Understanding the Black and Decker Electric Mower Parts Diagram

When it comes to maintaining your garden tools, having a clear grasp of the internal mechanisms can greatly enhance your experience. The individual elements that contribute to the smooth operation of these machines play a crucial role in their performance. By familiarizing yourself with the key structures and how they interact, you can ensure that your device remains in optimal condition for years to come.

Each component within these tools serves a unique function, working in harmony to deliver efficient results. Whether you’re looking to perform routine maintenance or address a specific issue, knowing the different assemblies is essential. This guide will help you break down these elements step by step, offering a detailed overview of the most important features and how they contribute to the overall system.

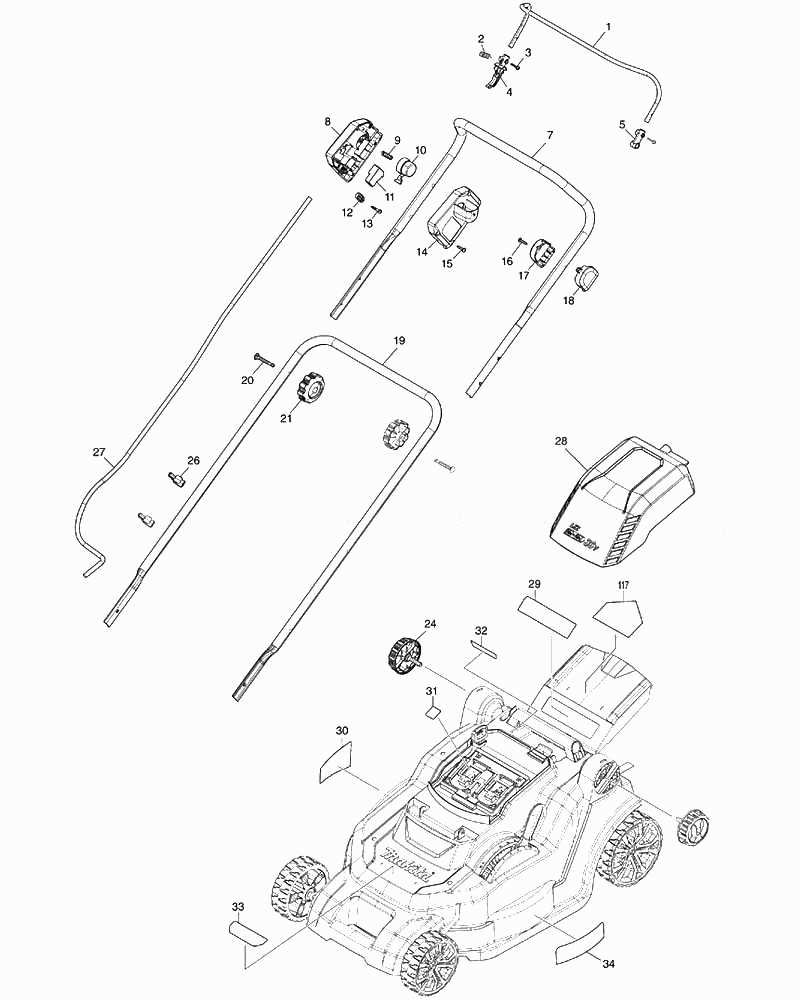

Black and Decker Electric Mower Parts Diagram

Understanding the various elements of a lawn cutting machine is essential for effective maintenance and troubleshooting. By recognizing how each component interacts, users can ensure smoother operation and longer equipment life. This section provides an overview of the key elements within the system.

Motor Assembly: The heart of the machine, this feature drives the blades and powers the cutting process. Ensuring its proper function is critical for optimal performance.

Cutting Mechanism: This section refers to the sharp blades responsible for trimming the grass. Regular maintenance of this part guarantees precise and efficient cutting results.

Control Panel: The interface for operating the machine. It allows users to manage different settings, making the tool versatile for various lawn conditions.

Wheel System:

Key Components of an Electric Mower

Understanding the crucial elements that make up this type of lawn equipment is essential for effective maintenance and operation. Each section contributes to the overall functionality and performance, ensuring smooth operation and optimal results.

Power Source: A reliable power supply is the foundation of the machine’s performance. It delivers the energy needed to drive the system, whether through a direct connection or stored energy from a power unit.

Cutting Mechanism: The cutting blades are central to the equipment’s functionality. These components rotate at high speeds to trim grass evenly, ensuring a neat and precise finish.

Control Unit: The control panel or handles allow the user to manage the machine’s speed and direction. It offers a simple interface for turning the system on and off, as well as adjusting the cutting height or operational mode.

