Comprehensive Guide to Chevrolet Aveo Parts Diagram

The intricate design of modern automobiles involves a vast array of interconnected elements that work in harmony to ensure optimal performance. A comprehensive overview of these components provides invaluable insights for enthusiasts and mechanics alike, allowing them to grasp the intricacies of automotive engineering.

When exploring the specific layout of various mechanisms, one can gain a clearer perspective on how each piece contributes to the overall functionality of the vehicle. This knowledge not only aids in maintenance but also enhances the ability to troubleshoot issues effectively.

For anyone looking to delve deeper into the subject, visual representations serve as an ultimate resource. They clarify the relationships between different parts, making it easier to identify and understand their roles within the vehicle’s architecture.

Understanding Chevrolet Aveo Components

This section aims to explore the various elements that make up a popular compact vehicle, shedding light on their functions and interconnections. By grasping how these components work together, one can gain valuable insights into vehicle maintenance and performance enhancement.

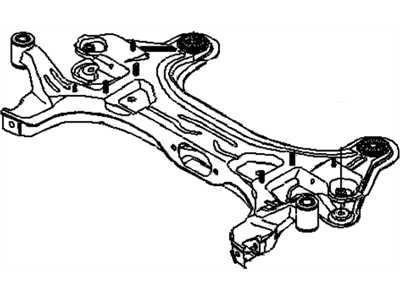

Key elements include the engine, transmission, and suspension systems, each playing a crucial role in ensuring smooth operation. The engine is the powerhouse, converting fuel into motion, while the transmission transfers power from the engine to the wheels, enabling movement. The suspension system, on the other hand, ensures stability and comfort during travel.

Understanding these components not only enhances your knowledge but also empowers you to make informed decisions regarding repairs and upgrades. This deeper appreciation can ultimately lead to improved longevity and performance of your vehicle.

Essential Parts for Aveo Maintenance

Regular upkeep of your vehicle is crucial for ensuring its longevity and performance. Familiarity with the key components that require attention can help maintain efficiency and safety on the road. This section highlights the vital elements that should be prioritized during routine inspections and servicing.

| Component | Function | Recommended Maintenance |

|---|---|---|

| Engine Oil | Lubricates engine components | Change every 5,000 miles |

| Air Filter | Ensures clean air intake | Inspect and replace every 15,000 miles |

| Brake Pads | Provide stopping power | Check thickness every 20,000 miles |

| Battery | Powers electrical systems | Test every 6 months |

| Tires | Ensure traction and handling | Rotate every 5,000 miles; check pressure monthly |

