Understanding Craftsman Weed Eater Parts Diagram for Efficient Repairs

When it comes to maintaining and operating outdoor machinery, familiarity with the essential elements that make up these tools is crucial. Each component plays a vital role in ensuring optimal performance and longevity. By gaining insight into the various segments of your equipment, users can troubleshoot issues more effectively and enhance their overall experience.

Illustrating the assembly and functionality of these tools provides a clear perspective on how they operate. Knowing the specific functions of each individual piece allows for more informed decisions regarding repairs and replacements. This knowledge empowers users to address problems proactively and keep their equipment in peak condition.

Whether you are a seasoned user or new to the realm of outdoor machinery, understanding the intricacies of these components can significantly impact your maintenance routines. By delving into the details of how these parts work together, one can ensure that their equipment performs at its best, enabling a more efficient and enjoyable outdoor experience.

Understanding Craftsman Weed Eater Components

When it comes to maintaining outdoor tools, grasping the various elements that make up these machines is essential. Each component plays a pivotal role in the overall functionality and efficiency, influencing performance and longevity. Recognizing how these parts interact allows for more informed decisions regarding repairs and upgrades.

Essential Elements: Key components include the motor, shaft, and cutting mechanism, each contributing to the machine’s capability. The motor serves as the powerhouse, converting energy into motion, while the shaft connects the motor to the cutting system, ensuring seamless operation.

Maintenance Tips: Regularly inspecting these elements can prevent costly repairs and enhance performance. Cleanliness and proper lubrication are vital in prolonging the lifespan of these devices, ensuring they remain effective over time.

