Craftsman Platinum 7.00 190cc Parts Diagram Guide

Delving into the intricacies of a high-powered outdoor machine can provide valuable insights into its maintenance and optimization. This comprehensive guide focuses on the fundamental elements that keep such a model running smoothly and reliably. Here, we’ll explore the major components that form the core of this engine model, helping you understand each piece’s unique role and functionality.

In the following sections, we’ll uncover detailed illustrations that reveal the exact placement and connections of various elements within this engine design. With a closer look at these sections, you can learn how each component interlinks, ultimately contributing to the machine’s performance. Such a clear breakdown can be invaluable, whether you’re aiming to perform routine upkeep or undertaking more extensive repairs.

Additionally, gaining a deeper understanding of this robust engine type can help you troubleshoot issues more effectively. With a thorough grasp of each element’s purpose, you’ll be better equipped to identify and resolve potential problems quickly. This guide will act as a resourceful companion for those seeking to enhance their knowledge and maximize the lifespan of their reliable outdoor power equipment.

Craftsman Platinum 7.00 190cc Overview

This high-performance lawn machine is designed for those seeking efficient and reliable yard maintenance. Built with a robust engine, it offers consistent power output, making it suitable for tackling various types of terrain. The well-engineered structure and user-friendly features ensure an enjoyable and productive mowing experience.

Engine Performance

The core of this yard tool is its strong motor, which provides substantial torque and durability. Engineered to handle both smooth and rugged surfaces, this machine ensures optimal cutting precision and evenness. Additionally, the enhanced fuel efficiency allows for longer operational periods, reducing the need for frequent refueling.

Ease of Use and Comfort

With ergonomic design features, this mower provides a comfortable grip and easy maneuverability, even on challenging landscapes. The intuitive controls are strategically placed, enabling users to adjust settings with minimal effort. This ensures a straightforward operation that can be mastered quickly, making lawn care a simpler task for homeowners.

Overall, this garden tool combines high functionality with ease of use, making it a practical choice for both experienced gardeners and beginners. Its durability and consistent performance contribute to an effective and enjoyable mowing routine.

