Understanding the Components of Poulan 3400 Chainsaw

The internal mechanisms of mechanical equipment rely heavily on each element working in unison. Understanding how different sections connect and interact is crucial for ensuring smooth operation and performing any necessary repairs. By exploring a detailed map of the various components, it’s easier to diagnose potential issues and maintain peak efficiency over time.

This guide focuses on a specific model, highlighting the main elements that contribute to its functionality. Whether you are looking to replace specific parts or simply gain a deeper understanding of the structure, this overview offers a clear and thorough breakdown of essential sections and how they work together.

With this resource, users can quickly locate specific areas of interest and proceed with the required maintenance tasks, ensuring long-term durability and performance. Each element is carefully detailed to provide clear insight into the intricate workings of this powerful machine.

Overview of the Poulan 3400 Chainsaw

This model is recognized for its durability and efficient performance, making it a reliable tool for various outdoor tasks. It combines a powerful motor with a well-designed structure to deliver precision and ease of use. Over the years, it has become a favorite among professionals and hobbyists alike due to its robust design and longevity.

Key Features and Design

- Ergonomic handle that ensures comfort during extended use.

- Efficient engine designed for high performance in demanding conditions.

- Advanced safety features that protect users during operation.

- Durable construction meant to withstand tough environments.

Maintenance Considerations

- Regular cleaning of the engine to prevent dust buildup and maintain optimal performance.

- Inspecting and replacing the cutting mechanism as needed to ensure smooth operation.

- Checking and adjusting the tension mechanism to enhance cutting accuracy.

- Lubricating moving components to reduce wear and extend the tool’s lifespan.

Key Components of the Chainsaw Body

The exterior structure of a cutting tool plays a crucial role in its overall functionality and ease of use. Each element of the framework contributes to both the performance and durability of the device. Understanding the individual sections of the body allows for more effective operation, maintenance, and troubleshooting.

Engine Housing

The engine housing forms the core of the body, protecting the internal mechanical components from external damage while providing ventilation to prevent overheating. This section also serves as a mounting point for other critical elements such as handles and control levers, ensuring the tool operates smoothly and safely.

Handle and Control System

The handles, along with the throttle and safety switches, form the interface between the user and the machine. Ergonomically designed grips ensure better control and reduced fatigue during extended periods of use. The control system allows precise adjustments to power and speed, enhancing overall cutting efficiency.