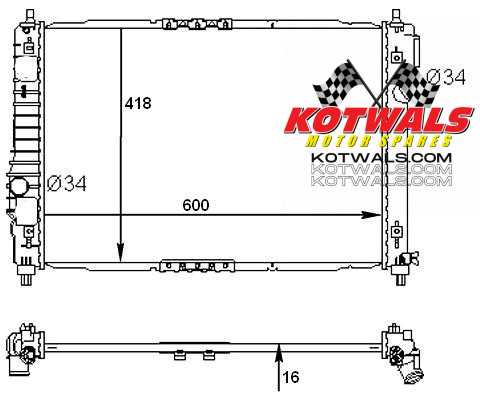

| Coolant | Regulates engine temperature | Flush and replace every 2 years |

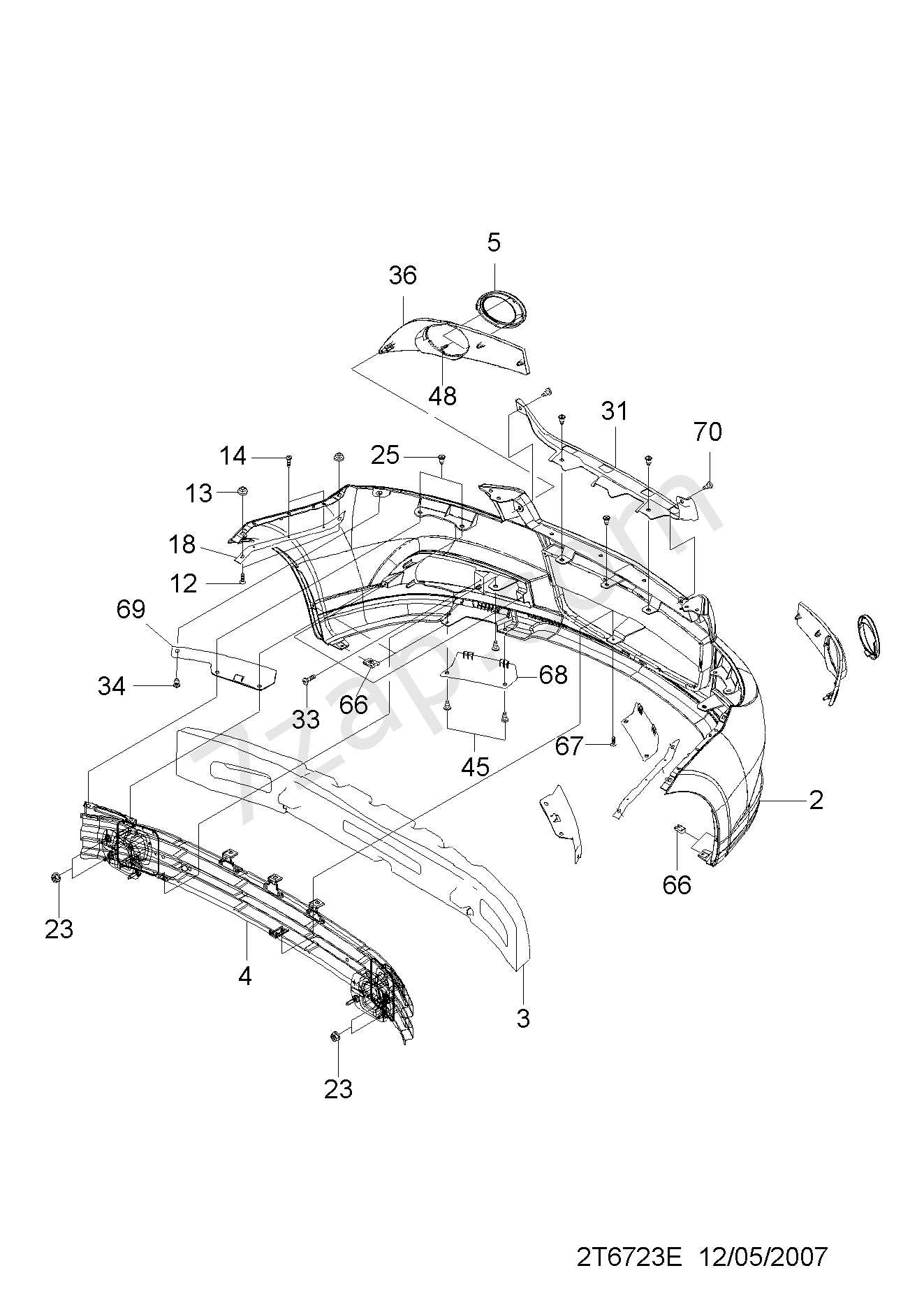

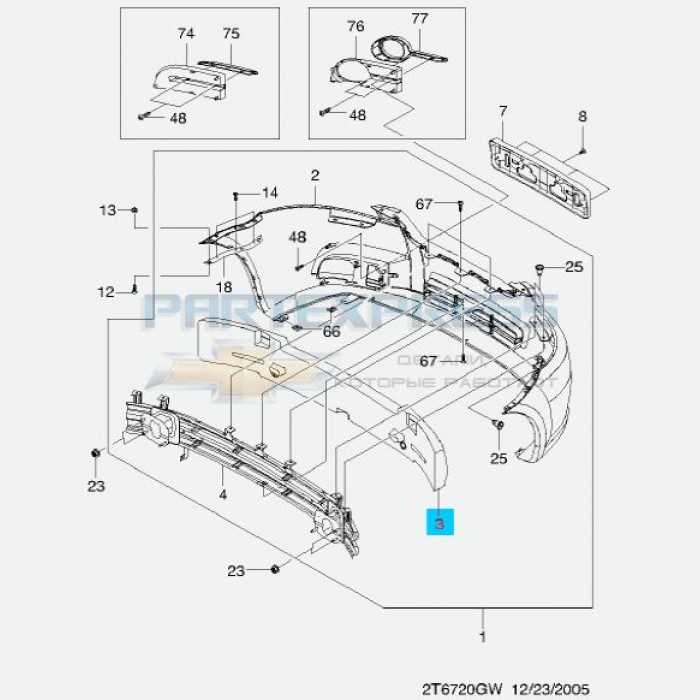

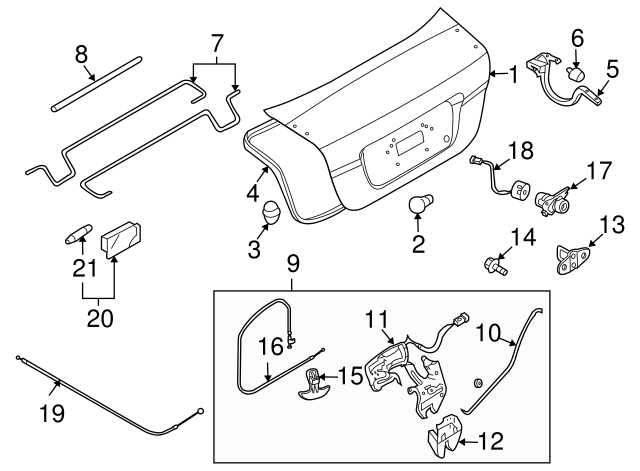

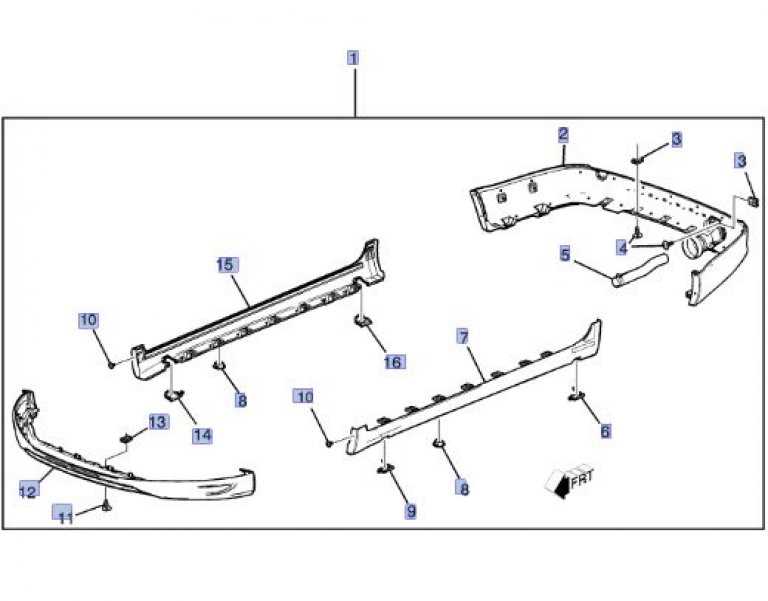

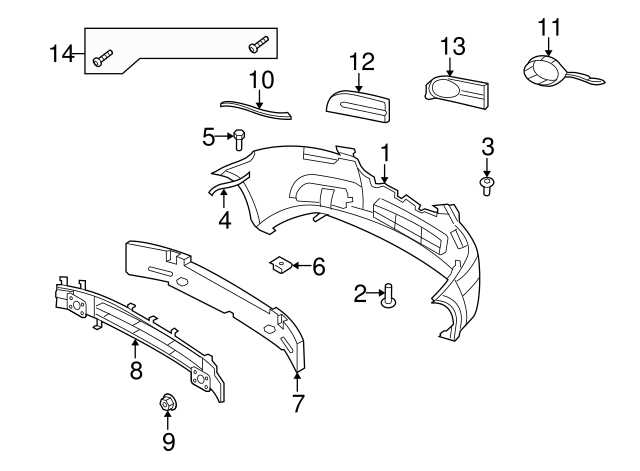

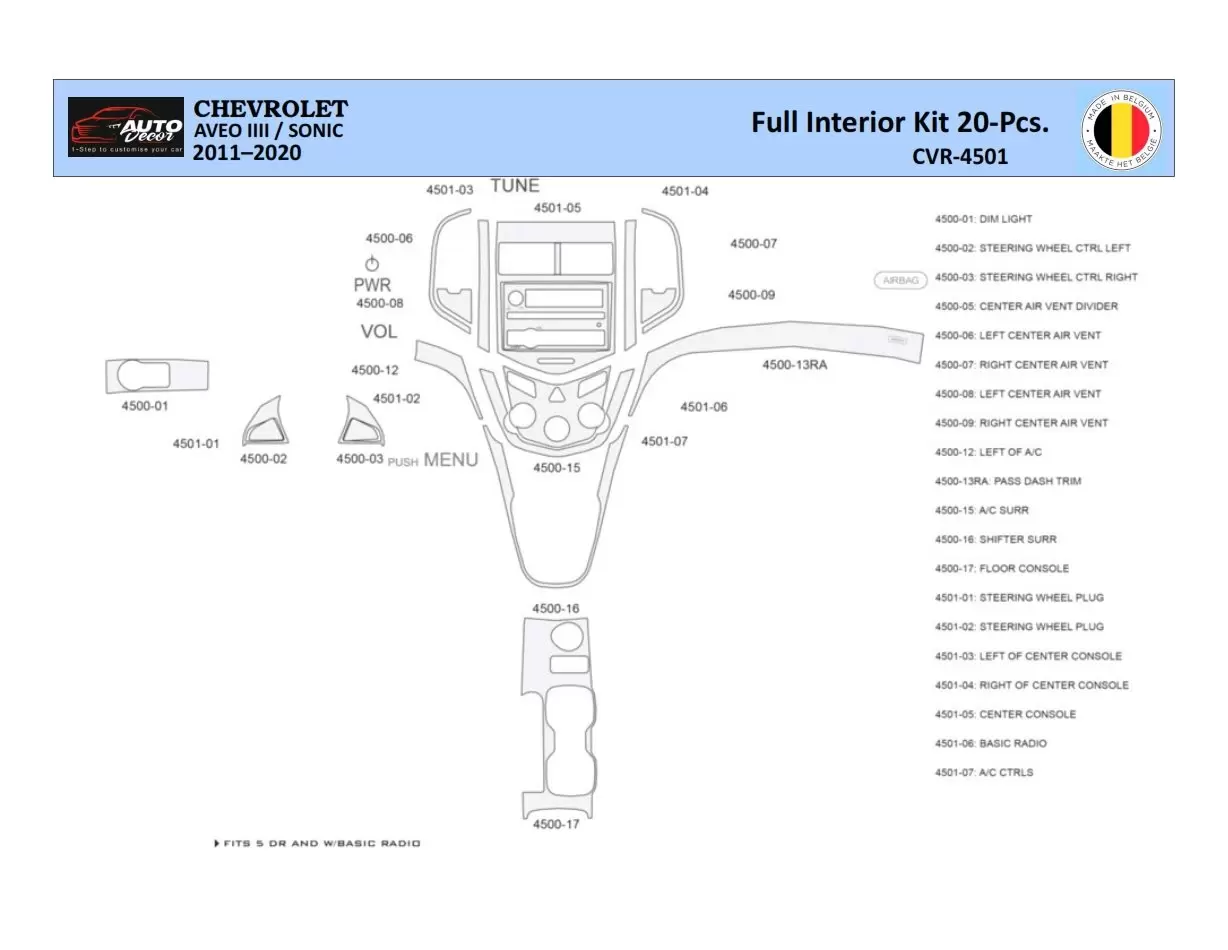

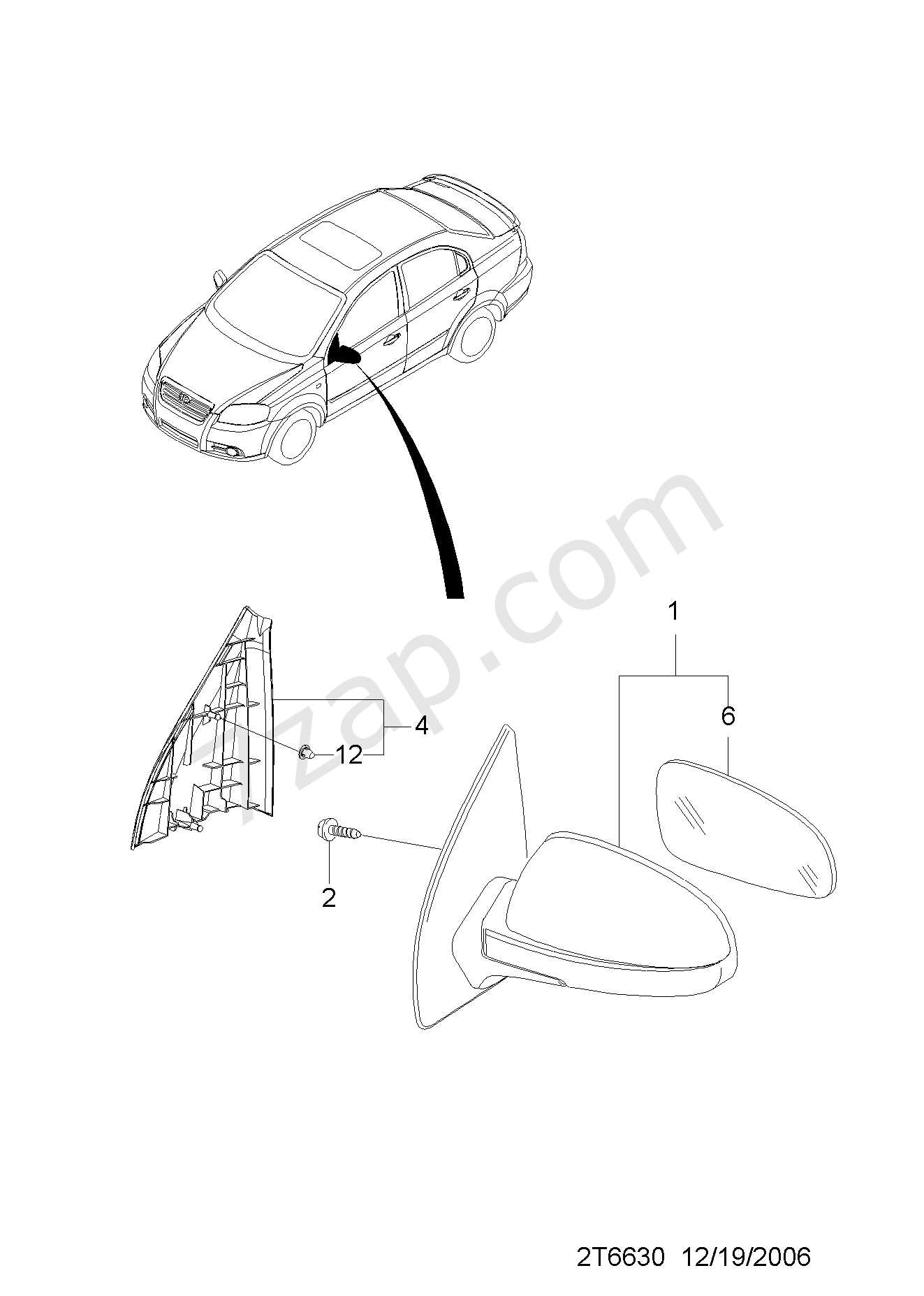

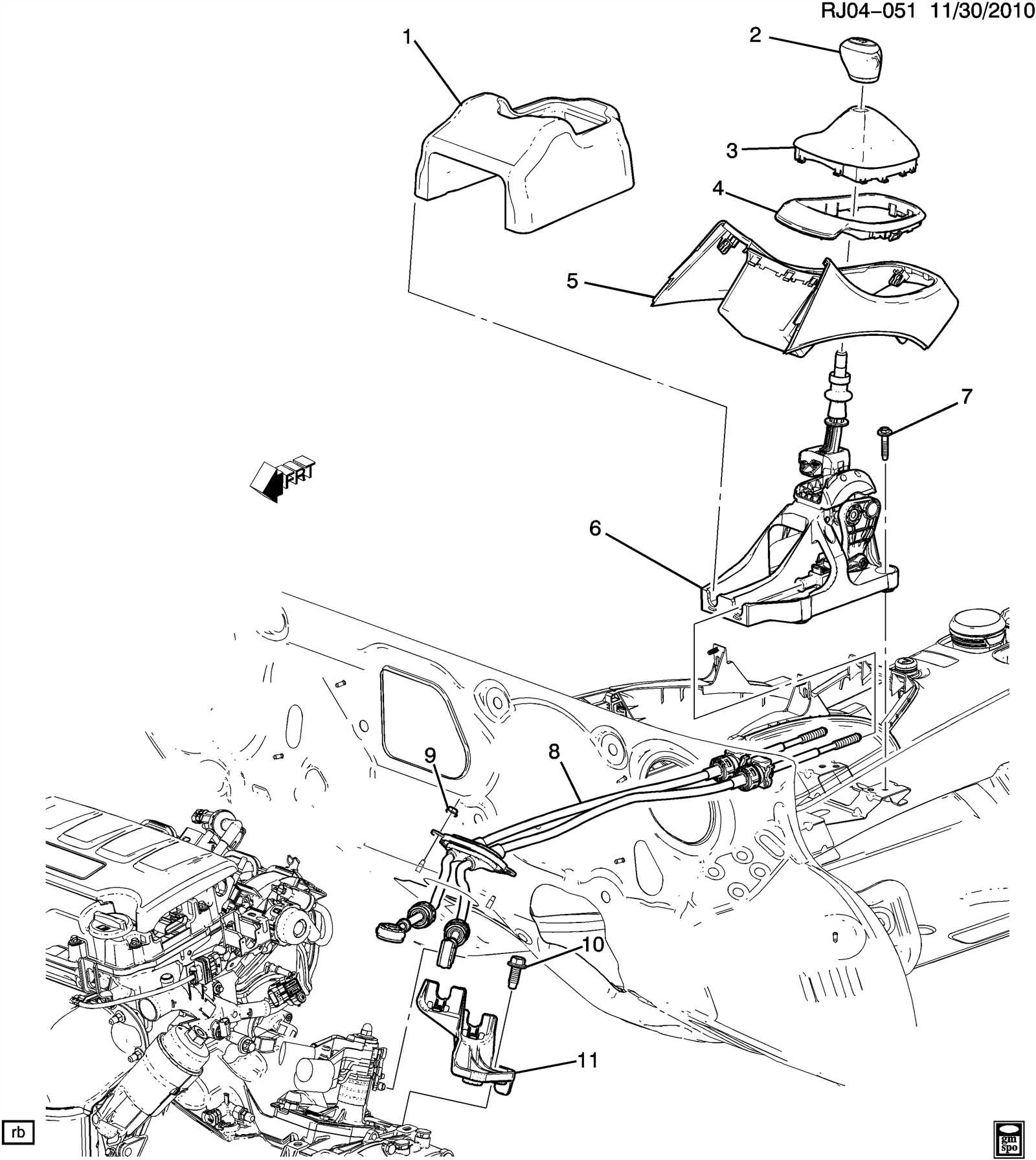

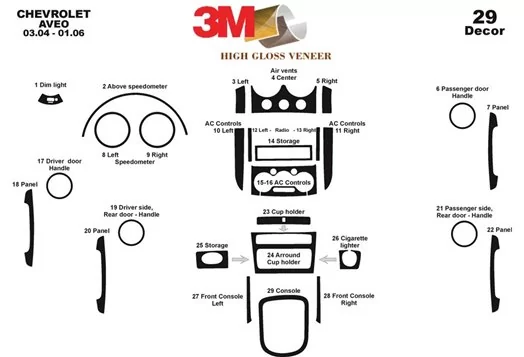

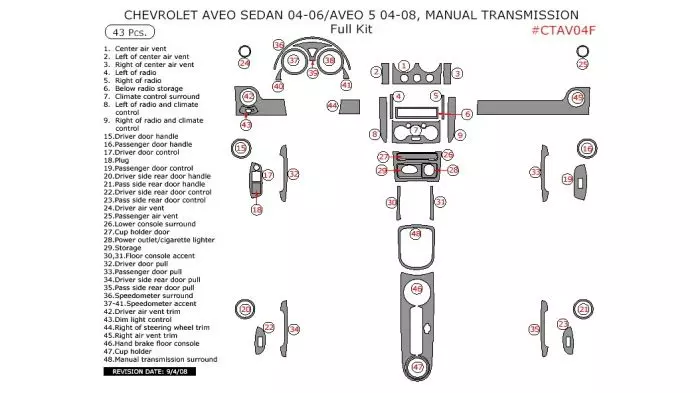

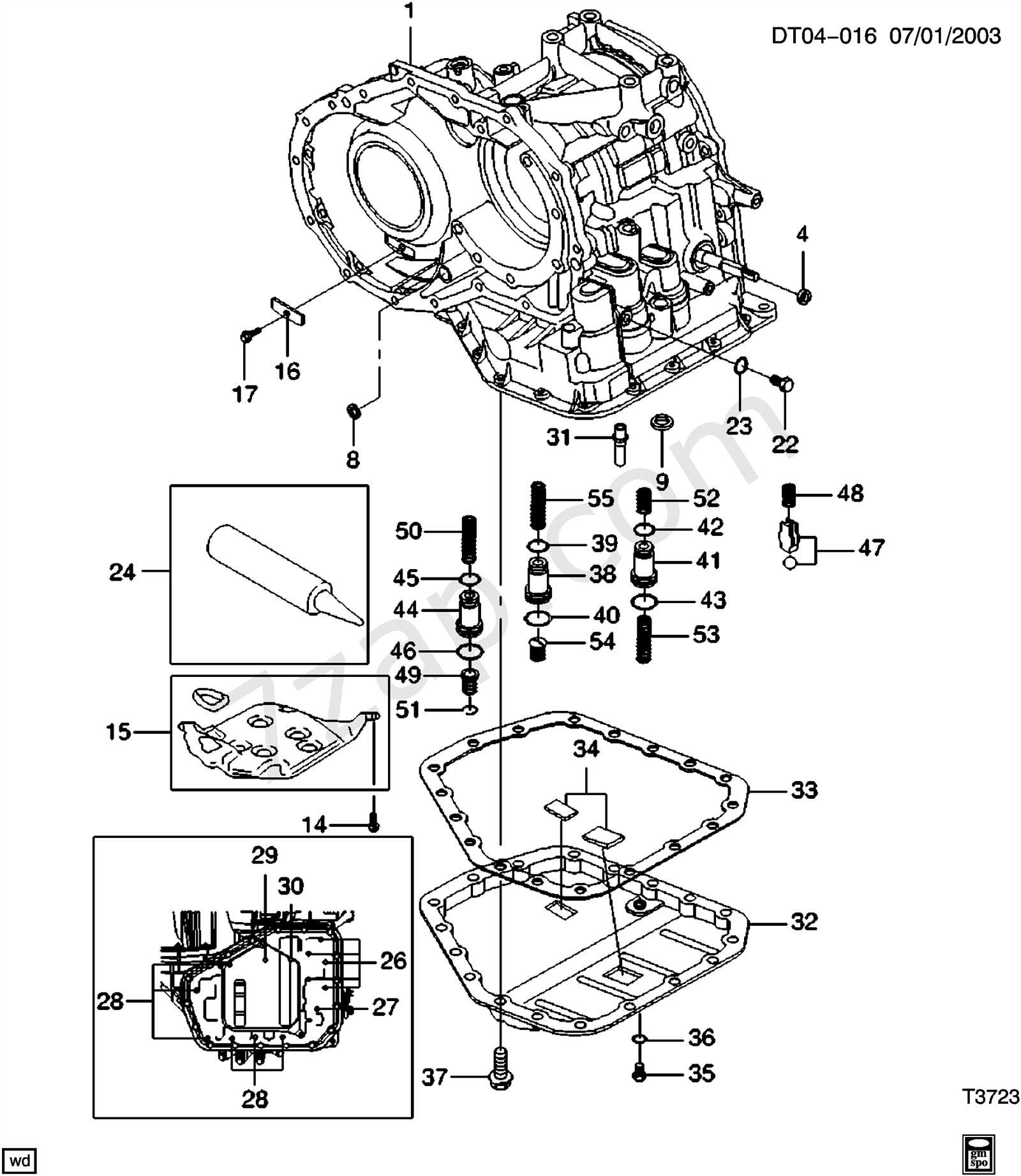

How to Read a Parts Diagram

Understanding a schematic representation of vehicle components is essential for effective maintenance and repair. Such illustrations provide valuable insights into the relationships and placements of various elements, enabling a smoother workflow when addressing mechanical issues.

Identifying Key Symbols

Familiarize yourself with the common icons and notations used in the illustration. Each symbol typically represents a specific component or function. Take notes of these symbols as they will be your guide throughout the process.

