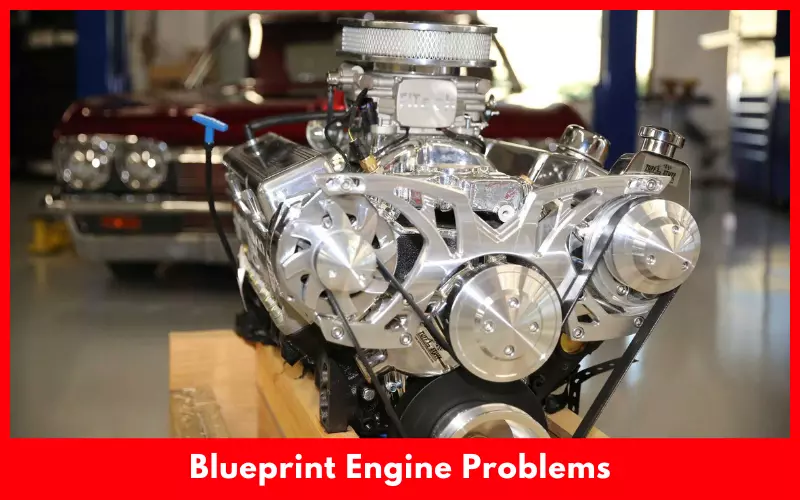

Comprehensive Guide to the Blueprint Chevy 350 Engine Diagram and Parts

The intricate world of automotive mechanics often revolves around a specific configuration that has captivated enthusiasts for decades. A thorough exploration of this robust configuration reveals the essential elements that contribute to its performance and reliability. By gaining insights into these components, one can appreciate the engineering marvel that lies beneath the hood.

In the realm of performance vehicles, the design and arrangement of various mechanical parts play a crucial role in achieving optimal functionality. Each element, from the core assembly to the auxiliary systems, has a distinct purpose and interacts harmoniously with others. Understanding these relationships is key for anyone looking to enhance their vehicle’s capabilities.

Whether you’re an avid hobbyist or a professional mechanic, having a comprehensive grasp of these components enables informed decisions regarding upgrades and maintenance. This knowledge ultimately leads to better performance and longevity, ensuring that your vehicle remains a thrilling driving experience.

Understanding the Chevy 350 Engine

The powertrain commonly found in many classic and modern vehicles is renowned for its reliability and performance. This assembly has become a staple in automotive culture, appreciated for its robust design and versatility.

Key features include a well-engineered configuration that balances power output with efficiency. Its architecture allows for easy customization, making it a favorite among enthusiasts seeking to enhance performance.

Moreover, understanding its inner workings can provide insights into maintenance and upgrades. By exploring the essential components and their functions, one can appreciate the craftsmanship that contributes to its enduring legacy.

Key Components of the Engine

The intricacies of an internal combustion unit are defined by a variety of essential elements that work in harmony to ensure optimal performance. Understanding these components provides insight into how power is generated and efficiency is maintained within the system.

Core Elements

Among the principal components, several play critical roles in the overall functionality. Each part contributes uniquely to the process of converting fuel into motion.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports other components. |

| Pistons | Convert combustion energy into mechanical work. |

| Crankshaft | Transforms linear motion of pistons into rotational force. |

| Camshaft | Regulates the timing of valve openings and closings. |

| Valves | Control the intake of air and the exhaust of gases. |

Supporting Elements

In addition to the main constituents, there are auxiliary elements that enhance efficiency and reliability. Together, they form a cohesive system that maximizes performance.

Importance of the Blueprint Diagram

The significance of a well-crafted schematic cannot be overstated in the realm of automotive design and assembly. Such a visual representation serves as a crucial reference point, ensuring that all components are correctly understood and effectively integrated. It provides clarity, minimizes errors, and enhances overall efficiency during both the building and maintenance processes.

Enhancing Accuracy

Having a detailed outline allows for precision in both the assembly and disassembly phases. When every element is clearly defined, the likelihood of misplacement or incorrect fitting is greatly reduced. This meticulous attention to detail is vital for achieving optimal performance and reliability.