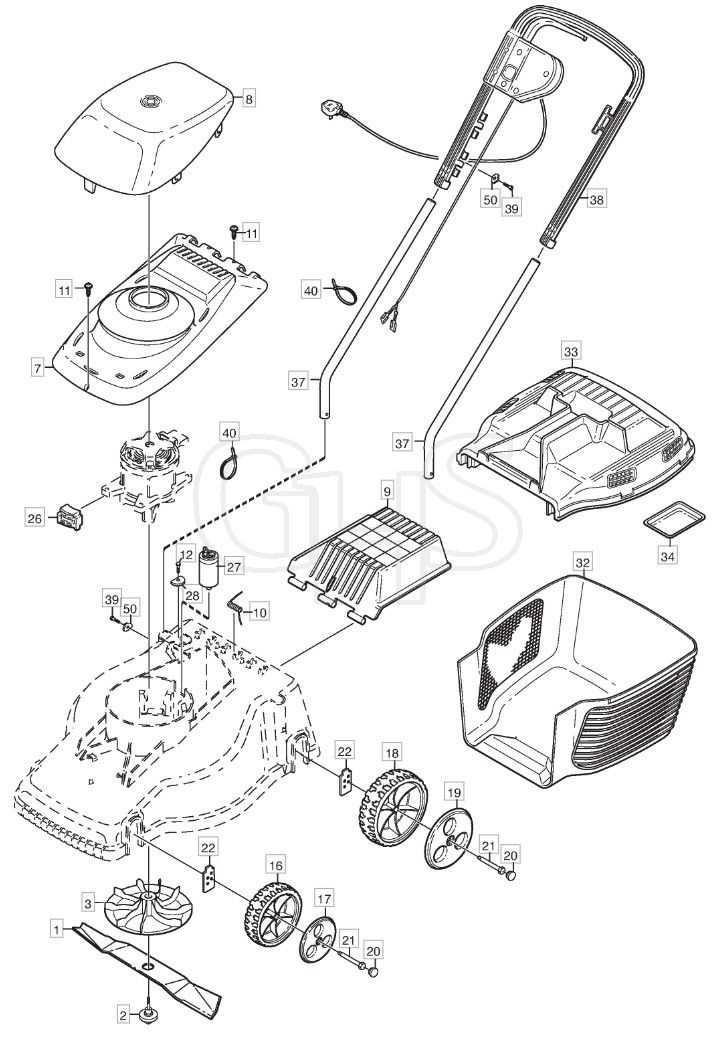

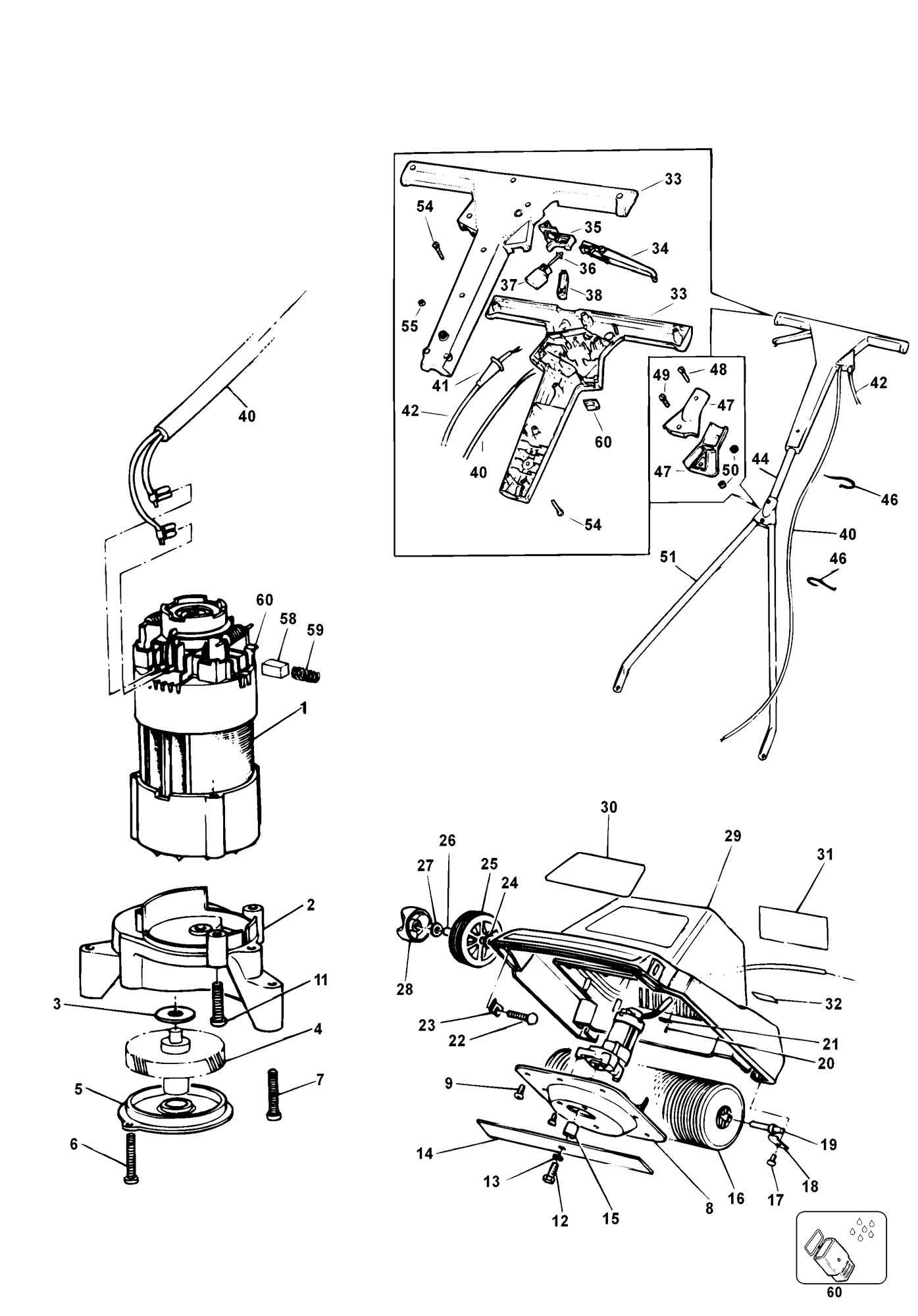

Understanding the Motor Assembly Structure

The internal layout of the motor is crucial to the overall functionality of the machinery. By familiarizing yourself with the key components and their interactions, you can ensure better maintenance and troubleshoot potential issues more effectively. This section provides a detailed look into the core sections of the motor configuration, focusing on how each element contributes to the performance and durability of the system.

Main Components of the Motor

The motor consists of several critical parts that work together to generate the necessary power. These include the rotor, stator, bearings, and brushes. Each component plays a unique role in converting electrical energy into mechanical movement. Understanding the purpose and location of these elements within the assembly allows for more efficient care and handling.

Interaction Between Elements

The motor’s internal elements are designed to function in harmony, ensuring smooth operation. For instance, the rotor and stator interact to produce a magnetic field that drives motion, while the bearings support rotational movement, reducing friction. Proper align

