Understanding the Craftsman T3000 Parts Diagram for Easy Maintenance

In the realm of machinery, comprehending the intricate assembly and components is crucial for effective maintenance and operation. By delving into the structure and individual elements, users can enhance their understanding and ensure optimal performance of their tools. This section aims to illuminate the essential features that contribute to the functionality of various devices.

Whether you’re a seasoned professional or a novice, having access to a visual representation of the various elements can significantly aid in troubleshooting and repairs. Identifying each component and its role within the whole can streamline the process of assembly and disassembly, making tasks more efficient and less daunting.

Furthermore, an organized view of the constituents not only facilitates better repairs but also promotes a deeper appreciation for the craftsmanship involved. This knowledge empowers users to take control of their machinery, ensuring longevity and peak performance with minimal downtime.

Understanding the Craftsman T3000

This section delves into a specific model known for its reliability and efficiency in various tasks. It’s designed for individuals seeking robust performance in their projects, offering a range of features that cater to both beginners and seasoned users.

Key attributes of this model include:

- Durability: Built with high-quality materials to withstand rigorous use.

- User-Friendly Design: Intuitive controls and ergonomic layout for ease of operation.

- Versatile Applications: Suitable for a variety of tasks, making it a valuable tool for both home and professional use.

Understanding the intricacies of this model involves familiarizing oneself with its components and how they work together. Key areas to explore include:

- Core Mechanisms: Insight into how the internal systems function harmoniously.

- Maintenance Practices: Guidelines to ensure longevity and optimal performance.

- Common Upgrades: Options available to enhance functionality and adaptability.

By grasping these elements, users can fully leverage the capabilities of this model, ensuring a productive and enjoyable experience in their endeavors.

Importance of Parts Diagrams

Understanding the components of any machinery or equipment is essential for efficient maintenance and repair. Visual representations of these elements provide clarity, allowing users to identify and source necessary items quickly. This not only enhances the repair process but also minimizes downtime, ensuring that devices operate smoothly and effectively.

Accurate identification of individual components is crucial for troubleshooting issues. By having a clear overview, users can pinpoint specific areas that require attention without unnecessary guesswork. This leads to quicker resolutions and reduces the risk of overlooking essential elements.

Moreover, comprehensive illustrations serve as valuable references during assembly or disassembly. They guide users through complex procedures, ensuring that each part is correctly positioned and secured. This attention to detail helps maintain the integrity and functionality of the equipment over time.

In addition, these visual aids facilitate communication between technicians and suppliers. When discussing replacements or repairs, having a detailed reference eliminates ambiguity, streamlining the procurement process and ensuring that the right items are obtained swiftly.

In summary, visual representations of machinery components play a vital role in effective maintenance and repair, promoting efficiency, accuracy, and better communication in technical tasks.

Key Components of T3000 Model

This section delves into the essential elements that constitute a particular model, highlighting their functions and importance. Understanding these core parts is vital for optimal performance and maintenance, ensuring longevity and efficiency in use.

Engine and Drive System

The engine serves as the powerhouse, driving the entire mechanism with precision and strength. Coupled with the drive system, it facilitates movement and functionality, allowing users to achieve their tasks effectively. Regular maintenance of these components ensures reliable operation and prevents potential breakdowns.

Control Mechanism

The control mechanism provides the user with the ability to manage various functions seamlessly. It often includes levers and switches that regulate speed, direction, and other crucial parameters. A well-designed control system enhances user experience and contributes to overall productivity.

