Understanding the Craftsman LTX 1000 Parts Diagram

Maintaining and operating your lawn machinery requires a solid grasp of its various elements and how they interact. A comprehensive overview of these components can significantly enhance your ability to troubleshoot and optimize performance. Familiarity with the assembly and functionality of each piece can lead to more efficient repairs and improvements.

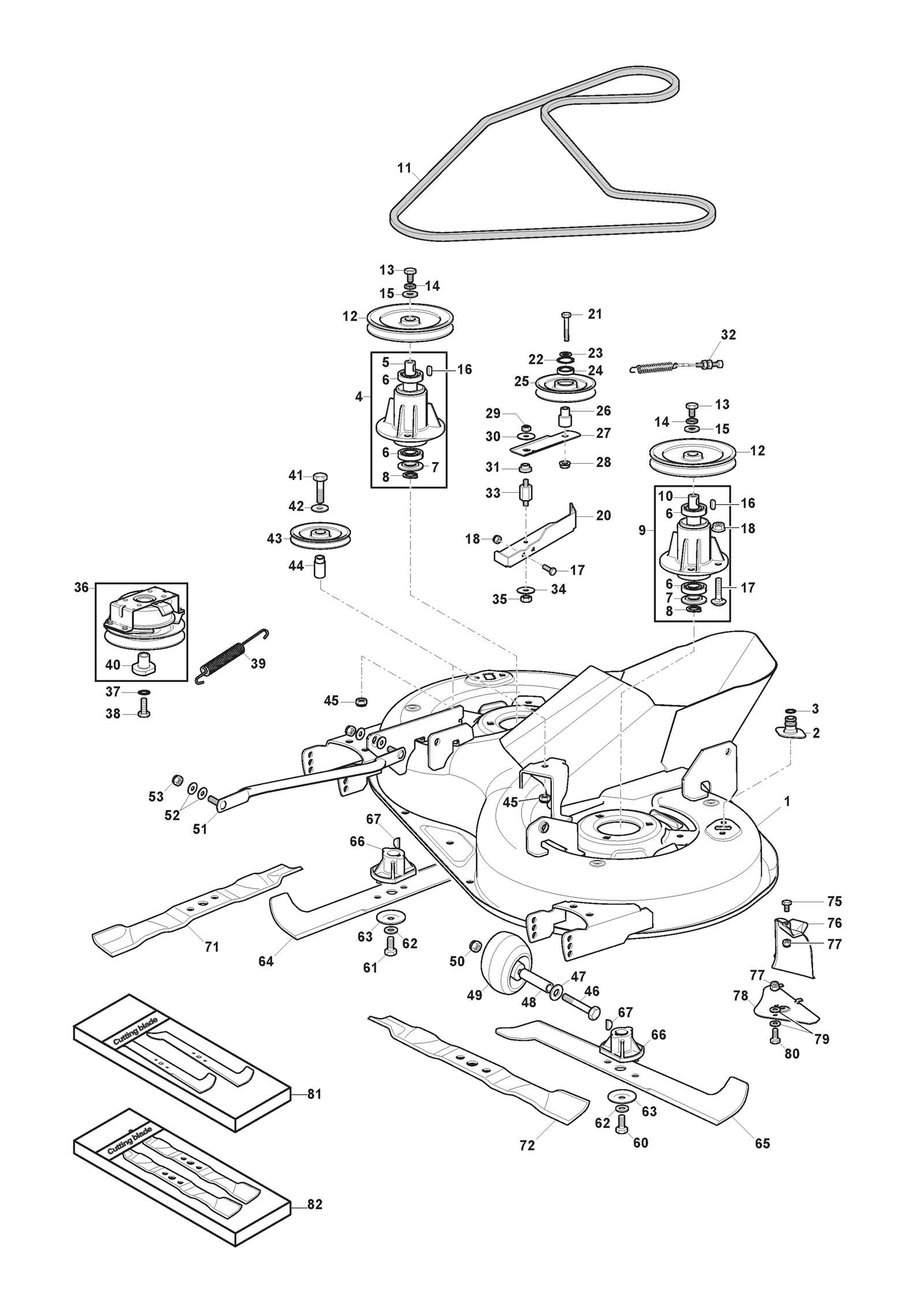

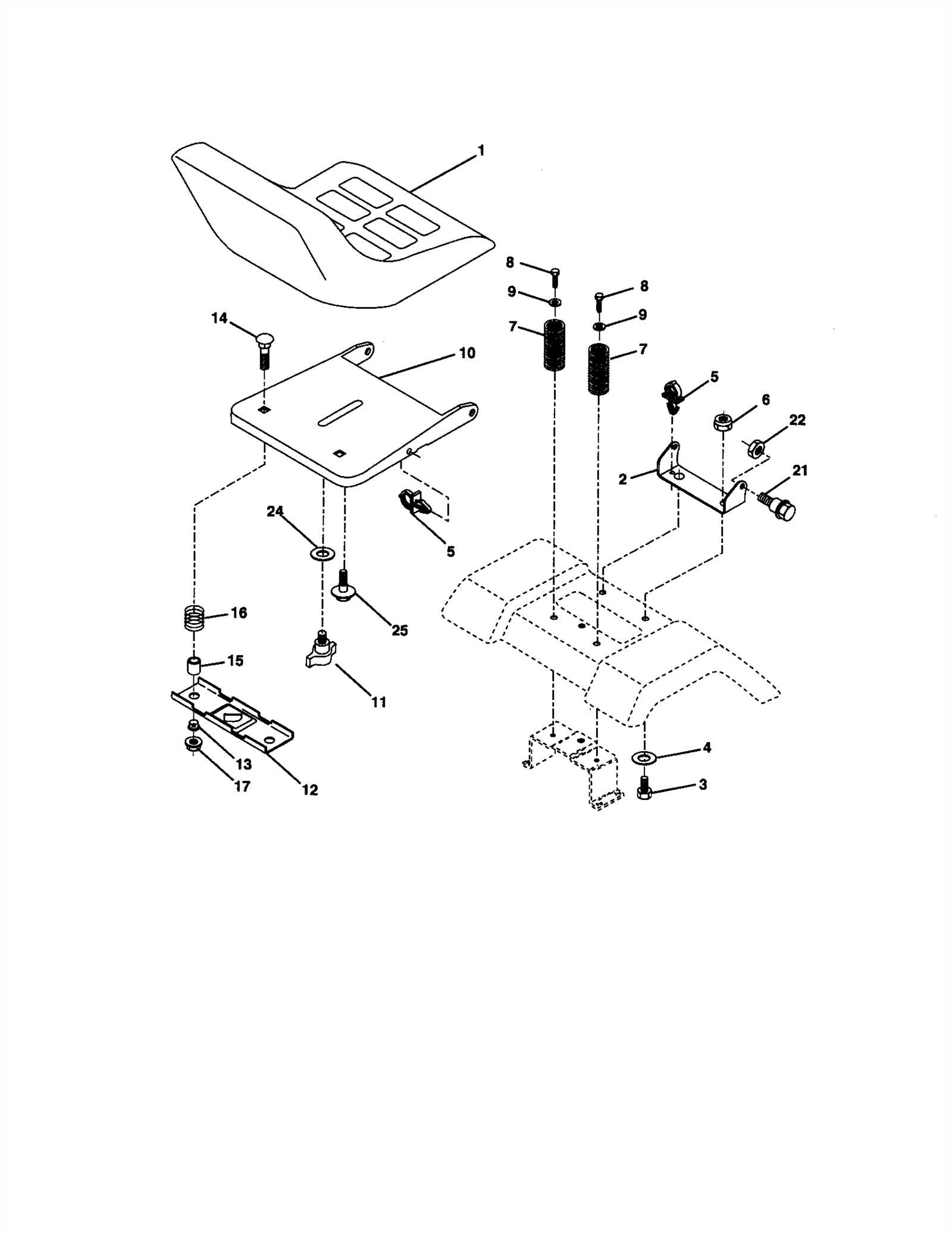

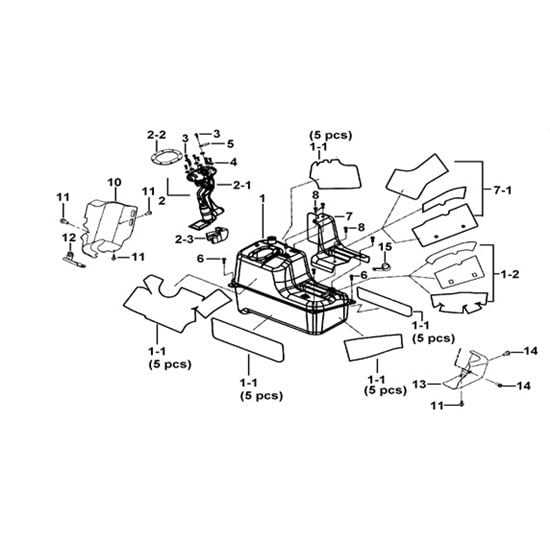

In this section, we will explore a detailed visual representation of the essential elements that make up your lawn care device. By examining the layout and relationships of these individual components, you can gain valuable insights into their respective roles and the overall mechanism of the equipment.

Whether you’re a seasoned enthusiast or a newcomer to lawn maintenance, understanding the intricacies of your equipment’s structure is the ultimate step toward achieving excellence in care. Let’s delve into the key features and how they contribute to the functionality of your device.

Understanding Craftsman LTX 1000 Components

Gaining insight into the various elements that make up a lawn care machine is essential for effective maintenance and repair. Each component plays a crucial role in the overall functionality and performance, ensuring smooth operation and longevity.

Key Components

- Engine: The powerhouse that drives the entire system.

