Comprehensive Guide to John Deere 42 Mower Deck Parts Diagram

Understanding the intricate assembly of lawn care machinery is crucial for optimal performance and maintenance. This section delves into the various elements that contribute to the overall functionality of a specific model. Each component plays a vital role in ensuring efficiency and longevity.

In exploring this topic, we aim to provide a clear representation of the necessary elements involved in the operation of this equipment. By familiarizing yourself with the essential pieces, you will be better equipped to address any issues that may arise.

Additionally, recognizing the relationship between each part can enhance your ability to perform repairs and upgrades effectively. An informed approach will lead to more productive outcomes and an improved understanding of your machinery.

Understanding John Deere Mower Decks

Exploring the mechanics behind cutting equipment is essential for achieving optimal performance in lawn care. This segment focuses on the fundamental components and their interrelations, providing insights into how these elements work together to enhance efficiency and effectiveness in grass maintenance.

Key Components of the Cutting Assembly

At the heart of this apparatus lies a collection of crucial elements that work in harmony. Each segment contributes to the overall functionality, ensuring that the machine operates smoothly. For instance, rotating blades are pivotal in achieving a clean cut, while the housing serves to protect these blades and improve aerodynamics. Understanding how these components interact can significantly improve maintenance practices.

Maintenance and Troubleshooting

Regular upkeep is vital for prolonging the lifespan of this equipment. Familiarity with common issues, such as uneven cuts or unusual noises, allows operators to address problems swiftly. Identifying wear and tear on specific components can prevent costly repairs and ensure that the machine continues to deliver peak performance.