Interpreting Connections

Pay close attention to the lines and arrows that connect different elements. These indicate how parts interact and fit together. Understanding these connections is crucial for troubleshooting and ensuring proper assembly.

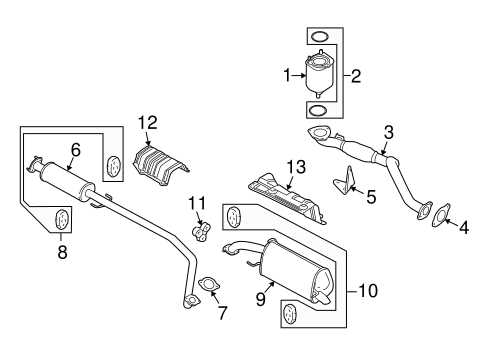

Common Issues with Aveo Parts

Over time, certain components in the vehicle can experience wear and tear, leading to various challenges for owners. These issues often stem from the natural aging process of mechanical and electrical elements, requiring routine checks and maintenance.

Frequent Electrical Problems

One of the most common concerns involves the electrical system, which can show signs of malfunction, such as faulty sensors or erratic dashboard warnings. Proper diagnostics and timely replacements of these elements can help avoid further complications.

Wear and Tear on Mechanical Components

Mechanical elements, such as suspension or braking systems, often encounter wear over time. Regular inspections and early detection of these issues can prevent more significant failures and ensure the vehicle remains in good working condition.