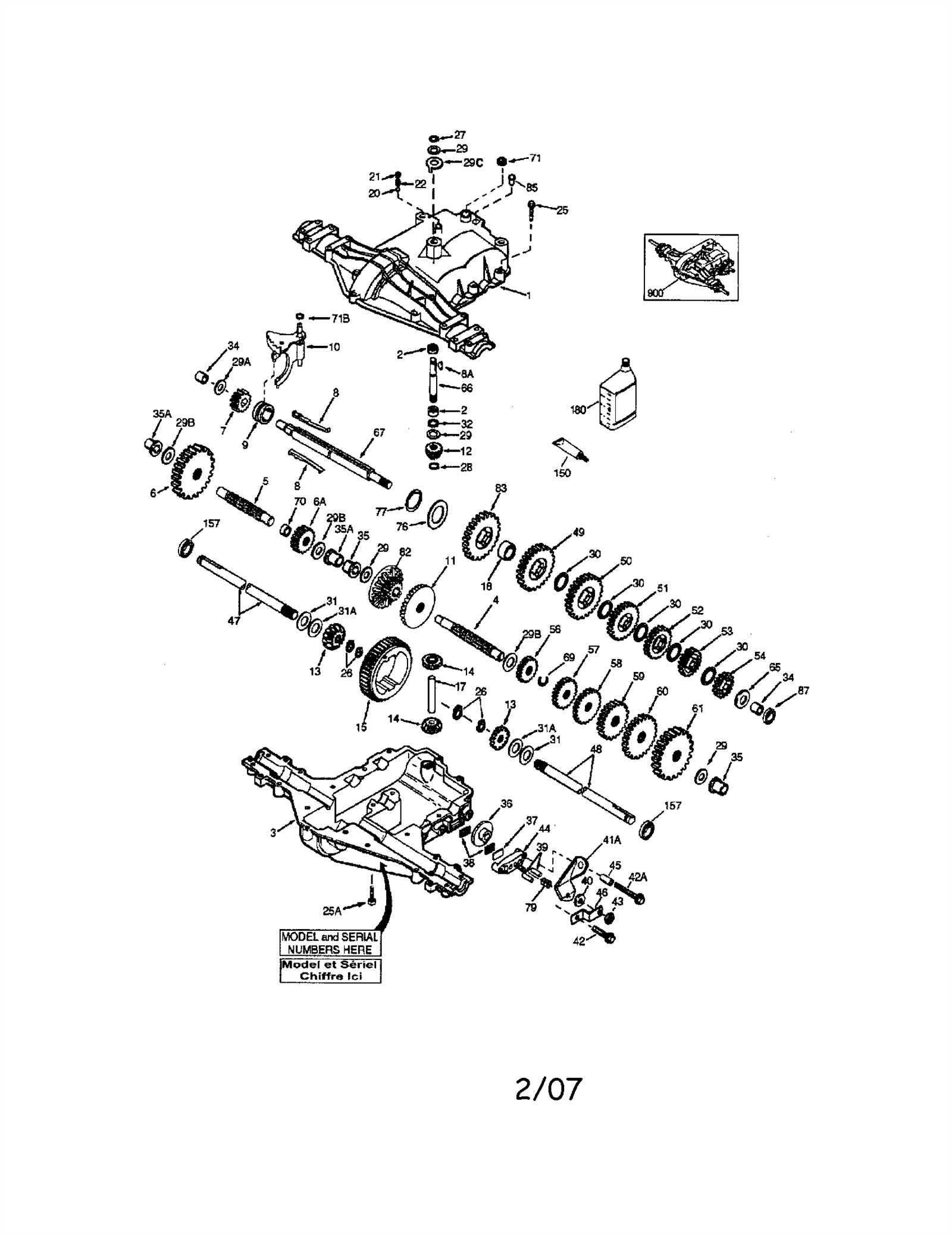

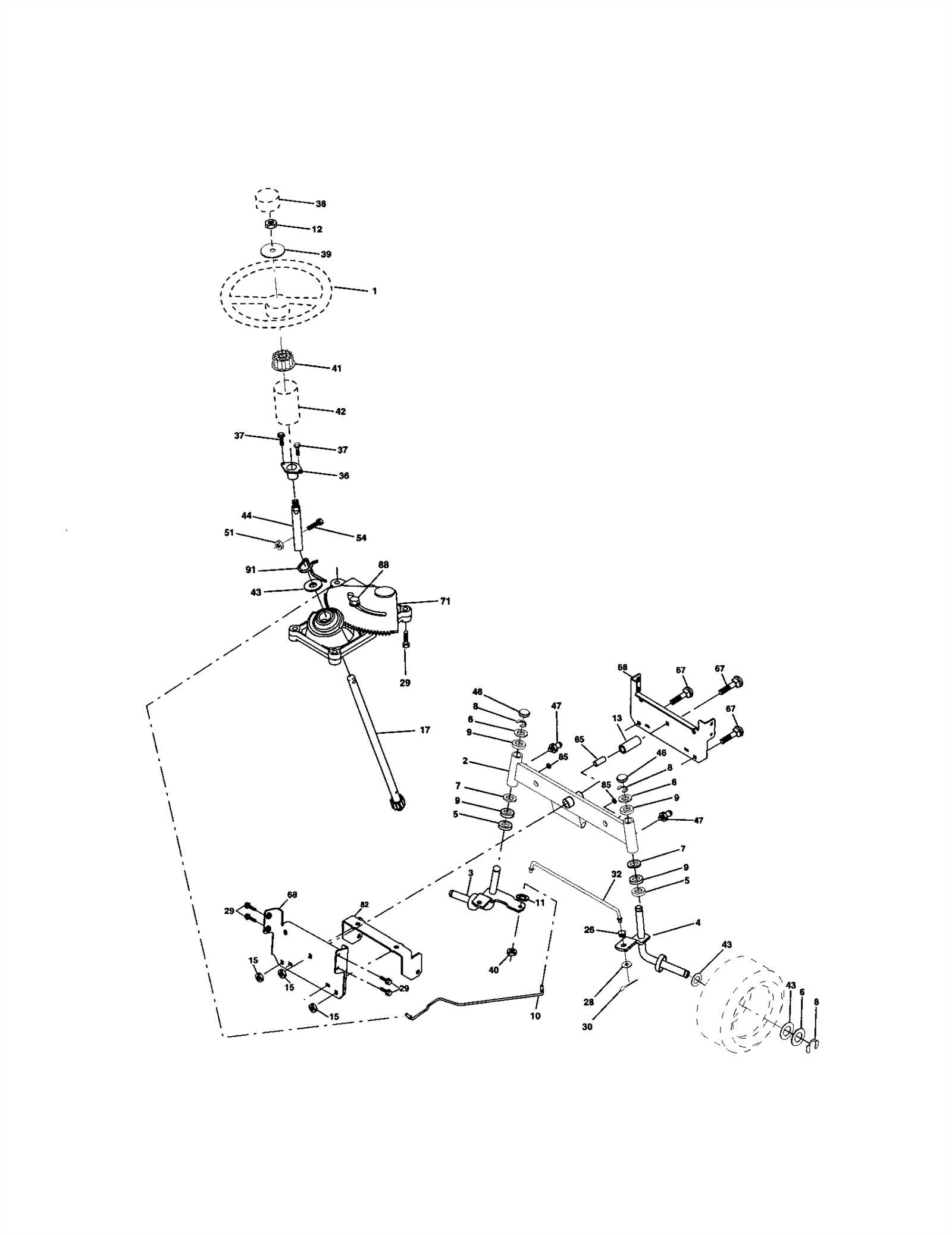

- Transmission: Facilitates smooth movement and speed adjustments.

- Deck: The cutting area, crucial for achieving an even trim.

- Wheels: Provide mobility and stability across different terrains.

Maintenance Tips

- Regularly check the engine oil and replace it as needed.

- Inspect the blades for wear and sharpen them periodically.

- Ensure the transmission fluid is at the recommended level.