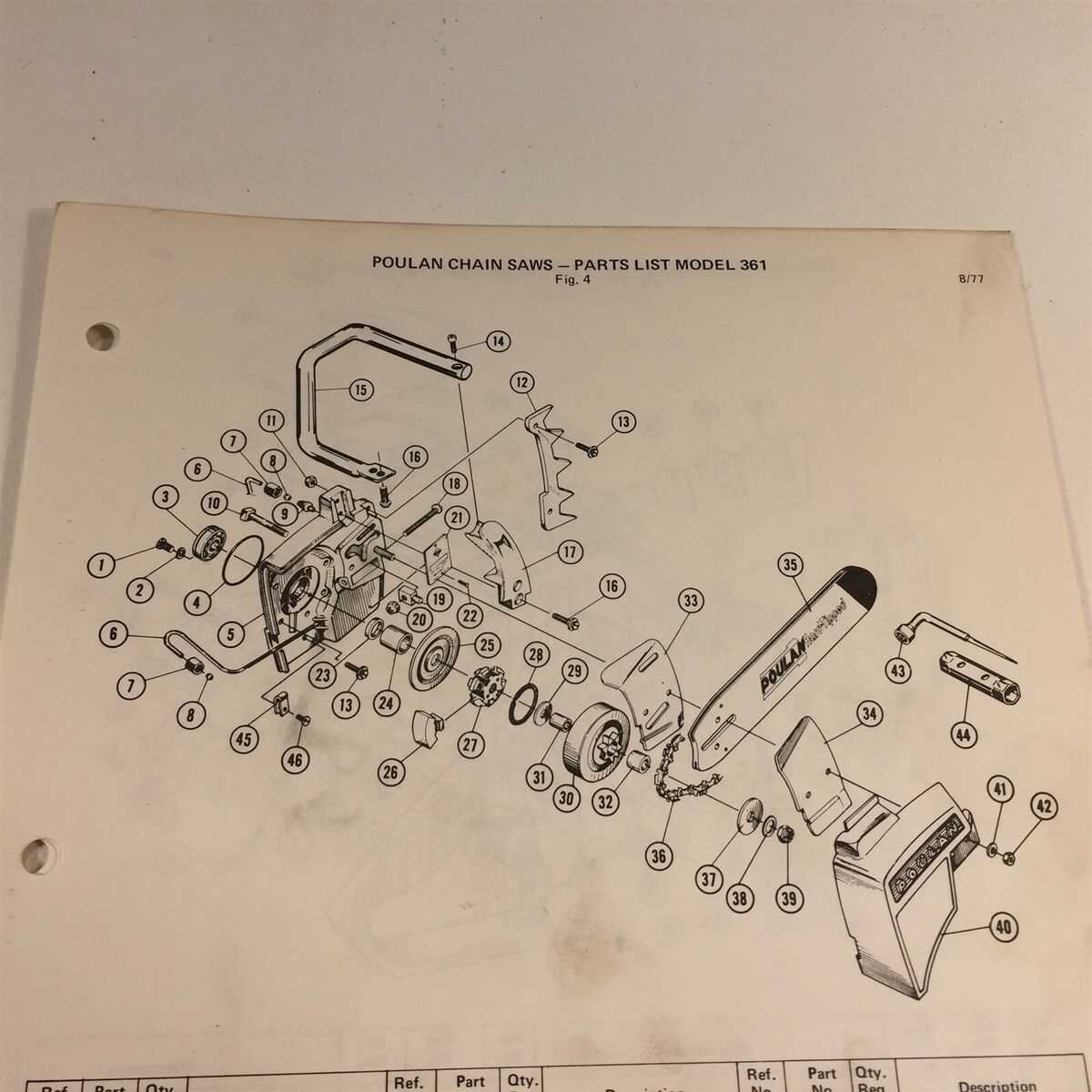

Understanding the Engine Assembly Structure

The engine assembly consists of various interconnected components that work together to convert fuel into mechanical power. These elements are intricately designed to ensure smooth operation and efficient energy transfer. To gain a deeper understanding of this assembly, it’s important to analyze how the individual parts interact and contribute to the overall performance.

Key elements of the engine system include moving and static components that manage the fuel intake, combustion process, and power output. Each part is engineered for specific functions, and when assembled, they form a cohesive unit responsible for driving the machine’s core operations. Identifying the main structural pieces can help maintain and troubleshoot the system more effectively.

