Understanding the Parts Diagram of a Craftsman 42 Inch Mower Deck

Maintaining your outdoor machinery is essential for ensuring optimal performance and longevity. A thorough grasp of the individual elements that make up your equipment can significantly enhance your maintenance routine. This section aims to provide a comprehensive overview of the essential components involved in a specific type of lawn care apparatus.

By exploring the intricate relationships between various segments, you can identify potential areas for improvement and efficient repairs. This knowledge is particularly beneficial for enthusiasts who seek to delve deeper into the mechanics of their tools. Understanding the ultimate functions of each element empowers users to make informed decisions regarding upkeep and enhancements.

Whether you are a seasoned professional or a novice in the realm of gardening, familiarizing yourself with these components is crucial. The following illustrations will guide you through the critical features and their roles in ensuring your equipment runs smoothly.

Understanding Craftsman Mower Deck Components

This section delves into the various elements that make up the cutting assembly of lawn care machinery. By grasping the functions and interconnections of these components, users can enhance performance and ensure longevity through proper maintenance and timely replacements.

Key Elements of the Cutting Assembly

The cutting assembly is composed of several crucial elements that work together to achieve efficient grass trimming. Understanding each part’s role is vital for effective upkeep.

| Component | Description |

|---|---|

| Blades | These sharp implements rotate to cut grass at desired heights. |

| Spindles | These support and rotate the blades, ensuring stable operation. |

| Lift Mechanism | This system raises and lowers the assembly for adjustable cutting heights. |

| Shell | The outer casing protects internal components while directing clippings. |

Maintenance Tips

Regular maintenance of these components can prevent costly repairs and prolong the lifespan of the machinery. Keep blades sharp, check spindles for wear, and inspect the lift mechanism for proper functionality to ensure optimal performance.

Importance of Mower Deck Maintenance

Proper upkeep of your cutting equipment is essential for ensuring optimal performance and longevity. Regular attention to this component not only enhances efficiency but also contributes to a healthier landscape. Neglecting maintenance can lead to diminished results and increased wear over time.

Regular inspections help identify wear and tear, allowing for timely replacements that prevent further damage. By keeping components clean and sharp, users can achieve a more precise cut, which is vital for the aesthetics of your lawn.

Additionally, routine care can improve safety by reducing the risk of malfunction during operation. Ultimately, investing time in maintenance yields significant benefits, including improved reliability and reduced long-term costs.

Common Issues with 42-Inch Mower Deck

When it comes to lawn maintenance equipment, various challenges can arise that hinder performance and efficiency. Understanding these prevalent problems can significantly enhance the user experience and extend the life of the machine. Identifying issues early can lead to more effective solutions and ultimately a healthier lawn.

Uneven Cutting

One of the most frequent complaints is uneven cutting, which can result from dull blades or improper leveling. Ensuring that blades are sharp and that the cutting platform is adjusted correctly is essential for achieving a uniform finish.

Clogging

Another common issue is clogging, often caused by wet grass or debris buildup. Regular cleaning and maintenance can help mitigate this problem, ensuring smoother operation and better results. Neglecting this aspect can lead to reduced performance and increased wear.