- Keep the wheels clean and properly inflated for optimal performance.

Parts Overview and Functionality

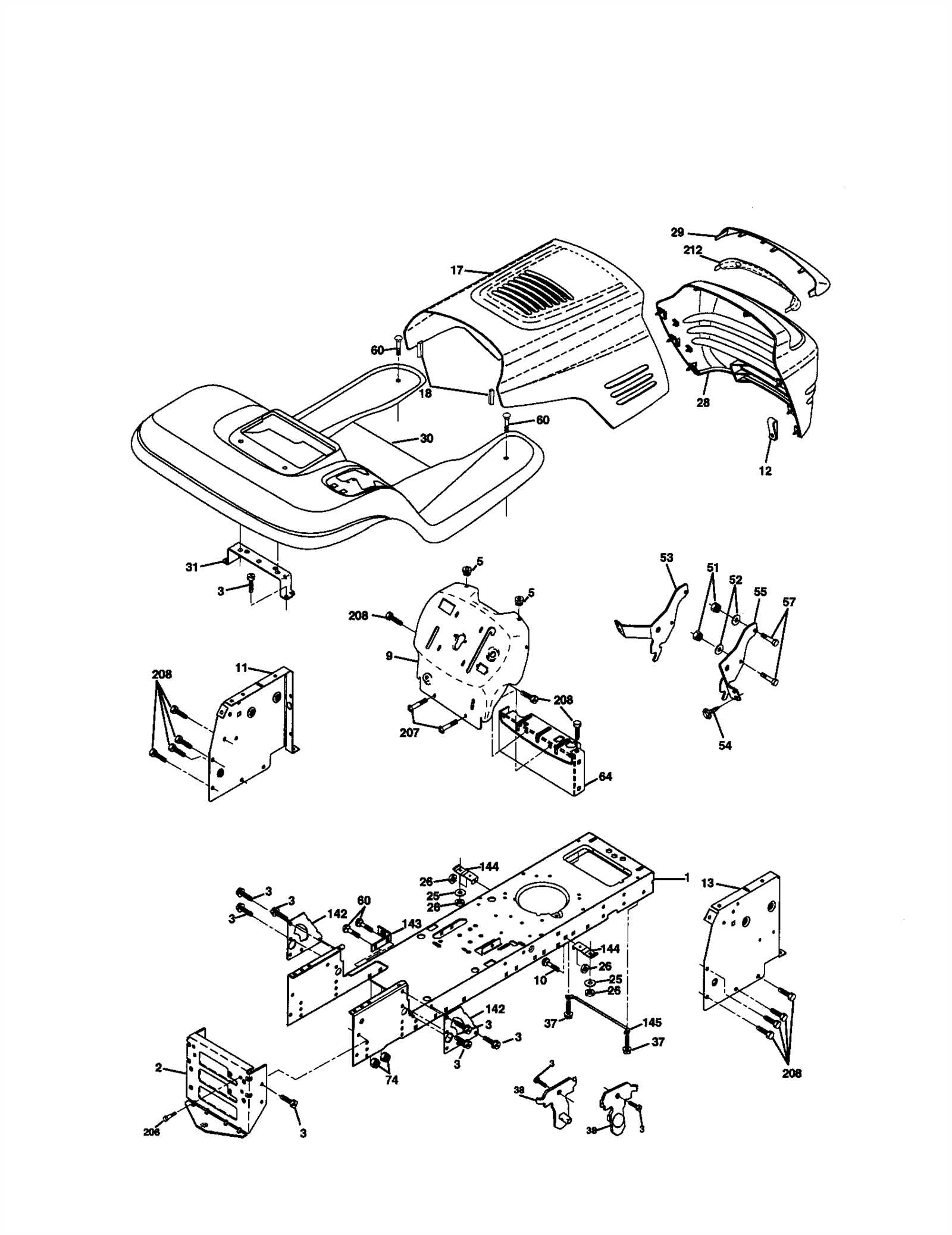

This section delves into the various components that contribute to the overall performance and efficiency of the machine. Each element plays a crucial role, working together to ensure optimal operation. Understanding these components can aid in maintenance and troubleshooting.