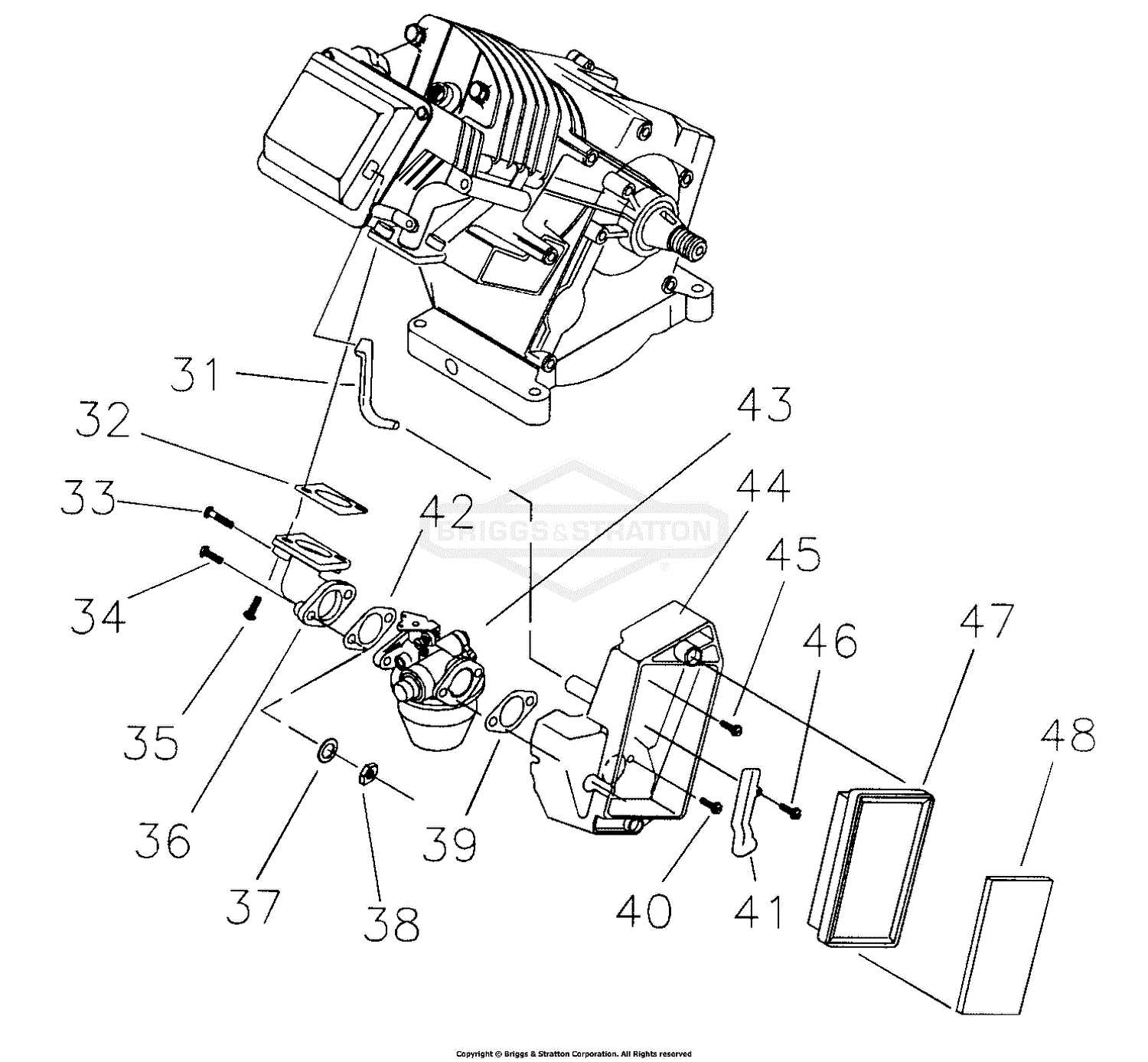

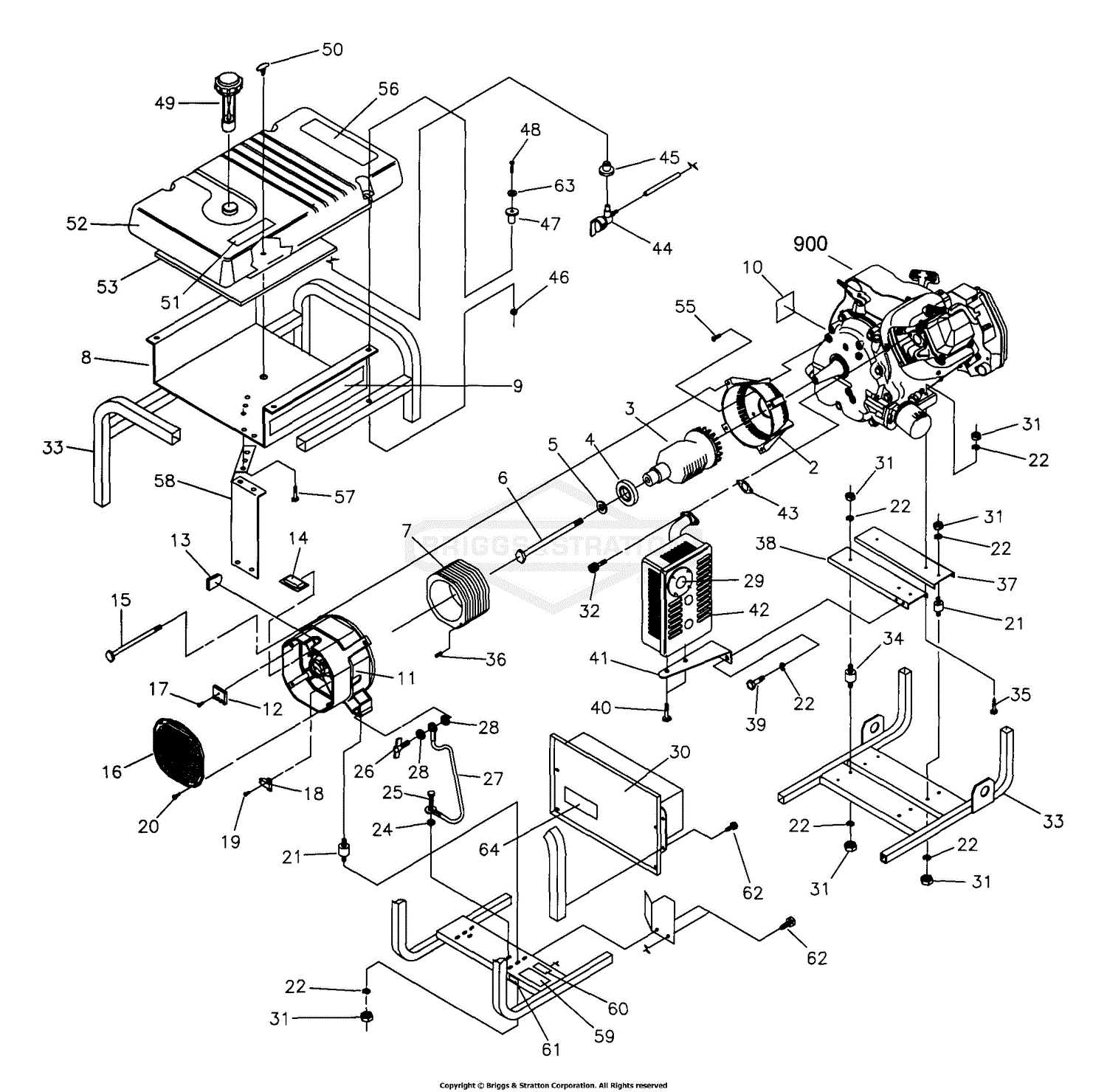

Engine Components and Their Functions

Understanding the essential elements within a small engine and their roles can greatly improve both maintenance and performance. Each component works in harmony, contributing to the overall operation and efficiency. This section outlines the key parts involved in this process, detailing their primary functions to help you better grasp how an engine operates as a whole.