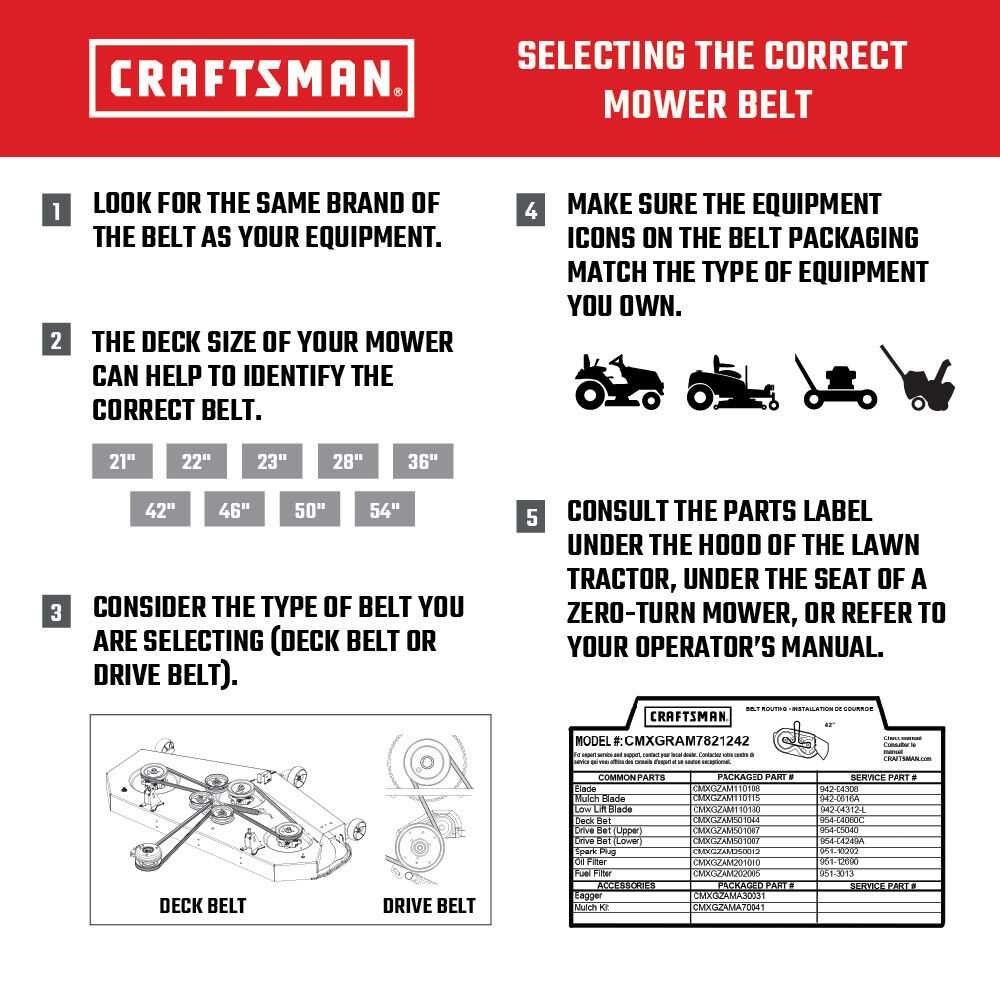

Parts Identification for Craftsman Models

Understanding the components of lawn care equipment is essential for effective maintenance and repair. Proper identification of each element not only aids in troubleshooting but also ensures optimal performance. This section aims to clarify the various components associated with specific models, guiding users in recognizing and sourcing the right elements for their machines.

For effective identification, it is crucial to consult the model number and serial information typically located on the equipment. This data assists in pinpointing compatible components and avoids the pitfalls of mismatched parts. Familiarity with common terminologies related to each element will enhance the user’s ability to communicate needs accurately when seeking assistance or purchasing replacements.