Key Components

- Engine: The powerhouse that drives the entire system, converting fuel into mechanical energy.

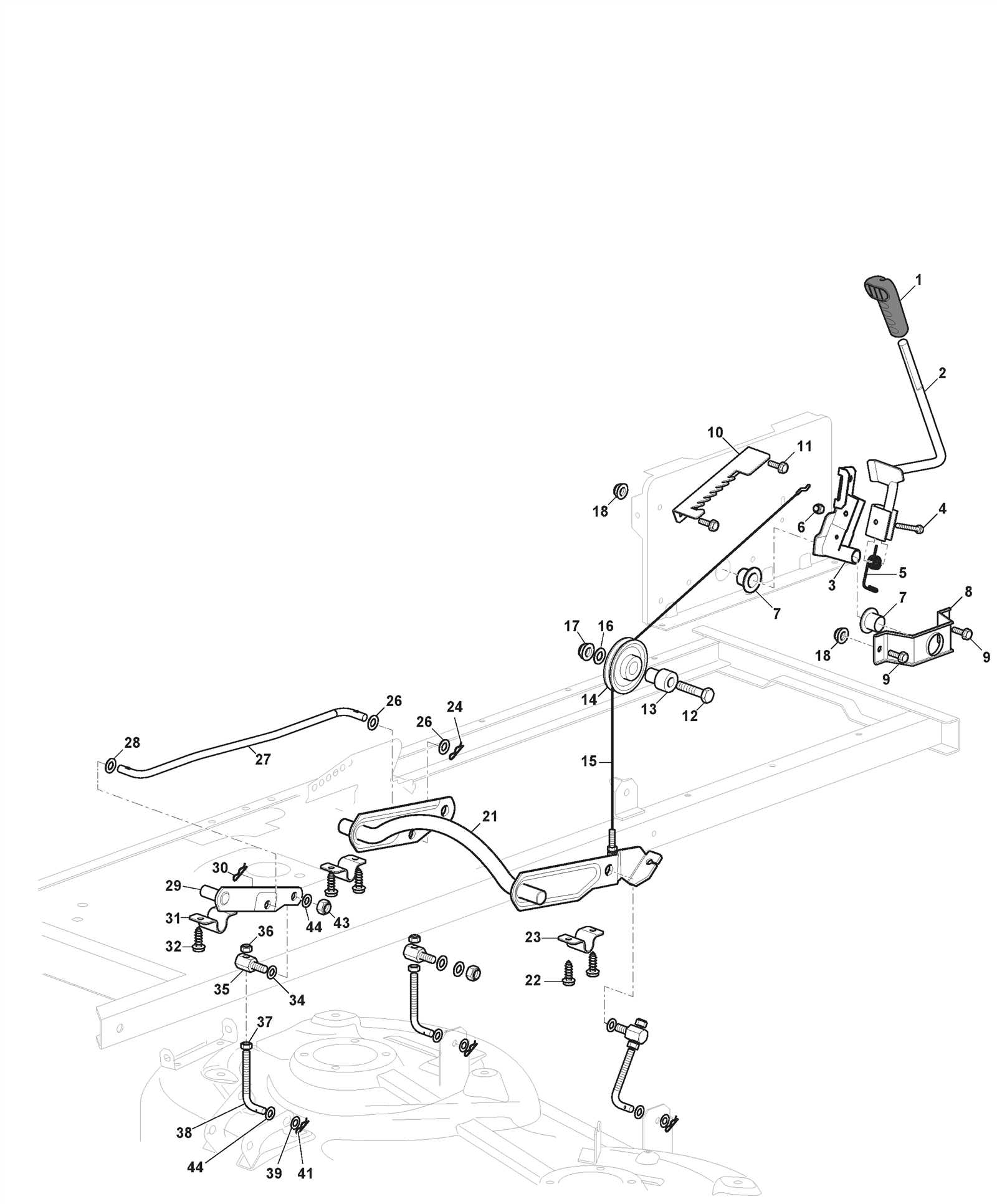

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for speed and direction changes.

- Chassis: The frame that supports all other components, providing stability and strength.

- Wheels: Essential for movement, their design affects traction and maneuverability.

