Understanding the Parts Diagram of Husqvarna 450 Chainsaw

Every outdoor enthusiast knows that the efficiency of their cutting equipment relies heavily on its individual elements. When exploring the intricate mechanics of these tools, one can uncover how each piece plays a vital role in overall performance. From the engine to the guide bar, understanding these components can enhance both maintenance and operational effectiveness.

In this section, we will delve into the specific aspects that contribute to the functionality of your cutting apparatus. By familiarizing yourself with the essential elements, you will be better equipped to troubleshoot issues, perform repairs, and ultimately extend the life of your equipment. A well-informed user can ensure that each component is in optimal condition, leading to a smoother and more efficient cutting experience.

Moreover, gaining insight into the arrangement and connection of these parts will empower you to make informed decisions when purchasing replacements or upgrades. An organized overview of the structure can serve as a valuable reference point, simplifying the process of understanding how your tool operates as a whole. Whether you’re a seasoned user or a novice, comprehending the makeup of your equipment is crucial for achieving the best results in any outdoor task.

Understanding the Husqvarna 450 Chainsaw

This section provides a comprehensive look at a powerful cutting tool widely used for various outdoor tasks. Recognizing its components and functionality is essential for efficient operation and maintenance.

Key features of this equipment include:

- Powerful engine for effective cutting.

- Lightweight design, enhancing maneuverability.

- Ergonomic handles for comfortable use.

- Advanced safety mechanisms to protect the operator.

When exploring this tool, consider the following critical aspects:

- Maintenance: Regular upkeep is vital to ensure longevity and performance.

- Usage: Understanding the correct techniques enhances efficiency and safety.

- Accessories: Additional attachments can expand functionality for different tasks.

- Troubleshooting: Familiarity with common issues allows for quick resolutions and reduces downtime.

By grasping these elements, users can maximize their experience and effectiveness with this essential outdoor tool.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, ensuring efficiency and safety during use. Familiarity with these parts allows users to make informed decisions regarding repairs and upgrades.

Main Elements

- Engine: The powerhouse that drives the entire machine, responsible for converting fuel into mechanical energy.

- Guide Bar: A long metal piece that supports the cutting chain and helps guide the tool during operation.

- Cutting Chain: The loop of sharp links that performs the actual cutting; its design and sharpness are critical for performance.

- Clutch: This component engages and disengages the cutting chain from the engine, allowing for control during idle and operation.

Supporting Features

- Fuel Tank: Stores the fuel necessary for the engine to operate.

- Oil Reservoir: Contains lubricating oil that reduces friction between the chain and guide bar.

- Air Filter: Prevents dirt and debris from entering the engine, ensuring optimal performance.