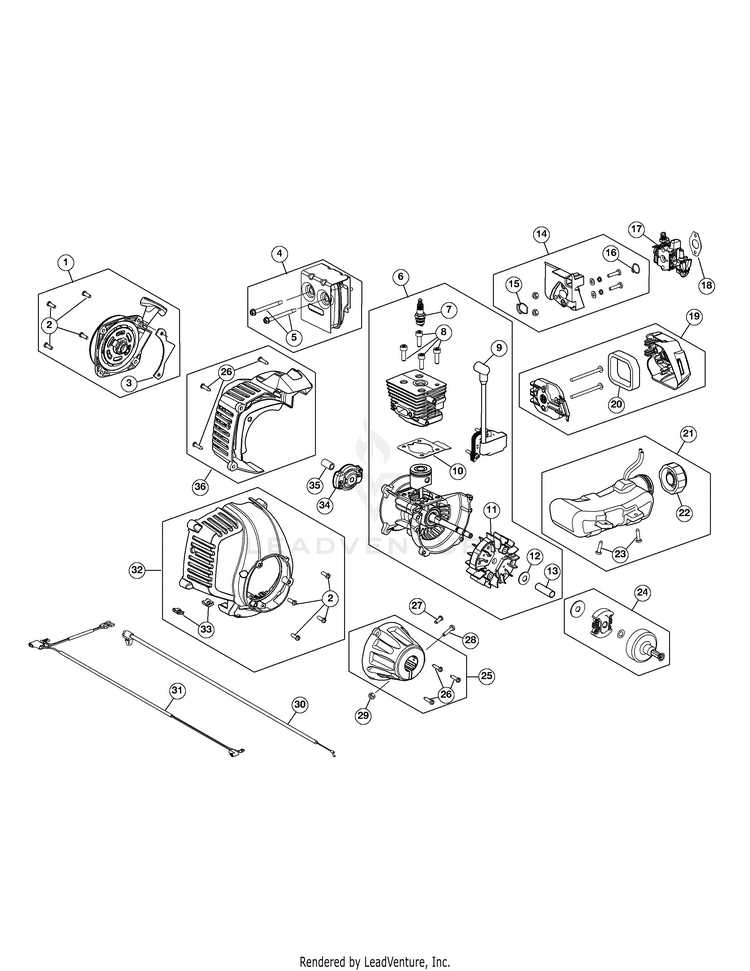

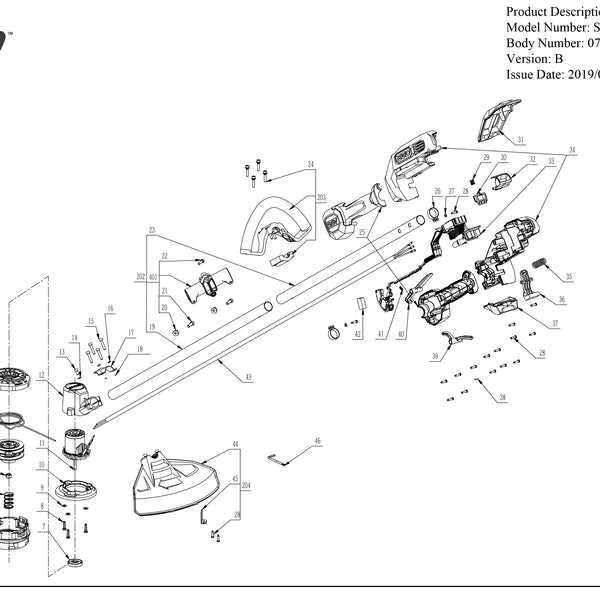

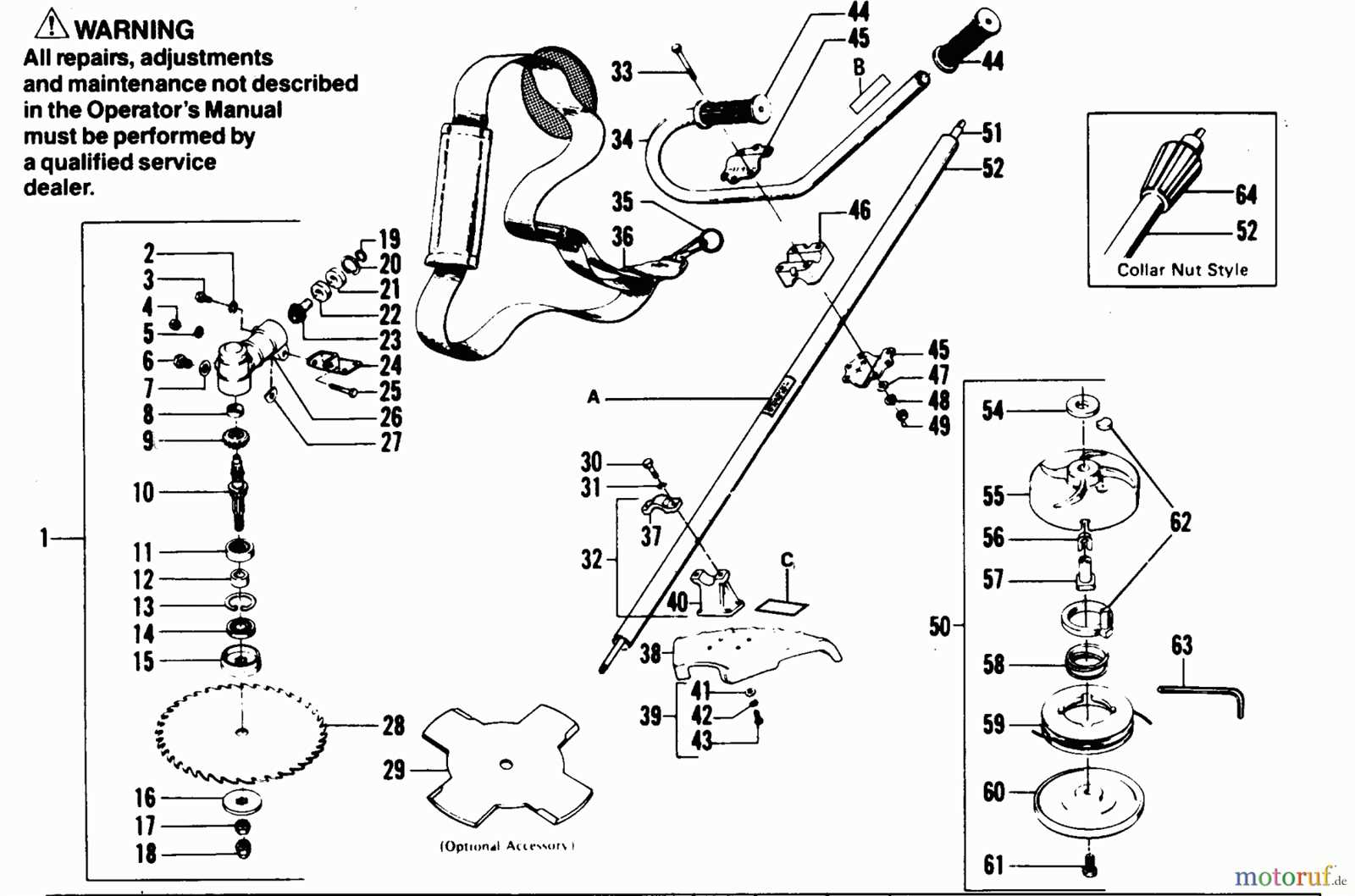

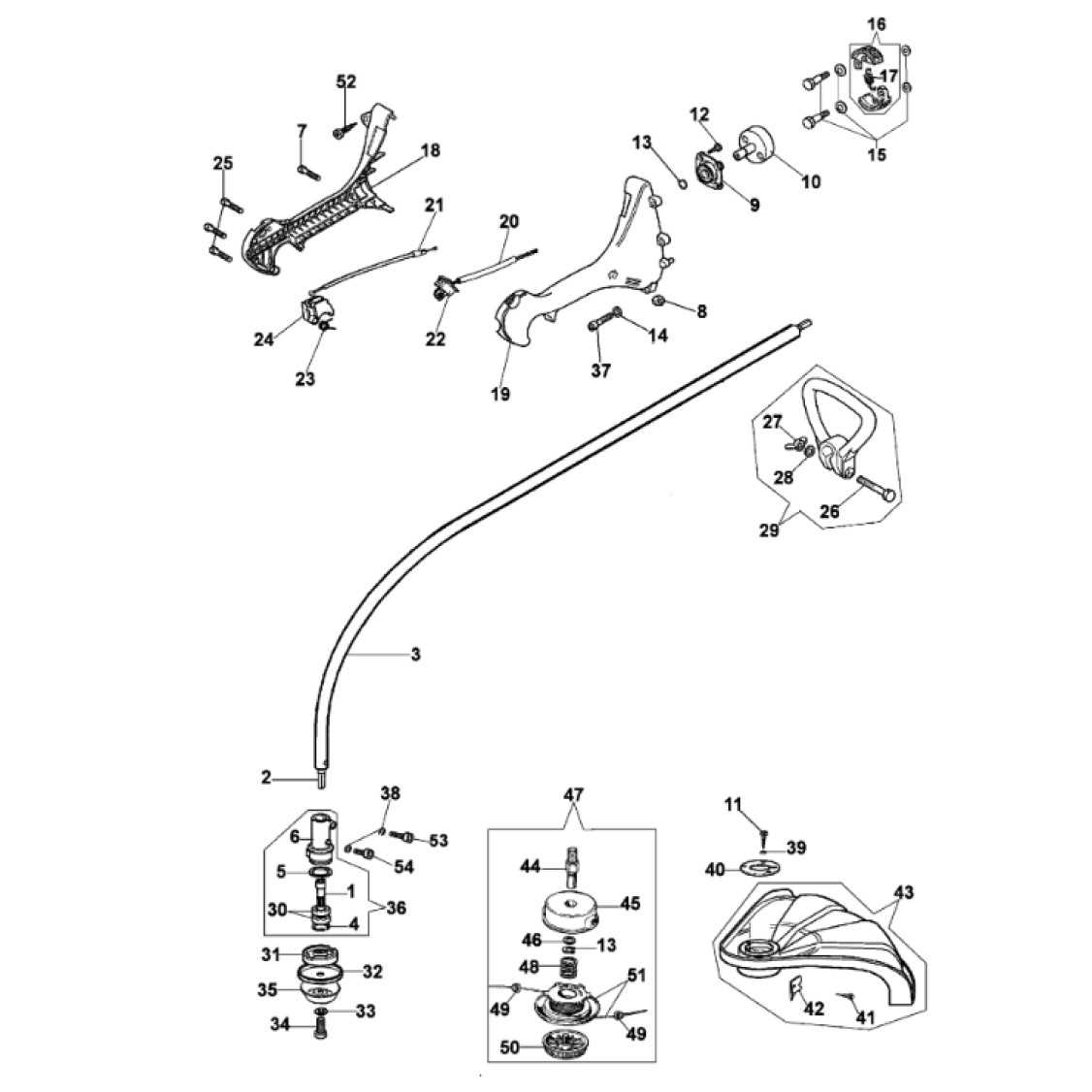

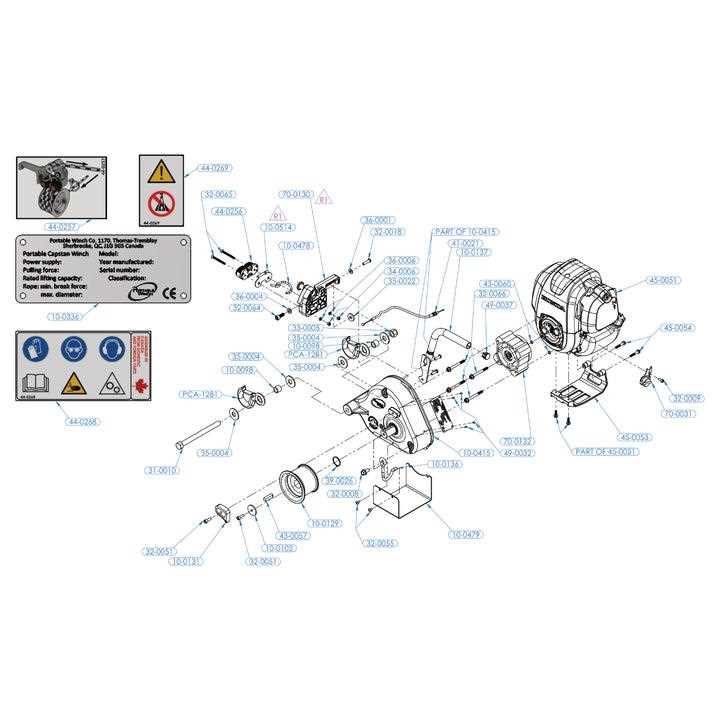

Importance of Diagram for Repairs

Understanding the layout of components is crucial for effective maintenance and troubleshooting. Visual representations not only clarify the arrangement of elements but also guide users in identifying issues and locating replacements. This enhances the repair process, ensuring that tasks are performed accurately and efficiently.

Enhancing Understanding

A visual schematic provides insight into how various parts interact, helping users grasp the overall mechanics. This knowledge enables quicker diagnosis of problems and fosters confidence in tackling repairs.

Simplifying Replacement

Clear illustrations simplify the process of finding and replacing components, reducing the risk of errors. With a proper reference, individuals can ensure they acquire the right items, streamlining their repair efforts.

Common Parts of a Weed Eater

Understanding the essential components of a trimming tool is crucial for maintenance and effective operation. Each element plays a significant role in the overall functionality and efficiency of the equipment.

Key Components

Engine: The heart of the device, providing the necessary power for operation.

Cutting Head: This section houses the line or blades, responsible for trimming grass and weeds.

Additional Elements

Fuel Tank: Stores the mixture required for combustion, ensuring the engine runs smoothly.

Handle: Offers control and maneuverability, allowing the user to navigate through various terrains.

