Understanding the Craftsman LT3000 Parts Diagram for Easy Repairs

When it comes to maintaining and repairing your machinery, having a clear view of its inner workings is essential. Knowing the layout and functionality of various elements can make troubleshooting significantly easier. This section aims to provide valuable insights into the intricate assembly of your device, facilitating a smoother experience whether you’re replacing a worn part or simply curious about how everything fits together.

Each component plays a critical role in the overall performance and efficiency of the system. By familiarizing yourself with these individual pieces, you not only enhance your understanding but also empower yourself to take on repairs with confidence. An organized overview will aid in identifying specific items and understanding their relationships within the whole.

Whether you’re a seasoned technician or a DIY enthusiast, having access to a detailed visual reference can streamline your work process. This guide serves as a helpful resource, allowing you to locate and address any issues that may arise. With the right information at hand, you can ensure that your equipment remains in optimal condition for years to come.

Understanding Craftsman LT3000 Parts

When maintaining a riding mower, it’s essential to grasp the various components that contribute to its efficient operation. Familiarity with each element not only aids in effective upkeep but also enhances troubleshooting skills, ensuring your machine runs smoothly for years to come.

Key Components Overview

Here are some fundamental parts that are crucial for the performance of your mower:

- Engine: The powerhouse that drives the entire machine.

- Transmission: Responsible for transferring power from the engine to the wheels.