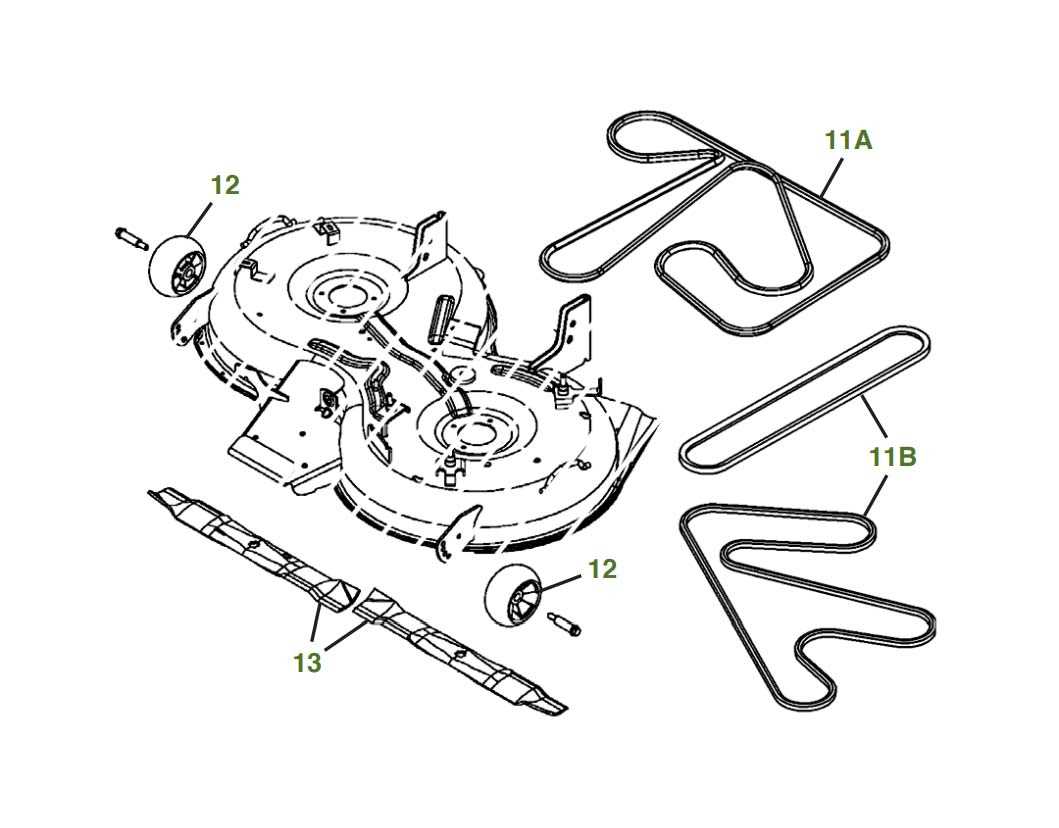

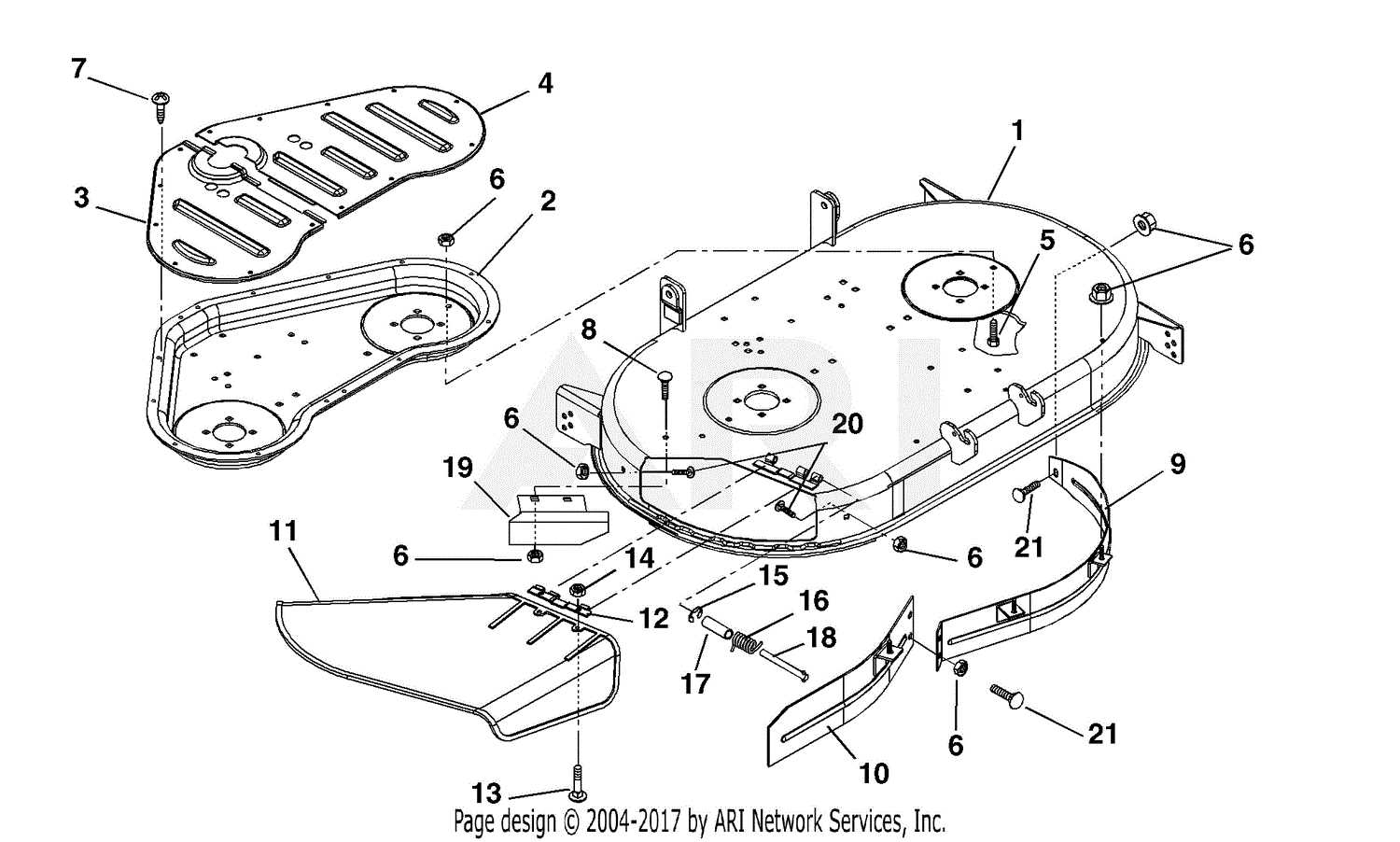

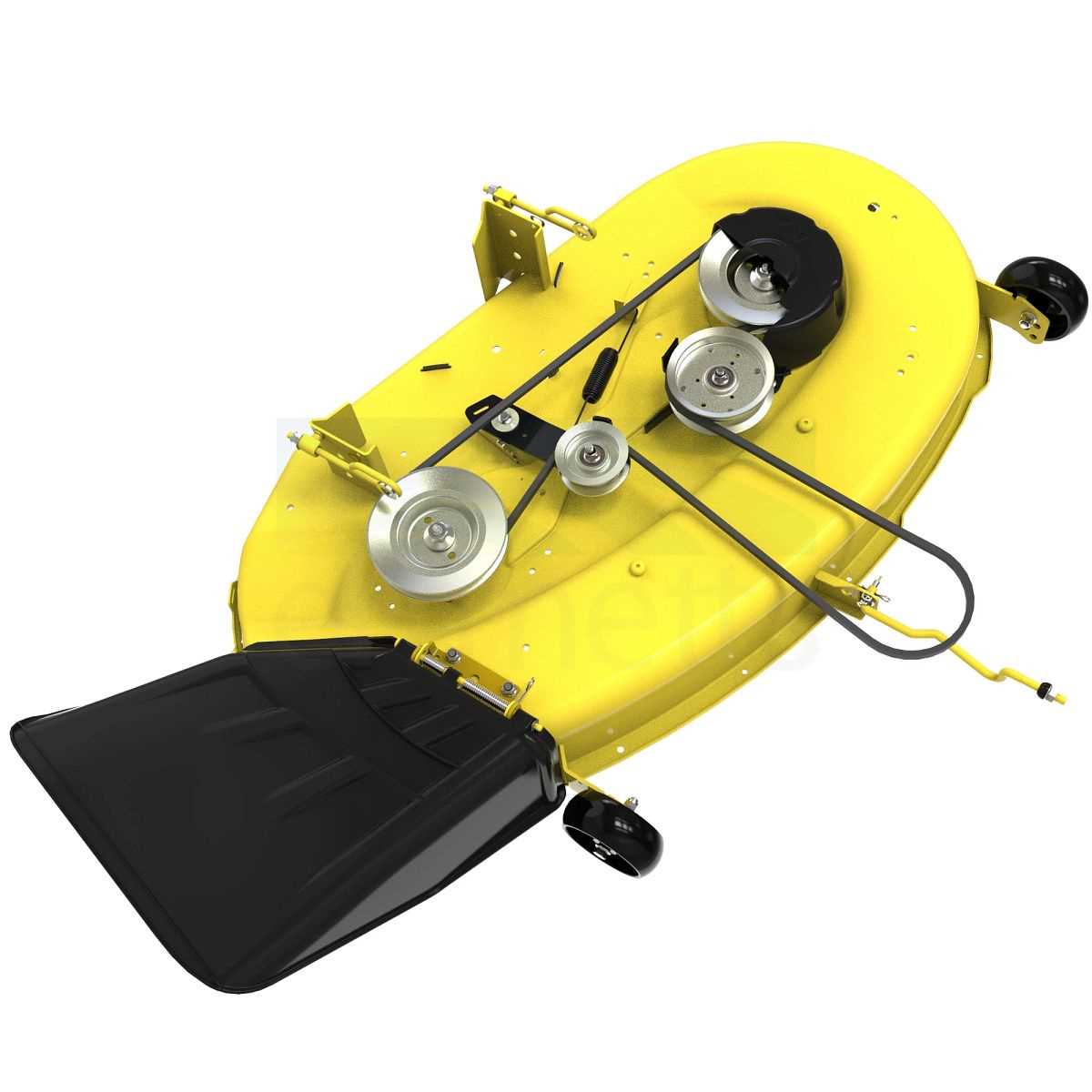

Components of the 42-Inch Deck

This section explores the essential elements that contribute to the efficient operation of a 42-inch cutting system. Each component plays a significant role in ensuring optimal performance and durability.

- Cutting Blades: The sharp edges that provide a clean cut and promote healthy growth.

- Spindle Assembly: The mechanism that holds the blades in place and allows for smooth rotation.

- Housing: The protective shell that encases the cutting mechanism, preventing debris from escaping.

- Belts: The drive elements that transfer power from the engine to the blades, crucial for operation.

- Wheels: Assist in maneuverability and stability during the cutting process.

Understanding these components helps users maintain and troubleshoot their equipment effectively.

Benefits of Regular Maintenance

Consistent upkeep is essential for enhancing performance and longevity. By following a routine maintenance schedule, you ensure that equipment operates smoothly and efficiently, which can prevent costly repairs in the long run.

- Improved Efficiency: Regular checks optimize functionality, leading to better fuel economy and performance.

- Extended Lifespan: Timely maintenance reduces wear and tear, helping machinery last longer.

- Cost Savings: Preventative care minimizes the likelihood of major breakdowns and unexpected expenses.

- Safety: Routine inspections can identify potential hazards, ensuring safe operation.

- Resale Value: Well-maintained equipment retains value, making it more appealing to future buyers.