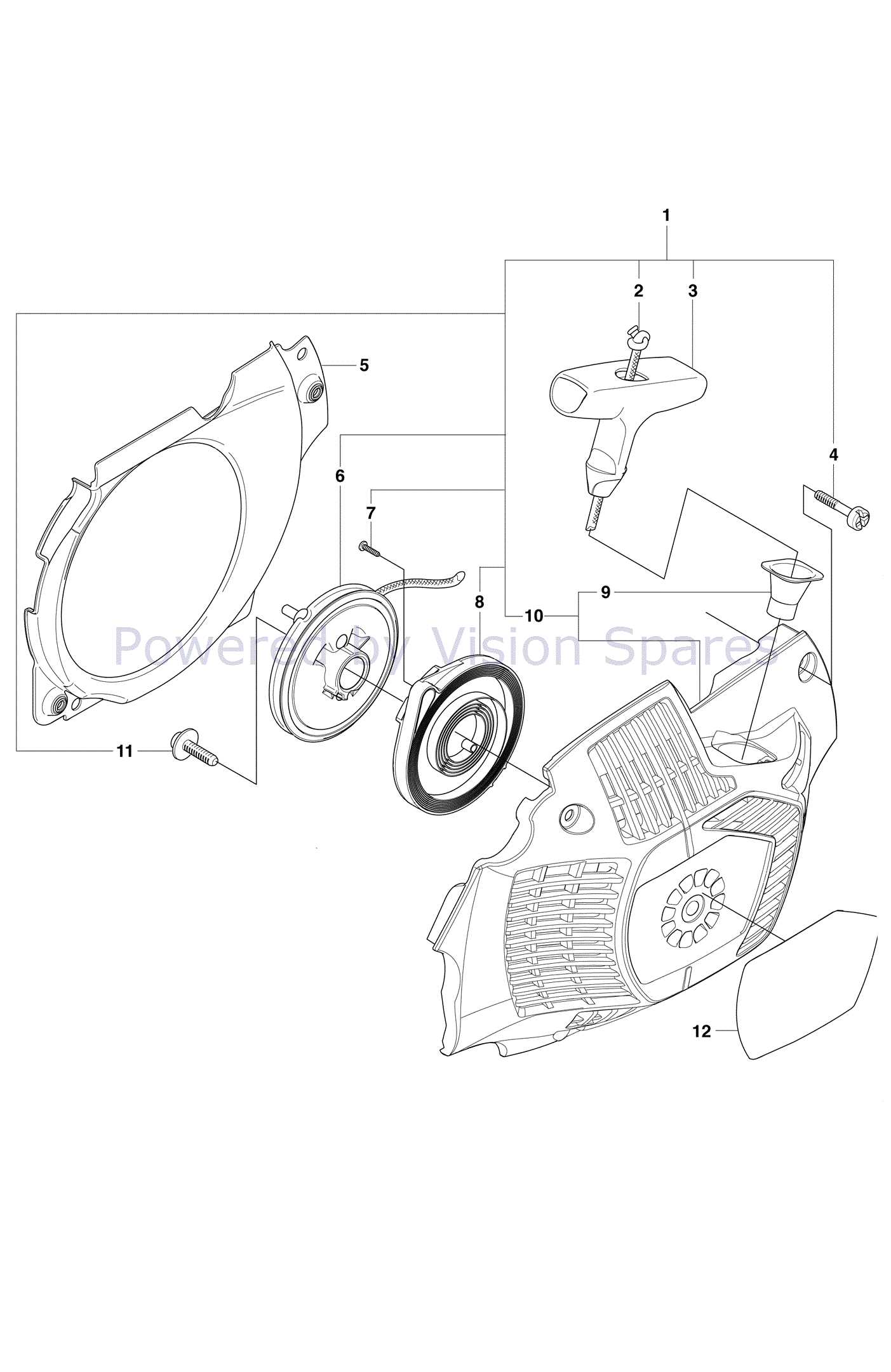

- Starter Mechanism: Engages the engine to initiate operation, often involving a pull cord or electric start.