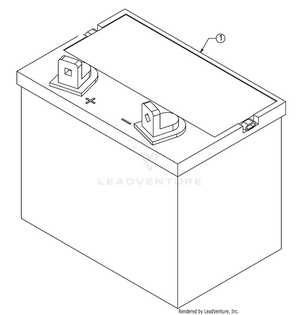

How to Read a Parts Diagram

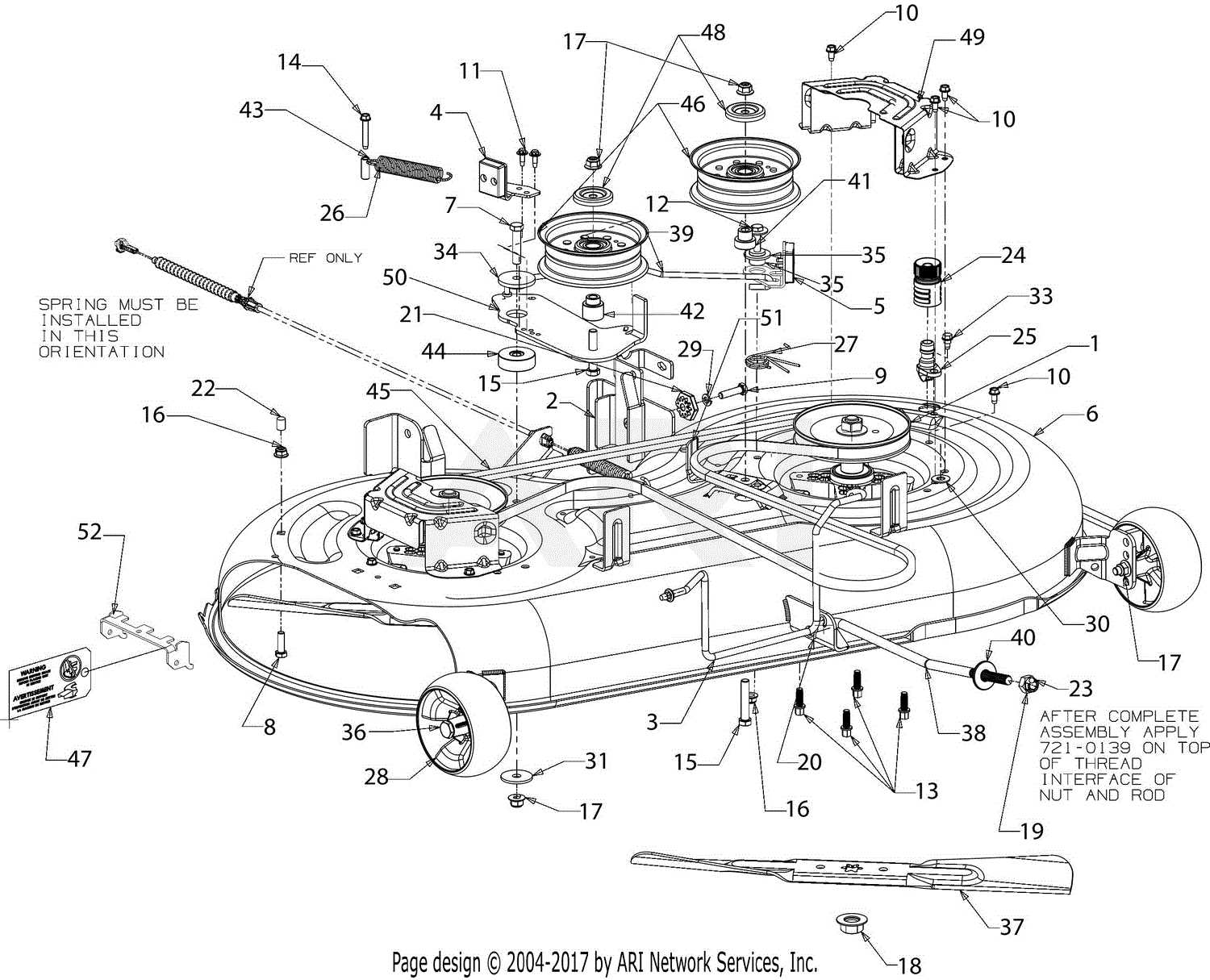

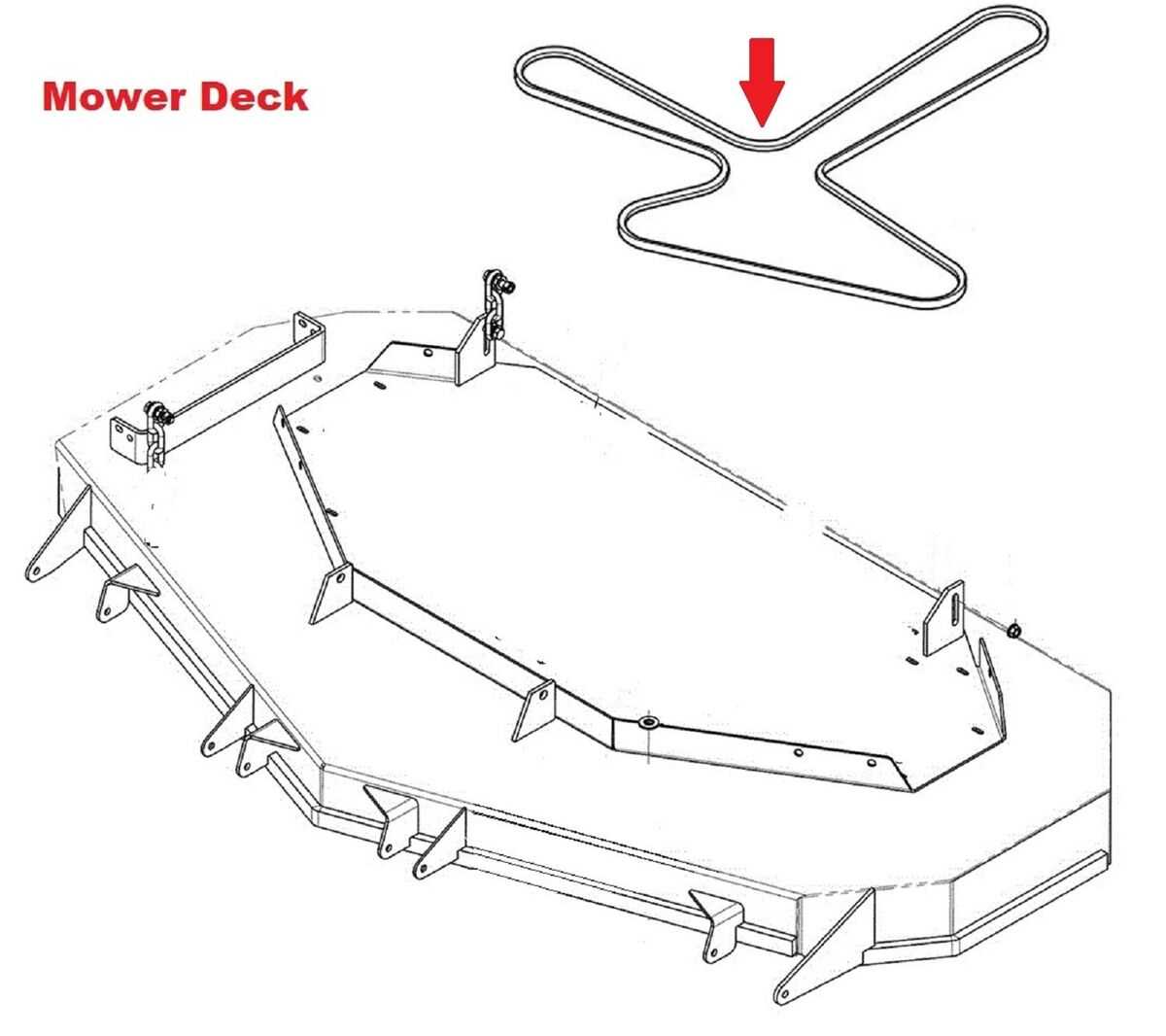

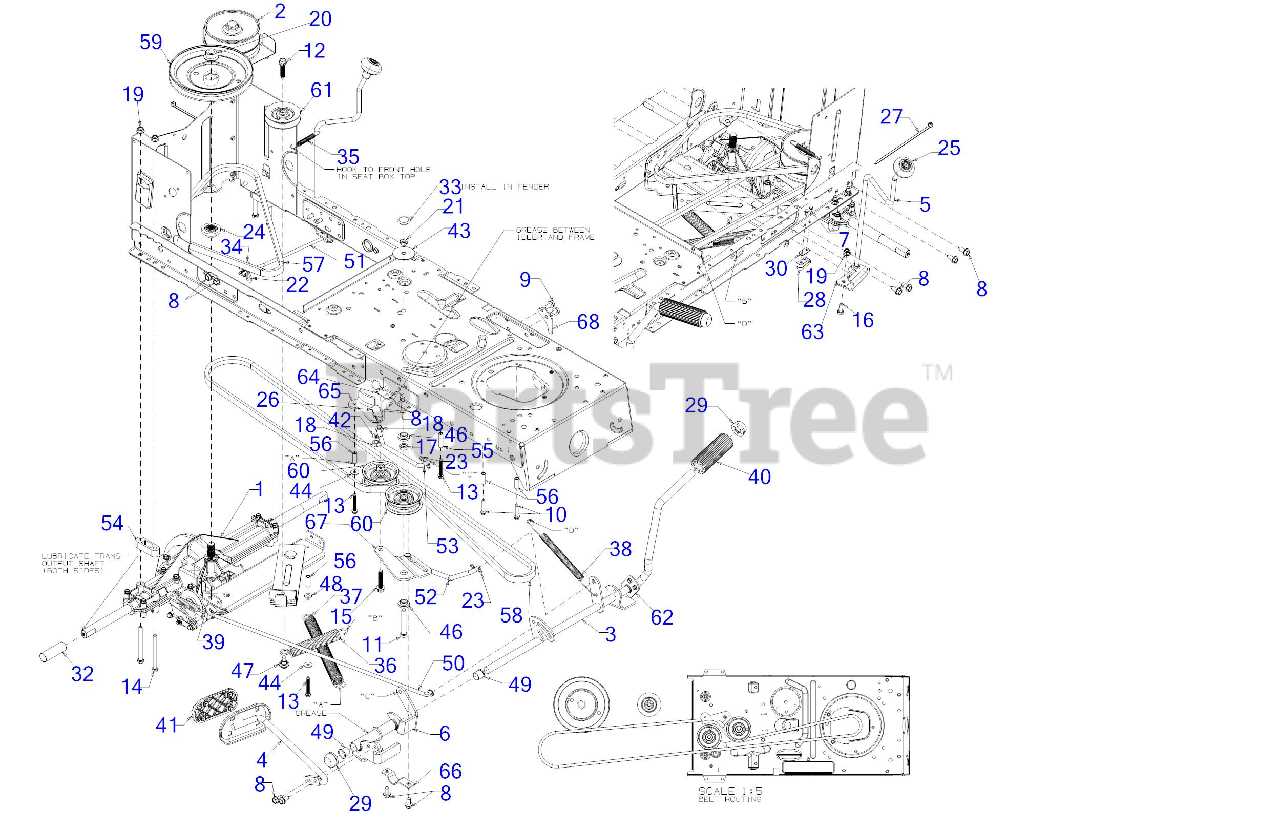

Understanding a schematic can significantly enhance your ability to repair or maintain equipment. These illustrations serve as visual guides, offering insights into the arrangement and function of various components. By familiarizing yourself with the symbols and layout, you can effectively identify the pieces you need and how they interact.

Begin by examining the layout. Typically, these representations will feature a clear arrangement of elements, often grouped by function or location within the device. Take note of the overall organization, as this will help you navigate the illustration more efficiently.

Next, familiarize yourself with the legend. Most visuals will include a key that explains the symbols and numbers used throughout. Understanding this legend is crucial, as it provides the context needed to decipher the information presented.

