Comprehensive Guide to Craftsman GCV160 Parts Diagram

In the realm of machinery and tools, a thorough comprehension of individual components is essential for effective maintenance and repair. This knowledge empowers users to identify specific parts that may require attention, ultimately enhancing the longevity and performance of the equipment. A visual representation of these elements can significantly aid in understanding their arrangement and function.

When dealing with mechanical systems, recognizing how each piece fits into the overall structure is crucial. Such insights facilitate troubleshooting and help ensure that any replacements are accurate and timely. Whether you are a hobbyist or a seasoned professional, mastering the layout of the elements involved can streamline your workflow and prevent unnecessary complications.

Moreover, having a clear overview of the construction not only simplifies repairs but also promotes a deeper appreciation of how machines operate. By familiarizing yourself with the various components, you can approach maintenance tasks with confidence and precision, ultimately leading to a more efficient and rewarding experience in handling your equipment.

Understanding Craftsman GCV160 Components

Grasping the intricate details of a small engine is essential for effective maintenance and repair. Each element plays a vital role in the overall functionality, contributing to the efficiency and longevity of the machine. Familiarity with these components not only aids in troubleshooting but also enhances one’s ability to perform regular upkeep.

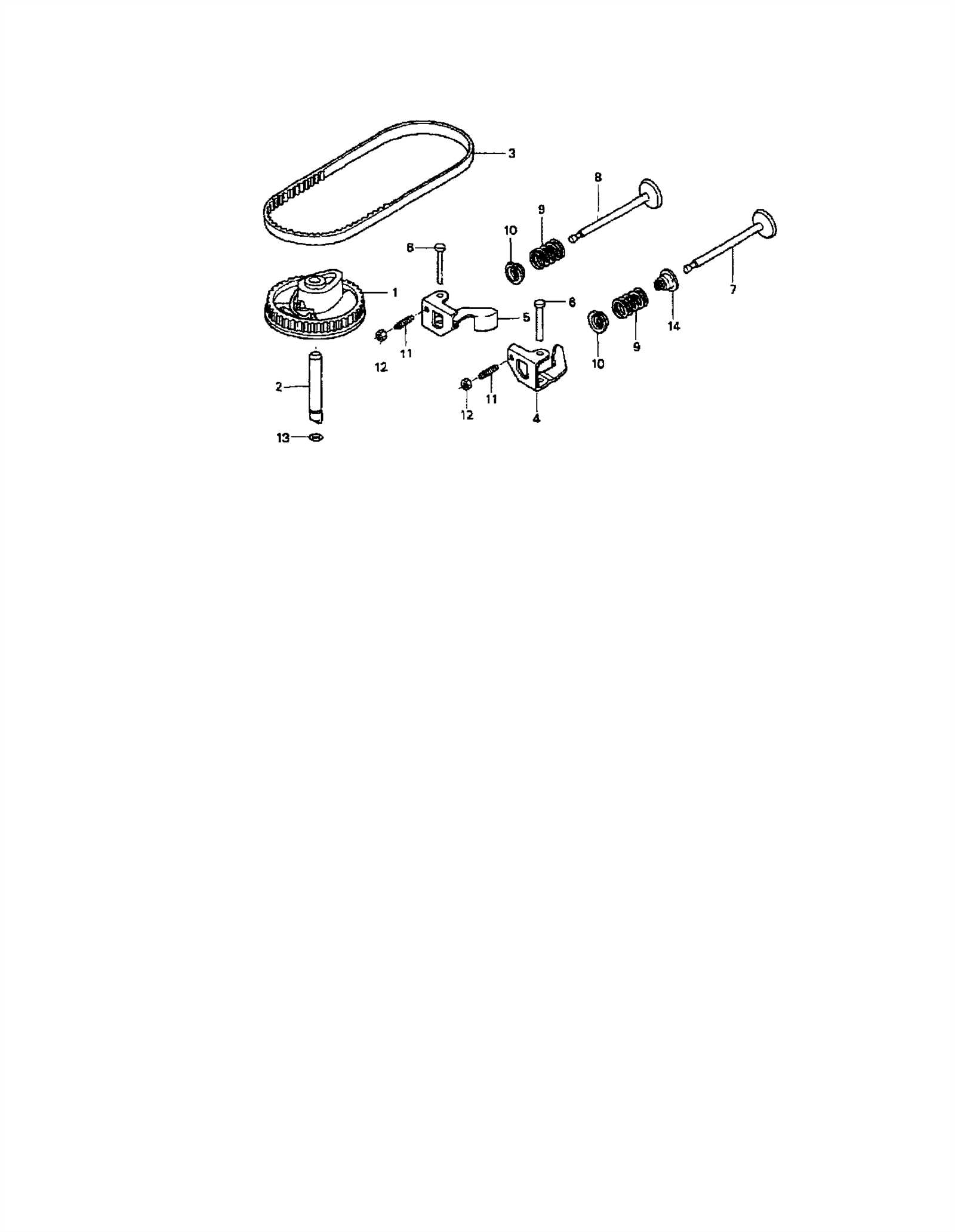

The power unit comprises several key elements, including the fuel system, ignition assembly, and cooling mechanism. Each section is designed to work harmoniously, ensuring optimal performance during operation. Recognizing the purpose and interrelation of these parts can simplify repairs and promote a deeper appreciation for the technology involved.

In addition to mechanical components, attention must be given to the structural framework, which supports the engine and houses various systems. Understanding the layout and accessibility of these features can streamline the repair process and reduce downtime. By becoming well-versed in the specifics, one can confidently address issues as they arise.

Ultimately, a comprehensive understanding of these mechanisms equips users with the knowledge needed to enhance performance, troubleshoot effectively, and extend the life of their equipment. Whether for personal use or professional purposes, mastering these components is invaluable.

