Complete Guide to Craftsman LT1000 Mower Deck Parts Diagram

Maintaining your outdoor machinery is essential for optimal performance and longevity. Proper knowledge of various components can significantly enhance your gardening experience, allowing you to tackle tasks with ease and efficiency.

In this section, we will explore a detailed breakdown of crucial elements that contribute to the functionality of your equipment. A comprehensive overview of these components not only aids in troubleshooting but also in making informed decisions regarding repairs and replacements.

By delving into the specifics of each part, users can better understand their significance and interrelation. This ultimate guide will empower you to keep your machine running smoothly and effectively throughout the seasons.

Understanding Craftsman LT1000 Mower

This section aims to provide insights into a popular outdoor machine designed for maintaining lawns and gardens. By exploring its components and functionality, users can enhance their understanding of how to effectively operate and maintain their equipment.

Key Features

The machine is equipped with various attributes that ensure efficient grass cutting and ease of use. These features contribute to its reliability and effectiveness in diverse gardening tasks.

Maintenance Tips

Regular upkeep is crucial for optimal performance. Here are essential maintenance practices to consider:

| Task | Frequency |

|---|---|

| Check oil level | Every use |

| Inspect blades | Monthly |

| Clean air filter | Every season |

| Sharpen blades | Every 25 hours |

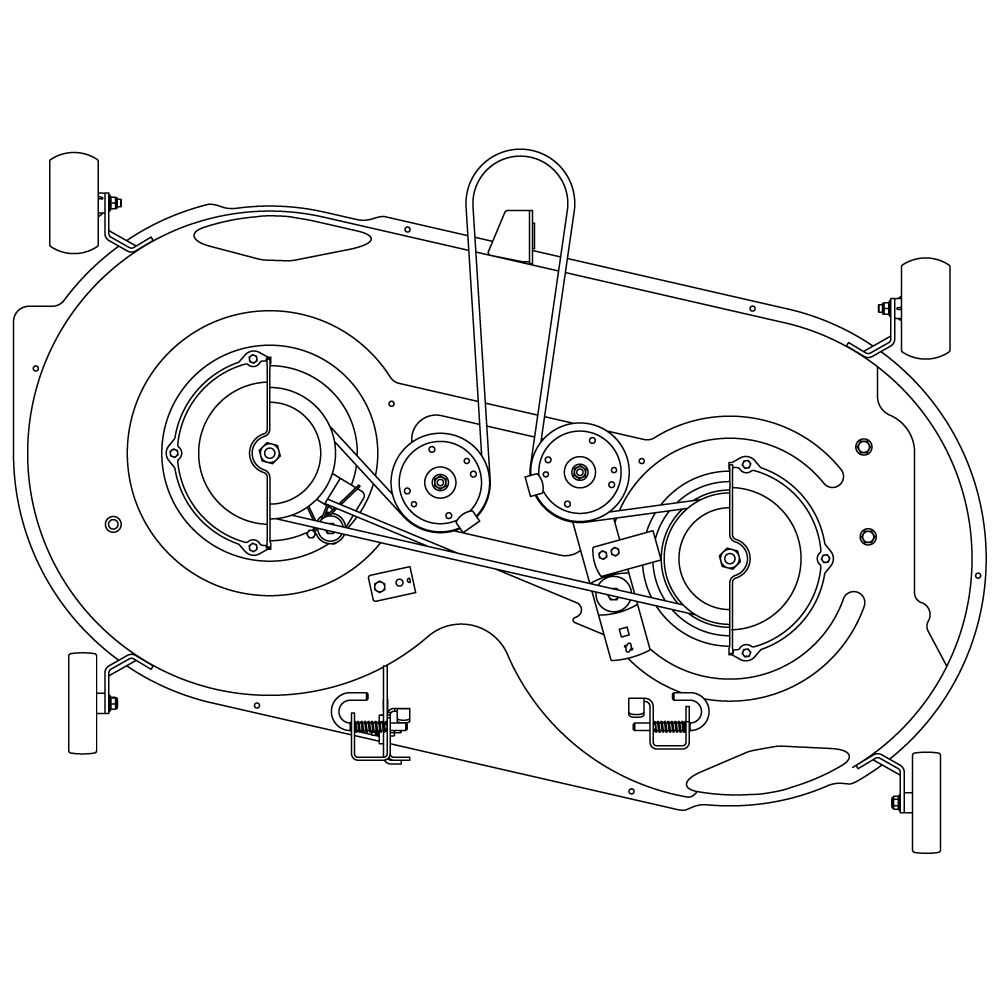

Essential Components of Mower Deck

The efficiency of any grass cutting machine relies heavily on its fundamental elements, which work in harmony to ensure optimal performance. Understanding these critical components is vital for effective maintenance and operation.