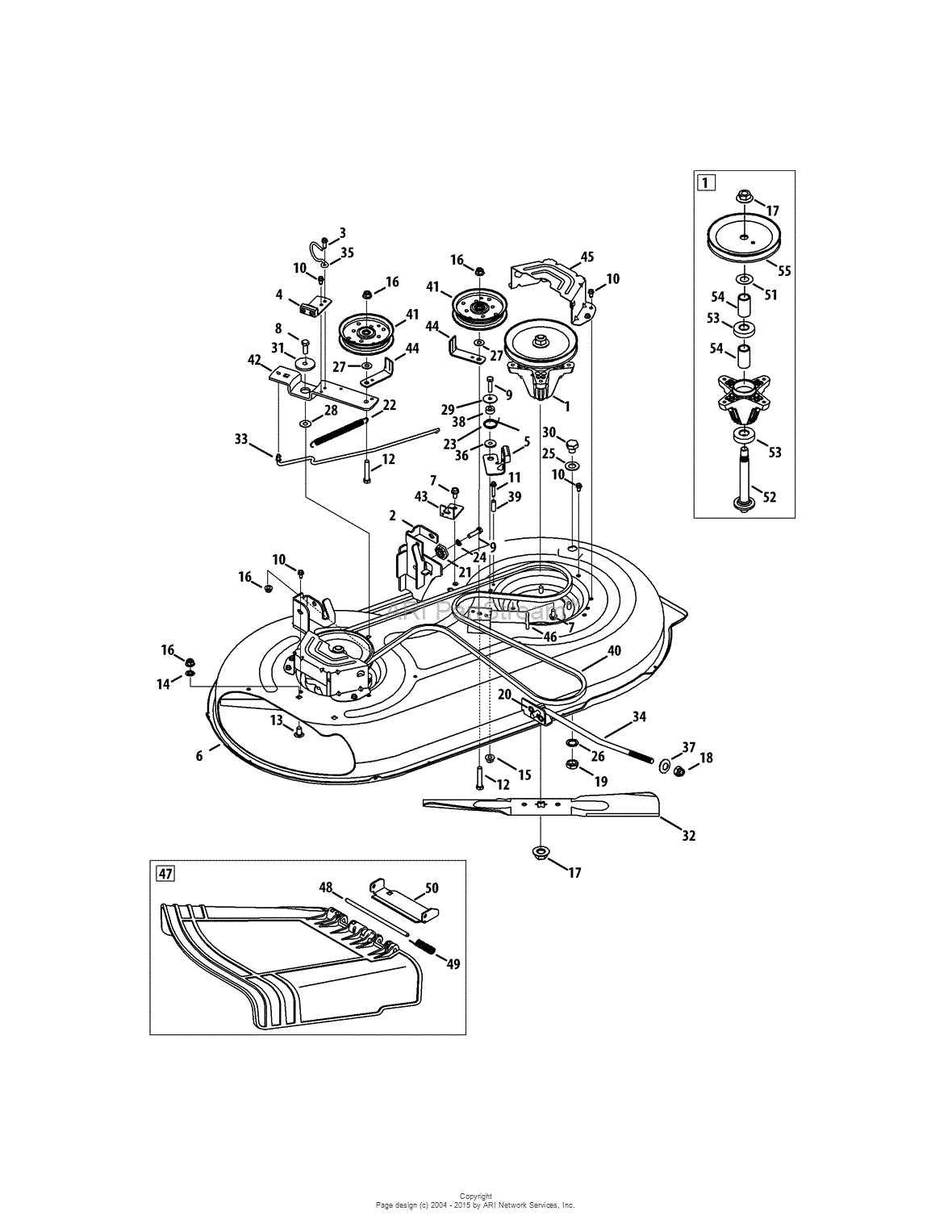

- Deck: The housing that protects and supports the cutting blades.

- Blades: The sharp instruments that trim the grass to the desired height.

- Wheels: Provide mobility and stability during operation.

Maintenance Tips

To ensure longevity and optimal performance, consider these maintenance tips:

- Regularly check and change the oil to keep the engine running smoothly.

- Inspect the blades frequently, sharpening or replacing them as needed.

- Clean the deck after each use to prevent grass buildup.

- Examine the tires for proper inflation and wear.

- Ensure all bolts and screws are tightened to avoid any loose components during operation.

Overview of the LT3000 Model

This section provides an insight into a popular lawn care machine known for its reliability and performance. Designed for both residential and light commercial use, this model has gained a reputation for its robust construction and ease of operation.

The machine features a variety of components that contribute to its efficiency and durability. Users appreciate the following aspects:

- Engine Performance: The model is equipped with a powerful engine that ensures optimal power for cutting grass and tackling tough terrain.

- Cutting Deck: A wide cutting deck allows for efficient mowing, reducing the number of passes required to achieve a well-manicured lawn.

- Comfortable Operation: Ergonomically designed seating and controls provide a comfortable experience for the operator during extended use.

- Durable Construction: High-quality materials enhance the machine’s longevity, making it suitable for various environmental conditions.

In addition to these features, maintenance and repair accessibility is a significant advantage, allowing users to easily find replacement components and service their machines as needed.

Overall, this model stands out in the market for its combination of efficiency, comfort, and reliability, making it a preferred choice for many lawn care enthusiasts.