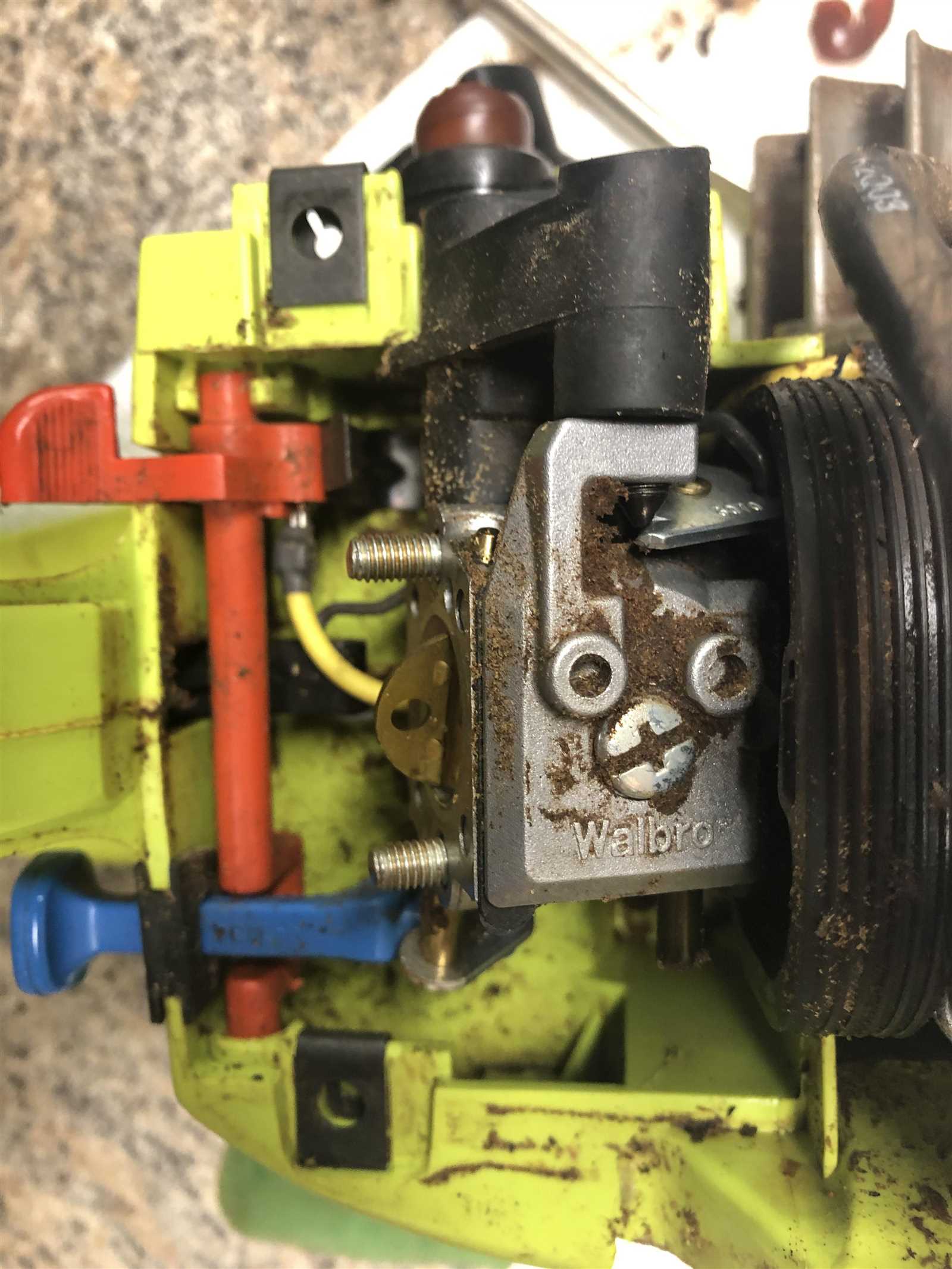

Carburetor System and Its Functions

The carburetor is a key element in ensuring the smooth operation of a small engine, as it regulates the flow of fuel and air needed for combustion. By maintaining an optimal mixture, this mechanism ensures the engine runs efficiently, providing power when needed. Understanding the various components of the system is essential for maintenance and performance tuning.

- Air Intake: This component manages the airflow into the carburetor, which is crucial for maintaining the correct fuel-air ratio.

- Fuel Delivery: Through a series of passages and valves, the system controls the precise amount of fuel entering the combustion chamber.

- Throttle Control: The throttle manages the engine’s speed by adjusting the amount of air entering the carburetor, thus influencing fuel intake.

- Choke Valve: This part helps in starting the engine by temporarily enriching the air-fuel mixture during cold starts.

- Idle Circuit: It ensures the engine runs smoothly at low speeds by providing a steady mixture of air and fuel.

Regular upkeep of the carburetor system is necessary to prevent performance issues, ensuring consistent power output and efficiency in various conditions.

Ignition Module and Spark Plug Location

Understanding the positioning of the ignition system is crucial for optimal engine performance. This section focuses on identifying where key components responsible for starting the engine are located, ensuring a reliable power-up each time. Proper maintenance and inspection of these elements are essential for smooth operation.

Identifying the Ignition Module

The ignition module is typically situated close to the engine’s core, where it manages the timing of electrical pulses necessary to ignite the fuel mixture. This module plays a vital role in maintaining the engine’s stability, especially during start-up and acceleration. Locating and accessing it requires familiarity with the engine’s layout and the surrounding components.