Blades are the primary tools responsible for trimming grass. Their sharpness and design greatly influence cutting quality.

Spindles serve as the support structure for the blades, allowing them to rotate smoothly. Regular inspection is essential to prevent wear and tear.

Chassis provides the framework that holds everything together, ensuring stability during use.

Wheels facilitate movement, playing a crucial role in maneuverability across various terrains.

Belts transfer power from the engine to the cutting components, making them vital for functionality.

Guards enhance safety by preventing debris from being thrown during operation, protecting both the operator and surrounding areas.

By familiarizing oneself with these essential elements, operators can ensure their equipment runs efficiently and effectively, extending its lifespan.

Importance of Mower Deck Maintenance

Regular upkeep of the cutting apparatus is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to decreased efficiency and increased wear over time, ultimately impacting the quality of the lawn care process.

Key reasons for maintaining the cutting mechanism include:

- Improved Performance: A well-maintained apparatus ensures a clean cut, promoting healthier grass growth.

- Extended Lifespan: Routine inspections and care can significantly prolong the lifespan of the equipment.

- Fuel Efficiency: Clean and sharp components reduce the strain on the engine, leading to better fuel consumption.

- Safety: Proper maintenance minimizes the risk of accidents and malfunctions, providing a safer working environment.

Additionally, regular checks help identify issues early on, preventing costly repairs and downtime. Following a consistent maintenance schedule can greatly enhance the effectiveness of the entire lawn care routine.

Common Issues with Craftsman LT1000 Deck

Maintenance of outdoor equipment can often reveal a range of challenges that users may encounter over time. Understanding these issues is essential for effective troubleshooting and ensuring longevity. Frequent problems include uneven cutting, noise during operation, and wear on critical components, which can hinder performance.

One prevalent issue is the uneven cutting height, which can result from misaligned blades or worn-out components. Regular inspection can help identify these discrepancies early. Additionally, unusual noises may indicate loose parts or damaged bearings, necessitating immediate attention to prevent further damage.

Another concern involves the accumulation of debris, which can obstruct airflow and lead to overheating. Routine cleaning and maintenance are vital in addressing this issue. Lastly, users often report problems with the drive system, which can affect movement and maneuverability. Timely intervention can mitigate these complications and enhance overall efficiency.