Facilitating Communication

Visual guides play a pivotal role in bridging communication gaps among team members. When individuals collaborate on a project, a clear schematic fosters better understanding and coordination. It ensures that everyone is on the same page, thereby streamlining workflows and enhancing teamwork.

How to Read Engine Schematics

Understanding mechanical layouts is essential for anyone involved in automotive repair or modification. These layouts provide a visual representation of how components interact and function together.

Here are key aspects to consider when interpreting these layouts:

- Symbols: Familiarize yourself with common symbols representing different components such as pistons, valves, and fuel systems.

- Connections: Pay attention to lines indicating connections, showing how various elements are linked.

- Flow Direction: Understand the flow of fluids or gases, often depicted with arrows, to grasp operational sequences.

- Component Labels: Look for labels that provide information on each part, including specifications and function.

By mastering these elements, you’ll enhance your ability to troubleshoot issues and optimize performance effectively.

Common Parts and Their Functions

This section highlights essential components found in automotive assemblies, focusing on their roles and interconnections. Understanding these elements is crucial for maintenance and performance optimization.

- Cylinder Block: The main structure housing the cylinders and supporting other components.

- Pistons: Move up and down within the cylinders, converting fuel into mechanical energy.

- Cylinder Head: Covers the top of the cylinders, containing valves and spark plugs.

- Crankshaft: Converts linear motion of pistons into rotational force.

- Camshaft: Controls the timing of valve openings and closings.

Each component plays a pivotal role in the overall functionality, ensuring efficient operation and power delivery.

Assembly Process of Chevy 350

The assembly of a classic American power unit requires precision, attention to detail, and a systematic approach. Each component plays a critical role in ensuring optimal performance and longevity. Understanding the sequence of assembly can greatly enhance both the experience and the results of the build.

Preparation and Organization

Before beginning the assembly, it is essential to gather all necessary components and tools. Organizing parts systematically can prevent confusion and streamline the process. Create a clean workspace and lay out each item, including fasteners and gaskets, for easy access during assembly.

Step-by-Step Assembly

The assembly begins with the foundation, typically the block. Once the block is prepared, the crankshaft is installed, followed by the connecting rods and pistons. Careful attention to torque specifications is crucial at this stage to ensure proper function. Next, the cylinder heads are affixed, allowing for the installation of valves and springs. Completing the assembly involves attaching components such as the intake manifold, oil pan, and various accessories, culminating in a thorough inspection to confirm that everything is secure and aligned.

Performance Upgrades for Chevy 350

Enhancing the power and efficiency of your vehicle can significantly improve your driving experience. By focusing on specific modifications, you can achieve a noticeable boost in performance and responsiveness. Below are some key upgrades to consider for maximizing output.

Key Modifications

- High-Performance Intake System

- Upgraded Exhaust Components

- Enhanced Fuel Delivery System

- Improved Ignition Timing

Benefits of Upgrades

- Increased horsepower and torque

- Better fuel efficiency

- Improved throttle response

- Enhanced overall driving dynamics

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of any mechanical system. Regular attention to key components not only ensures optimal performance but also prevents costly repairs down the line.

1. Routine Inspections: Regularly examine all critical elements to identify wear and tear early. This proactive approach can save time and resources.

2. Quality Fluids: Use high-grade lubricants and coolants. They play a crucial role in reducing friction and managing temperature, extending operational life.

3. Cleanliness is Key: Keep the system free from debris and contaminants. Dirt can lead to premature failure of vital components.

4. Follow Manufacturer Guidelines: Adhere to specified maintenance schedules and procedures for the best results.

5. Monitor Performance: Stay alert to any changes in functionality. Unusual sounds or vibrations may indicate underlying issues that need addressing.

6. Invest in Quality Parts: When replacements are necessary, choose reliable, high-quality alternatives to ensure durability and performance.

Identifying Genuine Parts vs. Counterfeits

In the world of automotive components, distinguishing authentic items from imitations is crucial for maintaining performance and safety. Counterfeit products can compromise functionality and lead to costly repairs. Understanding key indicators of originality can help enthusiasts make informed decisions and protect their investments.

