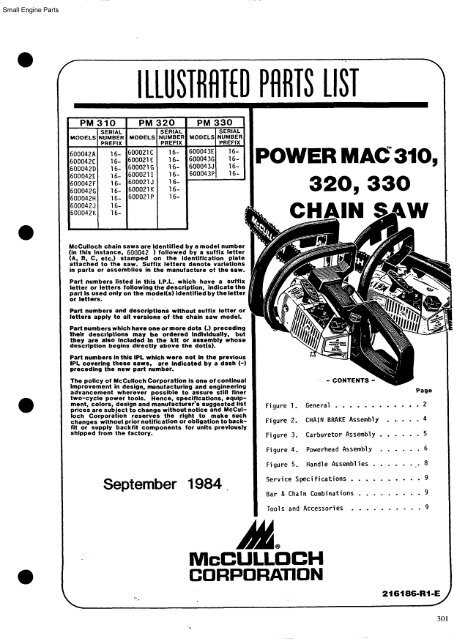

Parts Diagram for Mcculloch Mini Mac 35 Chainsaw

In the realm of compact outdoor equipment, having a clear understanding of each component is essential for optimal performance. Recognizing how the various elements interact can significantly enhance your experience and ensure the longevity of the device. This knowledge is not only beneficial for troubleshooting but also invaluable during maintenance and repair processes.

Whether you are looking to perform routine upkeep or need to replace a specific component, familiarizing yourself with the structure of your cutting tool will empower you to make informed decisions. Visual representations of these components provide clarity and can simplify the assembly and disassembly processes. With this insight, you can efficiently tackle any issues that may arise.

By delving into the intricacies of your device, you will gain confidence in your ability to manage its upkeep. Armed with this knowledge, you can ensure that your cutting tool remains in excellent working condition, ready to tackle any task with precision and ease.

Key Features of the Chainsaw

The compact cutting tool is designed for efficiency and versatility, making it suitable for various outdoor tasks. Its lightweight design enhances maneuverability, allowing users to tackle jobs with ease.

One of the standout characteristics of this equipment is its powerful engine, which provides substantial cutting power. High torque enables it to slice through thick wood effortlessly. Additionally, the tool features an automatic lubrication system that ensures the chain operates smoothly, reducing wear and tear during prolonged use.

Another important attribute is the ergonomic design, which offers a comfortable grip and reduces user fatigue. The integrated safety features, such as a chain brake, enhance protection, making it a reliable choice for both novice and experienced operators.

Lastly, the easy maintenance options contribute to the longevity of the tool. Quick adjustments and accessible components simplify servicing, ensuring the equipment remains in optimal condition for ongoing performance.