Replacing Worn-Out Components Effectively

To maintain the longevity of any vehicle, it’s crucial to address signs of wear and tear in essential mechanical elements promptly. Regular inspections and proactive replacements of deteriorating components ensure optimal performance and prevent costly breakdowns in the future. This guide will outline the steps to identify, assess, and replace key elements that may degrade over time.

Identifying Commonly Worn Components

- Examine brake pads for signs of thinning or uneven wear.

- Check belts and hoses for cracks or stiffness.

- Inspect suspension parts for wear or looseness.

Steps for Safe and Effective Replacement

- Ensure the vehicle is on a stable surface before beginning repairs.

- Use appropriate tools and follow the manufacturer’s guidelines for each specific component.

- Test the replaced parts to confirm proper installation and functionality.

Benefits of Using OEM Parts

Opting for original equipment manufacturer (OEM) components ensures a seamless fit and compatibility with your vehicle’s system. These components are designed to meet the precise specifications, offering enhanced performance and reliability over alternatives.

Quality and Durability

OEM components are manufactured to strict standards, guaranteeing long-lasting performance. Since they are built specifically for the vehicle, their durability often exceeds that of generic options, reducing the likelihood of future replacements.

Warranty and Support

By choosing OEM parts, you typically receive a manufacturer’s warranty, providing peace of mind in case of defects or issues. Additionally, these parts often come with technical support, ensuring any questions or concerns are addressed efficiently.

Aftermarket Parts: Pros and Cons

When considering vehicle maintenance or upgrades, many opt for third-party components instead of original options. These alternatives can offer both benefits and drawbacks, which should be carefully weighed before making a decision.

Advantages of Using Aftermarket Components

- Cost Savings: Non-original components often come at a lower price, making them a more affordable option.

- Variety of Choices: There is a wide range of products available, giving consumers the flexibility to choose the best fit for their needs.

- Improved Performance: Some third-party parts are designed to enhance specific aspects of a vehicle’s functionality.

Disadvantages to Consider

- Quality Variations: The quality of non-original components can vary greatly, and some might not meet the standards of original options.

- Compatibility Issues: There may be challenges in finding parts that perfectly fit the vehicle.

- Potential Warranty Void: Using third-party products can sometimes void the manufacturer’s warranty, leading to unexpected costs.

Tools Needed for Aveo Repairs

When it comes to maintaining or fixing your vehicle, having the right equipment is essential for completing tasks efficiently and safely. Whether you’re dealing with minor adjustments or more complex mechanical fixes, using the correct set of tools can significantly impact the quality of the work and ensure long-term reliability.