1. Cylinder and Piston

The cylinder forms the main body where the piston moves up and down. This motion is critical in converting fuel into mechanical power. The piston fits snugly within the cylinder, creating the necessary compression needed for ignition and power generation. Over time, ensuring these components remain well-lubricated is essential for optimal performance.

2. Carburetor and Air Filter

The carburetor is responsible for blending air and fuel before they enter the combustion chamber. By regulating this mixture, the carburetor ensures efficient fuel consumption and smoother engine operation. Paired with it, the air filter prevents dirt and debris from entering the system, keeping the internal components clean and extending the engine’s lifespan.

Other significant parts, such as the spark plug and crankshaft, each play a role in this intricate system. The spark plug ignites the fuel mixture, and the crankshaft transforms the piston’s linear movement into rotational force. Together, these elements form a powerful yet compact machine, capable of tackling various tasks with precision.

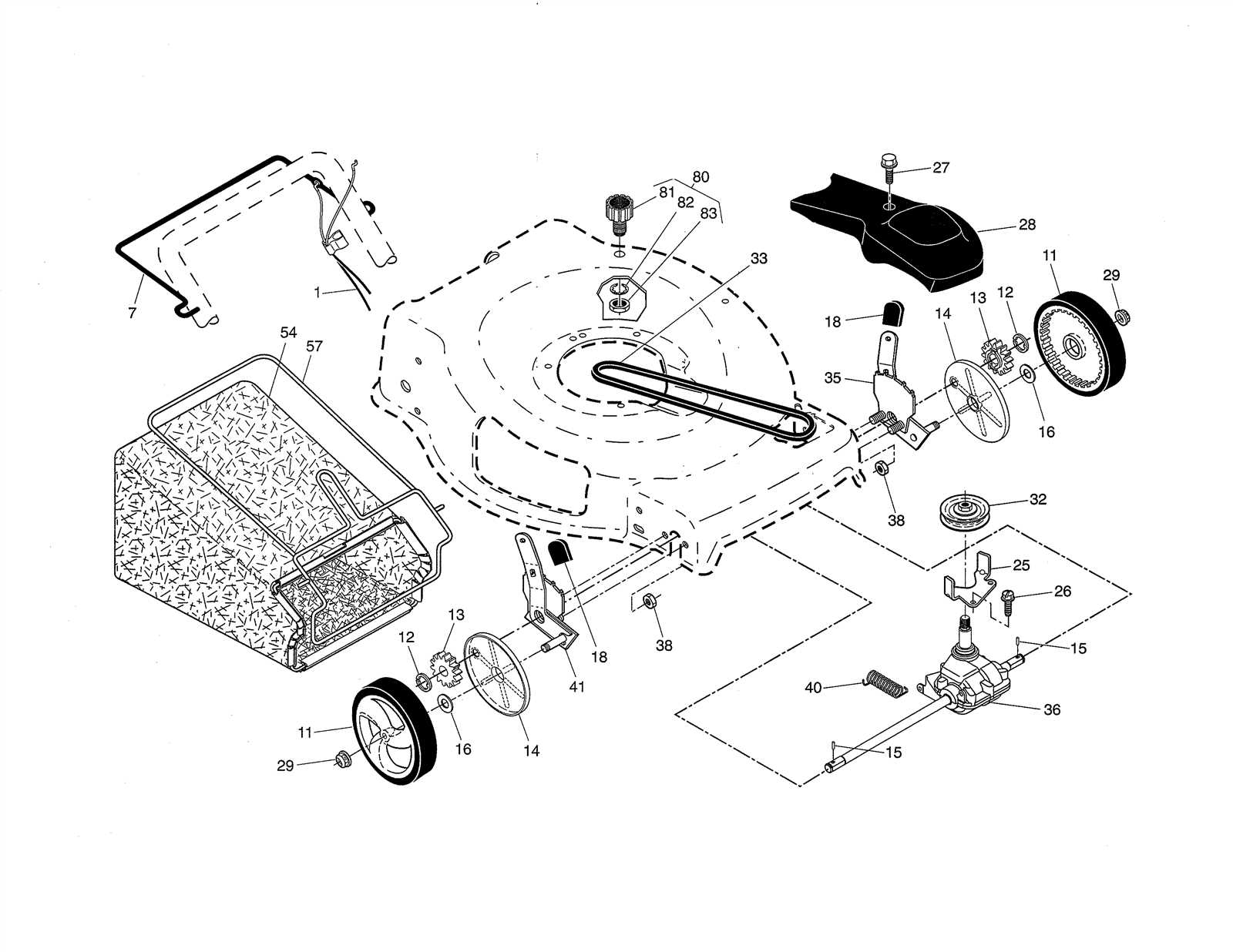

Blade System and Maintenance Tips

Understanding how the cutting system operates and knowing how to maintain it are essential for ensuring efficient performance and extending its longevity. This section offers insights on the overall structure of the cutting component and practical advice on routine upkeep to enhance its durability.