Key Characteristics of Authentic Components

Genuine items typically exhibit superior craftsmanship and attention to detail. Look for precise measurements, high-quality materials, and manufacturer branding. Additionally, reputable suppliers often provide documentation that certifies the authenticity of their offerings. Packaging can also be a telltale sign; authentic products usually come in branded boxes with clear labeling and safety information.

Recognizing Counterfeit Products

Counterfeit items often lack the same level of quality and consistency. Signs of imitation can include poor fit, inferior materials, and missing manufacturer logos. Price can also be a significant indicator; if a deal seems too good to be true, it often is. Always purchase from trusted sources and verify the legitimacy of the product to ensure you receive what you expect.

Typical Issues with Chevy 350 Engines

When it comes to certain popular powertrains, enthusiasts and mechanics often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems can aid in timely repairs and maintenance, ensuring longevity and optimal function.

Common Problems

Many owners report issues that arise due to wear and tear, design flaws, or improper maintenance. These problems can manifest in various ways, leading to decreased performance or even complete failure if not addressed promptly.

| Issue | Description | Potential Solution |

|---|---|---|

| Oil Leaks | Leaks often occur due to deteriorating seals or gaskets. | Regular inspection and replacement of seals can prevent leaks. |

| Overheating | Caused by a malfunctioning cooling system or low coolant levels. | Check coolant levels and inspect the radiator and hoses. |

| Fuel System Issues | Clogged fuel filters or failing injectors can lead to poor performance. | Routine cleaning and replacement of filters can help maintain efficiency. |

| Ignition Problems | Poor spark can result from worn-out spark plugs or faulty wiring. | Regularly replacing spark plugs and checking wiring is essential. |

Preventive Measures

To mitigate these common challenges, adhering to a strict maintenance schedule is vital. Regular oil changes, coolant checks, and component inspections can significantly reduce the likelihood of serious issues arising.

Comparing Different Engine Generations

The evolution of internal combustion power units over the years showcases significant advancements in technology, design, and performance. Each iteration introduces enhancements that cater to shifting demands in efficiency, power output, and emissions standards.

First Generation: The initial models laid the groundwork for what would become a staple in automotive engineering. These configurations were relatively simple, prioritizing basic functionality over intricate features.

Second Generation: As innovation progressed, the following iterations saw the integration of improved materials and more sophisticated fuel delivery systems. This generation marked a shift towards better reliability and increased horsepower.

Third Generation: Modern advancements have revolutionized performance, with a focus on electronic control and precision engineering. The latest models not only emphasize power but also enhance fuel economy and reduce environmental impact.

In conclusion, examining these various eras highlights the ultimate journey of development, revealing how each stage contributes to the performance and sustainability of today’s automotive landscape.

Resources for Chevy 350 Enthusiasts

For those passionate about automotive performance, finding quality information and tools is essential. This section aims to provide valuable resources to support enthusiasts in their projects and deepen their understanding.

- Online Forums: Communities where enthusiasts share experiences, troubleshoot issues, and exchange advice.

- Technical Manuals: Comprehensive guides detailing specifications, assembly, and maintenance.

- Parts Suppliers: Websites specializing in aftermarket components and upgrades.

- Video Tutorials: Platforms offering step-by-step guides for various modifications and repairs.

Engaging with these resources can enhance knowledge and improve skills, ultimately benefiting any project.

DIY Projects for Engine Improvement

Enhancing performance and efficiency can be an exciting journey for automotive enthusiasts. Engaging in hands-on projects allows for personal customization and deeper understanding of the mechanics involved.

- Upgrade Air Intake: Replacing the factory air system with a high-flow variant can significantly improve airflow.

- Exhaust System Modifications: Installing a performance exhaust can enhance sound and power delivery.

- Tuning Software: Utilizing software to adjust fuel maps and ignition timing can lead to optimal performance.

- Cooling System Enhancements: Upgrading radiators or fans can help maintain ideal operating temperatures during intense usage.

These projects not only increase the overall effectiveness of your vehicle but also provide a rewarding experience as you delve into the mechanics behind each enhancement.