Comprehensive Guide to Honda Civic 2007 Engine Parts Diagram

In the realm of automotive maintenance, a clear grasp of the fundamental elements that drive performance is essential. This knowledge not only aids in effective upkeep but also enhances the driving experience, ensuring longevity and reliability.

Delving into the intricate layout of these crucial components reveals their interconnectedness and ultimate importance in the vehicle’s operation. By examining each segment, enthusiasts and owners alike can gain insights into potential improvements and necessary repairs.

With a focus on visual representation, one can better appreciate how each piece fits into the larger system. This exploration serves as a guide for those eager to enhance their understanding and address any issues with confidence.

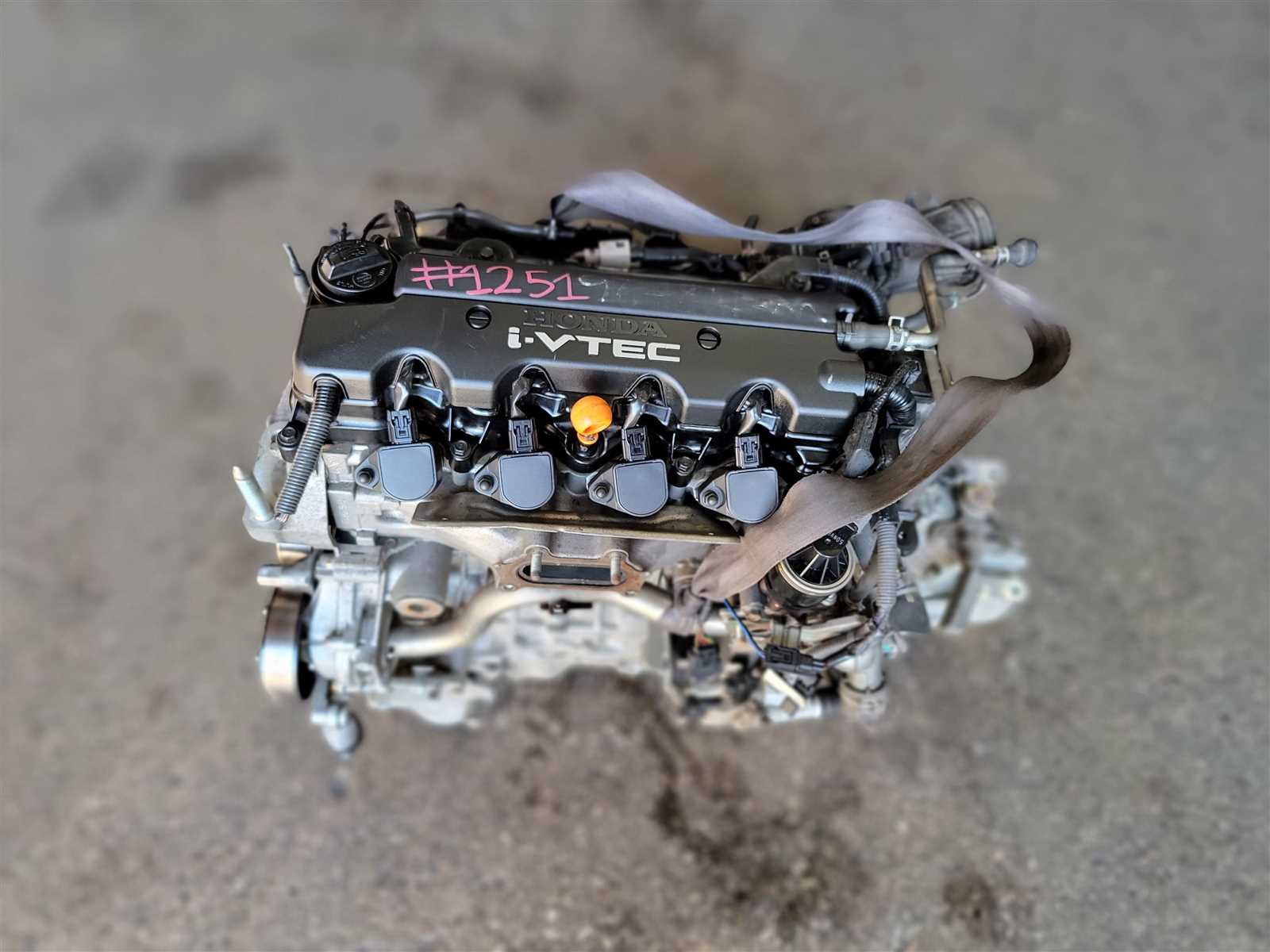

Understanding the Honda Civic 2007 Engine

This section aims to explore the intricate components that contribute to the performance and efficiency of a specific vehicle’s power source. By examining each element, we can gain insights into how they interact to create a reliable driving experience.