Blade and Deck Configuration Explained

The arrangement of the cutting component and the platform beneath plays a crucial role in overall performance and efficiency. Understanding how these two elements work together ensures better maintenance and operation, helping to achieve a more precise cut and prolonging the machine’s lifespan.

The cutting mechanism is designed to rotate at high speed, slicing through grass while maintaining an even height. The platform housing the blade provides stability and controls airflow, which is essential for collecting or mulching the clippings effectively. Different shapes and sizes of platforms impact how the grass is processed and discharged.

Properly aligning the cutting tool with the platform can improve cutting precision and reduce wear on both the components. Regular inspection and maintenance of these parts will also help to avoid uneven cuts and potential damage.

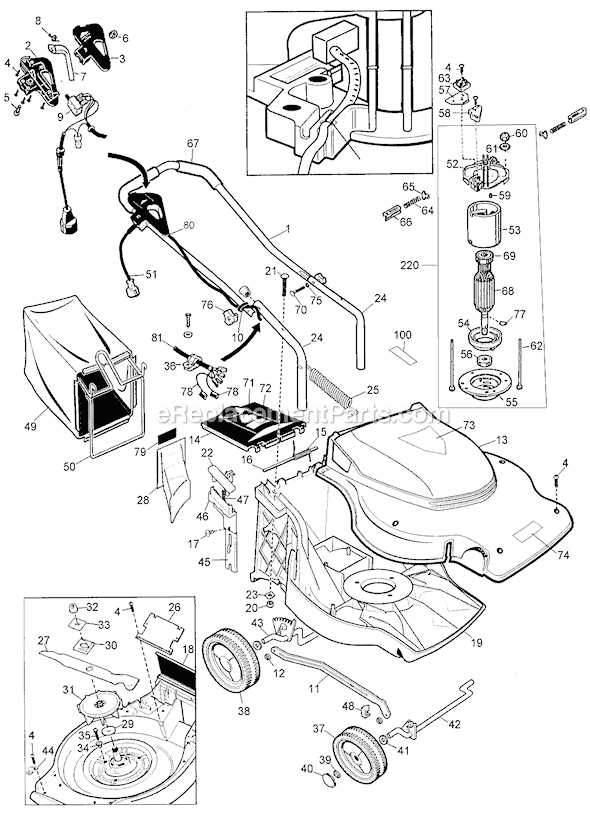

Wiring and Electrical Connections Overview

The configuration of cables and connection points plays a crucial role in ensuring optimal functionality of various devices. A well-structured system of connectors and pathways enables smooth transmission of power and signals, contributing to the reliability and safety of the equipment.