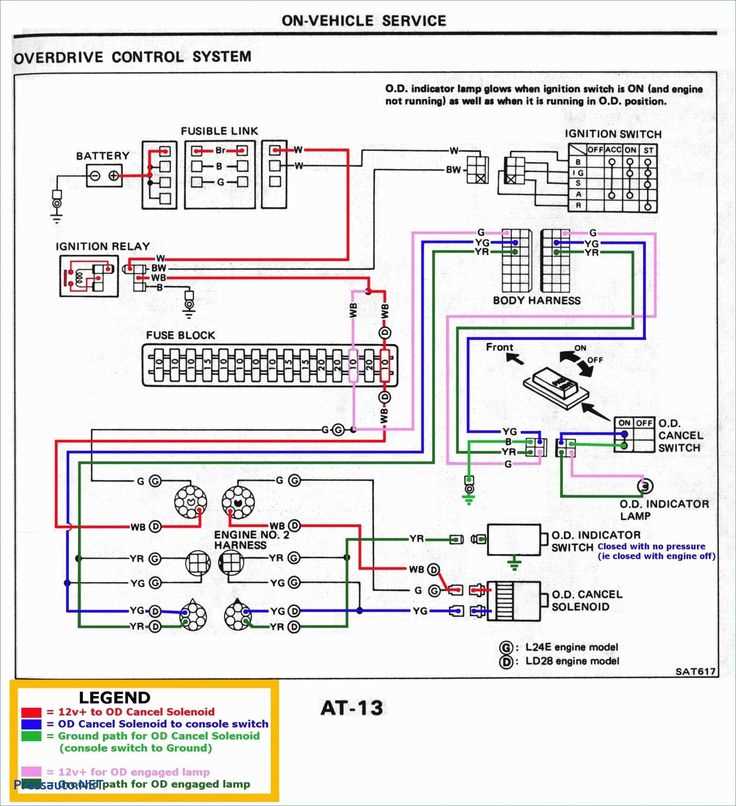

- Control System: The interface that allows the user to operate the machine effectively, including steering and speed adjustments.

Functionality of Each Element

- Engine: Delivers power, influencing the machine’s speed and performance under various loads.

- Transmission: Facilitates smooth gear changes, enhancing efficiency and driving experience.

- Chassis: Provides a solid foundation, ensuring durability and resilience against external forces.

- Wheels: Designed for optimal grip, impacting stability and control during operation.

- Control System: Ensures user-friendly operation, allowing for precise handling and adjustments in real-time.

Key Features of the LTX 1000

This powerful machine combines innovative technology with user-friendly design, making it an essential tool for both enthusiasts and professionals. Its robust construction ensures durability, while a variety of features enhance functionality and ease of use.

Durability and Performance

Built with high-quality materials, this equipment is designed to withstand demanding tasks. The engine provides consistent power, allowing users to tackle various projects efficiently. Additionally, the machine’s advanced cooling system prevents overheating, ensuring long-lasting performance.

User-Friendly Design

Ergonomically designed controls and an intuitive interface make operation straightforward. Features such as adjustable settings enable customization for specific needs, while safety mechanisms provide peace of mind during use. The compact size allows for easy storage and transport, adding to its practicality.

Common Issues and Solutions

In the realm of machinery maintenance, encountering challenges is an inevitable part of ownership. Understanding these typical problems and their corresponding fixes can greatly enhance the longevity and performance of your equipment. This section aims to address some prevalent concerns and offer practical solutions to ensure smooth operation.

Issue 1: Engine won’t start.

Solution: Check the fuel level, ensure the battery is charged, and inspect the ignition system for any faults.

Issue 2: Uneven cutting.

Solution: Examine the blades for sharpness and alignment; adjustments may be needed for optimal performance.

Issue 3: Excessive vibrations.

Solution: Ensure all components are tightly secured, and look for signs of wear on parts such as belts and bearings.

Issue 4: Poor maneuverability.

Solution: Inspect the wheels and tires for proper inflation and alignment, adjusting as necessary for better control.

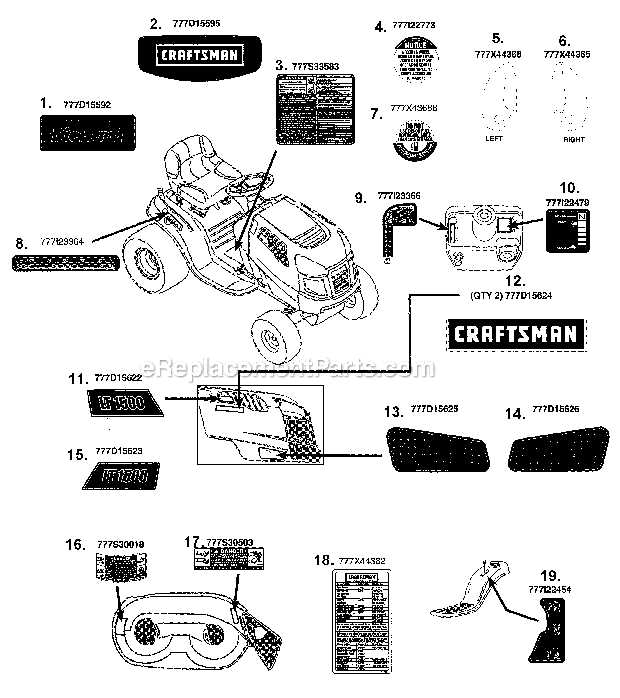

Finding Replacement Parts Easily

Locating suitable components for your machinery can often be a daunting task. However, with the right approach and resources, you can streamline the process and ensure you have the necessary elements for smooth operation.

Utilizing Online Resources

Numerous websites offer comprehensive catalogs of components for various models. By entering the model number, you can quickly access detailed listings that facilitate identification and ordering of required items.

Consulting Local Dealers

Engaging with local retailers or service centers can provide valuable insights. These establishments often maintain inventory and can assist in sourcing specific components efficiently.

In conclusion, whether you choose to explore online platforms or rely on local expertise, a proactive approach will enhance your ability to find what you need without unnecessary delays.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires regular attention and care. Implementing a routine maintenance schedule can significantly enhance its durability and efficiency.

Routine Checks

- Inspect moving parts for wear and tear.

- Clean the exterior regularly to prevent buildup.

- Check fluid levels and top up as necessary.

Storage Practices

- Store in a dry, sheltered location to prevent rust.

- Cover with a protective tarp to shield from dust and debris.

- Avoid direct sunlight to prevent material degradation.

