Comprehensive Guide to John Deere 185 Hydro Deck Parts Diagram

Maintaining a lawn care machine can be a complex task, especially when it comes to understanding its intricate mechanisms. Knowing the various elements that contribute to its functionality is crucial for effective repairs and optimal performance. This guide aims to illuminate the essential components that play a significant role in the operation of these machines.

When seeking to troubleshoot or replace specific components, having a clear visual representation can make a world of difference. Familiarity with the layout and design of these components allows for a more straightforward approach to maintenance. By breaking down each section, operators can better understand how to address issues and enhance their equipment’s longevity.

In this article, we will delve into a comprehensive overview of the key features and arrangements within this popular mowing machine. From the engine assembly to the drive system, each part is vital for ensuring the machine operates smoothly. Whether you are a seasoned technician or a novice user, having access to detailed information will empower you to tackle any challenge that comes your way.

Understanding John Deere 185 Hydro Deck

This section aims to explore the essential components and functionalities of a specific lawn maintenance machine. By examining its design and operation, users can enhance their familiarity with its mechanics and maintenance needs.

Key Features

- Powerful engine for efficient grass cutting

- Advanced maneuverability for easy navigation

- Durable build designed for long-term use

Maintenance Tips

- Regularly check fluid levels and replace as necessary.

- Inspect blades for wear and sharpen them periodically.

- Clean the undercarriage to prevent buildup of debris.