How to Read Parts Diagrams

Understanding schematics is crucial for anyone looking to maintain or repair machinery. These visual guides simplify the complexity of components, providing clarity on how everything fits together. By learning to interpret these illustrations, you can effectively identify the elements you need and the order in which they assemble.

Key Symbols and Annotations

Familiarize yourself with common symbols and labels used in these illustrations. Each symbol typically represents a specific component, while annotations often indicate part numbers or descriptions. Recognizing these elements is the first step toward successful repairs.

Following the Flow

Pay attention to the arrangement of components. This layout often reflects the assembly process, guiding you through the steps needed for disassembly or reassembly. By following the logical flow, you can ensure that everything aligns properly when putting it back together.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment requires a set of fundamental instruments to ensure efficiency and longevity. Utilizing the right tools not only simplifies the process but also enhances performance, making tasks smoother and more effective.

Basic Hand Tools

Having a reliable collection of hand tools is crucial. Items like screwdrivers, wrenches, and pliers are indispensable for adjustments and repairs. These essentials allow for quick fixes and fine-tuning, which can significantly improve functionality.

Cleaning Supplies

Regular cleaning is vital for optimal performance. Equip yourself with brushes, cleaning solutions, and rags to maintain equipment in peak condition. An organized maintenance routine, incorporating these cleaning tools, will ultimately extend the lifespan of your machinery.

Identifying Wear and Tear in Parts

Recognizing signs of degradation in components is crucial for maintaining optimal performance and longevity of equipment. Regular inspections help ensure that all mechanisms function smoothly and efficiently, preventing costly repairs or replacements.

Common Indicators of Deterioration

- Visible Damage: Cracks, dents, or discoloration can signal that a part is no longer effective.

- Unusual Noises: Any grinding, rattling, or squeaking sounds may indicate misalignment or damage.

- Reduced Performance: A noticeable decline in speed or power can suggest that components are wearing out.

Preventative Measures

- Conduct regular inspections to catch issues early.

- Clean components frequently to prevent buildup that can cause damage.

- Replace worn items promptly to maintain efficiency and safety.

Replacement Parts: When to Consider

Understanding the optimal time for component replacement can significantly enhance the performance of your outdoor equipment. Regular maintenance is crucial, as wear and tear can affect efficiency and longevity. Knowing when to act can prevent further damage and costly repairs.

Signs of Deterioration: Look for visible signs such as cracks, rust, or unusual noises. These indicators often signal that a specific component is failing and needs attention.

Performance Issues: If you notice a decline in functionality, it might be time to evaluate individual elements. A decrease in power or efficiency can often be traced back to worn-out pieces that require replacement.

Regular Maintenance: Adhering to a maintenance schedule can help identify potential issues before they escalate. Regular checks can save you time and money in the long run.

Ultimately, being proactive about replacements ensures your equipment remains in optimal condition, providing reliable service when you need it most.

DIY Maintenance Tips for Longevity

Regular upkeep is essential for ensuring your outdoor power tools remain efficient and last for years. By following a few simple practices, you can significantly enhance performance and prevent premature wear. This section will guide you through effective techniques to maintain your equipment, allowing you to tackle yard work with confidence.

Routine Cleaning

Cleaning your tools after each use is crucial. Remove any debris and dirt to prevent buildup that can cause damage over time. Use a soft brush and mild soap to keep surfaces clear and functional.

Inspect and Replace

Regularly inspect components for signs of wear or damage. Pay attention to moving parts and replace any that show signs of deterioration. Investing time in these checks can save you money on costly repairs later.