Basic Tools for General Repairs

For most standard repairs, you’ll require a combination of hand tools that cover basic mechanical needs. Wrenches, screwdrivers, and pliers are among the essentials to handle various nuts, bolts, and fasteners. It’s also advisable to have a torque wrench for ensuring accurate tightening, especially on critical components.

Specialized Equipment for Specific Tasks

For more advanced maintenance, specialized tools may be necessary. Items like a socket set with deep sockets, a brake caliper tool, or a serpentine belt tool can help address particular areas of the vehicle that require extra attention. These specialized items ensure that you can work on different parts of the system with precision and

Safety Tips for DIY Maintenance

Performing your own vehicle maintenance can be a rewarding experience, but it’s important to prioritize safety at all times. Whether you’re working under the hood or dealing with mechanical components, following the right precautions can prevent accidents and ensure smooth repair processes.

Essential Safety Gear

- Always wear protective gloves to shield your hands from sharp edges and harmful chemicals.

- Safety goggles are crucial to prevent debris or liquids from entering your eyes.

- Use sturdy, non-slip footwear to avoid slipping in oily or wet conditions.

Working Environment

- Ensure the workspace is well-lit to clearly see all components you’re working on.

- Keep your area clean and organized to avoid tripping over tools or parts.

- Make sure the vehicle is on a stable, level surface before starting any work, using proper supports like jack stands.

Handling Tools Safely

- Use the correct tool for each task to avoid damaging parts or injuring yourself.

- Regularly inspect your tools for wear and tear, and replace a

Where to Find Replacement Parts

When it’s time to replace components for your vehicle, finding the right ones can be a crucial task. Whether it’s for maintenance or addressing a specific issue, knowing where to source these items is essential to keeping your car in top condition.

- Authorized retailers – These vendors often offer genuine components directly from manufacturers.

- Online marketplaces – A wide range of options is available, from new to pre-owned, often with reviews to guide your selection.

- Auto salvage yards – For those seeking more affordable solutions, salvage yards can provide well-preserved, second-hand options.

- Local mechanics – Experienced professionals may have access to trusted suppliers and can help you find the appropriate items for your vehicle.