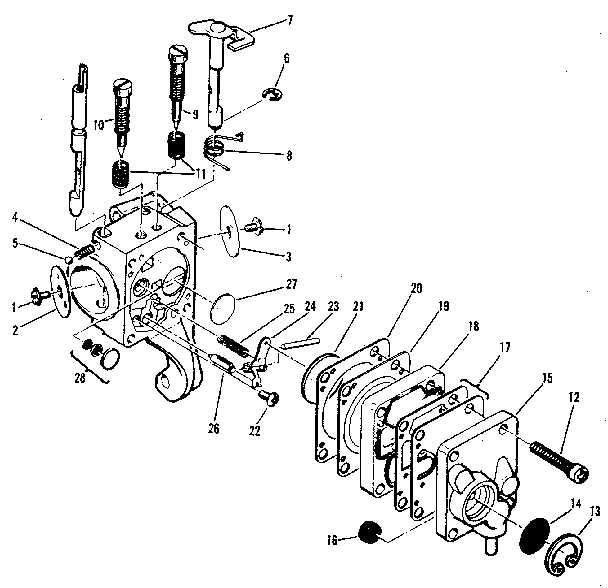

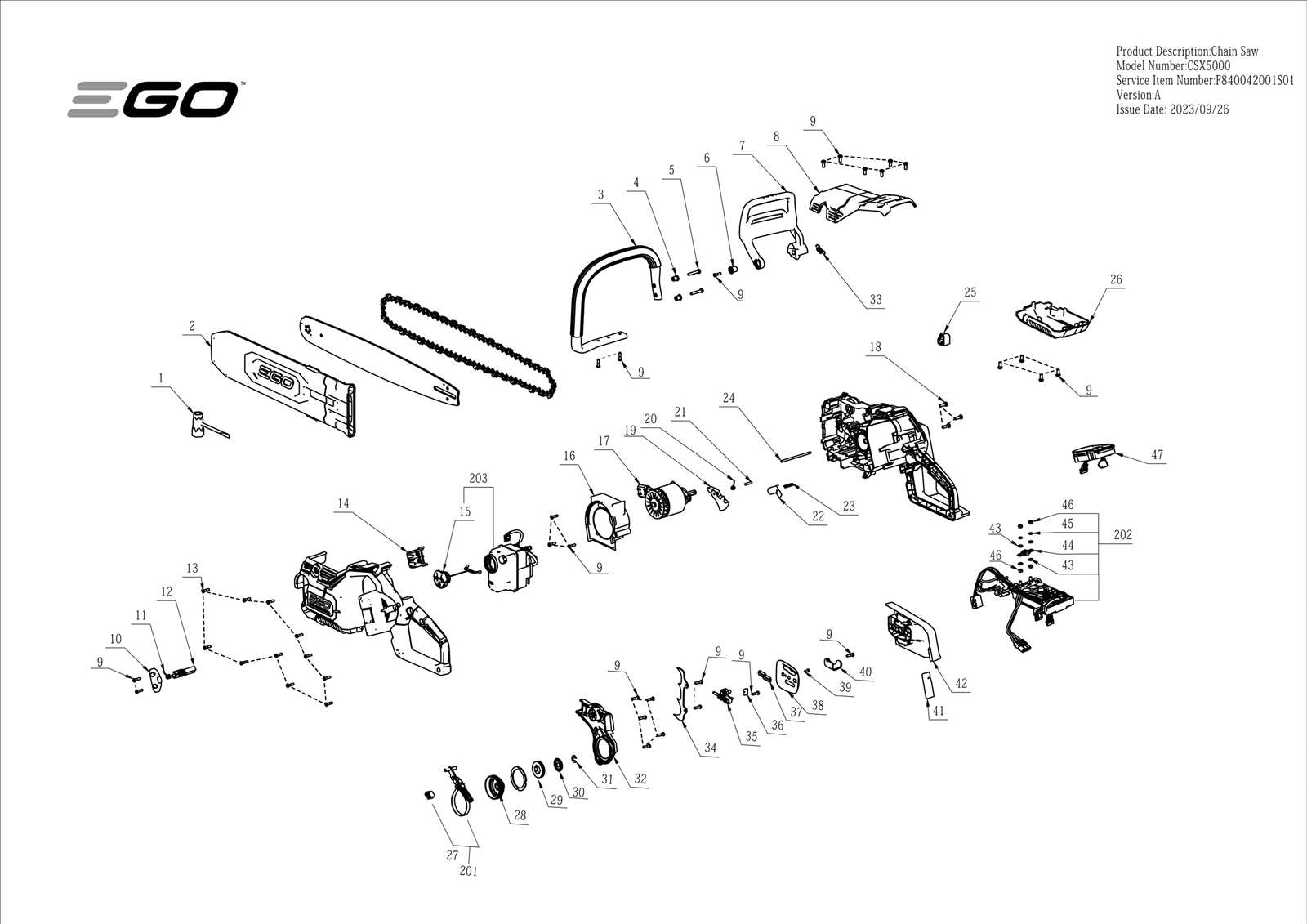

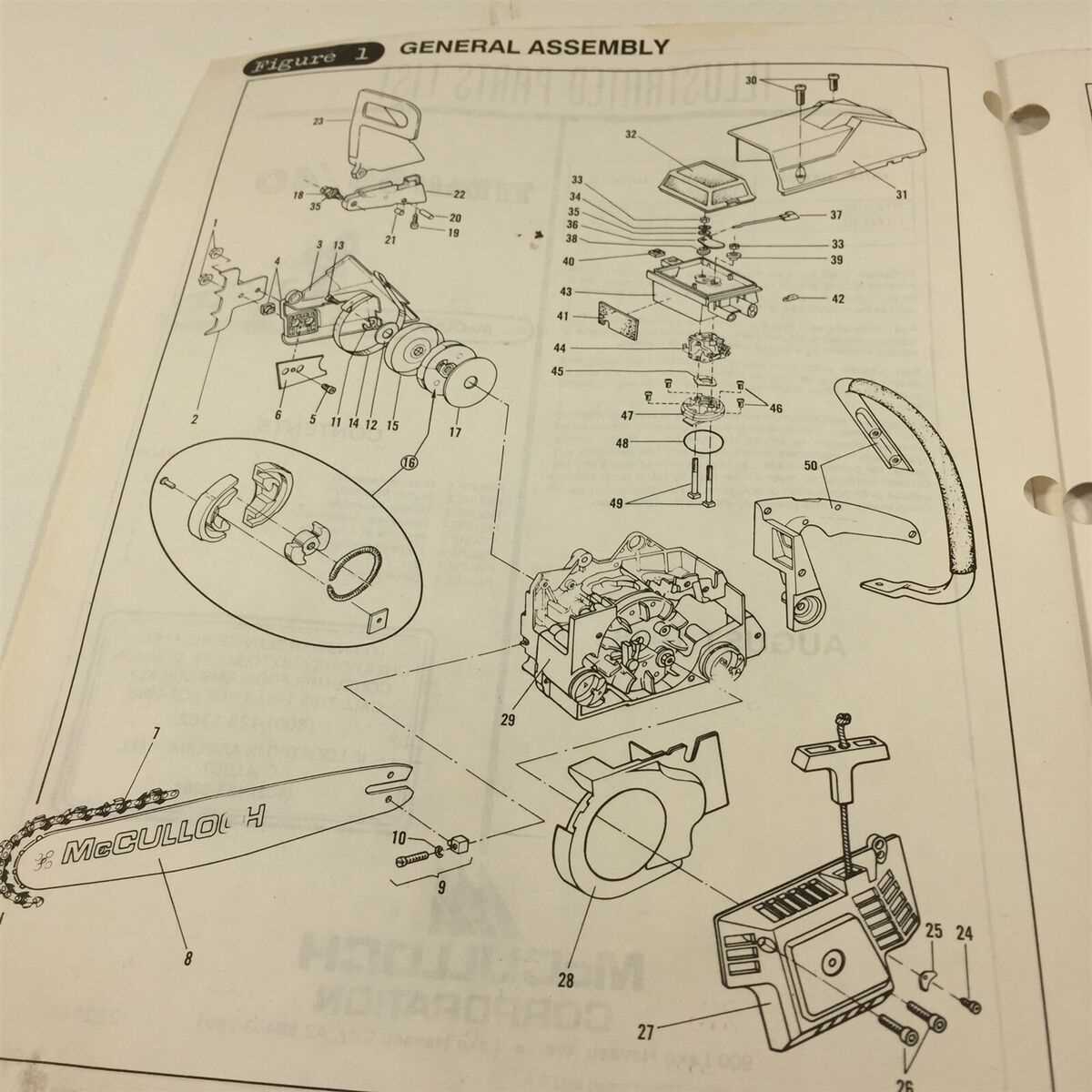

Understanding the Parts Diagram

The illustration depicting the various components of a cutting tool serves as an essential resource for users seeking to enhance their familiarity with the equipment. This visual representation enables individuals to identify each element and comprehend its specific function within the overall system.

In order to fully grasp the utility of this visual guide, it is crucial to recognize the significance of each section. Below are key points to consider:

- Component Identification: Each part is labeled clearly, allowing for easy reference when discussing repairs or maintenance.

- Functional Relationships: Understanding how different parts interact can aid in troubleshooting and performance optimization.

- Assembly Guidance: For those interested in assembly or disassembly, this resource provides a clear overview of how components fit together.

By utilizing this visual tool, users can develop a deeper understanding of their equipment, which ultimately leads to more efficient operation and care.