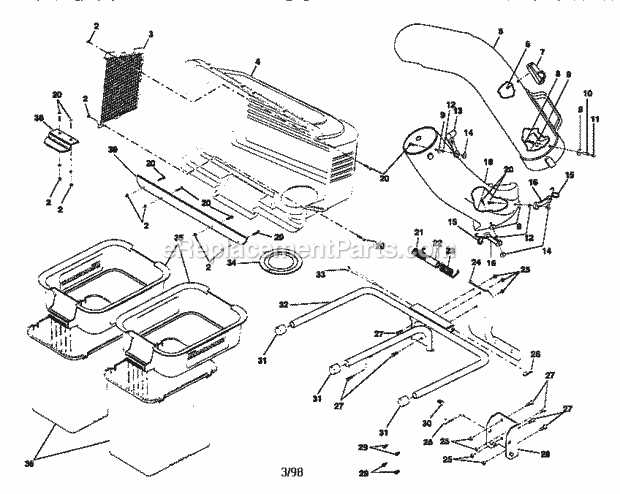

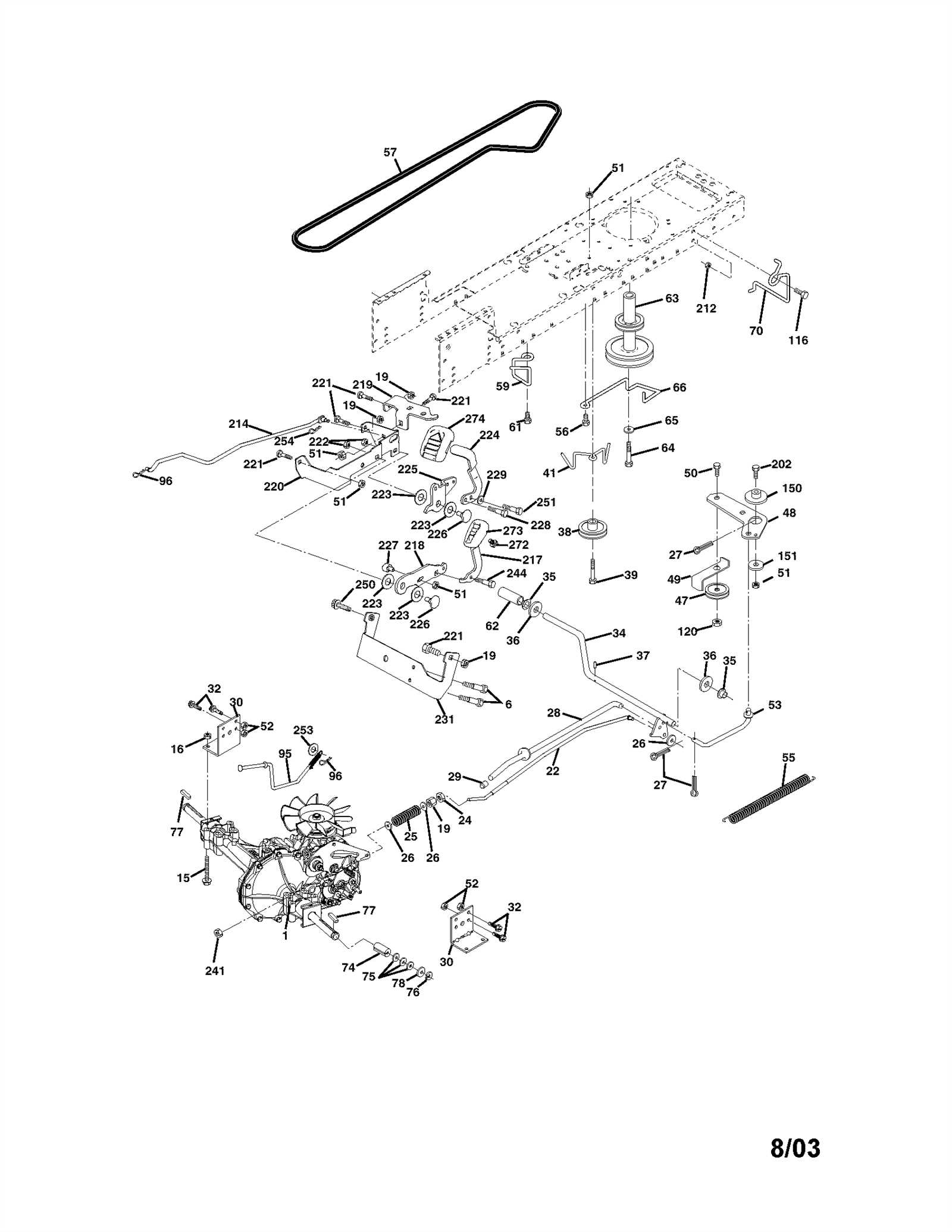

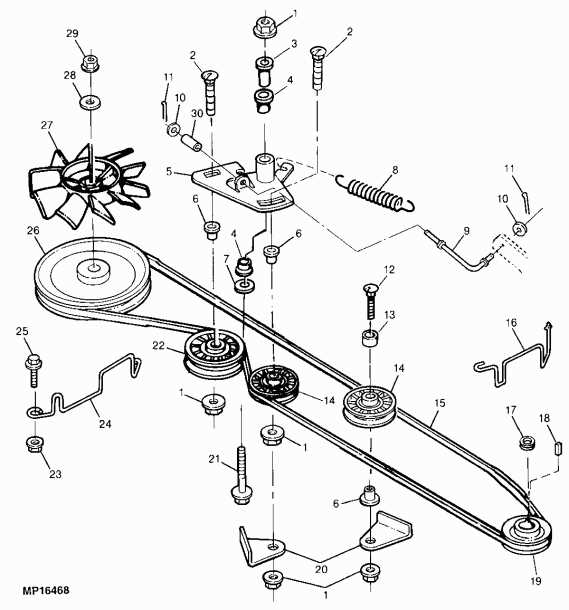

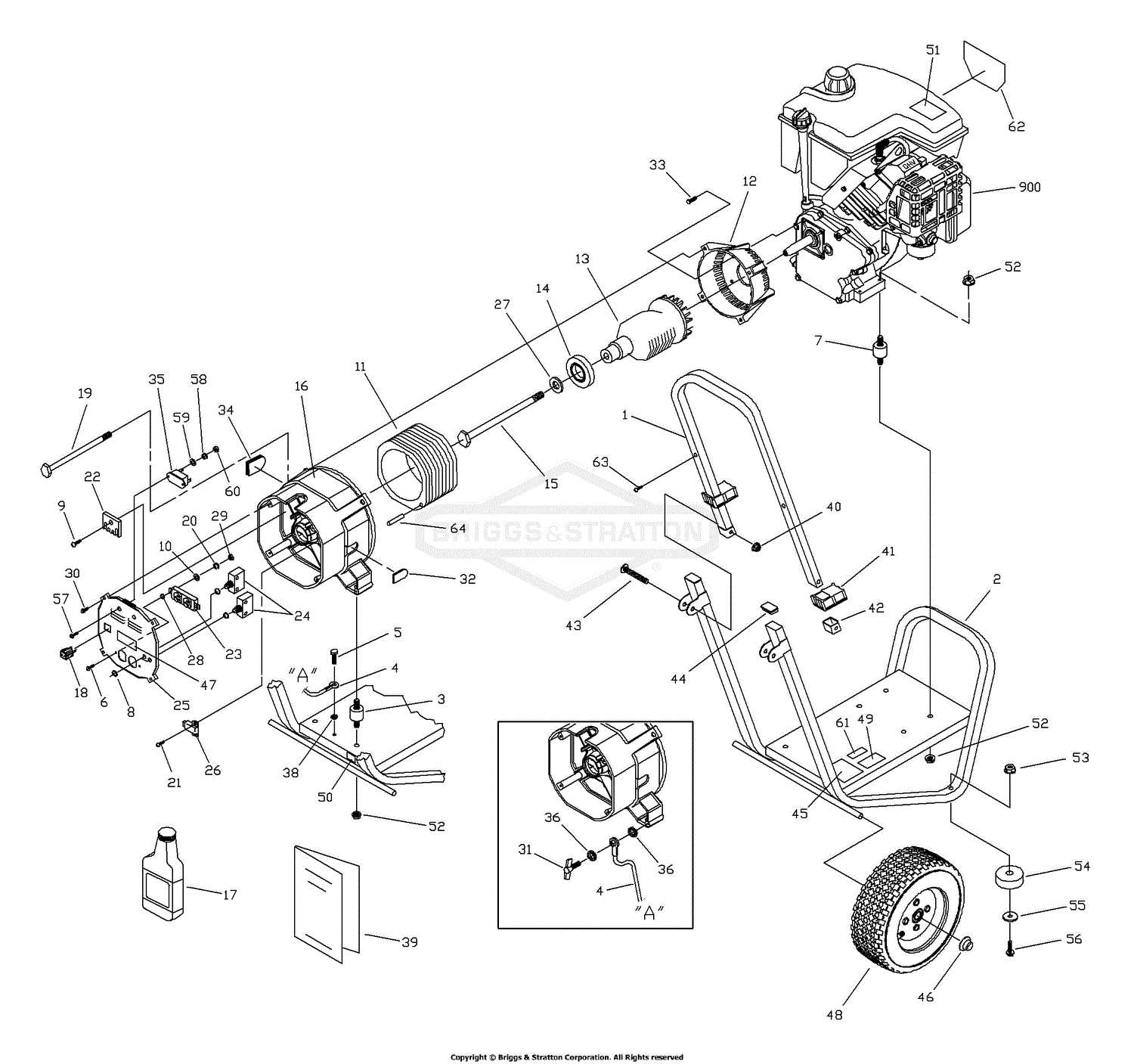

Importance of a Parts Diagram

A visual representation of components is essential for understanding the intricacies of any mechanical device. Such illustrations provide clarity and facilitate the identification of individual elements, enabling users to comprehend the overall structure and functionality more effectively.