Where to Find Authentic Parts

When seeking genuine components for your outdoor tools, it’s essential to know the right places to look. Authentic parts ensure optimal performance and longevity of your equipment, making sourcing them a critical task for any enthusiast.

| Source | Description |

|---|---|

| Official Retailers | Authorized dealers provide a wide range of genuine components, often with warranties. |

| Manufacturer’s Website | Direct access to original parts and specifications, ensuring compatibility. |

| Specialty Stores | Local shops focusing on outdoor equipment may carry specific authentic items. |

| Online Marketplaces | Reputable platforms offer authentic components, but verify seller ratings before purchasing. |

| Community Forums | Engaging with fellow users can lead to recommendations for reliable sources. |

Visualizing the Assembly Process

Understanding the assembly process of garden tools is crucial for ensuring efficient maintenance and repair. By visualizing the individual components and their interconnections, users can gain a clearer perspective on how these devices operate. This knowledge not only aids in troubleshooting but also enhances the ability to reassemble the equipment correctly after servicing.

Key Components and Their Functions

Each element of the equipment plays a specific role, contributing to the overall functionality. Below is a table summarizing some essential components and their respective purposes:

| Component | Function |

|---|---|

| Motor | Drives the entire mechanism, providing power for operation. |

| Shaft | Transfers motion from the motor to the cutting assembly. |

| Cutting Head | Engages with the vegetation, performing the primary task. |

| Handle | Provides control and maneuverability for the user. |

Assembly Steps Overview

When putting the tool together, it’s vital to follow a systematic approach. Begin by ensuring that all components are present and in good condition. Assemble the motor to the frame, attach the shaft, and secure the cutting head. Finally, check the handle for stability. Following these steps not only guarantees proper functionality but also extends the lifespan of the equipment.

Common Issues and Troubleshooting Guide

This section focuses on typical problems that may arise during the use of outdoor power tools and offers practical solutions to resolve them effectively.

- Engine Won’t Start:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Examine the air filter for clogs.

- Loss of Power:

- Ensure the tool is not overloaded.

- Inspect the fuel system for blockages.

- Check the ignition system for faults.

- Excessive Vibration:

- Check for loose or damaged components.

- Inspect the cutting attachment for imbalance.

- Ensure all screws and bolts are properly tightened.

- Difficulty in Starting:

- Confirm the choke is set correctly.

- Inspect the primer bulb for functionality.

- Ensure the throttle is engaging properly.

Safety Precautions During Repairs

When undertaking maintenance on outdoor equipment, it is crucial to prioritize safety to prevent accidents and injuries. Ensuring that proper precautions are taken can significantly reduce the risk of mishaps while working with mechanical components. Following these guidelines will help create a safer environment during the repair process.

Before starting any repair work, it’s important to prepare the workspace and gather all necessary tools. This will not only streamline the process but also minimize the chances of distractions that could lead to errors or injuries.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other protective equipment to shield against sharp edges and flying debris. |

| Disconnect Power Source | Ensure the device is unplugged or the battery is removed to avoid accidental starts during repairs. |

| Work in a Well-Lit Area | A bright workspace helps in identifying components clearly and reduces the risk of mistakes. |

| Read the Manual | Familiarize yourself with the equipment’s manual to understand the specific parts and their functions. |

| Keep Tools Organized | Maintain an orderly workspace to prevent tripping hazards and misplacing tools. |

| Be Mindful of Flammable Materials | Avoid using flammable substances near the work area to reduce fire risks. |

By adhering to these safety measures, you can ensure a more secure and efficient repair experience. Taking the time to implement these precautions is essential for protecting both yourself and your equipment.

Benefits of Regular Maintenance Checks

Conducting routine inspections and upkeep of your outdoor equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only helps identify potential issues early but also enhances the overall efficiency of the machinery. By dedicating time to care for your tools, you can save money and avoid unexpected breakdowns.

Enhanced Performance

Routine checks allow you to keep your machinery in peak condition. Over time, components may wear down or become clogged, hindering functionality. Timely maintenance ensures that all parts are clean and well-lubricated, contributing to smoother operation and improved results in your landscaping tasks.

Cost Savings

Investing in regular upkeep can lead to significant savings in the long run. By preventing minor issues from escalating into major repairs, you reduce the risk of costly replacements. Moreover, well-maintained tools tend to consume less fuel and operate more efficiently, ultimately lowering your operational expenses.