Inspect the Blade Regularly: Periodically checking the blade for any signs of wear or damage can prevent more serious issues from arising. Look for any nicks, bends, or dull edges that might affect the cutting quality. If you notice any of these, sharpening or replacing the blade may be necessary.

Sharpening Techniques: Maintaining a sharp edge on the cutting blade is key to achieving clean and precise cuts. Use a file or a grinder to sharpen the blade, following the original bevel. Remember to wear safety gloves and eye protection during this process, and always disconnect the power source before handling the blade.

Proper Cleaning After Use: Cleaning the blade and the surrounding area after each use helps to avoid corrosion and buildup that can hinder performance. Use a hose to wash off any debris or grass clippings, and dry the blade thoroughly before storing. This will help in keeping the blade in prime condition over time.

Blade Balancing: An unbalanced blade can lead to vibrations, which may affect the overall performance of the equipment. After sharpening, it’s wise to balance the blade by placing it on a nail or a balancing tool. This ensures the blade remains level on both sides, which supports smooth operation.

Regular maintenance not only enhances performance but also promotes safer operation, so make it a habit to examine the cutting system frequently and address any issues promptly.

Air Filter and Replacement Process

Keeping the air intake system clean is essential for optimal engine performance. Regular maintenance of the air filter ensures that the engine receives a steady flow of clean air, helping to prolong its lifespan and improve fuel efficiency. Understanding the basic steps for replacing this component can simplify the process and maintain peak engine function.

Step 1: Locate the Filter Housing

Begin by identifying the cover that encloses the air filter. Typically, this housing is situated near the engine, secured with simple clips or screws. Carefully unfasten the cover to access the filter inside.

Step 2: Remove the Old Filter

Gently lift out the old filter, being cautious not to dislodge any dirt or debris that may have accumulated. Examine the filter for excessive wear or damage. If it appears clogged or torn, replacing it with a fresh one is necessary.

Step 3: Insert the New Filter

Place the new air filter into the housing, ensuring it fits snugly and is aligned properly. Confirm that the filter’s edges are seated securely to prevent unfiltered air from bypassing it.

Step 4: Secure the Housing

Once the new filter is in position, reattach the cover by fastening the clips or screws. Ensure that the housing is tightly closed to maintain a proper seal, which is vital for effective filtration.

Regularly replacing the air filter promotes a cleaner combustion process and aids in maintaining consistent engine output. By following these straightforward steps, you can ensure the longevity of the engine and improve overall operational efficiency.

Understanding the Fuel System Layout

The fuel system is a crucial component responsible for delivering the necessary energy to the engine. By ensuring a smooth and efficient flow from the fuel storage to the engine’s combustion chamber, this system supports optimal performance. This section provides an overview of the various elements involved in the fuel delivery mechanism and highlights how they work together to power the machine.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel required for operation, supplying it to the system as needed. |

| Fuel Line | Acts as the pathway through which fuel travels from the tank to other parts of the system. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine, promoting cleaner combustion. |

| Carburetor | Mixes fuel with air in precise proportions for efficient combustion within the engine. |

| Primer Bulb | Manually pumps fuel into the carburetor to assist in starting the engine, especially when it’s cold. |

Oil Change Instructions for Longevity

Regular maintenance of lubrication fluids is crucial for ensuring the durability and efficient operation of outdoor power equipment. This essential procedure not only enhances performance but also extends the lifespan of the machinery. Proper oil replacement prevents overheating and reduces wear on engine components, ultimately leading to improved reliability and functionality.

Steps for Changing Oil

1. Begin by warming up the machine briefly to thin the oil, allowing it to drain more easily. Turn off the engine and let it cool for a few minutes.

2. Position a suitable container beneath the oil drain plug to catch the used fluid. Carefully remove the plug and allow the old oil to flow completely into the container.

3. Once drained, replace the drain plug securely.

4. Fill the engine with fresh lubricant using the recommended type and amount specified in the user manual. Be sure to check the oil level with the dipstick, adding more if necessary.

Post-Change Care

After changing the lubricant, run the engine for a few minutes to circulate the new oil throughout the system. Check for leaks around the drain plug and oil fill cap. Dispose of the old oil properly at a recycling center or an authorized disposal site to protect the environment.