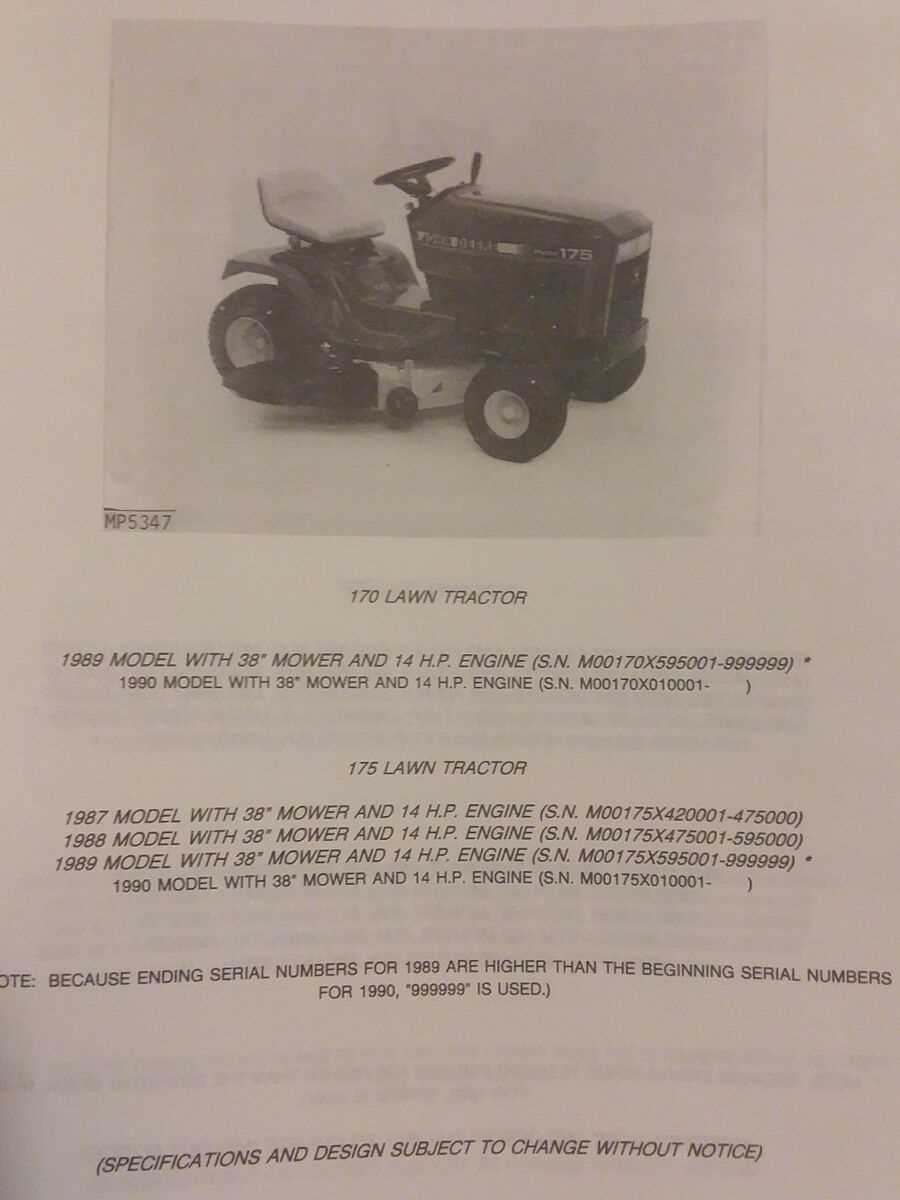

Overview of John Deere Models

This section provides a comprehensive look at various machinery models produced by a well-known agricultural and outdoor equipment manufacturer. Each model is designed to meet specific needs in lawn care, landscaping, and agricultural tasks, offering a range of features and capabilities that cater to different preferences and requirements.

Throughout the years, this brand has introduced numerous series, each distinguished by its unique specifications, performance metrics, and intended applications. From compact residential units to robust commercial-grade machines, the lineup demonstrates versatility and innovation, ensuring that users can find the perfect solution for their tasks.

Understanding the differences among models allows consumers to make informed decisions when selecting equipment that aligns with their operational demands. By exploring the features and benefits of each series, users can ultimately enhance productivity and efficiency in their endeavors.