Locating the Spark Plug

The spark plug, an essential element for igniting the fuel-air mixture, is usually found near the cylinder head. This component is easy to access for regular maintenance, ensuring that electrical discharge happens at the right moment for efficient combustion. Checking the spark plug regularly helps maintain strong performance and fuel efficiency.

Examining the Fuel Line and Tank

Understanding the components responsible for fuel transport is crucial for maintaining optimal performance. The fuel delivery system plays a vital role in ensuring the engine receives the necessary mixture for efficient operation. A thorough examination of these elements can help identify potential issues that may affect functionality.

The fuel tank serves as the reservoir for the fuel, providing the necessary supply to the engine. It’s essential to check for signs of wear, cracks, or leaks that could lead to fuel loss or contamination. Additionally, ensuring that the tank is securely mounted and properly sealed will prevent any unwanted spills and maintain pressure within the system.

Equally important is the fuel line, which channels fuel from the tank to the engine. Inspecting this line for blockages, kinks, or damage is critical, as any obstruction can impede fuel flow, resulting in decreased performance or starting difficulties. Regular maintenance of both the tank and fuel line will contribute to the longevity and reliability of the equipment.

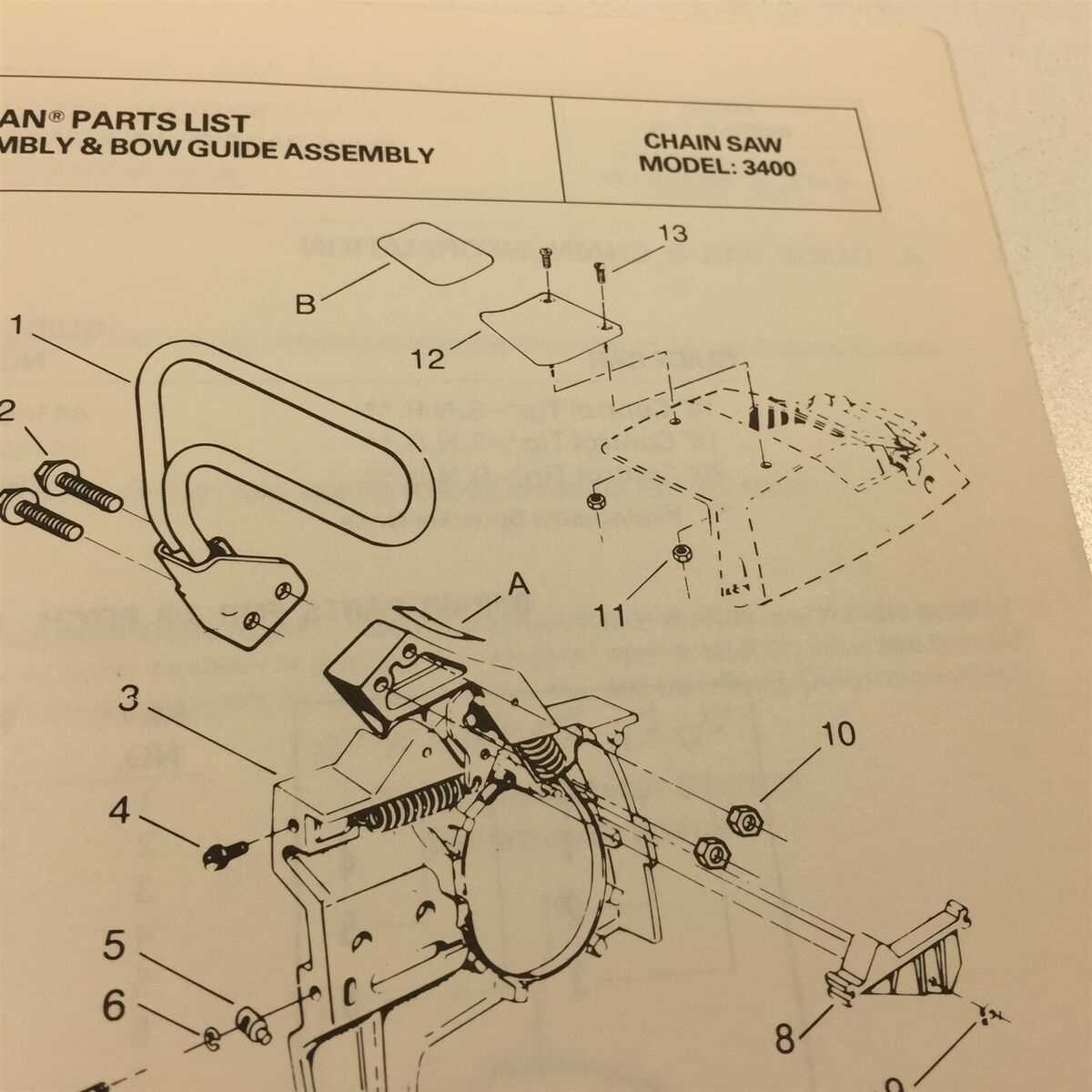

Guide Bar and Chain Mechanism Details

The guide bar and chain assembly play a crucial role in the overall functionality of a cutting tool. This mechanism is responsible for directing the chain during operation, ensuring efficient cutting while maintaining stability and control. Understanding the intricacies of this system is essential for optimal performance and maintenance.

Components of the System

The primary elements include the guide bar, which serves as the track for the chain, and the chain itself, which is designed with sharp teeth for effective cutting. The guide bar typically features a groove along its length, allowing the chain to fit securely while minimizing friction. Proper alignment and tension between these components are vital for achieving smooth operation and extending the lifespan of the tool.

Maintenance and Adjustment

Regular maintenance of the guide bar and chain is essential to ensure optimal performance. This includes checking for wear and tear, ensuring the chain is adequately tensioned, and lubricating the system to reduce friction. Neglecting these aspects can lead to decreased efficiency and potential damage to the components, ultimately affecting the overall effectiveness of the tool.