Key Components

Each element serves a unique function, from the combustion chamber to the exhaust system. Understanding their roles can enhance appreciation for automotive engineering.

Performance Insights

Evaluating the interplay of these components allows enthusiasts to delve into aspects like fuel efficiency and power output. Knowledge of these systems leads to informed decisions regarding maintenance and upgrades.

Key Components of the Engine

This section explores essential elements that contribute to the functionality of a motor. Understanding these components can provide insight into how power is generated and maintained throughout the vehicle’s operation.

Primary Elements

- Cylinder Block

- Pistons

- Cylinder Head

- Crankshaft

- Camshaft

Supporting Systems

- Fuel Delivery System

- Ignition System

- Cooling Mechanism

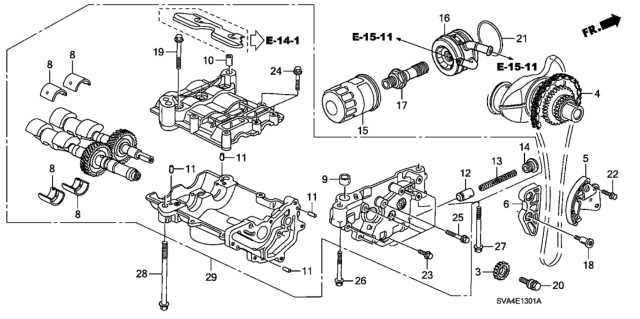

- Lubrication System

Each of these components plays a crucial role in ensuring optimal performance and longevity of the machinery.