Having a detailed breakdown of each segment is invaluable when it comes to maintenance and repairs. It allows individuals to pinpoint issues quickly and ensures that they can procure the correct replacements without unnecessary guesswork. This efficiency not only saves time but also enhances the longevity of the equipment.

Furthermore, these visual guides are instrumental for both seasoned technicians and novices. For experienced users, they serve as a quick reference, while for beginners, they offer a roadmap to learn and understand the assembly and operation of the machinery. Overall, such resources empower users, making tasks less daunting and promoting confidence in handling repairs.

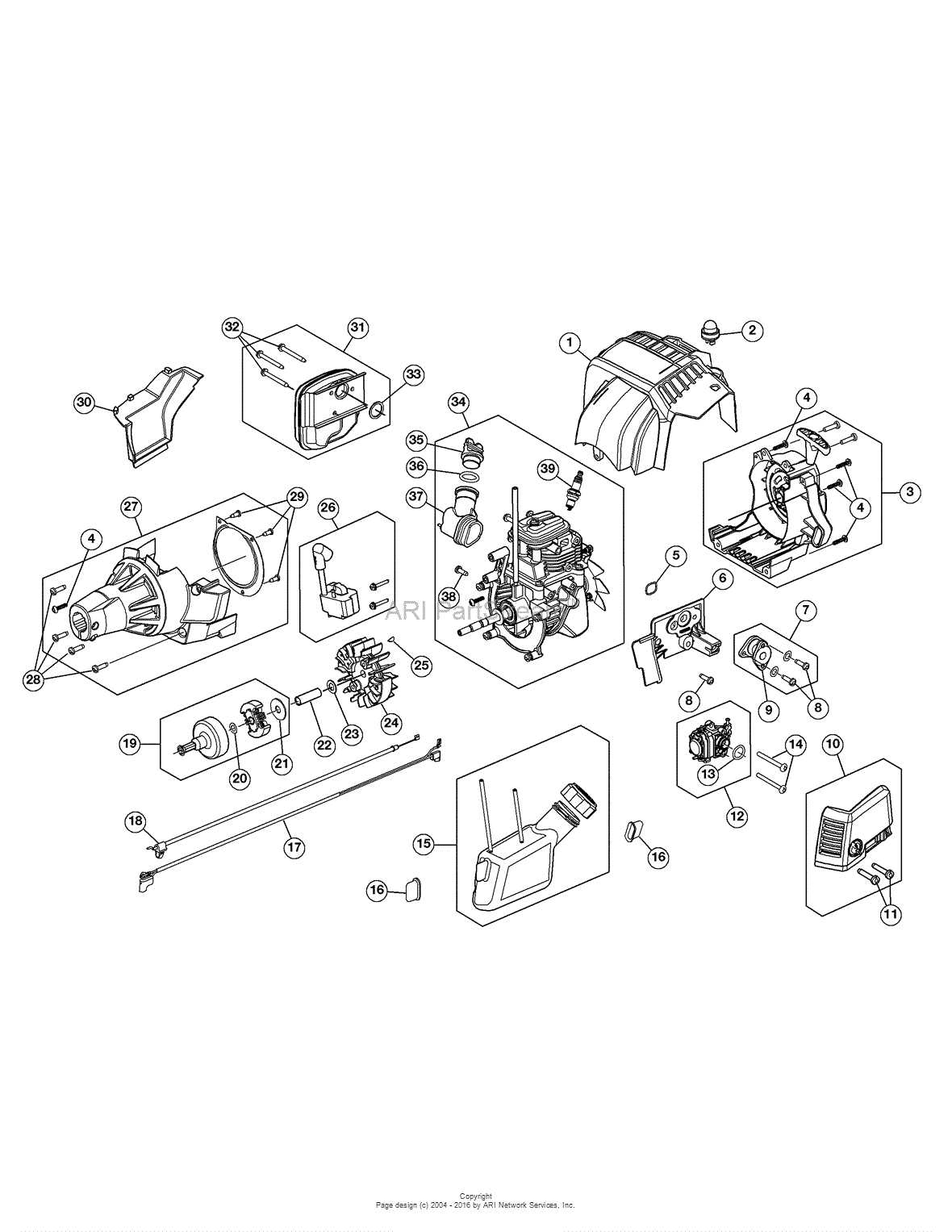

Identifying Key Components

Understanding the essential elements of your equipment is crucial for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance of the machine. By familiarizing yourself with these parts, you can enhance your troubleshooting skills and ensure a longer lifespan for your device.