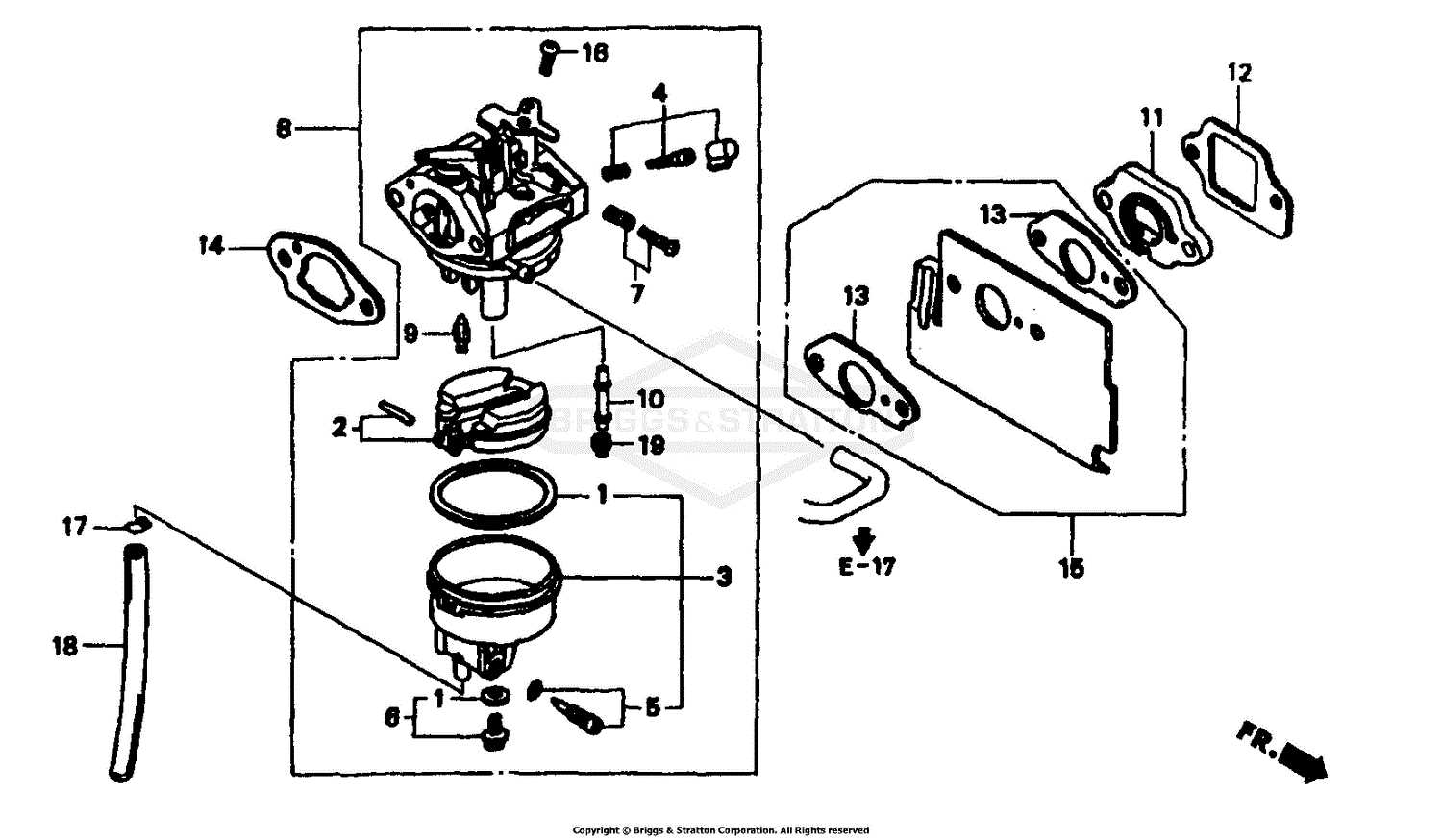

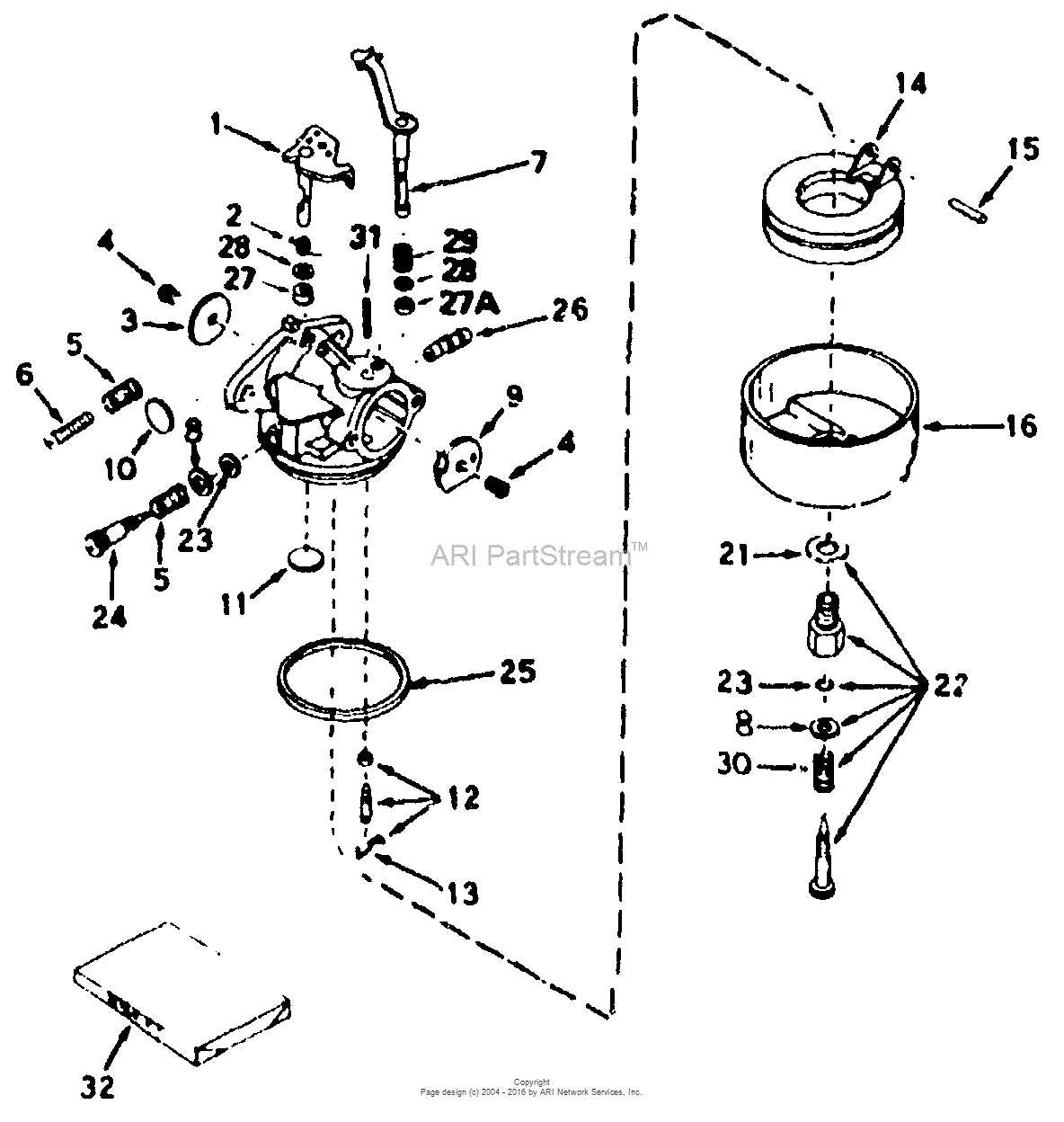

Carburetor Setup and Cleaning Guide

Proper configuration and maintenance of the fuel delivery mechanism are essential for optimal performance and efficiency of your outdoor equipment. This section provides insights into effectively setting up and cleaning the mechanism, ensuring smooth operation and prolonging the lifespan of your machine.

Configuration Steps

To achieve the best results, follow these essential steps for correct setup:

- Begin by reviewing the manufacturer’s specifications to understand the ideal adjustments for air and fuel mixtures.

- Ensure that all connections are secure and free from debris to facilitate proper airflow.

- Adjust the screws carefully, making minor changes and testing the engine’s performance after each adjustment.

Cleaning Process

Maintaining cleanliness is vital to prevent clogs and ensure efficient operation. Follow these guidelines:

- Remove the mechanism from the engine, taking care to note the arrangement of parts for reassembly.

- Use a carburetor cleaner to eliminate built-up residues, ensuring all passages are clear.

- Inspect and replace any worn or damaged components, including gaskets and O-rings, to maintain a tight seal.

- Reassemble the mechanism and reinstall it, making sure everything is secure before starting the engine.

Regular maintenance and proper setup of the fuel delivery system will significantly enhance performance and reliability, ensuring that your equipment remains in excellent working condition.

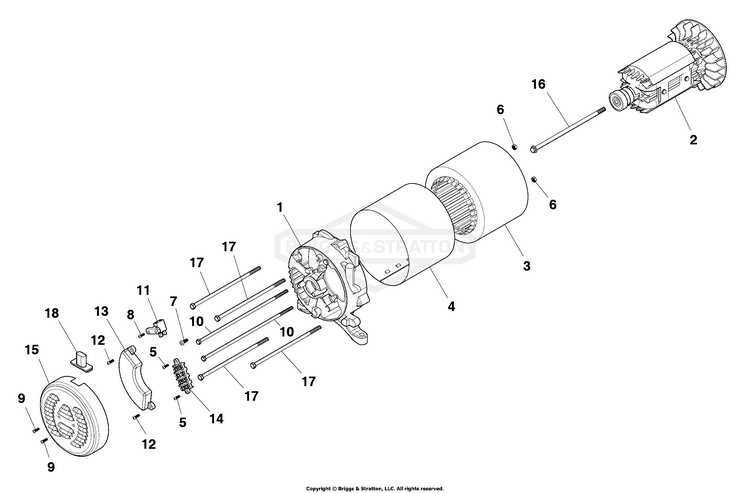

Ignition System and Spark Plug Care

The ignition system plays a crucial role in the overall performance of small engines. It is responsible for generating the spark that ignites the fuel-air mixture, ensuring efficient operation. Proper maintenance of this system, particularly the spark plug, is essential for optimal engine functionality and longevity.