Understanding the Layout of wiring systems is key to maintaining effective performance. Each link in the network serves a specific purpose, and any interruptions can lead to operational failures. Proper inspection and maintenance of these connections help in preventing disruptions and ensuring that the unit operates efficiently.

Important aspects to consider include identifying critical contact points, verifying the integrity of insulation, and ensuring that the wires are securely fastened. This helps reduce the risk of short circuits, overheating, or component damage, which could otherwise result in more serious issues.

Battery System and Power Supply

The power source of a garden cutting tool plays a crucial role in its overall performance and efficiency. Understanding the battery system and power delivery is essential for maintaining optimal functionality and ensuring longevity. This section explores the various components involved in providing reliable energy to the device.

- Battery Type: Typically, lithium-ion batteries are favored for their lightweight and high energy density.

- Voltage Rating: The voltage of the battery influences the tool’s cutting power, with higher voltages generally providing greater performance.

- Charging Mechanism: Modern charging systems may include fast-charging capabilities, enhancing user convenience and reducing downtime.

Proper maintenance of the power supply components is vital for ensuring effective operation. Regular checks and adherence to guidelines can prevent common issues such as:

- Poor connectivity due to corrosion or dirt buildup.

- Battery deterioration from improper charging practices.

- Overheating during extended use.

Utilizing the correct accessories and following manufacturer recommendations will contribute to a seamless experience. A well-functioning battery system not only enhances performance but also increases the lifespan of the gardening equipment.

Safety Features and Their Locations

When operating a lawn maintenance device, understanding the various safety mechanisms is crucial for ensuring user protection and optimal functionality. These features are strategically placed to minimize risks while maximizing efficiency during use.

Emergency Shutoff

The emergency shutoff switch is typically located near the handle, allowing for quick access in case of unexpected situations. This feature enables the user to halt the operation immediately, reducing the likelihood of accidents.

Guarding Mechanisms

Various guarding elements are positioned around the cutting area to prevent debris from being ejected during operation. These barriers are designed to protect the user from potential harm while also safeguarding the integrity of surrounding objects.

In addition to these mechanisms, operators should familiarize themselves with other features, such as safety interlocks and noise reduction systems, which further enhance the overall safety profile of the device.

Handle Assembly and Control Mechanism

The handle assembly is a crucial component of a grass-cutting machine, providing the user with a means to maneuver and operate the device efficiently. This section delves into the construction and functionality of the handle, highlighting its role in ensuring user comfort and operational ease.

Components of the Handle Assembly

The handle assembly consists of several key elements that work together to provide stability and control. These components include the handle grips, support frame, and adjustable settings for height and angle, allowing users to customize their experience according to individual preferences.

Control Mechanism Overview

The control mechanism integrates safety features and operational controls, enabling users to start, stop, and adjust the cutting height with ease. This ensures a seamless interaction between the operator and the machine, promoting a safe and efficient grass maintenance process.

| Component | Description |

|---|---|

| Handle Grips | Ergonomically designed for comfort and enhanced grip. |

| Support Frame | Provides structural integrity and stability to the assembly. |

| Height Adjustment | Allows users to customize the cutting height according to the grass type. |

| Safety Switch | Prevents accidental start-ups, ensuring user safety during operation. |

Wheels and Axle Design for Stability

The construction of wheels and axles is crucial for ensuring reliable performance and balance in various machinery. A well-thought-out design not only enhances maneuverability but also plays a significant role in maintaining stability during operation. This section explores the fundamental aspects of wheel and axle configurations that contribute to the overall effectiveness of the equipment.

Wheels serve as the primary interface between the device and the ground, directly impacting traction and control. The selection of wheel size and material can affect the ability to traverse uneven surfaces. Larger wheels often provide better obstacle clearance, while softer materials may enhance grip on different terrains.

Axles act as the backbone of the wheel system, supporting the weight and facilitating movement. A robust axle design minimizes flex and deformation, allowing for smoother operation. Additionally, precise alignment of the axles ensures that the wheels rotate uniformly, which is essential for effective steering and stability.