Identifying Major Components

Understanding the primary elements of a power tool is essential for effective maintenance and operation. Each component plays a vital role in the functionality and efficiency of the equipment. Familiarizing oneself with these elements can enhance the user’s ability to troubleshoot and perform repairs when necessary.

The following are key components that should be recognized:

- Engine: The powerhouse of the tool, responsible for providing the necessary energy.

- Guide Bar: A crucial part that directs the cutting chain and helps maintain stability during operation.

- Cutting Chain: The sharp loop that performs the actual cutting, making it a central feature of the tool.

- Fuel Tank: Contains the fuel needed to operate the engine, ensuring proper functionality.

- Handle: Provides the user with a secure grip and control over the tool.

- Brake System: A safety feature that helps stop the cutting chain quickly in emergencies.

Recognizing these elements aids in better care and enhances safety when utilizing the equipment.

Functionality of Each Part

The effective operation of a cutting tool relies on the seamless collaboration of its components. Each element plays a crucial role in ensuring that the device functions efficiently and safely. Understanding the purpose of each segment can enhance maintenance practices and improve overall performance.

Engine: The engine serves as the heart of the device, providing the necessary power for cutting. It converts fuel into mechanical energy, driving the entire mechanism.

Bar: The bar acts as a guide, holding the cutting chain in place. It enables precise cutting by allowing the chain to rotate smoothly around its length.

Chain: The chain is the primary tool for cutting through various materials. Its sharp teeth are designed to slice efficiently, making quick work of branches and logs.

Clutch: The clutch manages the connection between the engine and the chain. It disengages the chain when idling, preventing unnecessary wear and enhancing safety during operation.

Fuel System: This system ensures that the engine receives the right amount of fuel for optimal combustion. It includes components like the fuel tank and filter, which maintain proper fuel flow.

Lubrication Mechanism: Lubrication is essential for reducing friction between moving parts. This system distributes oil to the chain and bar, ensuring smooth operation and longevity.

Safety Features: Various safety mechanisms are integrated to protect the user. These may include a chain brake, which stops the chain instantly in case of kickback, enhancing user safety during operation.

Common Issues with Components

Understanding the frequent challenges associated with various elements of a mechanical device can significantly enhance its performance and longevity. By identifying these issues early, users can prevent further damage and ensure efficient operation. Below are some prevalent problems and their solutions.

1. Fuel System Problems

One of the most common issues relates to the fuel system. Inadequate fuel delivery can lead to performance issues, including:

- Difficulty starting the device

- Inconsistent power output

- Excessive smoke emission

Regular inspection of fuel lines and filters is essential to maintain optimal operation.

2. Ignition System Failures

Failures in the ignition system can result in the unit failing to start or stalling during use. Key indicators of ignition issues include:

- Unresponsive starter mechanism

- Frequent backfiring

- Irregular engine operation

Ensuring that spark plugs and ignition coils are in good condition can mitigate these problems.

Replacement Part Recommendations

When maintaining or restoring a tool, selecting the right components is essential for optimal performance and longevity. Understanding the key features and compatibility of different elements can greatly enhance the efficiency of your equipment. Below are suggestions for critical replacements that ensure smooth operation.

Essential Components

Here are some fundamental items to consider when looking for replacements:

| Component | Description |

|---|---|

| Fuel Filter | Prevents debris from entering the fuel system, ensuring clean fuel flow. |

| Air Filter | Helps maintain engine efficiency by trapping dirt and particles from the air. |

| Bar and Chain | Essential for cutting; ensures smooth operation and precise cuts. |

| Spark Plug | Ignites the fuel-air mixture, crucial for engine start-up and performance. |

Optional Accessories

In addition to vital components, certain accessories can enhance the usability of your tool:

| Accessory | Benefit |

|---|---|

| Protective Cover | Safeguards the unit during storage and transportation. |

| Oil Can | Facilitates easy lubrication of the chain and bar for extended life. |

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools is essential for ensuring efficiency and effectiveness. A well-equipped toolkit can simplify the process, making repairs more manageable and precise.

- Screwdrivers: Various types and sizes, including flathead and Phillips, are crucial for removing and securing components.

- Wrenches: A set of adjustable wrenches will help in loosening or tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: A collection of sockets in different sizes facilitates working with bolts in tight spaces.