Importance of Parts Diagrams

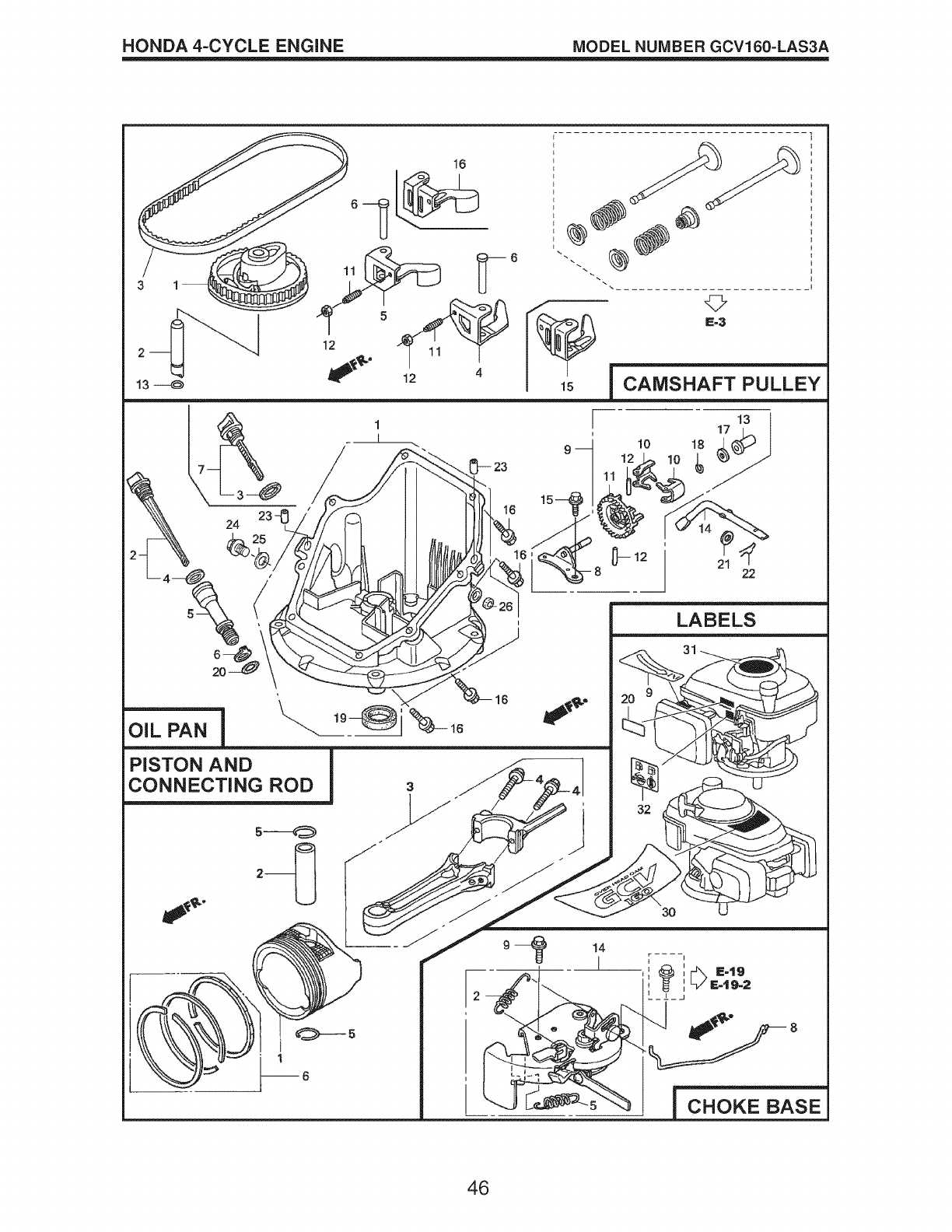

Understanding the individual components of a machine is crucial for maintenance and repair. Visual representations of these elements provide a clear overview, helping users identify specific sections and their functions. Such illustrations play a vital role in ensuring efficient and accurate servicing.

- Enhanced Clarity: Diagrams break down complex machinery into manageable parts, making it easier to comprehend their arrangement and interaction.

- Efficient Troubleshooting: When issues arise, visual aids allow users to pinpoint problematic components quickly, streamlining the diagnostic process.

- Facilitated Repairs: Having a clear view of all elements assists technicians in identifying necessary replacements and avoiding unnecessary disassembly.

- Improved Communication: Diagrams serve as a common language for technicians and customers, ensuring everyone is on the same page regarding repairs and maintenance.

In summary, visual representations of machine components are indispensable tools that enhance understanding, streamline repairs, and foster effective communication among users and technicians alike.

Common Issues with GCV160 Models

When it comes to small engines, several recurring challenges can affect their performance and reliability. Understanding these frequent problems can help users maintain their equipment effectively and avoid unnecessary repairs.