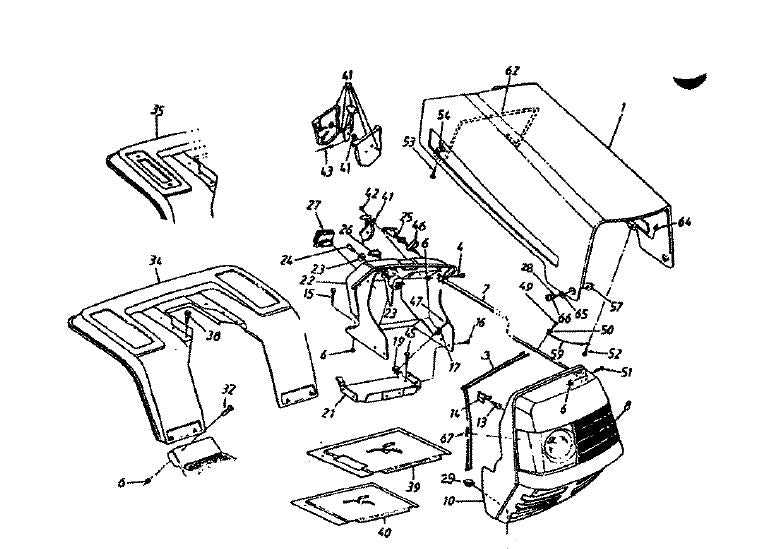

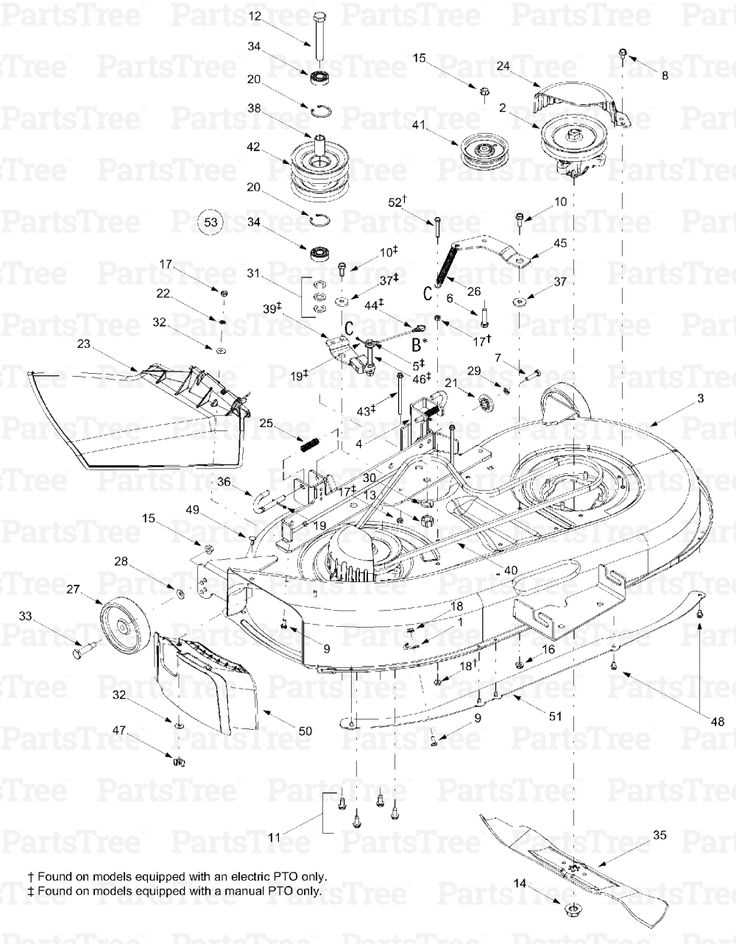

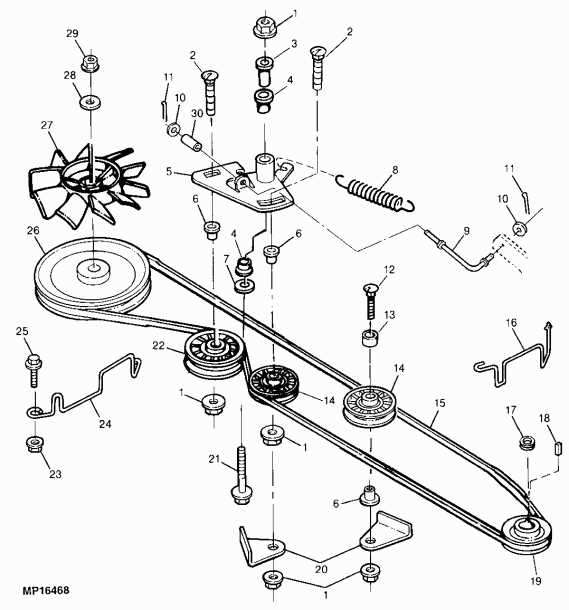

Identifying Mower Deck Parts

Understanding the various components of your cutting apparatus is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, ensuring optimal performance during operation. Familiarity with these sections allows for more efficient repairs and enhancements.

| Component | Description |

|---|---|

| Blade | The sharp metal element that performs the actual cutting action. |

| Spindle | The rotating mechanism that supports and drives the blade. |

| Housing | The outer shell that encases and protects the internal components. |

| Lift Arm | Enables the raising and lowering of the cutting mechanism for height adjustment. |