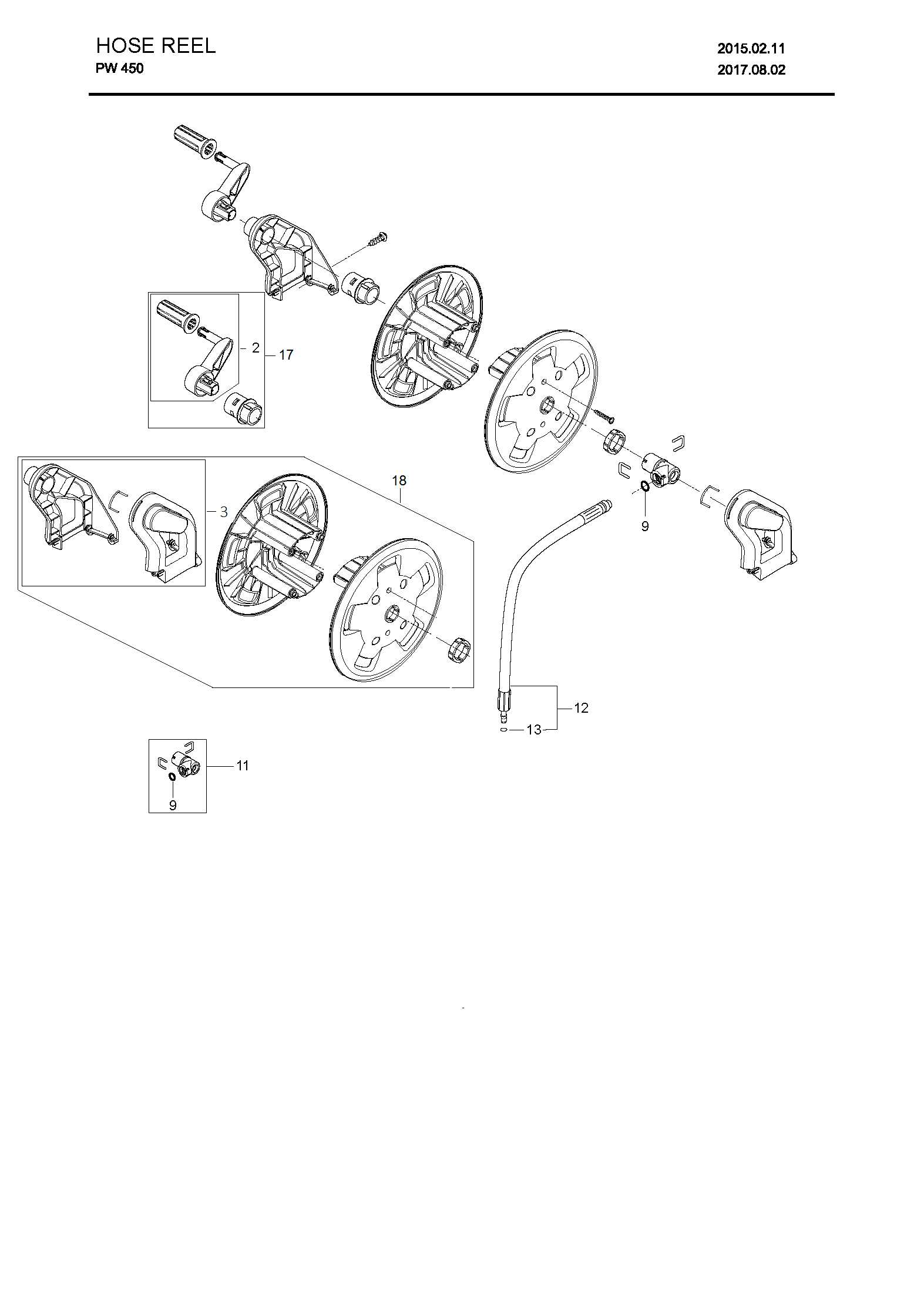

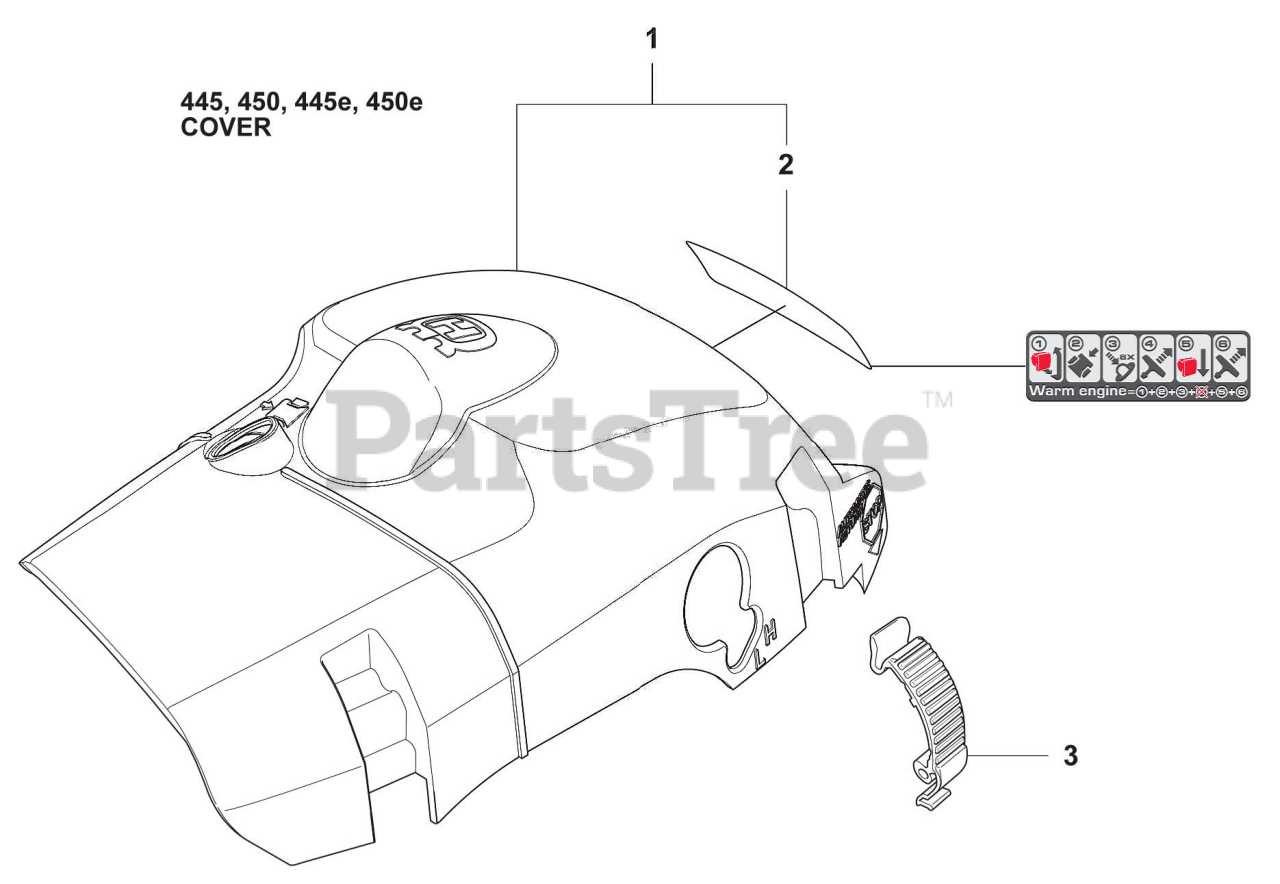

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone looking to repair or maintain their equipment. These visuals serve as a roadmap, detailing the components and their interconnections. By familiarizing yourself with the layout and symbols used, you can easily identify each item and its role within the assembly.

1. Familiarize Yourself with the Legend

Most technical illustrations include a legend or key that explains the symbols and numbering system used. This is your first step in deciphering the image. Take a moment to review it, as it will provide context for the components shown.

2. Identify the Main Components

Look for larger, central pieces first. These often form the backbone of the assembly. Once you locate them, you can understand how smaller parts connect and interact with them.

3. Follow the Lines and Arrows

Lines and arrows indicate how parts fit together or the direction of movement. Pay attention to these details, as they can clarify assembly processes and operational functions.

4. Note the Item Numbers

Each component typically has a unique identifier, often corresponding to a list of items for ordering replacements. Make a note of these numbers for easy reference when sourcing new parts.

5. Understand the Viewpoints

Technical illustrations may present components from various angles. Recognizing these perspectives will help you visualize how the parts come together in real life, enhancing your comprehension of the entire assembly.

By mastering these steps, you can effectively navigate and interpret technical visuals, making maintenance and repair tasks more straightforward and efficient.

Common Issues and Solutions

This section highlights frequent problems encountered with power cutting tools and provides effective remedies. Understanding these issues can enhance performance and extend the lifespan of your equipment.

- Starting Difficulties:

- Check the fuel mixture; use fresh fuel.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean and unobstructed.

- Loss of Power:

- Examine the fuel system for clogs or leaks.

- Adjust the carburetor settings as needed.

- Look for any blockages in the exhaust system.

- Chain Problems:

- Ensure proper tension; adjust if necessary.

- Lubricate the chain regularly.

- Replace a dull or damaged chain promptly.

- Vibrations:

- Check for loose screws or bolts.

- Inspect the anti-vibration system for wear.

- Ensure proper handling techniques are followed.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your power equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents potential issues that could lead to costly repairs. By following a few essential practices, you can keep your tools in excellent condition and ready for any task.

Regular Cleaning

After each use, it’s crucial to clean the exterior and the components of your device. Dust, debris, and sap can accumulate and hinder performance. Use a soft brush and a damp cloth to wipe down surfaces, paying special attention to air intake areas. This simple step promotes better airflow and efficiency.

Periodic Inspections

Conduct routine inspections to identify wear and tear early. Check the blade for sharpness and any signs of damage. Additionally, examine the fuel system and ensure all connections are secure. Replace worn components promptly to avoid more extensive damage. This proactive approach can significantly extend the life of your equipment.

Replacement Parts: What You Need

Understanding essential components for your cutting tool is crucial for maintaining performance and longevity. Selecting the right replacements ensures efficiency and safety during operation.

- Blades: Regularly inspect for wear and tear.

- Filters: Air and fuel filters need periodic replacement for optimal performance.

- Spark Plug: A vital element for ignition; check its condition frequently.

- Chains: Ensure compatibility and quality to avoid malfunctions.