Understanding the Ignition System

The ignition mechanism comprises various components, including the ignition coil, wires, and, most importantly, the spark plug. Each part must work in harmony to produce a reliable spark. Regular inspections can help identify issues early, such as damaged wires or worn components, which can significantly impact engine performance.

Maintaining Spark Plugs

Regular maintenance of the spark plug is vital for ensuring consistent ignition. Cleaning the plug can prevent carbon buildup, which can lead to misfires and poor performance. Additionally, it is essential to check the gap between the electrodes, as an incorrect gap can affect ignition timing. Replacing worn or damaged spark plugs at recommended intervals will enhance engine efficiency and reduce fuel consumption.

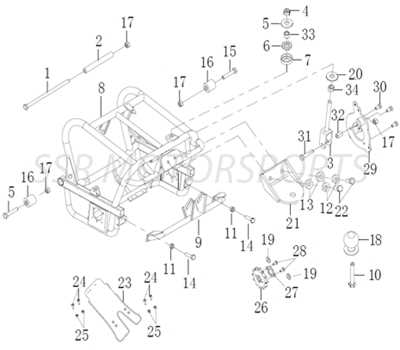

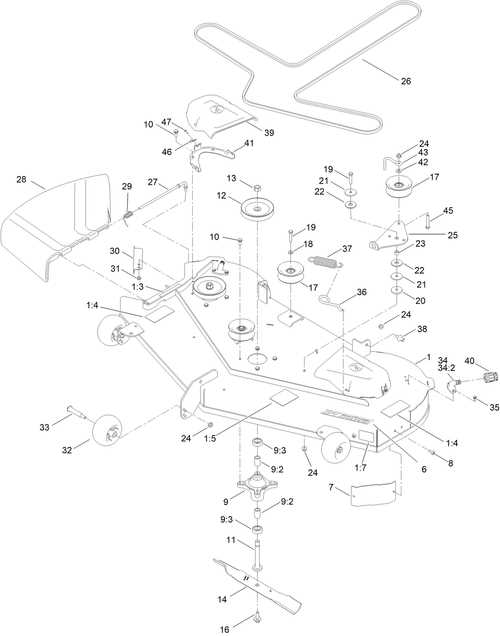

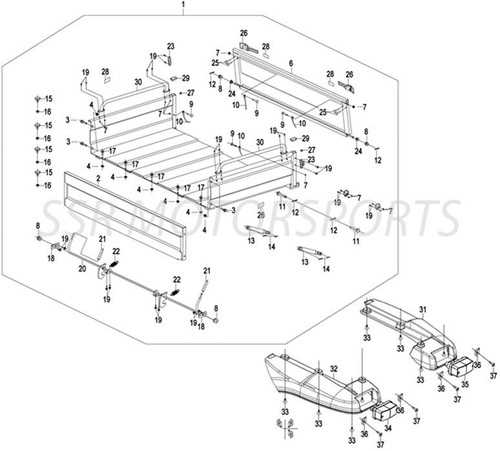

Deck Assembly and Adjustment Tips

Proper assembly and fine-tuning of the cutting platform are crucial for achieving optimal performance and longevity of your lawn maintenance equipment. Ensuring that all components fit together seamlessly and are adjusted correctly can greatly enhance the efficiency and effectiveness of your mowing tasks. This section provides essential guidelines for assembling and adjusting the deck to ensure it operates smoothly.

Assembly Instructions

To begin with, gather all necessary components and tools. Follow these steps to ensure a successful assembly:

- Start by securing the main frame to the cutting platform. Align the holes and insert the bolts, tightening them securely.

- Attach the blade assembly, ensuring that it is centered and firmly fastened.

- Connect any necessary belts or cables, making sure they are routed correctly to avoid interference with moving parts.

- Finally, check all connections and tighten any loose fittings to prevent vibration during operation.

Adjustment Techniques

Once the deck is assembled, adjustments are necessary to ensure an even cut and optimal performance. Follow these tips:

| Adjustment Type | Procedure |

|---|---|

| Cutting Height | Use the height adjustment lever to set the desired cutting height. Test on a small area and adjust as needed. |

| Blade Leveling | Check that the blades are level by measuring the distance from the ground to the blade tips on both sides. Adjust the height if necessary. |

| Belt Tension | Inspect the tension of the drive belt. It should be tight enough to prevent slipping but not so tight that it strains the motor. |

Throttle Control and Cable Mechanism

The throttle control system is a crucial component in regulating engine performance. It enables the operator to adjust the power output by controlling the air-fuel mixture entering the combustion chamber. This system consists of a series of interconnected elements that work together to ensure smooth operation and responsiveness to user input.