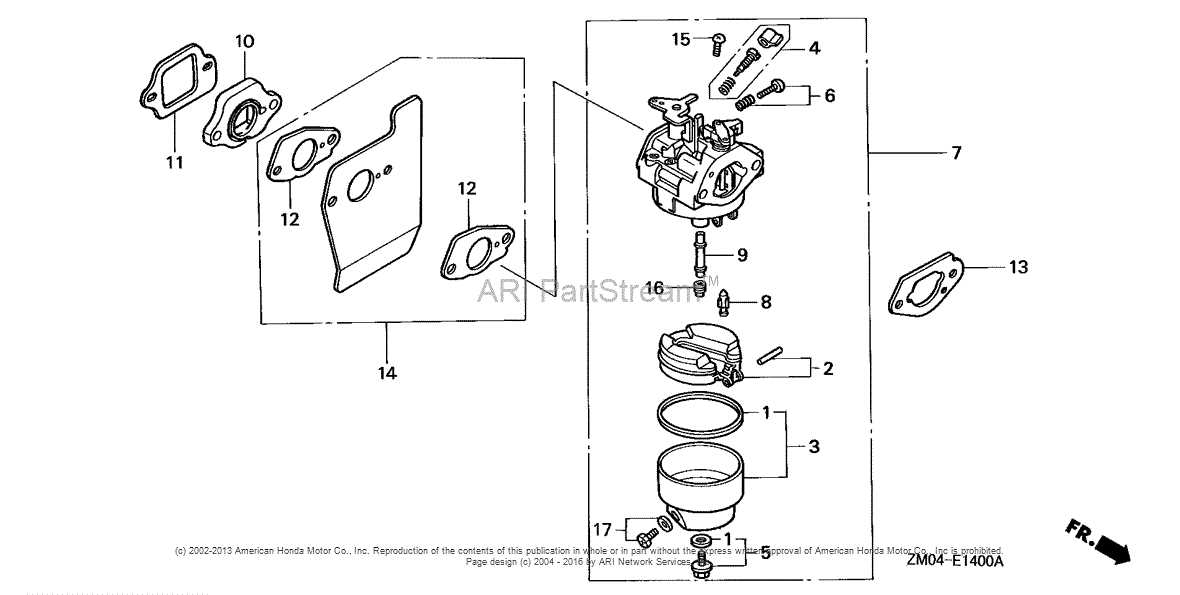

Fuel System Complications

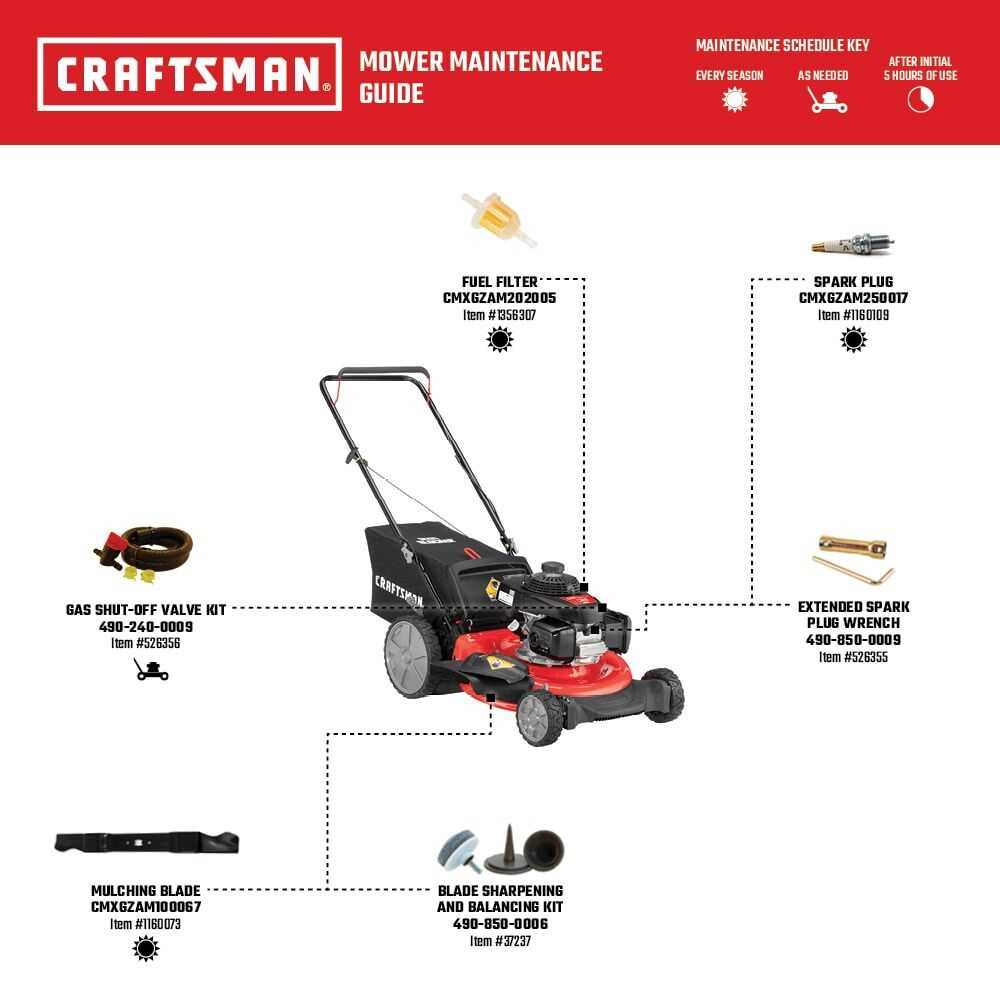

One of the primary issues encountered is related to the fuel system. Users may experience difficulty starting the engine due to stale fuel or clogged lines. It’s essential to ensure that fresh, clean fuel is used and that the fuel filter is checked regularly. Additionally, carburetor malfunctions can lead to improper fuel delivery, resulting in poor engine performance or stalling.

Ignition Troubles

Another common concern involves ignition components. Worn or damaged spark plugs can hinder the engine’s ability to start or run smoothly. Regular inspection and replacement of these parts are vital. Moreover, issues with the ignition coil or wiring can also contribute to inconsistent performance, emphasizing the need for routine maintenance.