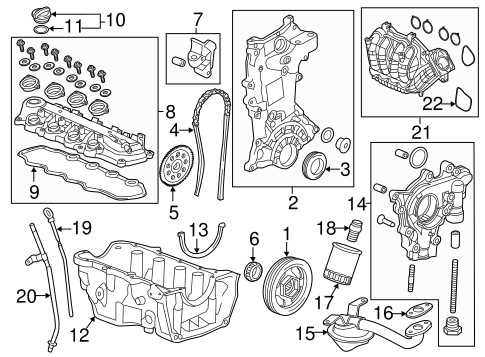

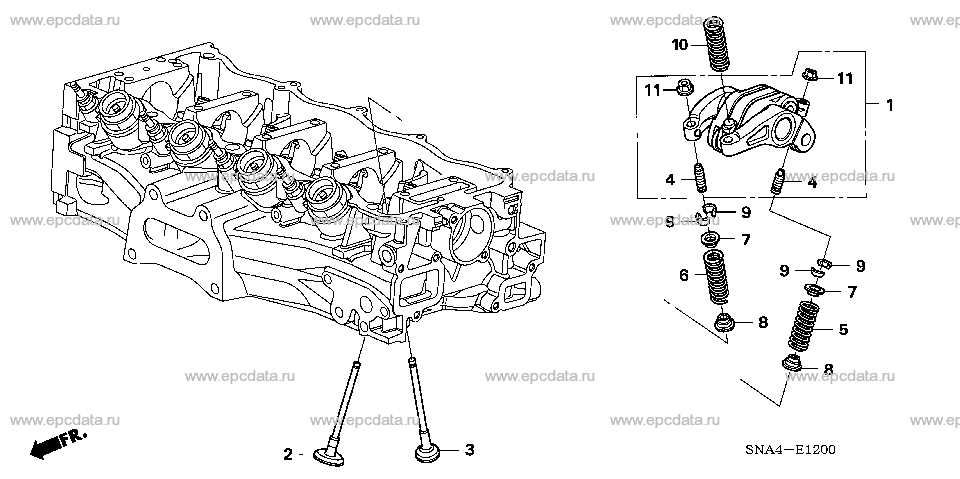

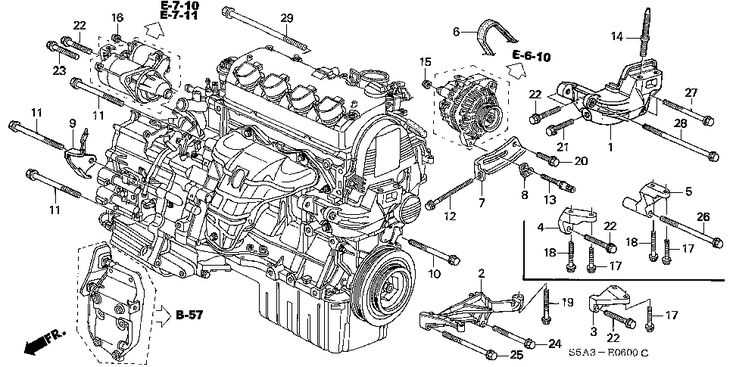

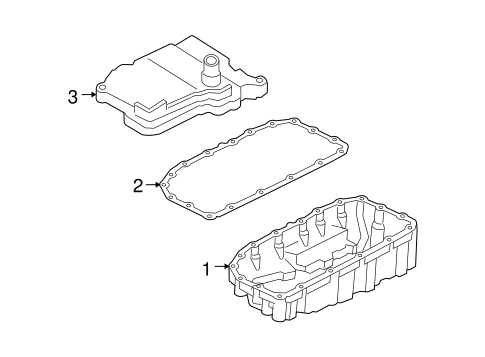

Visual Representation of Engine Parts

The intricacies of automotive mechanisms can often be better understood through graphical illustrations that capture the relationships and functions of various components. Such visual aids serve as crucial tools for enthusiasts and technicians alike, enhancing comprehension and facilitating maintenance or upgrades.

Detailed illustrations provide insight into the assembly and layout of crucial elements, showcasing how each component interacts within the larger framework. This approach not only aids in identifying individual sections but also highlights the significance of their collaborative roles in overall performance.

Moreover, high-quality representations can assist in troubleshooting by pinpointing areas of concern, making it easier to visualize potential issues. By using these graphical tools, one can delve deeper into the mechanical design and ultimately enhance their knowledge and skills.

Function of Each Engine Part

This section explores the vital roles played by various components within a motor, highlighting their significance in the overall operation of the vehicle.

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion into rotational force, driving the vehicle. |

| Pistons | Move within cylinders, compressing fuel-air mixture for combustion. |

| Cylinders | House the pistons and facilitate the combustion process. |

| Camshaft | Controls the opening and closing of intake and exhaust valves. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber. |

| Spark Plug | Ignites the fuel-air mixture, initiating the combustion process. |

| Exhaust Manifold | Collects and directs exhaust gases away from the engine. |

| Intake Manifold | Distributes the air-fuel mixture to each cylinder evenly. |

Common Issues with Engine Components

Understanding typical problems associated with vital mechanical elements is crucial for maintaining optimal performance. Various components can experience wear and tear, leading to decreased efficiency and potential failures.

- Overheating: Insufficient coolant flow or a faulty thermostat can cause excessive heat buildup.

- Leakage: Gaskets and seals may deteriorate, resulting in fluid leaks that can affect overall function.

- Wear: Piston rings and bearings can wear down, leading to poor compression and increased oil consumption.

- Noise: Unusual sounds may indicate issues with timing belts or tensioners, signaling the need for inspection.

- Vibration: Excessive shaking can be a sign of unbalanced components or misalignment.

Regular checks and timely interventions can prevent minor issues from escalating into major repairs.

Maintenance Tips for Engine Longevity

To ensure optimal performance and extend the lifespan of your vehicle’s powertrain, regular care and attention are essential. By adopting simple yet effective practices, you can mitigate wear and enhance reliability over time.

Routine Checks

Consistent inspections play a critical role in identifying potential issues before they escalate. Monitoring fluids, filters, and belts helps maintain functionality and safety.

Quality Components

Utilizing high-quality materials for replacements and upgrades can significantly impact durability. Investing in reliable parts promotes better operation and reduces the likelihood of failure.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces friction and prevents overheating |

| Air Filter Replacement | Every 15,000 miles | Enhances airflow and efficiency |

| Coolant Level Check | Monthly | Prevents overheating and protects components |

| Belts Inspection | Every 30,000 miles | Prevents breakdowns and costly repairs |

How to Identify Engine Problems

Recognizing issues within the mechanical system of a vehicle is crucial for maintaining its performance and longevity. Various signs can indicate malfunctions, ranging from unusual noises to changes in operational behavior. Early detection not only helps in avoiding extensive repairs but also ensures a smoother driving experience.

Common Symptoms to Watch For

Several indicators can suggest that something is amiss. Observing these symptoms can guide you toward identifying potential complications:

| Symptom | Possible Issue |

|---|---|

| Unusual Noises | Worn components or insufficient lubrication |

| Check Engine Light | Sensor malfunction or emissions problems |

| Decreased Performance | Fuel delivery issues or air intake problems |

| Excessive Smoke | Oil leakage or coolant burning |

| Overheating | Coolant leaks or thermostat failure |

Steps for Further Diagnosis

Upon noticing any of the symptoms, a systematic approach to further analysis is essential. Start by inspecting fluid levels, checking for leaks, and listening for specific sounds while the system is in operation. Utilizing diagnostic tools can also provide valuable insights into the underlying issues.

Replacement Parts for Honda Civic

Maintaining optimal performance of your vehicle often requires the timely replacement of various components. Understanding which elements need attention can enhance longevity and efficiency. This section explores essential alternatives available for various sections of your ride, ensuring you can keep it in peak condition.