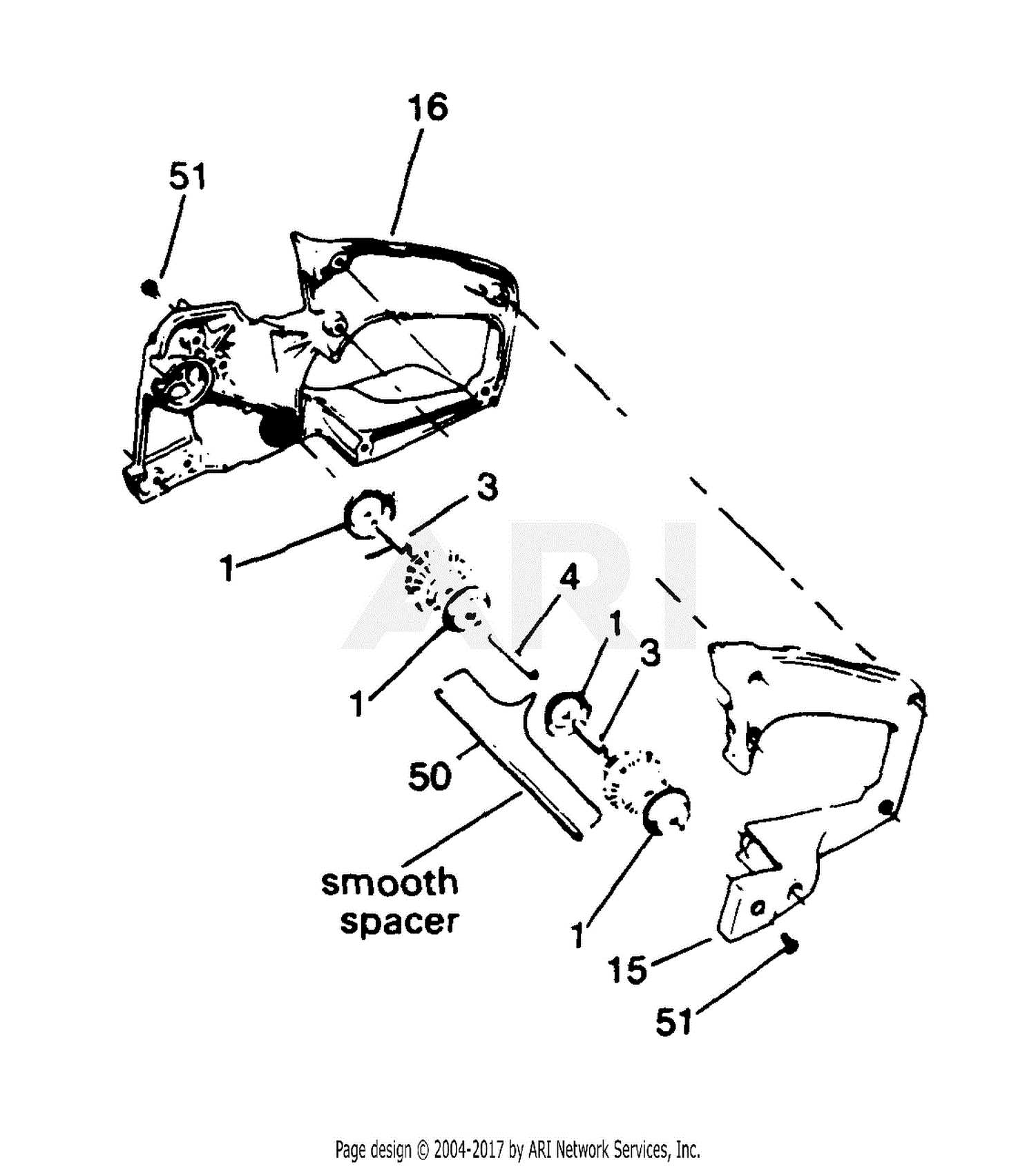

Clutch Assembly Breakdown

The clutch assembly is a vital component in power equipment, playing a crucial role in the transmission of power from the engine to the cutting mechanism. Understanding its structure and functionality is essential for effective maintenance and troubleshooting.

At the heart of the clutch assembly are several key components, including the clutch shoes, springs, and the drive drum. Clutch shoes are designed to engage and disengage the drive mechanism, while the springs provide the necessary tension to keep the shoes in place during operation. The drive drum acts as a connection point, allowing for the transfer of rotational force to the cutting tool.

Regular inspection and maintenance of the clutch assembly can prevent operational issues and prolong the lifespan of the equipment. Signs of wear, such as unusual noises or decreased performance, should prompt immediate attention to the assembly to ensure optimal functionality.

In summary, a thorough understanding of the clutch assembly’s breakdown aids in effective repairs and enhances the overall performance of the machinery, contributing to successful operations in various tasks.

Recoil Starter Mechanism and Maintenance

The recoil starter mechanism plays a crucial role in the operation of small engines, enabling them to initiate the combustion cycle efficiently. Understanding its components and ensuring regular upkeep is essential for optimal performance and longevity.

This assembly typically consists of a spring, rope, and a pulley, all designed to work harmoniously. When the operator pulls the starter rope, the spring unwinds, which rotates the engine’s flywheel, thus igniting the fuel-air mixture. Proper maintenance of this system helps prevent common issues, such as rope breakage or difficulty starting the engine.

- Regular Inspection: Check for wear on the starter rope and any visible damage to the pulley or spring. Regular inspections help identify potential problems before they escalate.

- Cleaning: Keep the mechanism clean from dirt and debris that may hinder its operation. Use compressed air or a soft brush to remove any buildup around the starter assembly.

- Lubrication: Apply a light machine oil to the moving parts of the recoil starter to ensure smooth operation. Avoid over-lubrication, which can attract dirt.

- Rope Replacement: If the starter rope shows signs of fraying or damage, replace it promptly. Use a rope of appropriate length and strength to ensure reliable starting.

By following these maintenance tips, operators can enhance the functionality of the recoil starter system, leading to a more reliable and efficient starting process for their equipment.

Air Filter Positioning and Replacement

The positioning and maintenance of the air filtration system are crucial for optimal performance and longevity of outdoor power equipment. A clean air filter ensures that the engine receives an adequate supply of clean air, which is essential for efficient combustion. Regular inspection and timely replacement can prevent engine wear and maintain the tool’s functionality.

Location of the Air Filter

The air filter is typically located near the engine, often secured by a cover that can be easily removed. It is important to familiarize yourself with its exact placement to facilitate routine checks and replacements.