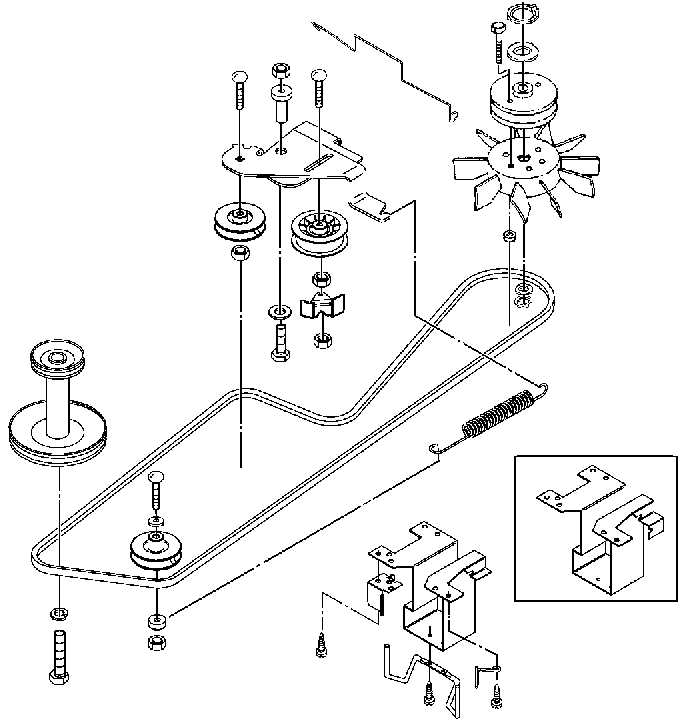

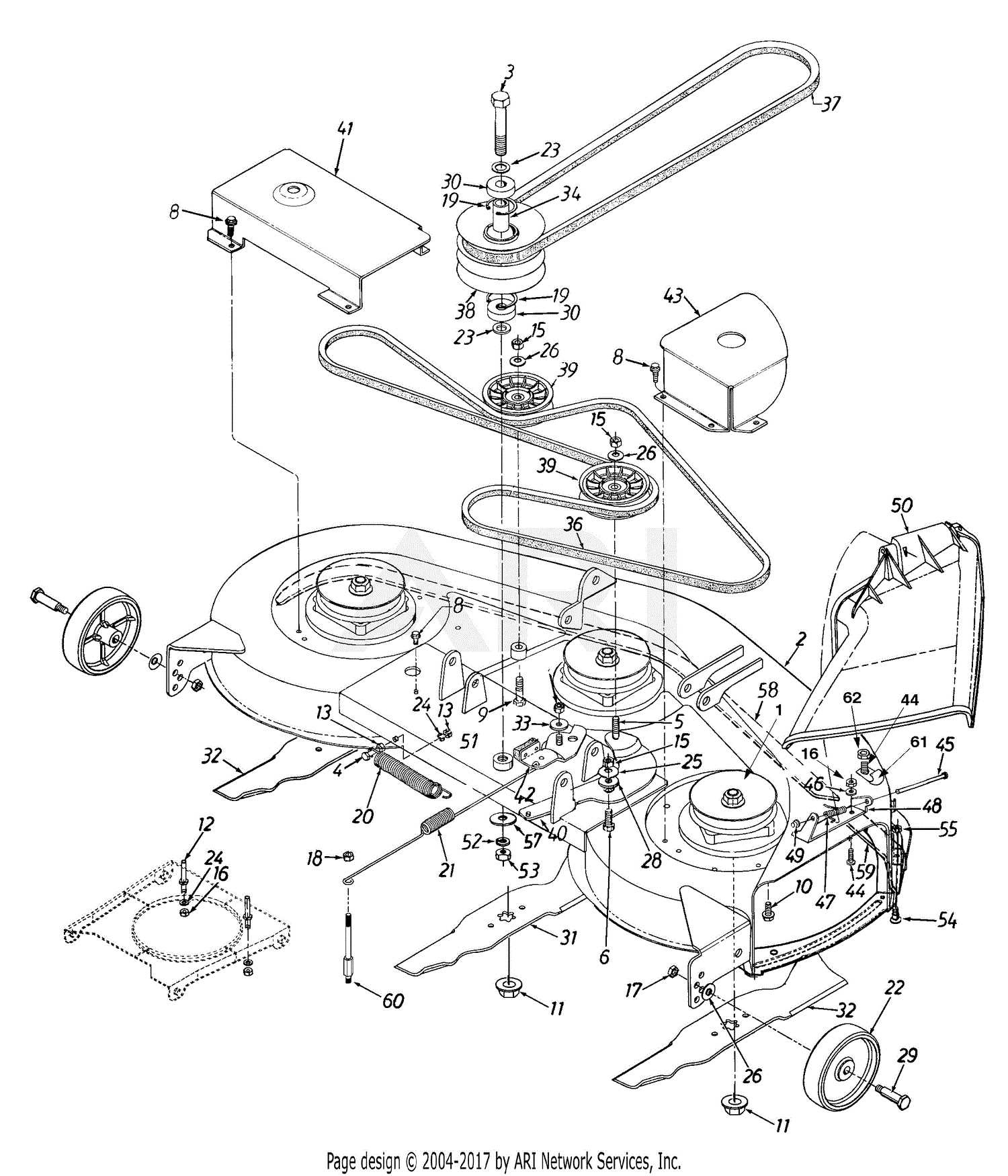

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for efficient maintenance and repairs. These visual representations serve as essential guides, enabling users to identify specific elements and their arrangements within machinery. When detailed, they enhance understanding and streamline the repair process.

Accuracy in these illustrations reduces the risk of errors, ensuring that each part is correctly installed and functioning as intended. Furthermore, a clear representation fosters effective communication among technicians and owners, facilitating better collaboration during repairs.

Ultimately, reliance on accurate visuals leads to improved longevity and performance of equipment, minimizing downtime and enhancing overall productivity. Investing time in studying these diagrams can significantly impact the effectiveness of maintenance efforts.

Common Issues with Hydro Decks

Operating machinery with hydrostatic systems can lead to a variety of challenges over time. Understanding these common problems can help in early detection and maintenance, ensuring optimal performance and longevity.

- Hydraulic Fluid Leaks:

Leaks can occur at various points, leading to reduced efficiency. Regular inspections are necessary to identify and address any signs of leakage.

- Temperature Fluctuations:

Excessive heat can cause fluid breakdown, impacting performance. Monitoring temperature levels can prevent overheating and maintain system integrity.

- Control Issues:

Operators may experience difficulties in maneuvering if the controls become unresponsive. Regular testing of the control system is essential for smooth operation.

- Wear and Tear:

Components can suffer from fatigue over time. Regular maintenance and timely replacements can minimize downtime and ensure reliable function.

By staying vigilant and addressing these issues promptly, users can maintain the efficiency and effectiveness of their equipment, avoiding costly repairs and extending its lifespan.