- Bar Nuts: Essential for securing components; replace if damaged.

By familiarizing yourself with these key components, you can make informed decisions when it’s time to upgrade or replace items, ensuring the ultimate functionality of your equipment.

Assembly Instructions for Beginners

Assembling power tools can be a rewarding experience, especially for those new to the task. Understanding the components and how they fit together is essential for successful operation and maintenance. This section provides clear guidance to help novices confidently put together their equipment with ease.

Step-by-Step Guide

Follow these steps to ensure a smooth assembly process:

| Step | Description |

|---|---|

| 1 | Gather all components and tools required for assembly. |

| 2 | Refer to the manual for specific part identification. |

| 3 | Start by connecting the base to the handle securely. |

| 4 | Attach the power source following the safety guidelines. |

| 5 | Ensure all screws and fasteners are tightened properly. |

| 6 | Perform a safety check to confirm everything is in place. |

Safety Tips

Always prioritize safety during assembly. Use protective gear, such as gloves and goggles, to prevent injuries. Additionally, work in a well-lit area and ensure that your workspace is free of clutter to minimize risks.

Safety Features of Husqvarna 450

Ensuring user protection is paramount in the design of power tools. Various integrated mechanisms enhance safety, reducing the risk of accidents during operation. These features are crucial for both novice and experienced users, providing peace of mind while performing demanding tasks.

Chain Brake System

A vital component, the chain brake system instantly halts the cutting chain in the event of kickback, preventing potential injuries. This feature allows for safer handling, especially when working in unpredictable conditions.

Low Vibration Technology

The incorporation of low vibration technology minimizes hand fatigue and increases control during use. By reducing vibrations, the tool enhances comfort and stability, enabling users to maintain focus and safety throughout their work.

Tools Required for Repairs

When tackling maintenance tasks, having the right instruments is essential for efficient and effective repairs. The proper tools not only ensure precision but also enhance safety during the process.

Basic Hand Tools: A set of screwdrivers, wrenches, and pliers are fundamental. These instruments allow you to access and remove various components easily.

Specialized Equipment: Depending on the model, specific tools such as a torque wrench or a specialized socket may be necessary for proper assembly and disassembly.

Safety Gear: Don’t overlook personal protective equipment. Gloves, goggles, and hearing protection are crucial to safeguard against potential hazards while working.

Cleaning Supplies: Keeping the working area tidy is vital. Have brushes, cloths, and appropriate solvents on hand to clean parts effectively during repairs.

With the right selection of tools, your repair process can be streamlined, making the ultimate goal of restoring functionality more achievable.

Comparing Models: Husqvarna 450 vs Others

When evaluating different models in the power tool market, it’s essential to consider various factors such as performance, durability, and user experience. Each model offers unique features that cater to specific needs, making it important to identify which one aligns best with individual requirements. This comparison aims to highlight how one popular option stacks up against its competitors in the same category.

Performance and Efficiency

In terms of performance, this renowned model stands out for its balance of power and fuel efficiency. Users often report that it provides a robust cutting experience while minimizing emissions. In contrast, some rival products may excel in raw power but lack efficiency, leading to higher operational costs over time. Efficiency is crucial for both casual users and professionals, as it directly impacts productivity and maintenance.

Design and Ergonomics

The ergonomic design of this particular model is frequently praised, allowing for extended use without causing fatigue. Many alternatives, while powerful, may compromise comfort for strength, which can deter prolonged handling. Comfort features such as grip and weight distribution are significant, especially for users engaged in lengthy tasks. Choosing a tool that balances usability with capability can enhance overall satisfaction and effectiveness.

Finding Genuine Parts Online

In today’s digital landscape, sourcing authentic components for your equipment has never been easier. The vast array of online platforms provides numerous opportunities to locate high-quality replacements that ensure optimal performance and longevity.

Understanding the importance of choosing genuine components is essential, as they significantly affect the reliability and safety of your machinery. When seeking replacements, researching reputable suppliers is key to avoid counterfeit options that could lead to malfunctions.

Utilizing online marketplaces, manufacturer websites, and dedicated forums can greatly enhance your chances of finding exactly what you need. Pay attention to customer reviews and ratings, as they offer valuable insights into the trustworthiness of the vendor.

By making informed choices and prioritizing authenticity, you can ensure your equipment remains in peak condition, ultimately enhancing your experience and efficiency.