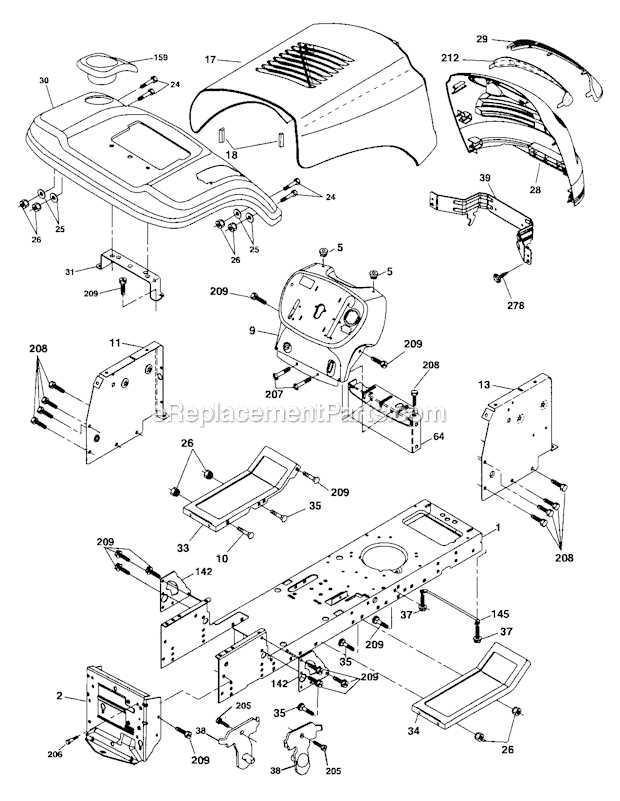

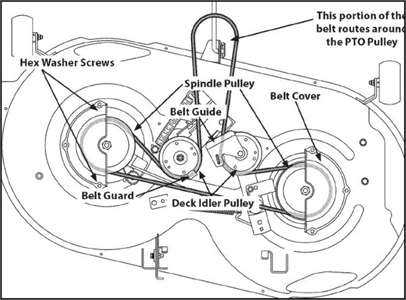

Moreover, visual references, such as schematics or exploded views, can be invaluable tools. They provide a clear overview of the arrangement and interaction between components, facilitating easier identification. Engaging with these resources will empower users to perform maintenance tasks with confidence, ensuring longevity and reliability in their outdoor equipment.

Tools Needed for Mower Repairs

When it comes to maintaining and fixing outdoor cutting equipment, having the right tools is essential for effective repairs and smooth operation. A well-equipped workspace can save time and ensure that every task is completed with precision. Below is a list of essential instruments you may need to tackle various repair tasks efficiently.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Wrench Set | Ideal for adjusting components and securing parts. |

| Screwdriver Set | For removing and fastening screws in various sizes. |

| Pliers | Useful for gripping and manipulating small parts. |

| Oil Can | To lubricate moving parts for optimal performance. |

| Safety Goggles | To protect eyes during repair work. |

| Work Gloves | To ensure safety and grip while handling tools. |

| Measuring Tape | For accurate measurements of components. |

Step-by-Step Mower Deck Disassembly

Disassembling the cutting apparatus can seem daunting, but with a systematic approach, it becomes manageable. This guide provides a structured method to break down the components, ensuring each part is carefully handled and documented for reassembly.

Begin by gathering the necessary tools, including wrenches, screwdrivers, and safety equipment. Disconnect the power source to ensure safety before proceeding. Carefully remove the outer casing and take note of the arrangement of each element.

Next, detach the blades by unscrewing the fasteners. Keep track of the order and orientation of the blades for easier reinstallation. Continue by disconnecting any belts or pulleys, ensuring that you record their placement for future reference.

Once the main components are removed, inspect the internal structure for wear and tear. Cleaning each piece will help maintain optimal performance once reassembled. Follow these steps methodically to ensure a successful disassembly and easy reassembly.

Replacement Parts Availability and Sources

Finding suitable components for your equipment is crucial for maintaining its performance and longevity. Understanding where to source these essentials can save time and ensure you have access to quality replacements. Various outlets provide a range of options, from authorized dealers to online retailers, catering to different needs and budgets.

Local Dealers are often the first stop for many users. They typically stock a variety of original components and can offer expert advice on selection and installation. Building a relationship with your local supplier can also lead to personalized service and special offers.

Online Retailers provide convenience and often a broader selection. Websites dedicated to outdoor equipment frequently feature user reviews, helping you assess the quality and fit of the items. Additionally, many online platforms offer competitive pricing, making them an attractive option.

Aftermarket Suppliers are another viable source. These companies produce compatible components that can be more affordable than original items. However, it’s essential to research the manufacturer’s reputation to ensure that you receive reliable and durable products.

Utilizing forums and community groups can also yield recommendations for sourcing components. Engaging with fellow users can provide insights into the best places to shop and the most reliable brands, enhancing your overall experience.

Ultimately, ensuring you have access to the right components involves exploring multiple sources and weighing the benefits of each. With the right information, you can keep your equipment in excellent condition for years to come.

How to Read Parts Diagrams Effectively

Understanding visual representations of components is essential for efficient maintenance and repair. By grasping the layout and symbols used, one can quickly identify what is needed and how pieces interact with each other.