Common Issues with Mower Decks

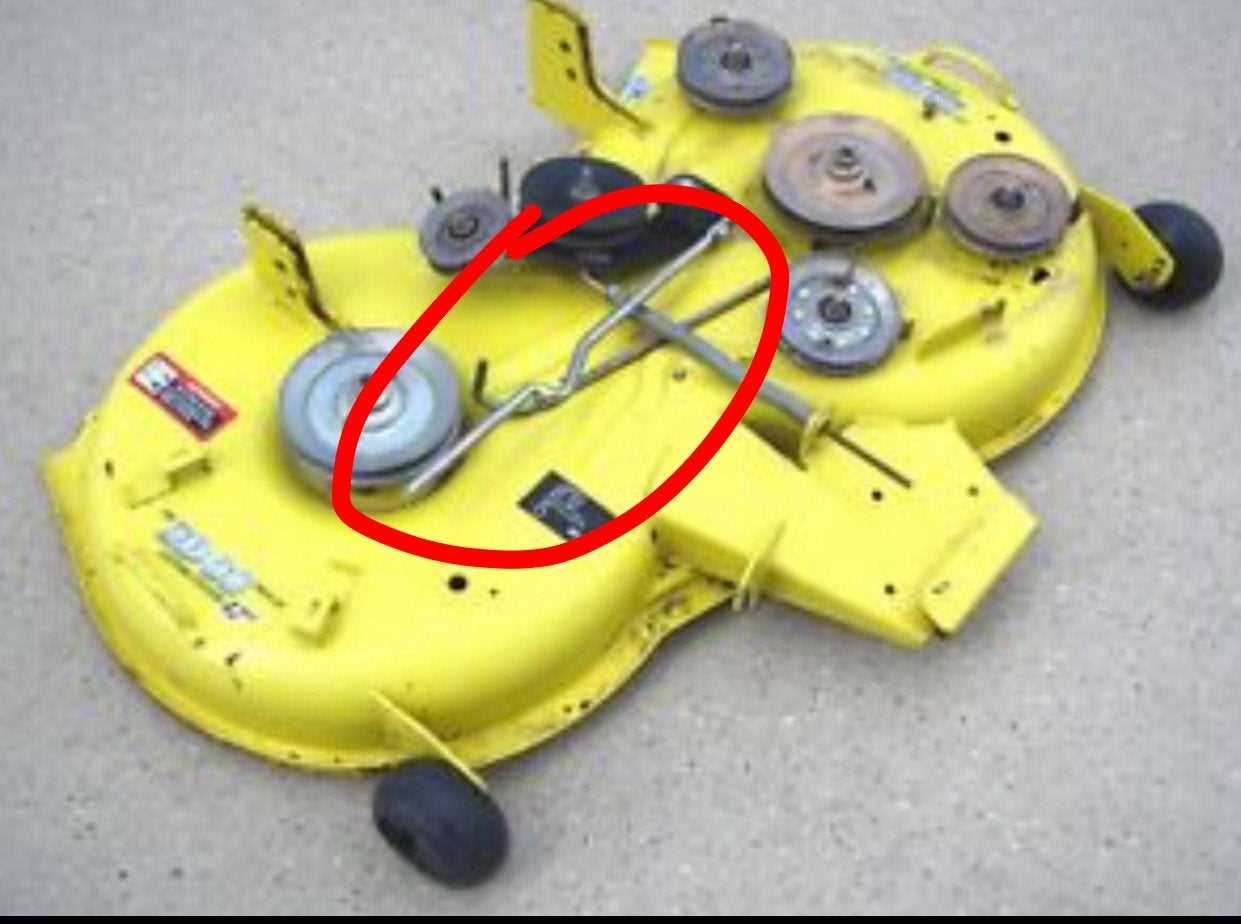

When it comes to cutting equipment, certain challenges often arise that can affect performance and efficiency. Identifying these common problems is crucial for maintaining the longevity and effectiveness of your machinery.

Uneven Cutting is a frequent issue, often caused by imbalanced blades or uneven tire pressure. Regular checks can help ensure a uniform cutting height.

Clogging is another major concern, which typically results from grass buildup. Keeping the undercarriage clean is essential for optimal operation.

Noisy Operation may indicate worn bearings or loose components. Inspecting these elements regularly can prevent further damage.

Rust and Corrosion can compromise structural integrity. Applying protective coatings and storing equipment in a dry place can mitigate this risk.

By addressing these prevalent issues, users can enhance the performance and lifespan of their cutting tools.

Identifying Replacement Parts

Understanding the components of your equipment is essential for maintaining optimal performance. Identifying necessary elements for replacement ensures seamless operation and longevity of your machine. A thorough inspection can help pinpoint which components require attention.

Common Components to Examine

When assessing your unit, focus on key areas that often wear down over time. Regular checks can prevent further damage and enhance efficiency.

| Component | Signs of Wear |

|---|---|

| Blade | Dull edges or visible damage |

| Belt | Cracks or fraying |

| Spindle | Unusual noises or excessive play |

Finding the Right Components

Utilizing a comprehensive guide can streamline the process of locating suitable replacements. Always refer to your equipment’s specifications for compatibility.