Stability is further enhanced by distributing weight evenly across the wheelbase. A wider stance can lower the center of gravity, reducing the likelihood of tipping during turns or on sloped surfaces. Incorporating features like suspension systems can also improve the overall stability, providing better shock absorption and maintaining contact with the ground.

In summary, an effective wheel and axle design significantly contributes to the overall functionality of the machinery. By prioritizing stability, manufacturers can ensure that users experience optimal performance and safety during operation.

Grass Collection and Discharge Mechanism

The mechanism responsible for gathering and releasing cut grass plays a vital role in maintaining a tidy lawn. This system is designed to enhance efficiency during the cutting process while ensuring that the clippings are effectively managed. Understanding its components and functionality can help users optimize their experience.

Components of the Collection System

- Grass Bag: This is the primary container that collects the clippings, allowing for easy disposal.

- Chassis: The framework supports the collection bag and houses various components of the cutting mechanism.

- Fan or Blower: Some models incorporate a fan to propel the cut grass into the bag, improving collection efficiency.

Discharge Options

There are two main methods for discharging the clippings:

- Bagging: The collected grass is stored in the bag for later disposal or composting.

- Side Discharge: Clippings are expelled directly onto the lawn, which can serve as natural fertilizer.

Understanding these features can enhance the user experience by allowing for better maintenance and care of the cutting device.

Maintenance Tips for Long-Term Performance

Ensuring optimal functionality over time requires consistent upkeep and attention to detail. By implementing a few simple strategies, users can extend the lifespan of their equipment and enhance its reliability. Regular maintenance not only improves performance but also prevents costly repairs in the future.

Regular Cleaning

Keeping your device free from debris and dirt is crucial. Follow these steps for effective cleaning:

- Detach any removable components before cleaning.

- Use a soft brush to remove grass clippings and dirt.

- Wipe surfaces with a damp cloth to eliminate any stubborn residue.

Inspecting Components

Routine inspections help identify wear and tear early on. Consider the following:

- Check the blades for sharpness and damage; sharpen or replace as needed.

- Examine the wheels and tires for proper inflation and wear.

- Inspect belts and cables for signs of fraying or deterioration.

By incorporating these practices into your maintenance routine, you can ensure your equipment remains efficient and functional for years to come.

Troubleshooting Common Mower Part Failures

Maintaining a lawn cutting machine is essential for its optimal performance and longevity. Identifying and addressing frequent component malfunctions can enhance efficiency and prolong the lifespan of the equipment. Understanding how to recognize issues and implement solutions is key to ensuring smooth operation.

Unresponsive Operation: If the machine fails to start, check the power supply, including the battery and charger. Ensure connections are secure and inspect for any visible damage. If the battery appears functional, the issue may lie within the motor or electrical circuitry.

Inconsistent Cutting Performance: Irregular or poor cutting quality can be attributed to dull blades or improper height adjustment. Regularly sharpening the blades and confirming the correct cutting height can significantly improve results. If the issue persists, examine the drive system for wear or damage.

Excessive Vibration: Noticeable vibrations during use may indicate loose or damaged components. Check for any misaligned parts, such as the blade assembly or wheels. Tightening loose screws and replacing damaged parts will help restore balance and stability.

Overheating: If the machine becomes excessively hot, it may be a sign of overuse or a blocked airflow. Allow the equipment to cool down and ensure that air vents are clean and unobstructed. Regular maintenance, including cleaning and checking for debris, can help prevent this issue.

Strange Noises: Unusual sounds can be an indicator of internal issues, such as foreign objects lodged in the mechanism or worn bearings. Stop using the machine immediately and inspect for any obstructions or damage. Addressing these concerns promptly can prevent further harm.

Where to Source Replacement Parts

Finding suitable components for your equipment can be a straightforward task when you know where to look. Various resources are available that offer a wide selection of replacements to ensure your device continues to operate smoothly. Whether you prefer shopping online or visiting local retailers, understanding the options can save you time and money.

Online Retailers

Online platforms provide a convenient way to access a vast array of components. Websites specializing in tool accessories often feature detailed catalogs, allowing users to search by model or part number. Be sure to check reviews and ratings before making a purchase to ensure the reliability of the source.

Local Hardware Stores

Local shops can be an excellent alternative for acquiring components quickly. Many hardware stores stock common items, and staff can assist in locating the right match for your needs. Additionally, visiting a store allows you to examine the item physically before purchase, ensuring compatibility.

In both cases, consulting the manufacturer’s website can provide guidance on specific requirements and additional authorized dealers. This can help you secure quality replacements that meet the necessary standards for your equipment.