Key Components to Consider

When replacing essential elements, focus on parts that directly affect performance and safety. Regular inspections can help identify wear and tear, leading to informed decisions about replacements.

Available Alternatives

| Component | Alternative Options |

|---|---|

| Battery | AGM, Lithium-Ion |

| Brake Pads | Semi-Metallic, Ceramic |

| Air Filter | Reusable, High-Flow |

| Alternator | Remanufactured, High-Output |

Engine Specifications and Performance Metrics

This section delves into the essential characteristics and operational capabilities of the power unit, providing a comprehensive overview of its design and efficiency. Understanding these attributes is crucial for enthusiasts and professionals alike, as they significantly impact the vehicle’s overall performance and reliability.

Displacement: The total volume of the combustion chambers, measured in liters, is a critical factor in determining the potential power output. A larger displacement often correlates with increased torque and horsepower.

Cylinder Configuration: The arrangement of the cylinders plays a vital role in the smoothness of operation and the balance of the system. Inline or V-configurations each have their advantages, influencing the dynamics of the drive.

Power Output: Measured in horsepower, this metric indicates the engine’s ability to perform under various conditions. Higher values typically result in improved acceleration and responsiveness.

Torque: The twisting force generated, measured in pound-feet or Newton-meters, is crucial for understanding the vehicle’s pulling capability and overall performance, particularly during acceleration.

Fuel Efficiency: Expressed in miles per gallon (MPG) or liters per 100 kilometers, this metric reflects how effectively the power unit utilizes fuel, impacting both running costs and environmental considerations.

Emission Standards: Compliance with regulations for harmful exhaust gases is essential for modern vehicles. Meeting these standards often requires advanced technologies and design strategies.

By examining these specifications and performance metrics, one can gain valuable insights into the operation and potential of the power unit, leading to more informed decisions regarding maintenance, upgrades, and driving experiences.

Tools Needed for Engine Repair

Proper maintenance and repair of a vehicle’s internal components require a well-equipped workspace. Having the right instruments at your disposal not only ensures efficiency but also enhances the quality of the work performed. Below is an overview of essential tools commonly utilized in mechanical overhauls.

Essential Hand Tools

Hand tools form the backbone of any repair job. These instruments allow for precision and versatility in various tasks. Here are some key tools you will need:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Sockets | To provide leverage and grip on fasteners in tight spaces. |

| Screwdrivers | For securing and removing screws. |

| Pliers | Useful for gripping and manipulating components. |

Power Tools

In addition to hand tools, power instruments can significantly expedite the repair process. These devices are designed for heavy-duty tasks, making them invaluable for serious maintenance projects.

| Tool | Purpose |

|---|---|

| Impact Wrench | For quickly removing and fastening bolts. |

| Drill | To create holes and drive screws efficiently. |

| Angle Grinder | Used for cutting and shaping metal parts. |

| Torque Wrench | To ensure bolts are tightened to the manufacturer’s specifications. |

Aftermarket vs. OEM Parts

When it comes to vehicle maintenance and repair, choosing between original equipment manufacturer (OEM) components and those produced by third-party manufacturers can significantly impact performance and longevity. Each option presents its own set of advantages and considerations, influencing both cost and quality.

OEM components are crafted by the same manufacturer that produced the original items for the vehicle. This ensures a precise fit and adherence to factory specifications, often resulting in superior reliability. However, they typically come at a higher price point, which may deter some vehicle owners.

On the other hand, aftermarket alternatives offer a wider range of pricing and may provide innovative solutions that enhance functionality. While these products can be more affordable and readily available, their quality can vary significantly. It’s crucial to research and select reputable brands to avoid potential issues with compatibility and durability.

Ultimately, the choice between these two types of components should be guided by individual needs, budget constraints, and long-term vehicle goals. Evaluating the specific circumstances surrounding each repair will help ensure an informed decision.

Resources for Further Research

When delving deeper into the mechanics of automotive components, a wealth of information is available for enthusiasts and professionals alike. Understanding the intricacies of vehicle systems requires access to reliable sources that offer detailed insights and comprehensive guides.

- Online Forums: Communities such as Reddit and dedicated automotive forums can provide valuable peer-to-peer advice and troubleshooting tips.

- Manufacturer Manuals: Official service manuals from manufacturers often include in-depth specifications and maintenance procedures.

- Educational Websites: Websites focused on automotive education offer articles, videos, and tutorials covering various aspects of vehicle mechanics.

- Technical Books: There are numerous publications that explore the design and function of vehicle systems, perfect for in-depth study.

- YouTube Channels: Many automotive professionals share practical tips and how-to videos that can aid in understanding complex concepts.

Utilizing these resources will enhance knowledge and provide clarity on various vehicle components, promoting better maintenance and repair practices.