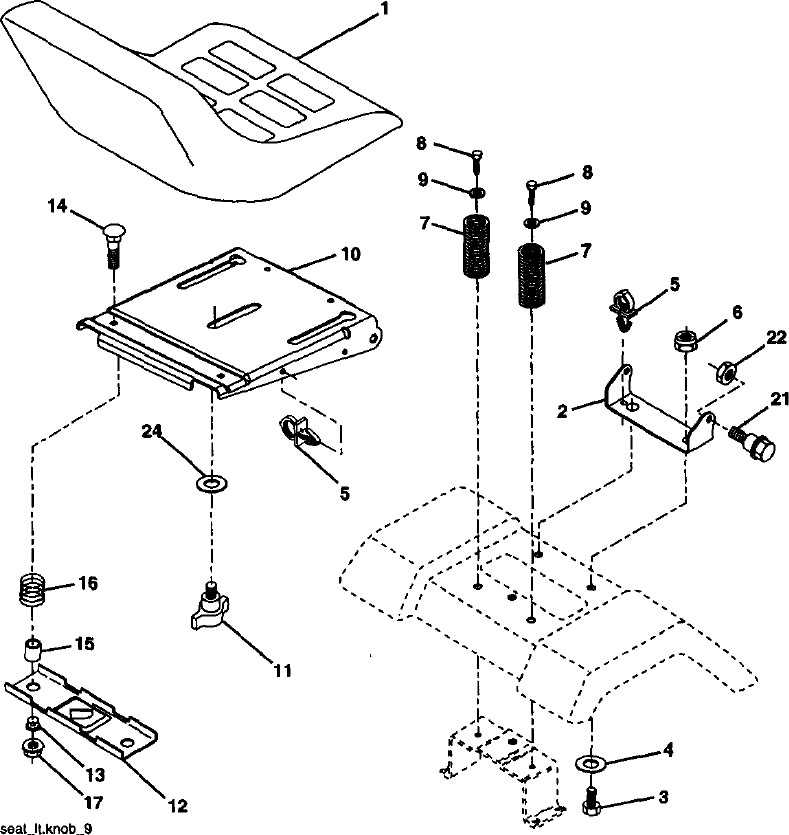

Assembly Instructions for New Owners

As a new owner, understanding the assembly process of your equipment is crucial for optimal performance. Following the correct steps will ensure that every component functions harmoniously, enhancing your overall experience.

Step 1: Begin by unpacking all items carefully, laying them out in an organized manner. This will help you familiarize yourself with each piece and streamline the assembly process.

Step 2: Refer to the included manual for a detailed overview of each component’s role. This knowledge will enable you to connect parts effectively.

Step 3: Assemble larger sections first, ensuring all connections are secure. Use the appropriate tools as suggested in the guide to prevent any damage.

Step 4: Once the main body is complete, attach any additional features or accessories as outlined. This step enhances functionality and provides a polished finish.

Step 5: Finally, conduct a thorough check to ensure all elements are in place and functioning correctly. This final inspection is key to ensuring longevity and performance.

By following these straightforward instructions, you can confidently set up your new equipment and enjoy its benefits to the fullest.

Compatibility with Other Models

Understanding the interchangeability of components between different equipment models can significantly enhance maintenance efficiency and extend the lifespan of your machinery. This section explores the compatibility of various units, providing insights on how to effectively source replacement elements.

Many models share similar construction and design features, allowing parts to be used interchangeably. This compatibility can simplify repairs and reduce downtime. Below are key considerations when evaluating part compatibility:

- Model Series: Check if the models belong to the same series or line, as they often utilize identical components.

- Manufacturer Guidelines: Always refer to the manufacturer’s specifications and recommendations for compatibility details.

- Dimensions and Specifications: Ensure that the dimensions and specifications of the parts match those of your existing components.

- Performance Requirements: Assess whether the performance characteristics of the replacement parts meet the operational demands of your equipment.

Additionally, some aftermarket suppliers provide cross-reference charts that can assist in identifying compatible alternatives across different brands and models. Utilizing these resources can lead to cost-effective repairs and improved machinery performance.

Upgrades to Enhance Performance

Improving the efficiency and effectiveness of your machine can significantly enhance its overall functionality. A variety of modifications can be made to optimize performance, whether it involves boosting power output, improving handling, or increasing durability. These upgrades can provide a smoother experience and extend the lifespan of your equipment.

Below are some key enhancements you might consider to elevate performance:

| Upgrade Type | Description |

|---|---|

| Engine Tuning | Adjusting the engine settings can lead to improved horsepower and fuel efficiency. |

| Suspension System | Upgrading the suspension can enhance stability and ride comfort, particularly on uneven terrain. |

| Blade Quality | Investing in high-quality blades can result in a cleaner cut and reduced wear on the machine. |

| Transmission Enhancements | Modifying the transmission system can improve responsiveness and acceleration. |

| Weight Distribution | Adjusting weight distribution can improve balance and maneuverability during operation. |

Implementing these upgrades can lead to a noticeable improvement in performance, making your equipment more efficient and enjoyable to use.

Resources for Troubleshooting

When faced with challenges in equipment maintenance, having access to reliable resources can make a significant difference. Numerous tools and guides are available to assist in identifying and resolving issues efficiently. From user manuals to online forums, these resources can help users understand common problems and their solutions.

Manufacturer Support: Direct support from the manufacturer often provides detailed insights. Their official website usually features troubleshooting guides, FAQs, and contact information for customer service, making it easy to obtain specialized assistance.

Online Forums and Communities: Engaging with fellow enthusiasts and users can yield practical advice and shared experiences. Websites dedicated to specific equipment types often have discussion boards where individuals can post questions and receive feedback from knowledgeable peers.