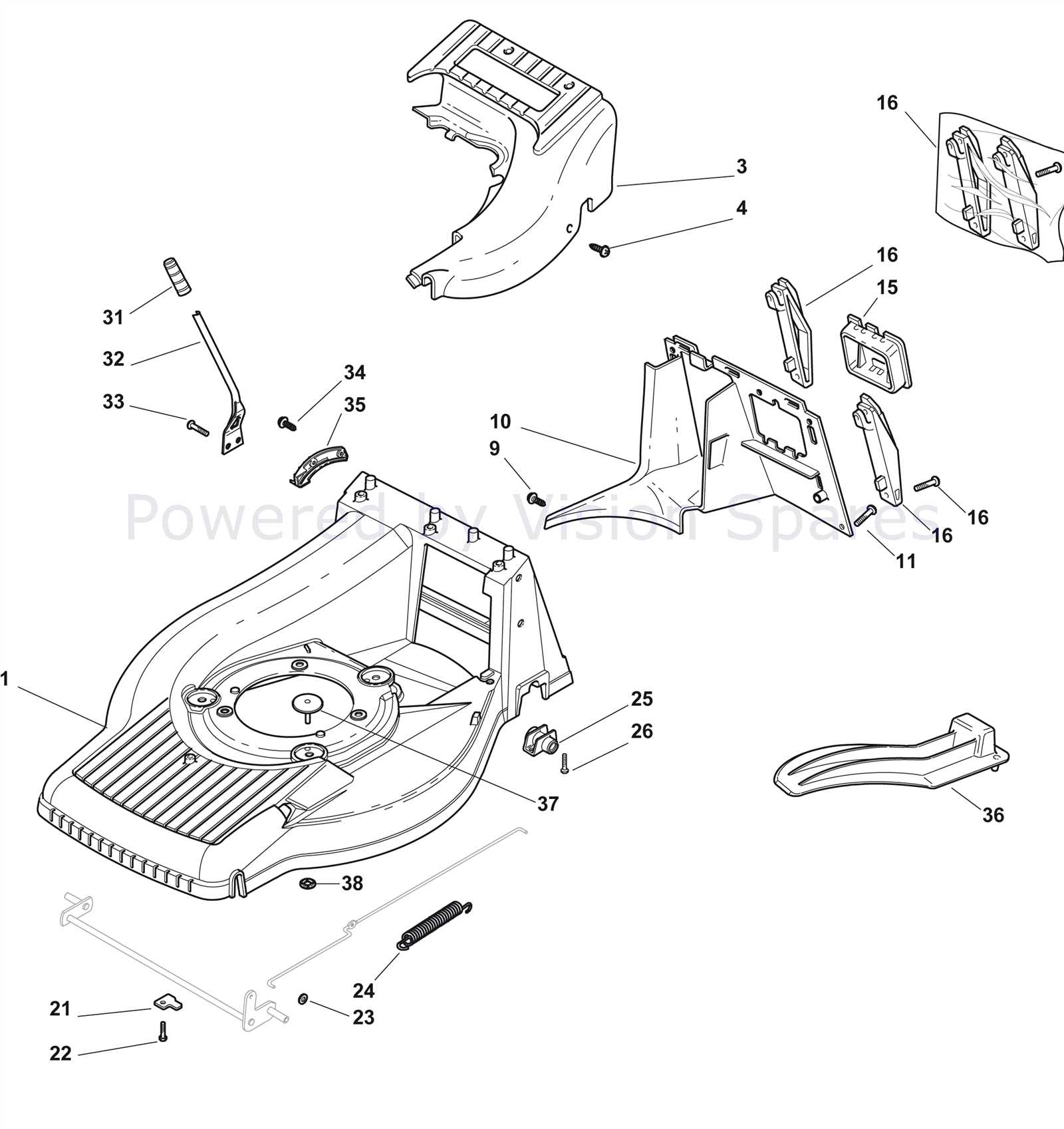

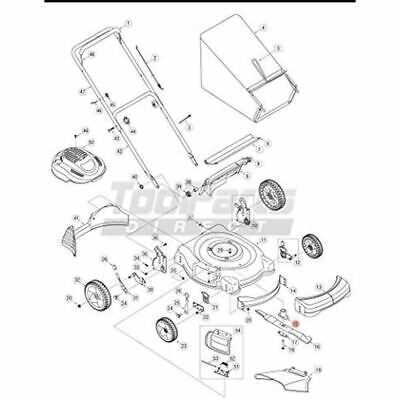

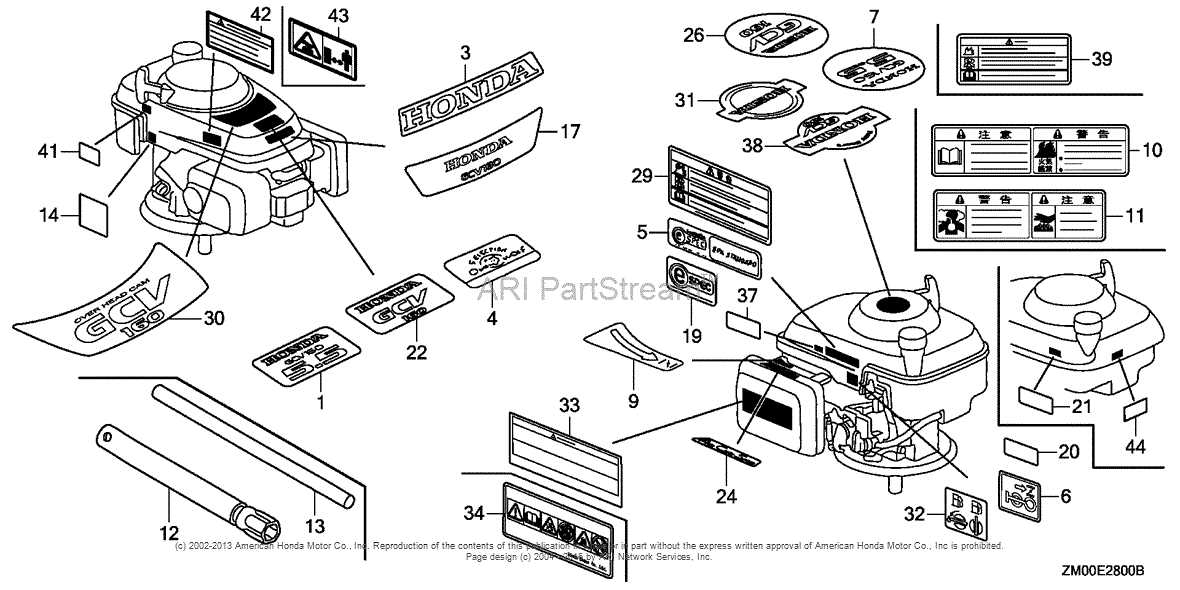

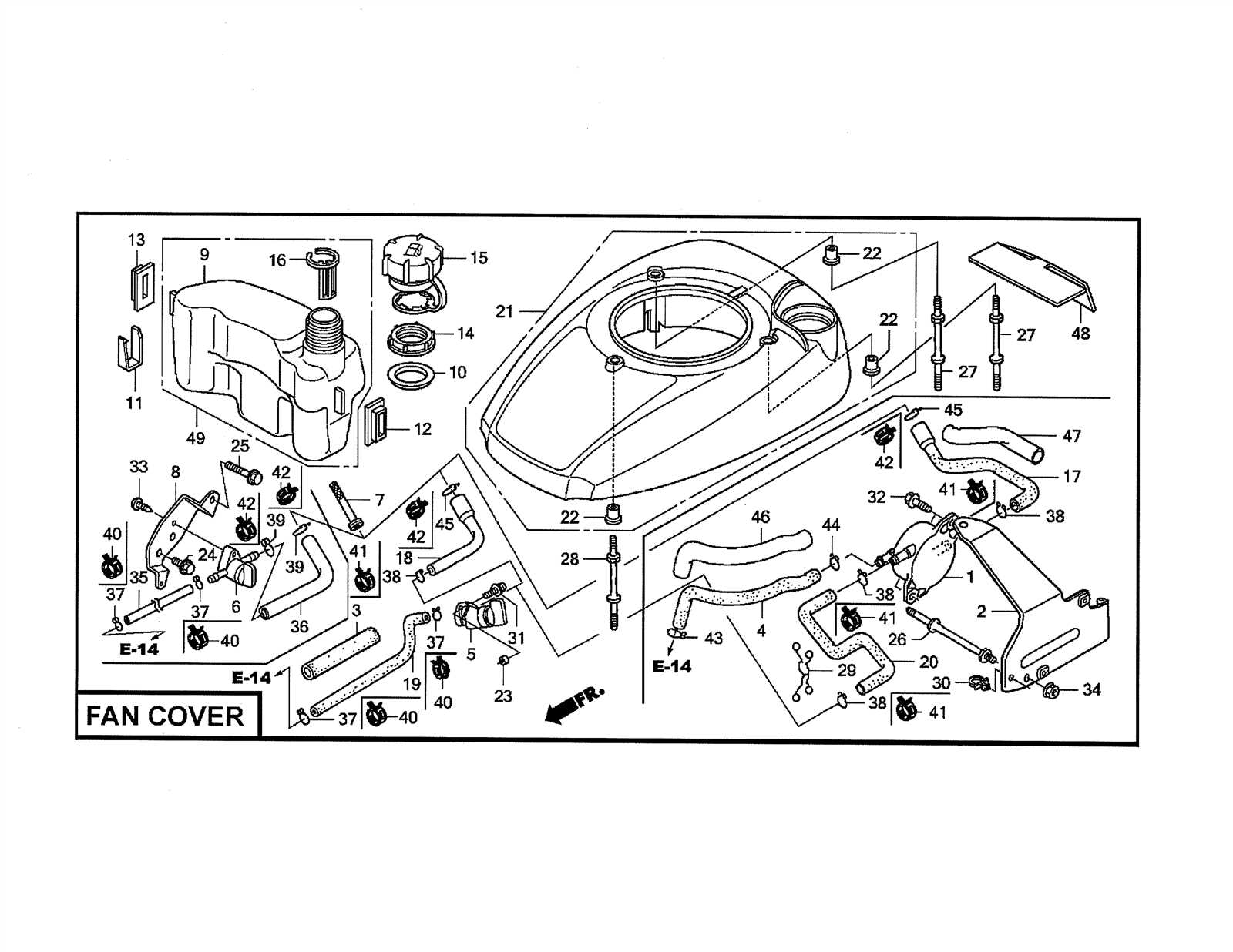

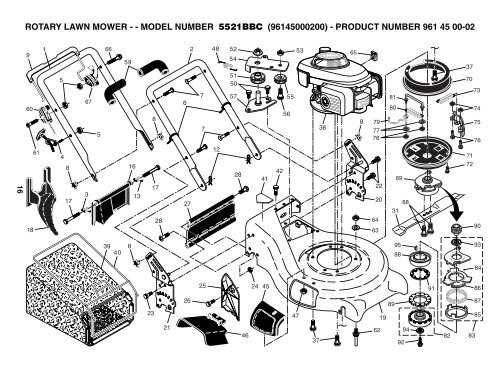

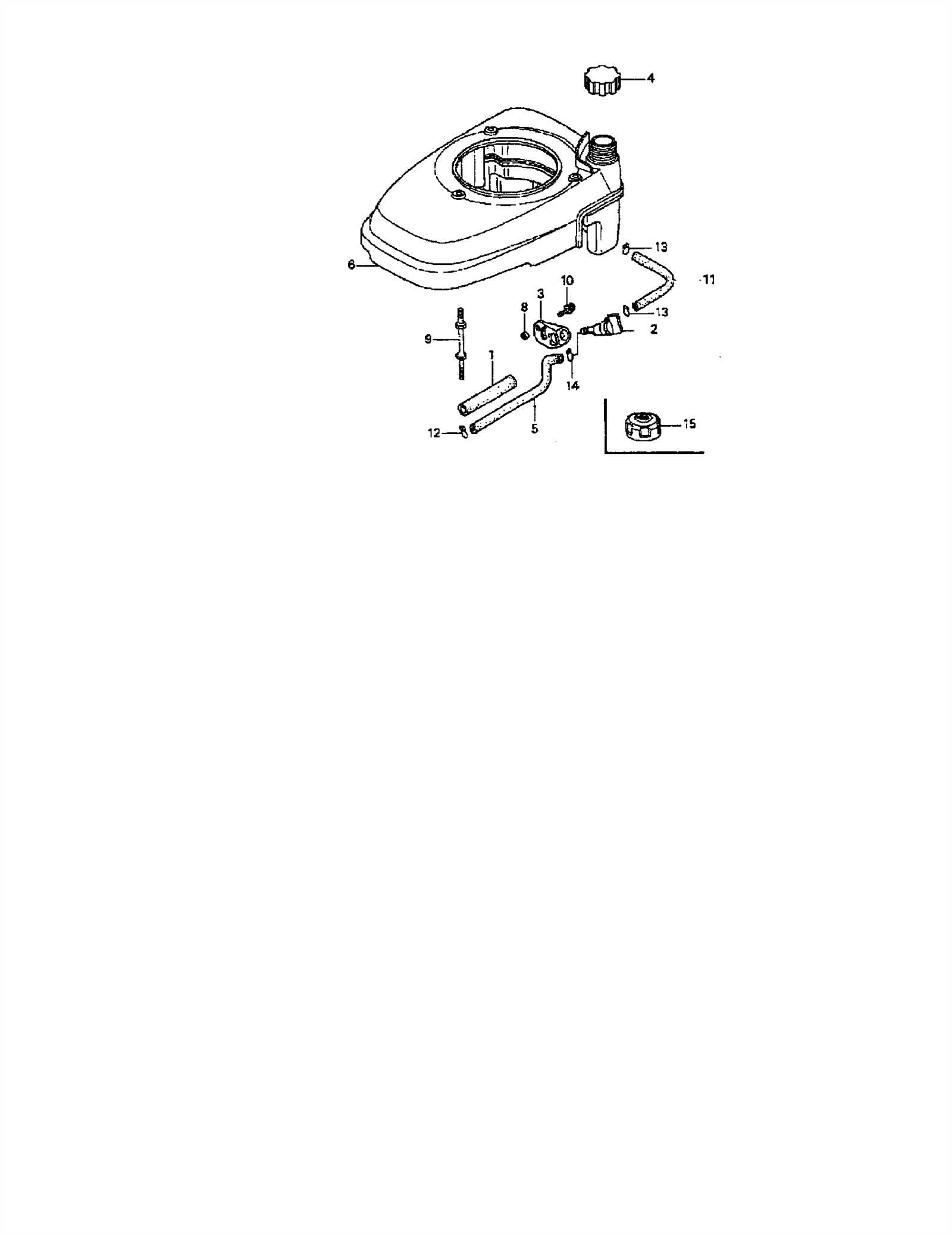

How to Read a Parts Diagram

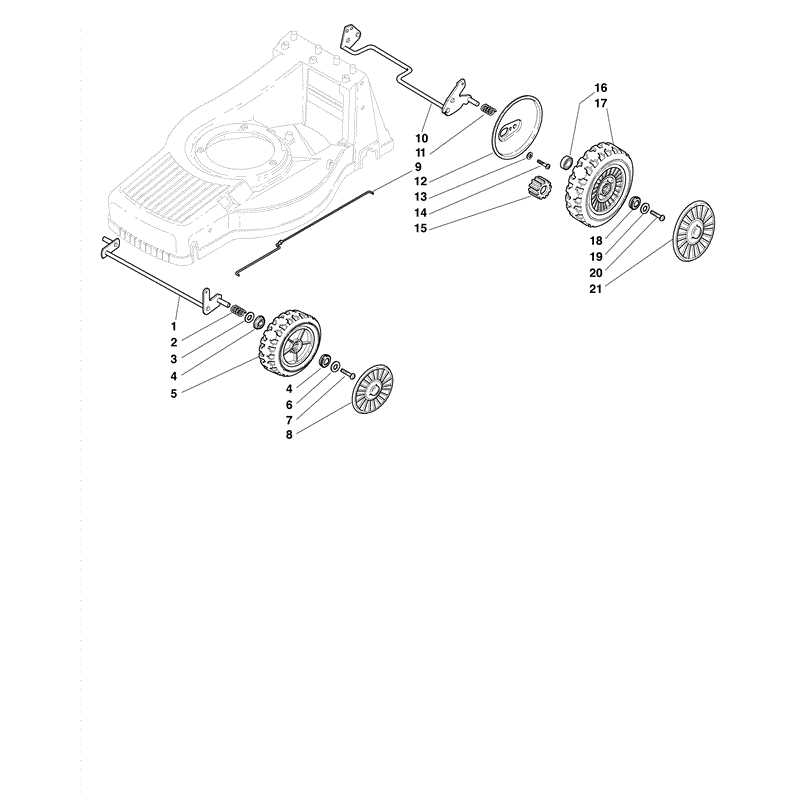

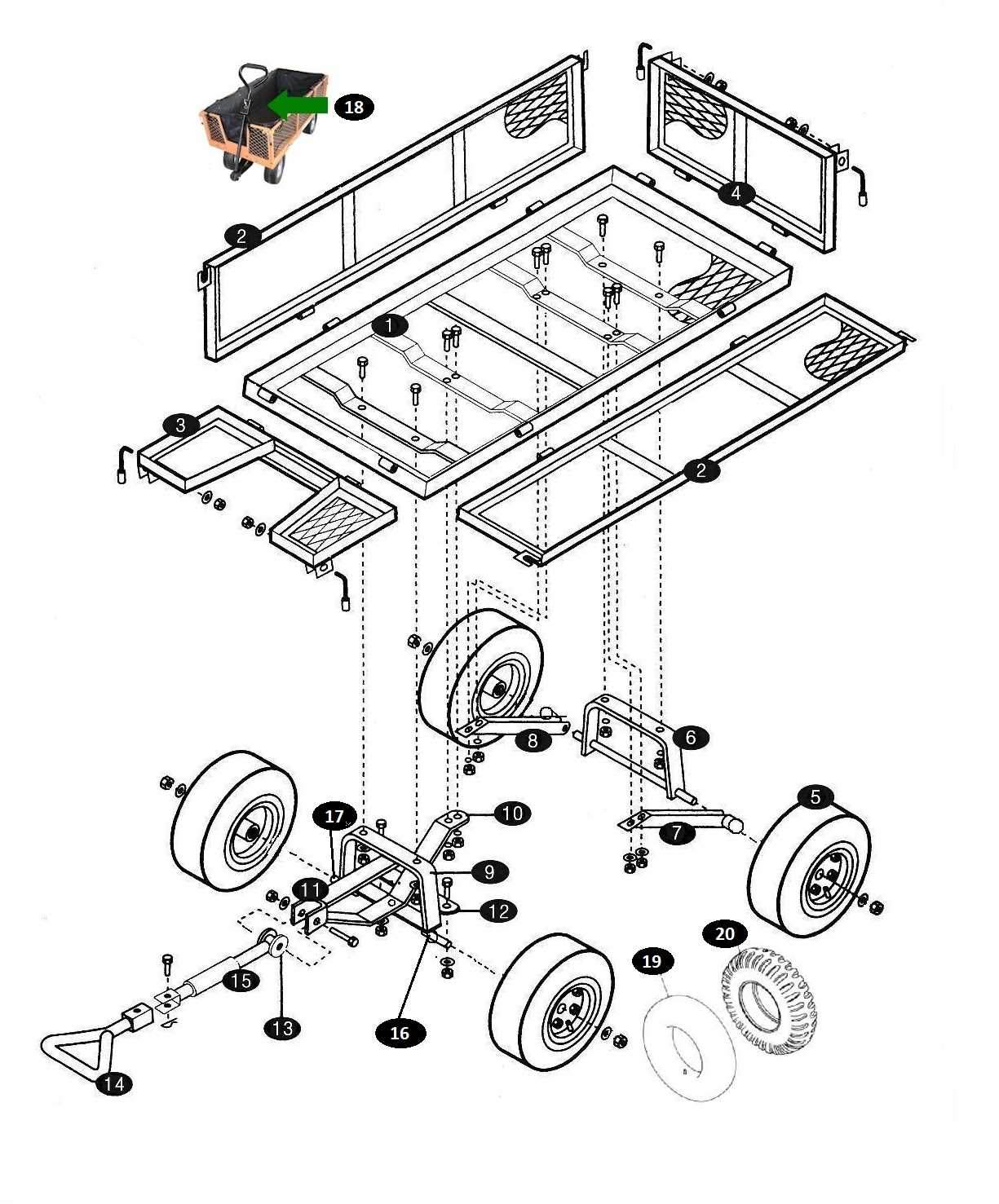

Understanding a schematic representation of components can significantly enhance your ability to repair or maintain machinery. These illustrations serve as visual guides, showcasing the individual elements and their interconnections, making it easier to identify the necessary replacements or repairs. By familiarizing yourself with the layout and symbols used in these visuals, you can streamline your work process and improve efficiency.

Identifying Components