Pay attention to the labels. Each component will usually have a designation or part number associated with it. These identifiers are essential for sourcing replacements or understanding the specific function of each element within the system.

Finally, cross-reference with your manual. If available, your user guide can provide additional details and context, allowing you to better understand how each piece fits into the overall mechanism. This collaborative approach will empower you to tackle repairs with confidence.

Common Issues with T3000 Parts

When dealing with specific equipment components, users often encounter a variety of challenges that can affect performance and longevity. Understanding these common concerns is essential for maintenance and troubleshooting.

Wear and Tear: Over time, regular use can lead to degradation of critical elements. Components may show signs of fatigue, such as cracks or excessive wear, which can compromise functionality.

Misalignment: Incorrect installation or shifting during operation can cause misalignment of moving parts. This can lead to increased friction and potential damage, necessitating adjustments to restore proper operation.

Corrosion: Exposure to moisture and harsh environments can result in rust and corrosion. This not only affects the aesthetics but can also impair performance and lead to failures if not addressed promptly.

Incompatibility: Using incorrect or non-compatible replacements can result in poor performance and increased risk of malfunction. It is crucial to ensure that any substitutions meet the required specifications.

Blockages: Accumulation of debris in crucial areas can lead to blockages that hinder operation. Regular cleaning and maintenance are vital to prevent such issues and ensure smooth functionality.

Finding Replacement Parts Online

Locating suitable components for your equipment has become increasingly straightforward with the rise of online marketplaces. Whether you need to repair a machine or upgrade its functionality, a wealth of resources is available at your fingertips. Navigating these platforms effectively can save time and ensure you find the right items to keep your devices running smoothly.

Start by identifying the specific item you require. Clear descriptions and model numbers will enhance your search results. Utilize various e-commerce sites and specialized retailers that cater to machinery and tools. Many of these platforms offer extensive catalogs, making it easier to browse through numerous options.

Additionally, consider checking user reviews and ratings to gauge the reliability of the components. This information can provide insights into the quality and performance of the items you are considering. Don’t hesitate to reach out to sellers for clarification on compatibility or specifications if needed.

Lastly, keep an eye out for discounts and promotions. Many online retailers offer seasonal sales, which can lead to significant savings. By approaching your search strategically, you can find the ideal replacements without overspending.

Maintenance Tips for Craftsman Equipment

Ensuring the longevity and efficiency of your tools requires regular upkeep and attention. Proper maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By following a few straightforward practices, you can keep your equipment in top condition for years to come.

Regular Cleaning

Keep your tools free of dust, debris, and grime. After each use, take a moment to wipe down surfaces with a soft cloth. For more thorough cleaning, consider using a gentle detergent and water. Make sure to dry all parts completely to prevent rust and corrosion.

Lubrication and Inspection

Routine lubrication is crucial for smooth operation. Check moving parts regularly and apply the appropriate lubricant as specified in the user manual. Additionally, inspect components for any signs of wear or damage. Addressing small issues promptly can prevent larger problems down the line.

Remember: Consistent maintenance not only extends the life of your equipment but also ensures that you get the most out of your investment.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Whether you need replacements for repairs or upgrades, sourcing genuine items ensures compatibility and reliability. Here are some reliable options for obtaining these essential items:

- Official Manufacturer Website: The most reliable source is often the manufacturer’s own site, where you can find the exact items designed for your equipment.

- Authorized Retailers: Many stores are certified to sell original components. Look for local shops or online platforms that have a reputation for quality.

- Specialty Parts Dealers: Certain online retailers specialize in providing a wide range of original items, often with detailed descriptions and specifications.

- Local Repair Shops: Established repair centers frequently have access to authentic components and can order them on your behalf.

Before making a purchase, always verify that the source is reputable to avoid counterfeit products. Investing in original components will help ensure the efficiency and safety of your equipment.