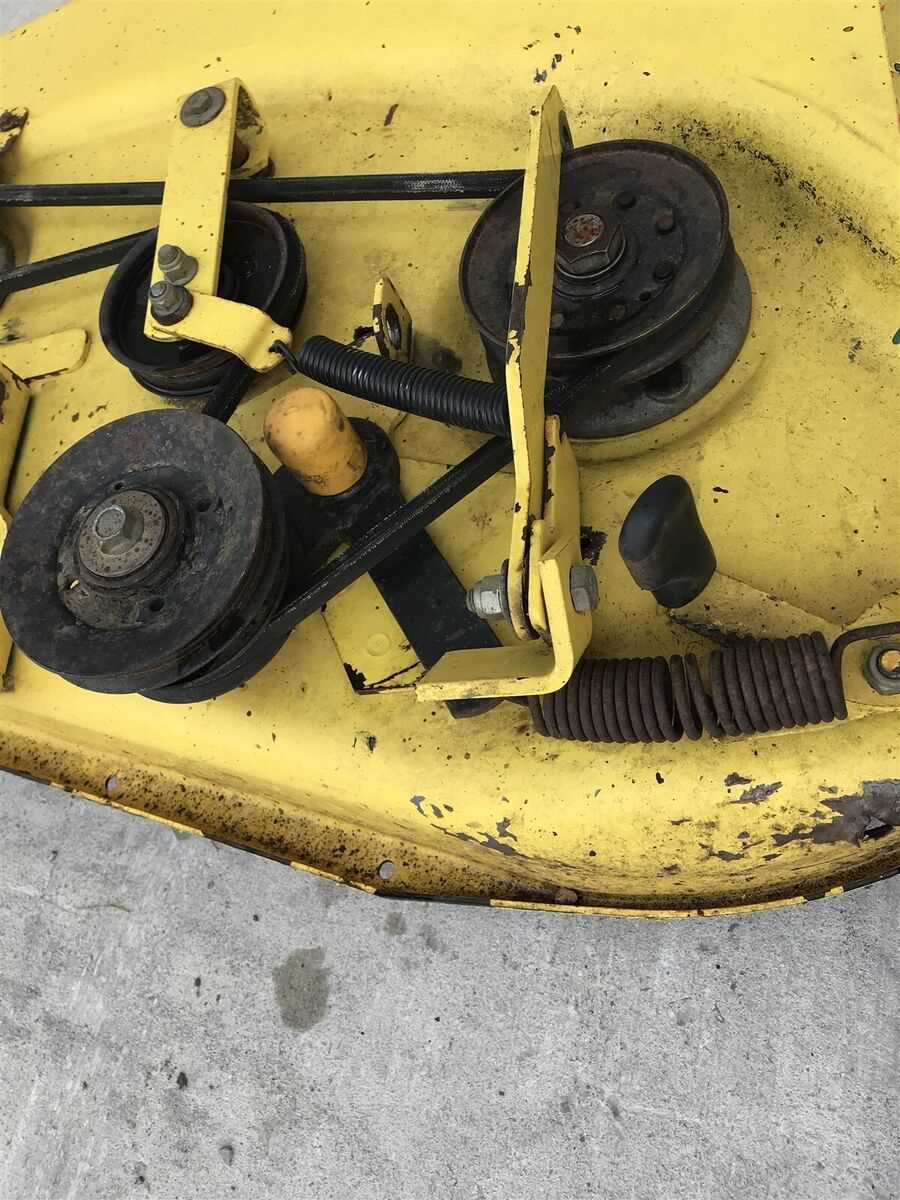

Components of the 185 Hydro Deck

This section explores the various elements that contribute to the functionality and efficiency of the mower’s operational system. Understanding these components is crucial for maintenance and repair, ensuring optimal performance and longevity.

Key features include the cutting mechanism, which provides precision and adaptability across different terrains. The drive system plays a vital role in power transfer, enhancing maneuverability. Additionally, the chassis supports the overall structure, ensuring stability and durability during use.

Another significant aspect is the control assembly, which allows users to manage speed and direction effortlessly. Lastly, safety components are integrated to protect the operator and equipment, highlighting the importance of design in user experience.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visual representations provide valuable insights into the components of a machine and how they interact with one another. Familiarity with these images can greatly enhance your ability to identify, source, and replace necessary items.

Here are some key steps to effectively interpret these illustrations:

- Familiarize Yourself with the Symbols: Various symbols and notations are commonly used in technical illustrations. Recognizing these can help you quickly identify components.

- Read the Legend: Most illustrations include a legend that explains the symbols and numbers used. Always consult this section for clarity.

- Identify the Main Components: Start by locating the primary elements of the machine. This will give you a framework for understanding the overall layout.

- Trace the Connections: Look for lines that connect different parts. These often indicate how components fit together or interact.

- Pay Attention to Numbers: Each item is typically numbered for easy reference. Make note of these numbers as they relate to the parts list.

By following these steps, you can gain a clearer understanding of technical illustrations, making your repair or maintenance tasks more efficient and effective.

Finding Replacement Parts Online

Locating components for outdoor equipment has become increasingly convenient thanks to online resources. Users can now explore a vast array of options to ensure their machines run smoothly. The ability to compare prices, check availability, and read customer reviews adds to the efficiency of this process.

Utilizing Online Marketplaces

One effective method is to browse popular online marketplaces. These platforms often feature numerous sellers, making it easier to find the desired item at competitive prices. Always check the seller’s ratings and return policies to ensure a positive buying experience.