Engine: This is the powerhouse of the machine, responsible for converting fuel into mechanical energy. Regular checks on this part can prevent significant issues.

Transmission: The transmission system transfers power from the engine to the wheels, facilitating movement. Awareness of its components can aid in diagnosing speed-related problems.

Chassis: The frame supports all other elements and maintains the structural integrity of the equipment. Inspecting it for wear can prevent safety hazards.

Control System: This includes levers and switches that manage various functions. A clear understanding of these controls is vital for optimal operation.

Wheels: These elements provide mobility and must be maintained for proper traction and stability. Regular tire checks can enhance performance.

By recognizing and understanding these vital components, you empower yourself to make informed decisions regarding maintenance and repairs, ultimately leading to improved efficiency and reliability.

Common Issues with LT3000 Parts

When maintaining outdoor machinery, users often encounter various challenges related to individual components. These issues can lead to decreased performance and increased frustration. Understanding the common problems associated with these elements can help in troubleshooting and ensuring the equipment operates smoothly.

Frequent Problems

- Wear and Tear: Over time, components may degrade due to prolonged use, leading to reduced efficiency.

- Incorrect Installation: Improperly installed elements can result in malfunction or even damage to surrounding parts.

- Corrosion: Exposure to moisture and chemicals can cause rust, impacting functionality and lifespan.

- Compatibility Issues: Using non-compatible components can create performance discrepancies and safety hazards.

Troubleshooting Tips

- Regularly inspect components for signs of damage or wear.

- Ensure proper installation by following the manufacturer’s guidelines.

- Store equipment in a dry place to prevent corrosion.

- Always verify compatibility when replacing parts.

Where to Find Replacement Parts

When it comes to maintaining and repairing your equipment, sourcing the right components is essential for optimal performance. Whether you’re looking for original or compatible alternatives, numerous avenues are available to help you locate what you need.

Online Retailers

One of the most convenient options is to explore online marketplaces. Numerous websites specialize in offering a wide variety of components, making it easy to compare prices and find the exact items required. Sites such as Amazon and eBay often have listings for both new and used materials, allowing you to choose based on your budget.

Local Repair Shops

Another valuable resource is local repair shops. Many of these establishments maintain a stock of commonly needed components and may also offer installation services. Establishing a relationship with a local expert can provide you with insights into the best options for your specific needs, ensuring you make informed decisions.

Benefits of Using Original Parts

Utilizing authentic components in your machinery or equipment brings numerous advantages that can enhance performance and longevity. These high-quality items are designed specifically for your device, ensuring compatibility and efficiency. Choosing original replacements can significantly reduce the likelihood of malfunctions and promote a smoother operational experience.

Quality Assurance

One of the primary benefits of original components is their superior quality. Manufactured under strict standards, these items are crafted from durable materials that withstand wear and tear. This attention to detail results in reliable performance, ultimately saving time and money on frequent repairs or replacements.

Optimal Performance

When you opt for genuine replacements, you can expect optimal functionality. These components are engineered to work seamlessly with your equipment, maximizing efficiency and productivity. Ensuring that every part works harmoniously allows for a smoother operation, which is vital for maintaining the overall health of your machinery.

DIY Repairs for LT3000

Maintaining outdoor machinery can seem daunting, but with the right approach, you can tackle common issues effectively. This section focuses on simple repair techniques that empower you to keep your equipment running smoothly. Whether you’re addressing minor wear or needing to replace specific components, understanding the basics will help you avoid costly repairs.

Identifying Common Issues

Before diving into repairs, it’s crucial to identify what might be wrong. Typical problems include poor starting, uneven cutting, or unusual noises. By observing the symptoms, you can narrow down potential causes and determine the necessary fixes.

Gathering Tools and Materials

Having the right tools on hand is essential for any repair task. Basic items such as wrenches, screwdrivers, and pliers are often all you need. Additionally, keep replacement parts accessible to minimize downtime. Consult your owner’s manual for guidance on specific components you may need.