| Belts | Transmits power from the engine to various moving parts. |

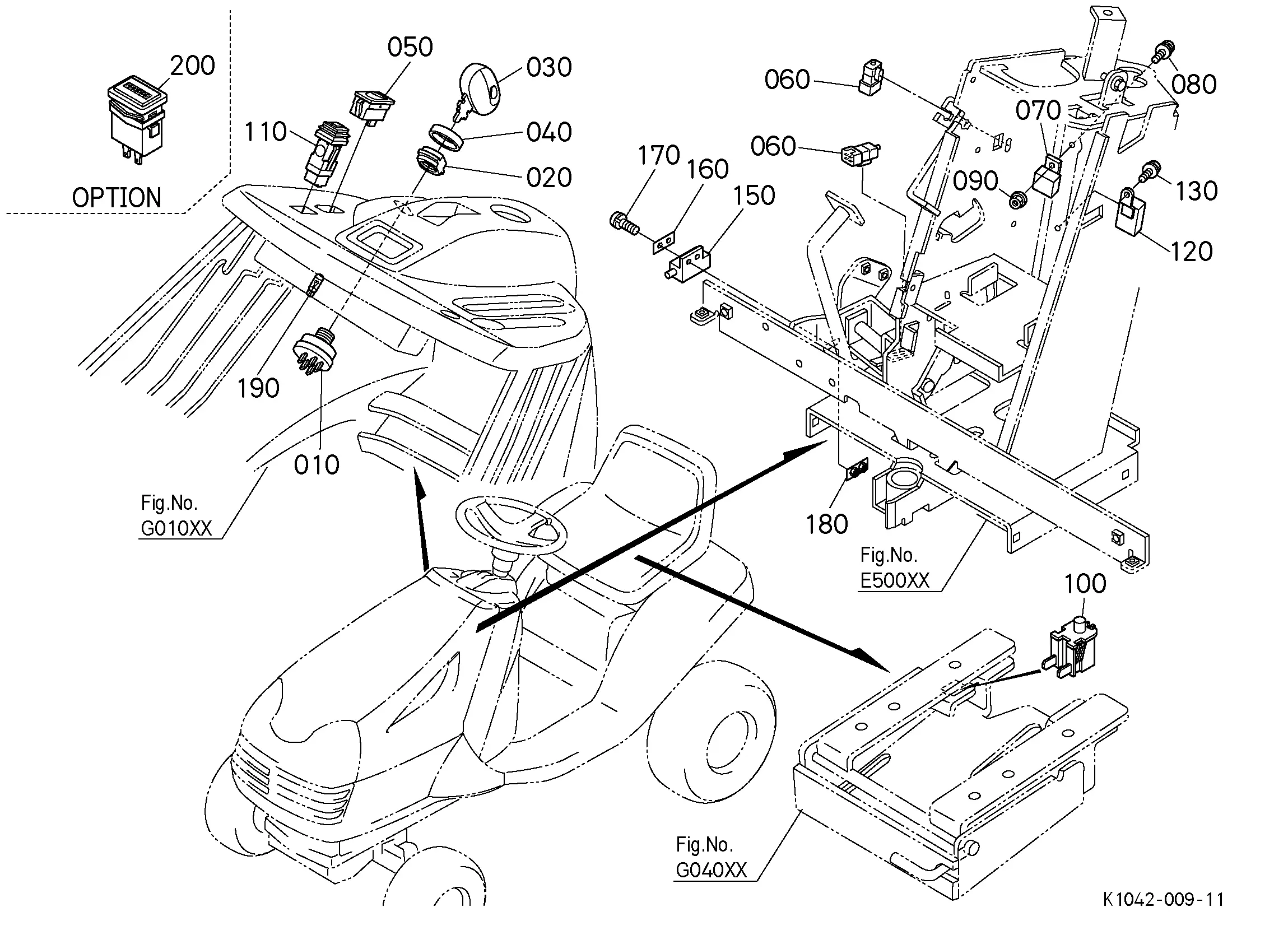

How to Access Parts Diagram

Understanding the components of your outdoor equipment is essential for effective maintenance and repairs. Accessing a visual reference of these elements can simplify the process, enabling you to identify specific pieces quickly. This guide will outline the steps necessary to locate and utilize these valuable resources.

Finding the Right Resource

Start by searching for the manufacturer’s official website, where you can often find technical documents and visual guides. These resources may include downloadable manuals or interactive tools that highlight each component. Additionally, online forums and communities dedicated to lawn care equipment can provide insights and shared diagrams from fellow users.

Utilizing the Diagram Effectively

Once you have located a visual reference, familiarize yourself with its layout. Pay attention to labeling and numbering, as these will correspond to specific components. This will not only aid in identifying parts during repairs but also enhance your understanding of how the equipment operates as a whole.

Replacing Damaged Mower Deck Components

Maintaining the efficiency of your outdoor cutting equipment is essential for optimal performance. Over time, certain elements may wear out or become damaged, necessitating their replacement to ensure smooth operation and longevity.