Steps for Replacement

To ensure proper function, follow these steps when replacing the air filtration element:

| Step | Description |

|---|---|

| 1 | Power off the equipment and disconnect the spark plug for safety. |

| 2 | Remove the cover that protects the air filter. |

| 3 | Carefully take out the old filter and inspect the housing for debris. |

| 4 | Insert the new filtration element, ensuring a snug fit. |

| 5 | Reattach the cover securely and reconnect the spark plug. |

By following these steps, users can ensure their equipment remains in top condition, contributing to improved efficiency and durability.

Muffler and Exhaust System Components

The muffler and exhaust assembly play a crucial role in the overall performance of any power equipment. These elements work together to redirect exhaust gases produced during operation, ensuring that the machine runs efficiently while minimizing noise levels. A well-functioning exhaust system contributes to the longevity of the engine and enhances user comfort.

Muffler Functionality

The primary purpose of the muffler is to reduce the sound generated by the engine’s exhaust. By employing a series of chambers and baffles, it effectively dampens noise while allowing exhaust gases to escape. Proper maintenance of the muffler is essential, as any blockages or damage can lead to increased noise and decreased performance.

Exhaust System Parts

The exhaust system comprises several critical components, including the exhaust pipe, gaskets, and mounting hardware. The exhaust pipe channels gases from the engine to the muffler, ensuring efficient gas flow. Gaskets create a seal between the exhaust pipe and muffler to prevent leaks, which can lead to reduced efficiency and performance. Regular inspection and replacement of these components are vital to maintaining optimal functionality.

Chain Tensioner and Adjustment Tips

Maintaining the proper tension of the cutting element is crucial for optimal performance and safety during operation. A correctly adjusted tensioner not only enhances cutting efficiency but also extends the lifespan of the component. This section provides insights on how to effectively manage tension and ensure reliable operation.

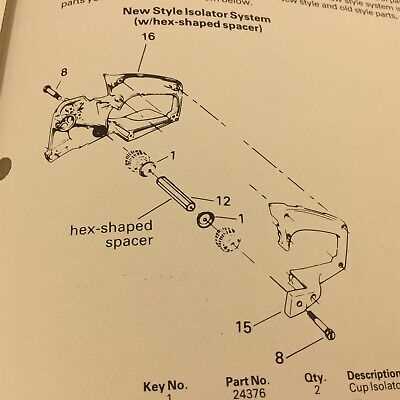

Understanding the Tensioner Mechanism

The tensioning device plays a vital role in securing the cutting element in place. It typically consists of a screw or lever system that allows for adjustments. Understanding how this mechanism works is essential for achieving the correct tightness. A well-functioning tensioner will ensure that the chain remains snug against the guide bar while allowing it to rotate freely.

Adjustment Procedures

To adjust the tension, first, ensure that the unit is powered off and the cutting element is not in motion. Loosen the adjustment screw slightly, then pull the cutting element away from the guide bar. Gradually tighten the adjustment screw until the chain is firm but can still be rotated by hand. Always double-check the tension after adjustments to ensure it remains secure during use.

Handle Assembly and User Comfort Features

The handle structure of outdoor cutting tools plays a crucial role in enhancing user experience and ensuring operational efficiency. Ergonomic design elements contribute to a comfortable grip, reducing fatigue during extended use. Understanding these components can significantly improve handling and overall satisfaction.

Key aspects of the handle assembly include the grip material, shape, and additional features aimed at providing stability and control. These elements are vital for maintaining precision during operation and minimizing strain on the user’s hands and wrists.

| Feature | Description |

|---|---|

| Ergonomic Grip | Designed to fit the natural shape of the hand, reducing fatigue and enhancing comfort. |

| Vibration Dampening | Special materials or designs that absorb vibrations, improving user comfort during operation. |

| Safety Switches | Integrated features that prevent accidental activation, ensuring a safer user experience. |

| Adjustable Handle | Allows customization of grip height or angle, catering to various user preferences and tasks. |

Incorporating these features not only improves user satisfaction but also enhances overall performance, making operations smoother and more enjoyable. Proper maintenance of these components ensures longevity and reliability of the equipment.