At the heart of the throttle control is the cable mechanism, which transmits the user’s input from the control lever to the throttle body. This mechanical connection is essential for translating motion into the desired engine response. Proper functioning of this system is vital for achieving optimal performance and efficiency.

| Component | Function |

|---|---|

| Throttle Lever | Allows the operator to adjust the throttle position. |

| Cable | Transfers movement from the throttle lever to the throttle body. |

| Throttle Body | Controls the airflow into the engine based on the throttle position. |

| Return Spring | Ensures the throttle returns to the idle position when the lever is released. |

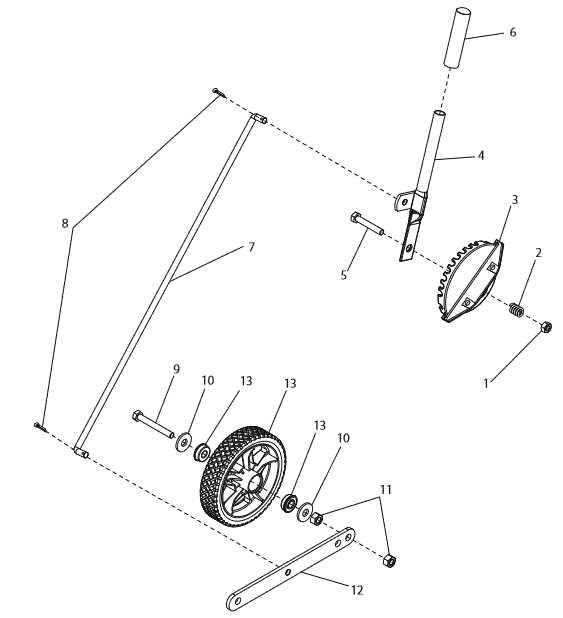

Wheels and Height Adjustment Guide

Maintaining the optimal performance of your equipment involves understanding the essential components that contribute to mobility and stability. The wheels play a crucial role in ensuring smooth movement across various terrains, while height adjustment features allow for personalized operation based on user preference and the environment.

Wheels: Selecting the appropriate wheels is vital for achieving the desired maneuverability. Consider factors such as tread design, size, and material. For instance, larger wheels can enhance mobility on uneven surfaces, while softer compounds provide better traction on soft ground.

Height Adjustment: The ability to modify height is crucial for adapting to different tasks. Ensure the adjustment mechanism is easy to operate and provides a range that accommodates various needs. Regularly check for wear and tear on adjustment levers and locks to maintain safety and efficiency during use.

By focusing on these aspects, users can ensure their equipment performs optimally, allowing for efficient operation tailored to specific requirements.

Handle Assembly and Comfort Features

The handle assembly is a crucial component that greatly influences the usability and comfort of any outdoor tool. It is designed to provide ease of maneuverability and a secure grip, enhancing the overall user experience. Various features are integrated to ensure that the user can operate the equipment with minimal strain and maximum control.

- Ergonomic Design: The shape of the handle is crafted to fit comfortably in the hand, reducing fatigue during prolonged use.

- Soft Grip Material: High-quality, non-slip materials are used to cover the handle, ensuring a firm grasp even in wet or challenging conditions.

- Adjustable Heights: Some models feature height adjustment options, allowing users of different sizes to find their ideal grip position.

- Vibration Dampening: Advanced technology is utilized to minimize vibrations transmitted through the handle, enhancing comfort and reducing user fatigue.

- Integrated Controls: User-friendly controls are strategically positioned within easy reach, allowing for effortless adjustments while operating the tool.

These elements collectively contribute to a more enjoyable and efficient experience, enabling users to focus on their tasks without unnecessary discomfort or distraction.

Bagging System and Clipping Management

Efficiently managing grass clippings and debris is essential for maintaining a tidy outdoor space. A well-designed collection system not only simplifies cleanup but also enhances the overall functionality of lawn care equipment. Understanding the components and operation of such systems can greatly improve their effectiveness and user experience.

Components of the Collection System

The collection mechanism typically consists of a bag or container that captures cut grass and leaves during operation. This container is usually designed for easy attachment and removal, allowing for quick disposal of collected material. Durability and capacity are critical factors in selecting the right system, as they determine how often the bag needs to be emptied during use.

Clipping Management Techniques

Implementing effective clipping management techniques can significantly reduce the need for disposal. Mulching is one such method, where finely chopped grass is redistributed back onto the lawn, providing valuable nutrients to the soil. Additionally, regular maintenance of the cutting blade ensures clean cuts, resulting in less clumping and easier collection of debris. Understanding these techniques promotes a healthier lawn and maximizes the utility of the collection system.