The first step in interpreting these visuals is to recognize the various elements depicted. Each part is typically labeled with a unique identifier, which corresponds to a list of items. This list provides detailed information such as the part number, description, and sometimes even the quantity required for your specific task. Pay close attention to these labels as they are crucial for ordering the correct replacements.

Understanding Connections

Another key aspect to focus on is how the components are connected. Lines or arrows often indicate relationships and flow between elements, guiding you on how they interact within the overall system. Understanding these connections can help you diagnose issues more effectively and ensure that any new components fit seamlessly into the existing setup.

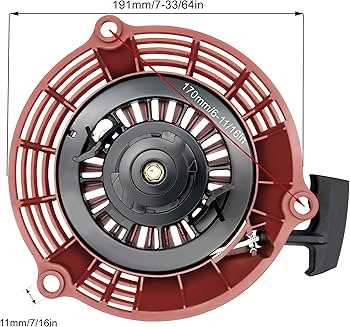

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, locating the right components is essential for ensuring optimal performance. Fortunately, there are several avenues you can explore to obtain high-quality replacements that will keep your machinery running smoothly.

Authorized Dealers and Retailers

One of the most reliable sources for obtaining essential components is through authorized dealers and retailers. These outlets often carry a wide selection of genuine items, ensuring compatibility and durability. Visiting a local dealer allows you to receive expert advice and assistance in finding the correct replacement for your specific model.

Online Marketplaces and Specialized Websites

The internet offers a wealth of options for sourcing components, with numerous online marketplaces and specialized websites dedicated to outdoor equipment. Websites often provide detailed listings, including specifications and user reviews, which can guide you in making an informed decision. Be sure to verify the seller’s reputation and check return policies before finalizing your purchase.

In addition to these options, local hardware stores and repair shops may also have the necessary items or be able to order them for you. Exploring multiple sources increases your chances of finding the right components quickly and efficiently.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any outdoor equipment. Regular attention to detail not only enhances performance but also reduces the risk of costly repairs. Implementing a few straightforward practices can significantly improve efficiency and reliability over time.