Identifying which components need attention is the first step in the process. Common signs of wear include:

- Uneven cutting results

- Unusual noises during operation

- Visible damage or cracks in structural parts

Once you have pinpointed the affected areas, follow these guidelines for successful replacements:

- Gather the necessary tools and replacement components.

- Ensure the equipment is powered down and disconnected from any power source.

- Carefully remove the damaged parts, taking note of how they are installed.

- Install the new components, ensuring a secure fit.

- Test the equipment to confirm proper functionality.

By addressing damaged elements promptly, you can enhance the performance and extend the lifespan of your equipment.

Tools Needed for Mower Repairs

When maintaining outdoor machinery, having the right equipment is crucial for efficient repairs. A well-equipped toolkit can streamline the process and ensure that tasks are completed effectively. Whether addressing minor issues or performing extensive overhauls, specific instruments are essential for success.

Wrenches and Sockets: A variety of sizes will help you tackle different fasteners. Ensure you have both metric and standard options for versatility.

Screwdrivers: A selection of flathead and Phillips screwdrivers is vital for removing and securing components. Magnetic tips can enhance convenience.

Diagnostic Tools: Using multimeters and spark testers can aid in identifying electrical issues quickly, ensuring that problems are pinpointed without unnecessary guesswork.

Safety Gear: Always prioritize safety by using gloves, goggles, and ear protection during repairs to prevent injury.

Cleaning Supplies: Brushes, rags, and degreasers are important for maintaining cleanliness, which can extend the lifespan of your machinery.

Equipping yourself with these essential tools not only enhances the repair process but also promotes a deeper understanding of your equipment’s functionality.

Tips for Effective Mower Deck Care

Maintaining the undercarriage of your lawn care equipment is crucial for optimal performance and longevity. Regular attention can prevent issues and enhance the overall efficiency of the machine, ensuring a neat and tidy lawn. Below are essential practices to help you keep everything in top shape.

Regular Cleaning

One of the simplest yet most effective maintenance tasks is routine cleaning. Grass clippings, dirt, and debris can accumulate, leading to rust and reduced functionality. After each use, consider the following cleaning methods:

| Method | Description |

|---|---|

| Manual Scrubbing | Use a stiff brush to remove stubborn buildup from the surface. |

| Water Spray | Utilize a hose to rinse away loose debris, ensuring to dry thoroughly afterward. |

| Pressure Washing | For heavy grime, a pressure washer can effectively clean without damaging components. |

Routine Inspections

Conducting regular inspections is vital for early detection of wear and tear. Look for signs of damage, such as cracks or rust, and address any issues immediately. Check the alignment and sharpness of blades, ensuring they are in optimal condition for efficient cutting.

Aftermarket Parts vs. Original Parts

When maintaining or repairing lawn care equipment, the choice between replacement components can significantly impact performance and longevity. Understanding the distinctions between alternatives offered by third-party manufacturers and those produced by the original equipment maker is essential for informed decision-making.

Benefits of Aftermarket Options

Third-party replacements often provide a cost-effective solution, frequently available at lower prices compared to original items. Many users appreciate the variety of designs and enhanced features that may not be present in factory options. Additionally, some aftermarket manufacturers specialize in specific improvements, offering performance enhancements or durability that surpasses the standard offerings.

Advantages of Original Components

Original replacements typically ensure compatibility and reliability, as they are designed specifically for the equipment in question. Using these parts can also help maintain warranty coverage and support from the manufacturer. In terms of quality assurance, original components often undergo rigorous testing, providing peace of mind regarding their performance and longevity.

Resources for Mower Deck Troubleshooting

When encountering issues with lawn care equipment, having the right resources at your disposal can significantly streamline the troubleshooting process. Understanding how various components function and interact is essential for effective problem-solving. A wealth of information is available to guide users through common challenges, ensuring maintenance and repair tasks are managed efficiently.

Online forums and communities provide invaluable support, where enthusiasts share experiences and solutions. Video tutorials on platforms like YouTube offer step-by-step guidance for visual learners, covering everything from basic maintenance to complex repairs. Additionally, official manuals and guides often contain troubleshooting sections that address specific problems and suggest remedies.

Utilizing diagrams and schematics can aid in visualizing component arrangements, making it easier to identify potential faults. Consulting local repair shops for professional advice or service can also be beneficial, especially when facing intricate issues. By leveraging these resources, users can enhance their understanding and improve the longevity of their equipment.