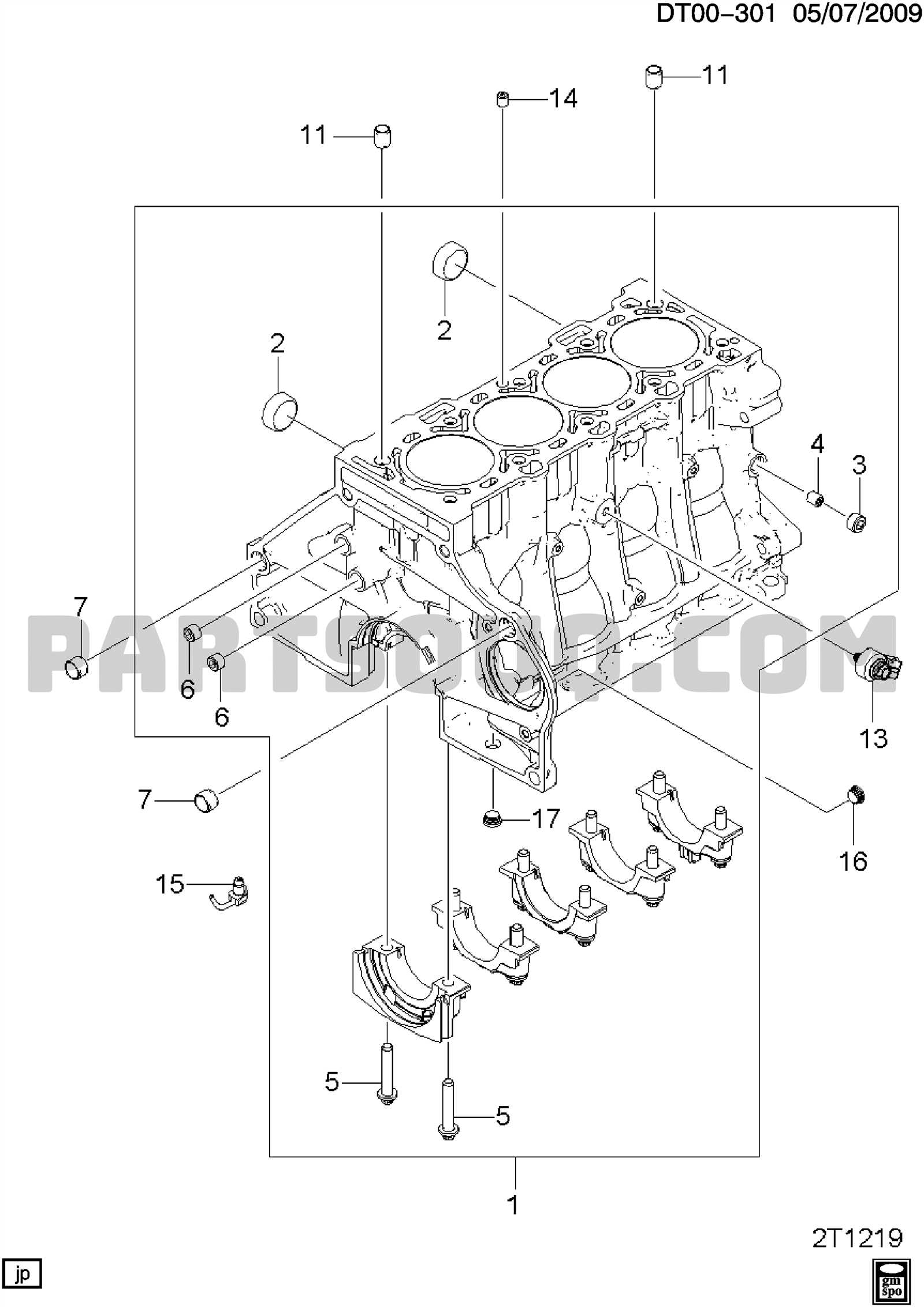

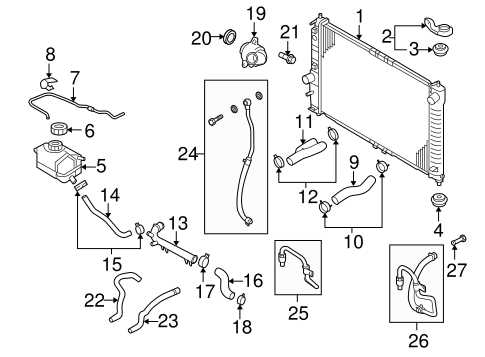

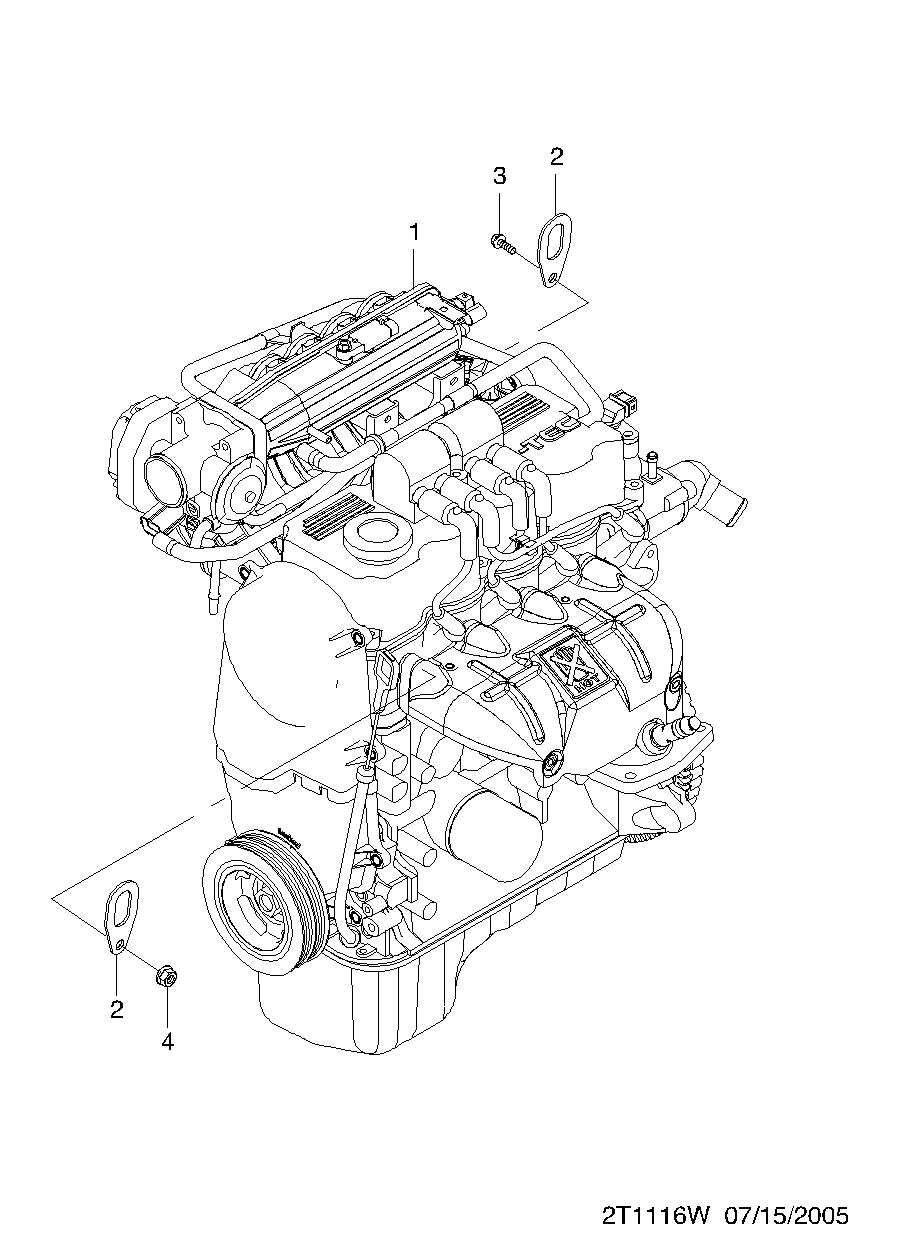

Understanding the Aveo Engine Layout

The design and arrangement of an engine play a crucial role in how efficiently a vehicle performs. A well-organized engine layout allows for better maintenance, easier access to key components, and improved functionality. It’s essential to have a clear understanding of the placement of major components such as the cylinder head, intake manifold, and other integral parts of the motor system to ensure proper operation and servicing.

Key Components Overview

The primary elements of the engine include the combustion chamber, valves, and fuel delivery systems, each contributing to the overall power generation and smooth running of the motor. Understanding the interaction between these parts is critical for diagnosing issues and optimizing performance.

Efficient Maintenance

Knowing how different parts of the engine are positioned helps in performing routine checks and repairs more effectively. Familiarity with the layout can significantly reduce the time required for identifying potential problems and conducting necessary maintenance tasks.