Start with routine inspections to identify wear and tear early. Check for any loose components or signs of damage, and address these issues promptly. Keeping the machine clean is equally important; remove debris and buildup to prevent overheating and mechanical failure.

Regularly change the oil and replace filters as recommended by the manufacturer. This helps maintain optimal engine performance and minimizes wear. Additionally, sharpening blades or tools ensures they operate efficiently, leading to better results and less strain on the equipment.

Storing the machine properly when not in use can also prolong its life. Keep it in a dry, sheltered area to protect it from the elements. Consider using protective covers to guard against dust and moisture, which can cause corrosion over time.

Lastly, familiarize yourself with the user manual for specific maintenance recommendations and schedules. Following these guidelines can help you avoid common pitfalls and keep your equipment in peak condition for many years.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right instruments at your disposal is essential. Proper tools not only facilitate the repair process but also ensure that tasks are completed efficiently and safely. This section outlines the essential equipment that will aid you in your repair endeavors.

Essential Hand Tools

Basic hand tools are indispensable for any repair work. A set of screwdrivers, including both flathead and Phillips, is necessary for loosening and tightening screws. Pliers and wrenches come in handy for gripping and turning nuts and bolts. Additionally, having a good quality hammer can assist in driving items into place or removing them when needed.

Power Tools and Safety Equipment

For more complex repairs, power tools like drills and saws can save considerable time and effort. Ensure you also have access to a reliable work light to illuminate your workspace. Safety should be a priority; thus, protective gear such as gloves, goggles, and a mask are crucial to protect yourself from potential hazards during the repair process.

Identifying Parts by Number

Understanding how to recognize components by their numerical designations is essential for efficient maintenance and repair tasks. This method not only simplifies the ordering process but also ensures accuracy when replacing specific elements. By familiarizing yourself with the numbering system, you can save time and avoid potential errors.

Here are some key steps to effectively identify components:

- Consult the Manual: Always refer to the user manual or technical guide, which usually includes a comprehensive list of components along with their corresponding numbers.

- Use Online Resources: Many manufacturers provide digital catalogs or databases where you can search by number to find detailed information about each item.

- Cross-reference with Similar Models: Sometimes, components from related models share the same numerical designations, so checking alternative sources can be helpful.

When you locate a number, consider the following tips:

- Check for Updates: Occasionally, manufacturers update part numbers, so ensure that you are using the most current information.

- Verify Compatibility: Not all components are interchangeable, even if they appear similar. Double-check specifications to avoid issues.

- Keep a Record: Maintain a personal log of numbers and their descriptions for future reference, streamlining the process for subsequent repairs.

By following these guidelines, you’ll be better equipped to navigate the world of components and enhance your repair efficiency.

Comparing GCV160 to Similar Models

When evaluating outdoor power equipment, it’s essential to consider various models that offer comparable features and performance. By examining different options, users can make informed decisions based on their specific needs and preferences.

Key Features to Consider

- Engine performance: Look for horsepower and torque ratings.

- Fuel efficiency: Consider models that provide longer runtime on a single tank.

- Weight and portability: Assess how easy it is to transport and maneuver the equipment.

- Maintenance requirements: Evaluate the ease of access for repairs and routine maintenance.

- Warranty and support: Review the manufacturer’s warranty and available customer service.

Similar Models Overview

-

Model A

- Notable for its superior fuel efficiency.

- Offers enhanced torque for tougher tasks.

-

Model B

- Lightweight design for better portability.

- Features an advanced air filtration system.

-

Model C

- High power output suitable for heavy-duty applications.

- Includes a user-friendly control panel.

By comparing these models, users can identify the one that best meets their requirements, balancing performance, efficiency, and usability. This approach ensures optimal satisfaction and effectiveness for various outdoor tasks.

Customer Reviews on Parts Quality

Feedback from users regarding the quality of components plays a crucial role in understanding their performance and durability. Customers often share their experiences, which can help potential buyers make informed decisions. Here, we explore the insights gathered from various reviews to shed light on the overall satisfaction levels.

Many consumers highlight the following aspects:

- Durability: Users frequently mention how long the components last under regular use.

- Fit and Compatibility: A common point of discussion is whether the pieces fit well with their machines.

- Ease of Installation: Reviews often cover how straightforward it is to install these components.

- Performance Improvement: Customers often note enhancements in functionality after replacing old parts.

In terms of ratings, users generally provide positive feedback:

- Over 75% express satisfaction with the quality.

- Many report significant improvements in performance.

- Negative reviews typically focus on isolated incidents rather than widespread issues.

Overall, the collective feedback indicates a strong preference for reliable and effective components, confirming their importance in maintaining optimal machine performance.

DIY Repair vs. Professional Help

When faced with a malfunctioning tool or equipment, individuals often grapple with the decision of whether to tackle the repair themselves or enlist the aid of a specialist. This choice can hinge on various factors, including the complexity of the issue, personal skill level, and the resources available. Each approach carries its own set of advantages and challenges, making it essential to weigh the options carefully.

Advantages of DIY Repair

Taking on repairs independently can be a rewarding experience, providing a sense of accomplishment and the opportunity to learn new skills. It often involves lower costs, as it eliminates labor fees associated with hiring a professional. Moreover, many find the process enjoyable and a chance to engage with their tools in a more meaningful way.

When to Seek Professional Assistance

Despite the allure of DIY, some situations may necessitate professional intervention. Complicated repairs that require specialized knowledge or tools can lead to more harm than good if attempted alone. Furthermore, time constraints or a lack of confidence in one’s abilities may make hiring a skilled technician the more practical option. Ultimately, understanding when to seek help can save time, money, and frustration in the long run.