Video Tutorials: Many individuals find visual aids beneficial. Platforms like YouTube host a plethora of instructional videos that demonstrate step-by-step procedures for resolving common issues, making complex tasks more approachable.

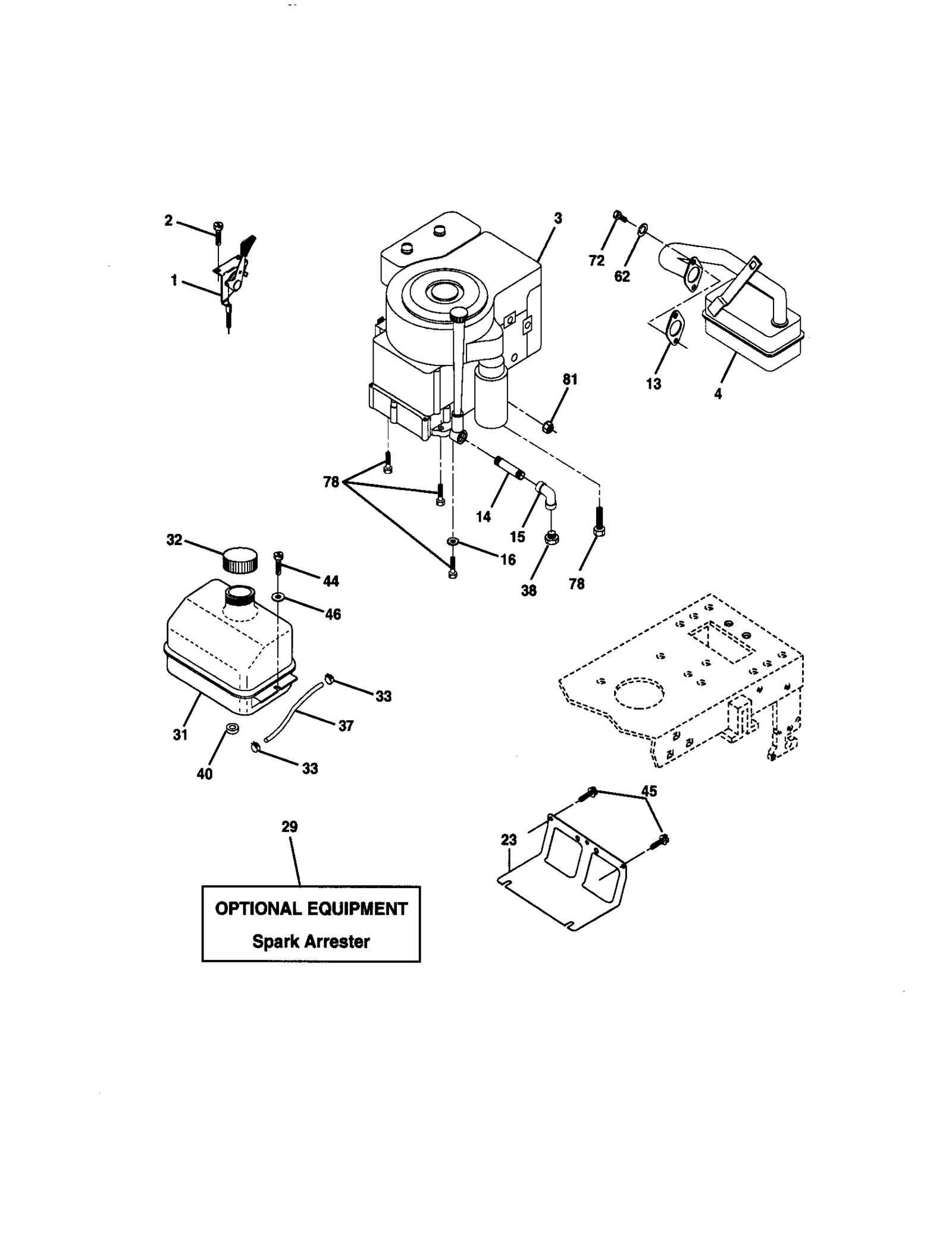

Repair Guides: Comprehensive repair manuals and guides can be invaluable. These resources provide in-depth explanations and diagrams that detail the disassembly and reassembly of equipment, allowing for a clearer understanding of the repair process.

Parts Suppliers: For those needing replacements, suppliers often offer parts catalogs and diagrams. These resources help identify specific components and ensure that the correct parts are ordered for repairs.

By leveraging these resources, users can navigate troubleshooting more effectively, ultimately enhancing their experience and prolonging the life of their equipment.

Benefits of Using Original Parts

Utilizing authentic components for maintenance and repairs brings numerous advantages that enhance both performance and longevity. Original items are designed specifically for the equipment, ensuring compatibility and optimal functionality.

- Quality Assurance: Genuine components are manufactured to meet stringent quality standards, which guarantees reliability and durability.

- Perfect Fit: These items are crafted to exact specifications, reducing the risk of improper installation and subsequent issues.

- Enhanced Performance: Authentic parts are engineered to work seamlessly with the machinery, maximizing efficiency and effectiveness.

- Warranty Protection: Using original items often helps maintain warranty coverage, safeguarding your investment over time.

- Improved Safety: Genuine components reduce the likelihood of malfunctions, which can pose risks during operation.

Incorporating original components into your maintenance routine is a proactive choice that leads to greater peace of mind and sustained performance.