements or upgrades. By recognizing distinct features and specifications, enthusiasts can ensure they choose the correct version for their needs. This guide aims to simplify the process of identifying different variations of these machines.

Key Features to Observe

When attempting to distinguish between models, pay close attention to specific attributes such as engine size, design, and operational mechanisms. These elements often provide crucial insights into the tool’s capabilities and intended use.

Utilizing Model Numbers

Model numbers serve as a vital resource for accurate identification. Typically located on the casing, these alphanumeric codes can lead users to detailed information regarding the machine’s specifications and compatibility with components.

How to Use a Parts Diagram

A visual representation of components is an essential tool for anyone looking to understand or repair a mechanical device. By examining this illustrative guide, users can identify each element, understand its function, and determine how they fit together. This process not only simplifies repairs but also enhances overall comprehension of the machinery.

To begin, locate the specific section relevant to the issue at hand. Each element is typically numbered or labeled, allowing for easy reference. Cross-referencing with the accompanying manual can provide further insights into the function and importance of each component.

When disassembling the equipment, it’s advisable to keep the visual aid nearby. This will help in tracking removed elements and ensuring that nothing is overlooked during reassembly. Additionally, noting any wear or damage while referencing the illustration can guide replacement decisions.

Finally, consult the guide throughout the repair process. This ensures that each piece is accurately positioned and functions as intended, ultimately leading to a successful outcome. Mastery of this visual tool can greatly enhance both efficiency and confidence in handling repairs.

Essential Tools for Repairs

To effectively maintain and fix outdoor machinery, having the right equipment is crucial. This section outlines the key instruments that facilitate smooth and efficient repairs, ensuring longevity and optimal performance of your devices.

Basic Hand Tools

Among the foundational items, a set of wrenches, screwdrivers, and pliers stands out. These tools are vital for loosening and tightening various components, allowing for easy access and adjustments. Quality hand tools not only enhance your efficiency but also minimize the risk of damaging sensitive parts.

Specialized Instruments

In addition to basic tools, certain specialized devices are essential for in-depth work. Torque wrenches help apply the correct amount of force, while spark plug wrenches make ignition system maintenance straightforward. Investing in these specialized tools can significantly streamline the repair process.

Finding Replacement Parts Online

When it comes to maintaining your outdoor tools, sourcing the right components can make all the difference. The internet offers a plethora of resources that simplify the search for suitable replacements. By utilizing various online platforms, you can quickly locate the necessary items to keep your equipment in peak condition.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides detailed catalogs and ensures authenticity. |

| Online Marketplaces | Websites like eBay or Amazon offer a variety of options from multiple sellers. |

| Specialty Retailers | Stores focused on outdoor equipment typically carry a wide range of necessary items. |

| Forums and Community Groups | Engaging with fellow enthusiasts can lead to recommendations for reliable sources. |

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your outdoor power tool, regular upkeep is essential. Proper care not only enhances efficiency but also reduces the risk of unexpected breakdowns. By following a few straightforward practices, you can keep your equipment running smoothly for years to come.

1. Clean After Use: Always remove debris, sawdust, and any residue after each session. This prevents build-up that can affect functionality. Use a brush or compressed air to reach difficult areas.

2. Regular Inspections: Frequently check the condition of various components. Look for signs of wear, such as fraying or cracking. Early detection of issues can save you from costly repairs.

3. Lubrication: Ensure that moving parts are adequately lubricated. This minimizes friction and prevents premature wear. Use the recommended oil types for optimal results.

4. Fuel Maintenance: Use high-quality fuel and avoid storing it for extended periods. Old fuel can lead to performance issues. Always mix fuels according to manufacturer guidelines if required.

5. Store Properly: When not in use, keep your equipment in a dry, cool place. Protect it from moisture and extreme temperatures, which can cause damage over time.

6. Follow Manufacturer Recommendations: Adhere to the guidelines provided by the manufacturer regarding maintenance schedules and replacement intervals. This ensures that your tool operates as intended.

By implementing these practices, you can significantly enhance the reliability and longevity of your equipment, ensuring that it remains a valuable asset for your outdoor projects.

Upgrading Your Chainsaw Components

Enhancing the functionality of your cutting tool can significantly improve its performance and longevity. By selecting quality components and implementing upgrades, you can tailor your equipment to better suit your specific needs and working conditions.

Benefits of Upgrading

- Improved Efficiency: Enhanced components can lead to faster and more precise cutting.

- Increased Durability: Upgrading to higher quality materials can extend the lifespan of your equipment.

- Better Safety Features: Modern advancements can provide added safety mechanisms, reducing the risk of accidents.

Key Components to Consider

- Bar and Chain: Opt for a longer bar or a more aggressive chain design to handle tougher materials.

- Engine Upgrades: Consider a more powerful engine for increased cutting capability.

- Fuel System: A high-performance carburetor can enhance fuel efficiency and performance.

- Handle Grips: Upgrading to ergonomic grips can improve comfort and reduce fatigue during extended use.

Investing in these enhancements can yield noticeable improvements in your cutting tasks, making your tool more efficient and enjoyable to use.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation and the use of protective gear can significantly reduce risks associated with mechanical work. Understanding potential hazards and implementing safety measures ensures a secure environment for repairs.

Essential Protective Gear

Before starting any repair activities, equip yourself with the following safety items:

| Item | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris and dust |

| Gloves | Prevents cuts and abrasions |

| Hearing Protection | Reduces noise exposure |

| Steel-Toed Boots | Protects feet from heavy objects |

Work Area Setup

Ensure your workspace is clean and organized. Keep tools and materials in designated areas to minimize tripping hazards and distractions. Adequate lighting is essential for identifying small components and ensuring precision during repairs.

Customer Support and Resources

Accessing reliable assistance and resources is essential for maintaining and repairing outdoor power tools. Whether you need guidance on troubleshooting, recommendations for quality components, or general advice on usage, having the right support can enhance your experience and ensure longevity.

Online Guides: Numerous websites offer detailed manuals and instructional materials, helping users navigate common issues and find suitable replacements.

Customer Service: Reaching out to dedicated support teams can provide personalized help. Many companies have knowledgeable representatives ready to assist with inquiries or concerns.

Community Forums: Engaging with fellow enthusiasts through online forums allows users to share experiences, tips, and solutions, creating a collaborative environment for learning and improvement.

Utilizing these resources can significantly contribute to the ultimate performance and reliability of your equipment.

FAQs About Homelite Chainsaw Parts

This section addresses common inquiries regarding components for your outdoor cutting tool. Understanding the intricacies of these elements can enhance maintenance and performance.

| Question | Answer |

|---|---|

| What are the most frequently replaced components? | Typically, the chain, bar, and air filter are among the most commonly replaced items. |

| How can I identify a specific component? | Consult the user manual or refer to the manufacturer’s website for detailed specifications and identifiers. |

| Are aftermarket options reliable? | Aftermarket alternatives can vary in quality, so it’s essential to choose reputable brands. |

| How often should I perform maintenance? | Regular maintenance is recommended after every few uses to ensure optimal functionality. |