Step-by-Step Repair Process

Start by disconnecting the power source to ensure safety. Follow a systematic approach: first, inspect the affected area, then remove any damaged parts. Replace them with new components, ensuring a snug fit. Reassemble the machine and test it to confirm that the issue has been resolved.

Preventive Maintenance Tips

To extend the lifespan of your equipment, regular maintenance is key. Clean air filters, check oil levels, and sharpen blades periodically. Establishing a routine can help prevent problems before they arise, ensuring your machinery remains in peak condition.

With these straightforward guidelines, you can confidently tackle repairs and enjoy a more efficient and reliable outdoor experience.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its long-lasting performance and reliability. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, saving you time and money in the long run. By adopting a proactive approach to care, you can extend the lifespan of your machinery significantly.

Routine Checks

Conducting frequent inspections can help identify potential issues before they escalate. Pay close attention to key components, and ensure everything is functioning as it should. Here are some critical areas to focus on:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Engine | Check oil levels and change as needed | Every 25 hours of use |

| Blades | Sharpen and inspect for damage | Every 10 hours of use |

| Filters | Clean or replace as necessary | Every 50 hours of use |

| Belt | Check for wear and proper tension | Every 20 hours of use |

Storage Tips

How you store your equipment can greatly affect its longevity. Make sure to keep it in a dry, sheltered location to protect it from the elements. Additionally, consider the following tips for optimal storage:

- Clean the machine thoroughly before storing.

- Remove fuel to prevent degradation.

- Cover with a protective tarp to shield from dust and moisture.

Upgrading LT3000 Features

Enhancing the capabilities of your equipment can significantly improve its performance and longevity. By implementing various upgrades, users can adapt their machines to better meet specific needs and preferences. Whether you are looking to boost efficiency or add convenience, there are numerous options to consider.

One effective way to enhance functionality is by upgrading the power system. A more robust engine can provide increased torque and speed, allowing for more demanding tasks. Additionally, incorporating advanced electrical components can improve reliability and reduce maintenance needs.

Another aspect to focus on is the addition of ergonomic features. Upgrading seats and handles can greatly enhance user comfort, especially during extended use. These modifications not only improve the overall experience but also contribute to better control and maneuverability.

Finally, consider enhancing the attachment options available. Investing in a variety of compatible tools can expand the versatility of your machine, making it suitable for a wider range of applications. This adaptability can turn a standard piece of equipment into a multi-functional workhorse.

Comparing Parts with Other Models

When considering components for a particular machine, it’s essential to analyze how they align with those from similar models. This comparison not only aids in identifying compatible alternatives but also provides insights into performance and longevity. By examining various aspects such as dimensions, functionality, and durability, users can make informed decisions that enhance their equipment’s efficiency.

Key Differences

Several factors can differentiate components among similar machines. Below are some critical areas of comparison:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Material | Steel | Aluminum | Composite |

| Weight | 15 lbs | 10 lbs | 12 lbs |

| Compatibility | High | Medium | High |

Finding Suitable Alternatives

When searching for compatible components, it’s advisable to consider both manufacturer recommendations and user experiences. Reviewing forums and product reviews can reveal valuable insights into what works best across different models. Additionally, exploring aftermarket options can sometimes yield superior alternatives that enhance overall performance.

Resources for Craftsman Owners

Owning a quality machine comes with the responsibility of maintaining and enhancing its performance. Whether you’re looking for repair guides, replacement components, or tips on optimal usage, there are numerous resources available to support you in your endeavors. Accessing reliable information can significantly extend the life of your equipment and improve your overall experience.

Online Communities

- Forums: Engage with fellow enthusiasts on specialized discussion boards where you can share experiences and ask for advice.

- Social Media Groups: Join Facebook or Reddit communities dedicated to owners where you can find tips and share your journey.

- YouTube Channels: Discover instructional videos that provide visual guidance on repairs and maintenance tasks.

Official Support Channels

- Manufacturer’s Website: Visit the official site for access to manuals, troubleshooting guides, and the latest updates on products.

- Customer Service: Reach out to support for assistance with specific issues or inquiries regarding your equipment.

- Local Retailers: Many stores offer in-person assistance and can order parts directly for you.