Manufacturer Websites and Forums

Another reliable approach is visiting manufacturer websites or specialized forums. These sites frequently provide resources such as detailed catalogs and guides, helping users identify the correct components. Engaging with community forums can also yield valuable insights and recommendations from fellow enthusiasts.

Maintenance Tips for Hydro Decks

Proper upkeep of your equipment’s cutting platform is essential for optimal performance and longevity. Regular attention ensures that your machine operates efficiently and minimizes the risk of breakdowns. Here are some key strategies to maintain your mowing apparatus effectively.

- Regular Cleaning: After each use, remove grass clippings, dirt, and debris. This prevents rust and buildup that can affect performance.

- Inspect Blades: Check the cutting blades frequently for dullness or damage. Sharpen or replace them as needed to ensure a clean cut.

- Check Belts: Examine drive belts for signs of wear or fraying. Replacing worn belts promptly can prevent further damage to the equipment.

- Lubricate Moving Parts: Apply appropriate lubricants to pivot points and bearings to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals.

- Monitor Fluid Levels: Regularly check oil and hydraulic fluid levels. Keeping these fluids at optimal levels ensures smooth operation and prevents overheating.

By adhering to these maintenance practices, you can extend the life of your equipment and enhance its performance. A well-cared-for machine not only works better but also provides a safer operating environment.

Comparing John Deere Deck Designs

When examining various mowing configurations, it’s essential to evaluate the distinct characteristics that differentiate them. Each design serves specific needs and operational preferences, impacting efficiency and performance in diverse landscapes.

Key Features to Consider

- Cutting Width

- Height Adjustment Mechanisms

- Material Durability

- Blade Configuration

Performance Comparisons

- Efficiency in Grass Cutting

- Handling of Uneven Terrain

- Ease of Maintenance

- Noise Levels During Operation

Tools Required for Repairs

Effective maintenance and restoration of equipment necessitate a range of specialized tools. Having the right implements on hand can significantly streamline the process, ensuring both efficiency and precision. This section highlights essential tools that facilitate various repair tasks.

Basic Hand Tools

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These are fundamental for disassembly and assembly, allowing easy access to internal components. Additionally, a reliable socket set is crucial for tackling stubborn fasteners.

Advanced Equipment

For more intricate repairs, consider investing in advanced equipment like torque wrenches and diagnostic tools. These devices enable accurate adjustments and help identify underlying issues, ultimately enhancing performance and longevity.

Identifying Worn Components

Recognizing signs of deterioration in machinery is crucial for maintaining optimal performance. Regular inspections help in pinpointing issues before they escalate, ensuring longevity and efficiency. This section outlines the key indicators to look for when assessing component wear.

Common Signs of Wear

Several factors can signal that a component is nearing the end of its life cycle. Look for unusual noises, vibrations, or decreased functionality, which may indicate wear and tear. Additionally, physical inspection can reveal cracks, fraying, or rust.

Inspection Checklist

| Component | Signs of Wear |

|---|---|

| Belts | Cracking, fraying, or glazing |

| Blades | Chipping, dullness, or bending |

| Bearings | Excessive play, noise, or overheating |

| Filters | Clogging or discoloration |

Aftermarket vs. OEM Parts

When it comes to sourcing components for machinery, enthusiasts often face a crucial decision. Understanding the differences between various types of components can significantly impact performance and longevity.

Key Differences

- Quality: OEM products are typically manufactured to meet specific standards, while aftermarket options may vary in quality.

- Price: Aftermarket alternatives are often more affordable, making them appealing for budget-conscious consumers.

- Availability: Aftermarket components may be easier to find, especially for older models.

Considerations for Choice

- Evaluate the specific requirements of your equipment.

- Consider long-term costs versus immediate savings.

- Research the reputation of aftermarket suppliers.

Resources for DIY Repairs

When tackling repairs on your machinery, having access to the right resources can significantly enhance your experience and outcome. Utilizing manuals, online forums, and instructional videos can empower you to perform maintenance tasks efficiently and confidently. A well-rounded toolkit and understanding of components are essential for successful DIY endeavors.

Manuals and Guides

Comprehensive manuals provide detailed insights into the specific components and their functions. They often include troubleshooting tips, maintenance schedules, and assembly instructions. Utilizing these resources can streamline your repair process and minimize errors.

Online Communities

Engaging with online forums and communities dedicated to machinery repairs can offer invaluable support. Experienced users often share their knowledge, tips, and troubleshooting advice, creating a collaborative environment for enthusiasts and DIYers alike. Such interactions can deepen your understanding and help you solve challenges effectively.