DIY Repairs Using the Diagram

Understanding the layout and components of your equipment can significantly simplify the repair process. With a clear representation of the various elements, you can effectively troubleshoot issues and identify the necessary fixes. This guide will help you leverage this visual tool to enhance your repair skills and complete tasks independently.

Benefits of Visual Guides

Using a schematic representation offers several advantages:

- Quick identification of parts and their functions.

- Streamlined troubleshooting process.

- Enhanced confidence in performing repairs.

- Reduction in the time spent on maintenance.

Steps for Effective Repairs

- Gather all necessary tools and materials before starting.

- Refer to the visual guide to locate the malfunctioning components.

- Carefully disassemble the affected area, noting the placement of each part.

- Replace or repair the damaged elements as indicated.

- Reassemble everything according to the layout, ensuring all pieces fit securely.

- Test the functionality of your equipment to confirm the repair was successful.

By following these steps, you can effectively use the schematic representation to carry out your own repairs, saving time and resources while gaining valuable skills.

Benefits of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and efficiency of any machinery. By dedicating time to routine care, users can prevent costly repairs and enhance the overall performance of their equipment. Below are some key advantages of maintaining your tools regularly.

Enhanced Performance

- Regular inspections and tune-ups help identify and rectify minor issues before they escalate.

- Proper lubrication and cleaning can significantly improve the operation of moving parts.

- Consistent maintenance ensures that tools operate at optimal levels, providing better results in tasks.

Cost Savings

- Preventive care reduces the likelihood of major breakdowns, which can be financially burdensome.

- Extending the lifespan of equipment means fewer replacements and lower long-term costs.

- Regular maintenance often leads to improved fuel efficiency and reduced energy consumption.

Incorporating routine maintenance into your schedule not only enhances functionality but also saves money in the long run, making it a wise investment for any user.

Community Resources for T3000 Owners

For enthusiasts and users of a popular tool model, finding a network of support can be invaluable. This community offers a wealth of information, tips, and shared experiences that can help troubleshoot issues and enhance your usage. Whether you’re looking for advice on maintenance, upgrades, or simply seeking to connect with fellow users, these resources can be incredibly beneficial.

Online Forums and Discussion Groups

One of the most effective ways to engage with other owners is through online forums dedicated to similar equipment. Here, users can ask questions, share solutions, and post reviews about various aspects of their tools. Active participation in these communities fosters a sense of camaraderie and ensures that no one has to navigate challenges alone.

Local Workshops and Meetups

Many regions host workshops and meetups focused on tool usage and repair. These gatherings provide a hands-on opportunity to learn from experienced users and professionals. Attending these events can not only enhance your skills but also allow you to build connections within your local community.

Exploring Upgrades and Modifications

Enhancing the performance and functionality of your equipment can significantly improve your overall experience. By incorporating various enhancements, users can tailor their tools to better suit specific needs and tasks. This section delves into potential modifications and upgrades that can elevate your machine’s capabilities.

Performance Boosts: Upgrading components such as motors or blades can lead to increased efficiency and productivity. Consider investing in high-quality parts that are designed to withstand rigorous use, ensuring longevity and reliability.

Customization Options: Personalizing your device through aesthetic modifications can not only improve its look but also increase its usability. From ergonomic handles to custom paint jobs, the possibilities are vast. Tailoring your equipment to your preferences can enhance comfort during extended use.

Safety Enhancements: Incorporating safety features is crucial for any tool user. Adding guards, improved switches, or upgraded safety mechanisms can provide peace of mind while working. Prioritizing safety through thoughtful modifications is essential in any upgrade process.

Compatibility Considerations: When exploring enhancements, ensure that new parts or accessories are compatible with existing systems. Researching specifications and user reviews can help in making informed decisions that will optimize functionality without compromising integrity.

Overall, upgrading and modifying your tools can lead to a more enjoyable and efficient experience. By carefully selecting enhancements and considering both performance and safety, you can create a setup that truly meets your unique requirements.