Familiarize Yourself with Symbols

Each illustration employs unique icons to denote different elements. Spend time learning these symbols, as they serve as a key to unlocking the diagram’s meaning. Recognizing these symbols can significantly streamline your search for specific items.

Follow the Flow of Assembly

Most visual guides illustrate a logical sequence. Pay attention to how components connect, which will help you understand the overall structure. This holistic view allows for a clearer understanding of the assembly process and simplifies troubleshooting.

Tips for Preventing Deck Damage

Maintaining the integrity of your cutting platform is essential for optimal performance and longevity. By adopting some proactive measures, you can significantly reduce the risk of harm and ensure a smooth operation.

- Regular Cleaning: Remove grass clippings, debris, and dirt after each use to prevent corrosion and buildup.

- Inspect for Wear: Periodically check for signs of wear or damage, including cracks or rust, and address them promptly.

- Proper Storage: Store your equipment in a dry, sheltered area to protect it from the elements and avoid moisture-related issues.

- Adjust Height: Set the cutting height appropriately for your terrain to avoid scalping and excessive strain.

- Avoid Obstacles: Clear your work area of rocks, branches, and other obstacles that could cause impact damage.

Implementing these strategies will help maintain the functionality and extend the life of your equipment, ensuring efficient operation for seasons to come.

Adjusting Mower Deck Height Properly

Achieving the ideal cutting height is crucial for maintaining a healthy lawn. Proper adjustment ensures an even trim while promoting grass health and preventing stress on the blades. By fine-tuning the height, you can enhance the overall appearance and vigor of your yard.

| Height Setting | Grass Type | Recommended Height |

|---|---|---|

| Low | Bermudagrass | 1-2 inches |

| Medium | Fescue | 2-4 inches |

| High | Kentucky Bluegrass | 3-4 inches |

Regularly checking and adjusting the cutting height according to the type of grass and seasonal changes will yield the best results. Always refer to the manufacturer’s guidelines to achieve the ultimate performance.

Worn Parts: Signs to Look For

Identifying deteriorated components is essential for maintaining optimal performance. Recognizing early indicators can save time and prevent further damage to the equipment.

Common Indicators of Wear

- Unusual noises during operation

- Inconsistent cutting performance

- Excessive vibration

- Visible cracks or breaks in components

Inspection Tips

- Regularly check for physical damage.

- Monitor the quality of cuts and adjust as needed.

- Listen for abnormal sounds while in use.

- Evaluate the condition of belts and blades frequently.

Safety Precautions During Maintenance

Maintaining your outdoor equipment is essential for optimal performance and longevity. However, it is crucial to prioritize safety throughout the maintenance process to prevent accidents and injuries. Here are some vital precautions to consider.

- Always disconnect the power source before beginning any maintenance tasks.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Keep work areas clean and free of debris to avoid tripping hazards.

- Use tools correctly and inspect them for any signs of wear or damage.

Additionally, consider the following tips:

- Ensure that the machine is on a stable surface before working on it.

- Never attempt to make repairs while the engine is running.

- Be cautious of sharp blades and edges during maintenance.

- Follow the manufacturer’s instructions for specific maintenance procedures.

By adhering to these safety measures, you can help ensure a secure and effective maintenance experience.

Benefits of Regular Equipment Inspections

Conducting routine assessments of machinery is essential for maintaining optimal performance and longevity. Regular evaluations help identify potential issues before they escalate, ensuring that equipment operates smoothly and efficiently.

Enhanced Safety: Frequent inspections significantly reduce the risk of accidents by addressing hazards promptly. This proactive approach protects both operators and bystanders, fostering a safer working environment.

Cost Efficiency: Identifying and resolving minor problems early can save considerable expenses in repairs and replacements. Investing time in regular checks leads to longer-lasting machinery and minimizes downtime.

Improved Performance: Equipment that receives consistent attention operates at peak efficiency, ensuring tasks are completed effectively. This reliability contributes to overall productivity and satisfaction in operations.

Compliance: Regular inspections ensure adherence to safety regulations and industry standards, protecting organizations from potential legal issues and penalties.

Ultimately, incorporating routine evaluations into maintenance schedules is vital for maximizing both performance and safety in any operational setting.