- Measuring Tools: A tape measure or caliper ensures accurate measurements when replacing or adjusting parts.

- Cleaning Supplies: Brushes, cloths, and cleaning agents assist in maintaining a clean working environment.

- Safety Gear: Gloves, goggles, and masks provide protection while performing repairs.

By preparing these essential tools, individuals can tackle repairs with confidence and improve their chances of success.

Maintenance Tips for Longevity

Proper upkeep of your cutting tool is essential for enhancing its lifespan and ensuring optimal performance. Regular maintenance not only prevents wear and tear but also keeps the equipment functioning at its best. Following a few straightforward practices can significantly extend the life of your device.

Here are some key maintenance tips:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and sap buildup after each use to prevent clogging and overheating. |

| Lubrication | Apply appropriate oil to moving parts to reduce friction and avoid premature wear. |

| Inspect Components | Check for signs of damage or wear regularly and replace any compromised parts promptly. |

| Sharpening | Keep the cutting edge sharp to ensure efficient cutting and reduce strain on the motor. |

| Proper Storage | Store the tool in a dry, secure place to protect it from the elements and accidental damage. |

How to Read a Parts Diagram

Understanding the layout of a component representation is crucial for effective maintenance and repair tasks. Such illustrations provide a visual guide that simplifies the identification of each element within a mechanical system. By familiarizing yourself with the common symbols and structure, you can enhance your ability to work on various equipment effectively.

Key Elements to Look For

When examining a schematic representation, pay attention to the following components:

- Labels: Each section is typically accompanied by a label, indicating the specific function or identity of the item.

- Connections: Lines or arrows demonstrate how various elements interact, helping you understand the flow of operation.

- Numbers: These often correspond to a list of items, making it easier to reference parts during ordering or discussions.

Tips for Effective Interpretation

- Familiarize Yourself: Take time to understand common symbols used in such illustrations; this will speed up your comprehension.

- Use a Reference List: Keep a list of terminology handy for quick reference while analyzing the schematic.

- Practice: Regularly reviewing different representations will improve your skills and confidence over time.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Proper preparation and adherence to guidelines can significantly mitigate risks associated with handling equipment and tools. It is vital to follow best practices to create a secure environment for both the technician and the equipment being serviced.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial during any repair procedure. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and sturdy footwear to safeguard the feet. Ensuring that clothing is not loose can also help prevent entanglement in moving parts.

Work Area Organization

Maintaining an organized work area enhances safety and efficiency. Clear the workspace of unnecessary items and ensure that tools are within reach. Good lighting is essential for visibility, and having a first aid kit nearby can provide immediate assistance in case of an emergency. Following these organizational practices helps to reduce the likelihood of accidents during repairs.

Where to Buy Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its performance and longevity. There are various avenues to explore when searching for high-quality replacements. Understanding these options can ensure you acquire the right items efficiently.

Online Retailers

Numerous online platforms offer a wide selection of components for various machinery. Websites dedicated to hardware and tools often provide detailed specifications and user reviews, making it easier to choose the appropriate replacements. Additionally, many manufacturers maintain their own online stores, which can be an excellent source for genuine items.

Local Hardware Stores

Physical stores can be a convenient alternative for those who prefer to see items before purchasing. Local hardware outlets frequently carry a range of components, and staff can assist in identifying the correct products for your needs. It’s advisable to call ahead to ensure they have the desired items in stock.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding a specific model of a cutting tool. Customers often share their insights on performance, reliability, and ease of use, which can be invaluable for potential buyers. Feedback typically reflects on various aspects such as efficiency, maintenance, and overall satisfaction with the product.

Many users appreciate the lightweight design and maneuverability, making it ideal for various tasks. They frequently mention how user-friendly it is, especially for those who are new to using such equipment. Additionally, several reviews emphasize the power and effectiveness, stating that it handles both small and medium jobs efficiently.

However, some feedback also points out areas for improvement. A few users have noted that certain components may require more frequent replacement, indicating a need for better durability in specific parts. Overall, the gathered reviews provide a comprehensive view of the tool’s strengths and weaknesses, assisting others in making informed decisions.