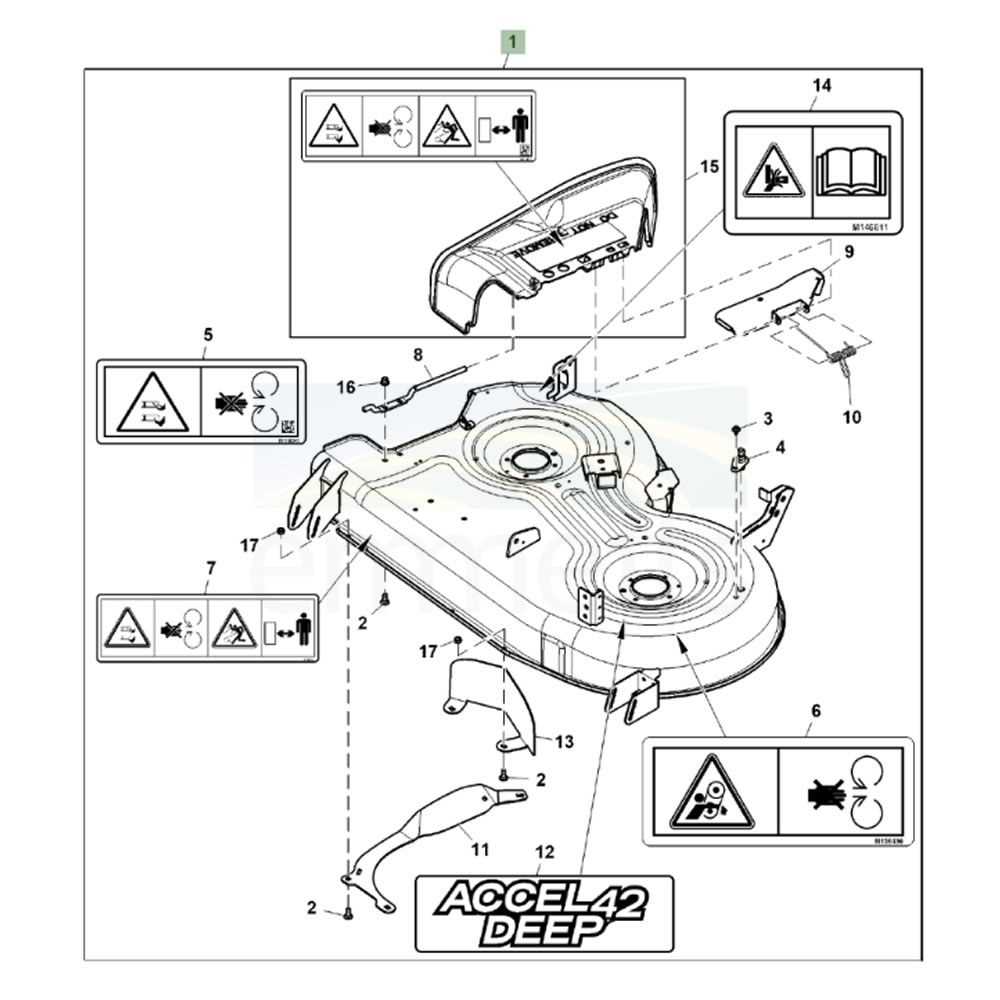

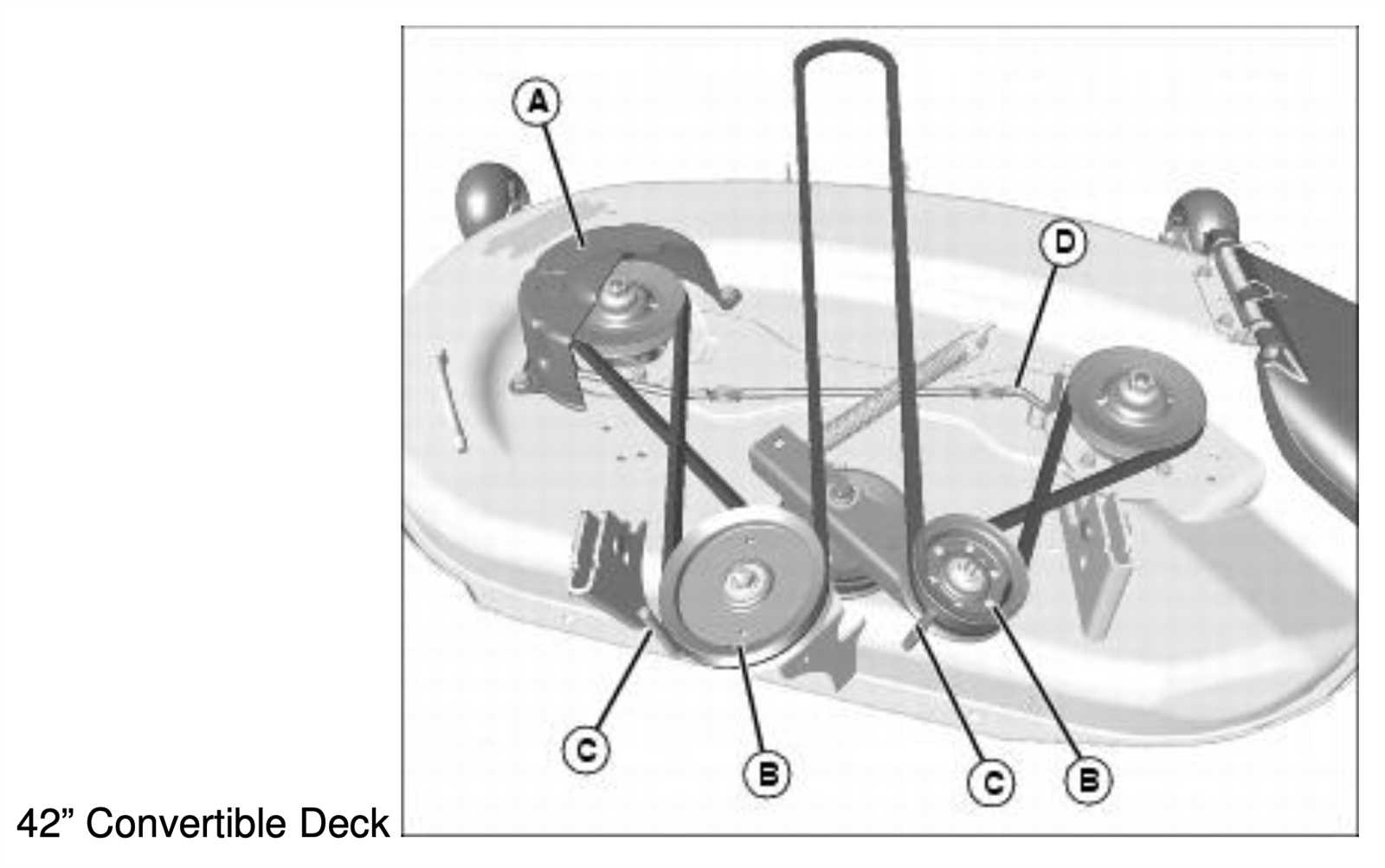

Exploring Diagram Features

Understanding the intricacies of mechanical illustrations is essential for effective maintenance and repair. These visual representations serve as valuable tools, providing clarity on the components and their interrelationships within various machinery. By delving into these features, users can enhance their comprehension and facilitate better handling of equipment.

| Feature | Description |

|---|---|

| Component Identification | Each element is clearly labeled, enabling easy recognition and understanding of its function. |

| Relationship Mapping | Illustrations demonstrate how different parts interact, showcasing their connections and dependencies. |

| Maintenance Guidance | Visuals often include tips for upkeep, highlighting areas requiring regular attention. |

| Assembly Instructions | Step-by-step visuals guide users through the assembly process, reducing the likelihood of errors. |

Utilizing these features can significantly improve operational efficiency, making the tasks of repair and upkeep more straightforward and accessible.

How to Read a Parts Diagram

Understanding a schematic representation is essential for effective maintenance and repair. These visual aids provide a clear overview of components and their relationships, allowing users to identify and locate specific items easily. Mastering this skill enhances your ability to address issues efficiently and select the correct replacements.

Identifying Components

Each symbol or illustration corresponds to a specific element within the system. Pay close attention to labels and numbers that indicate the parts’ positions. Familiarizing yourself with common terminology will help you navigate the illustration with ease.

Utilizing Reference Numbers

Reference numbers serve as a guide for locating and ordering replacements. They often appear next to each element, making it simple to match components with their corresponding descriptions in a catalog. Cross-referencing this information can ensure you obtain the ultimate fit for your needs.

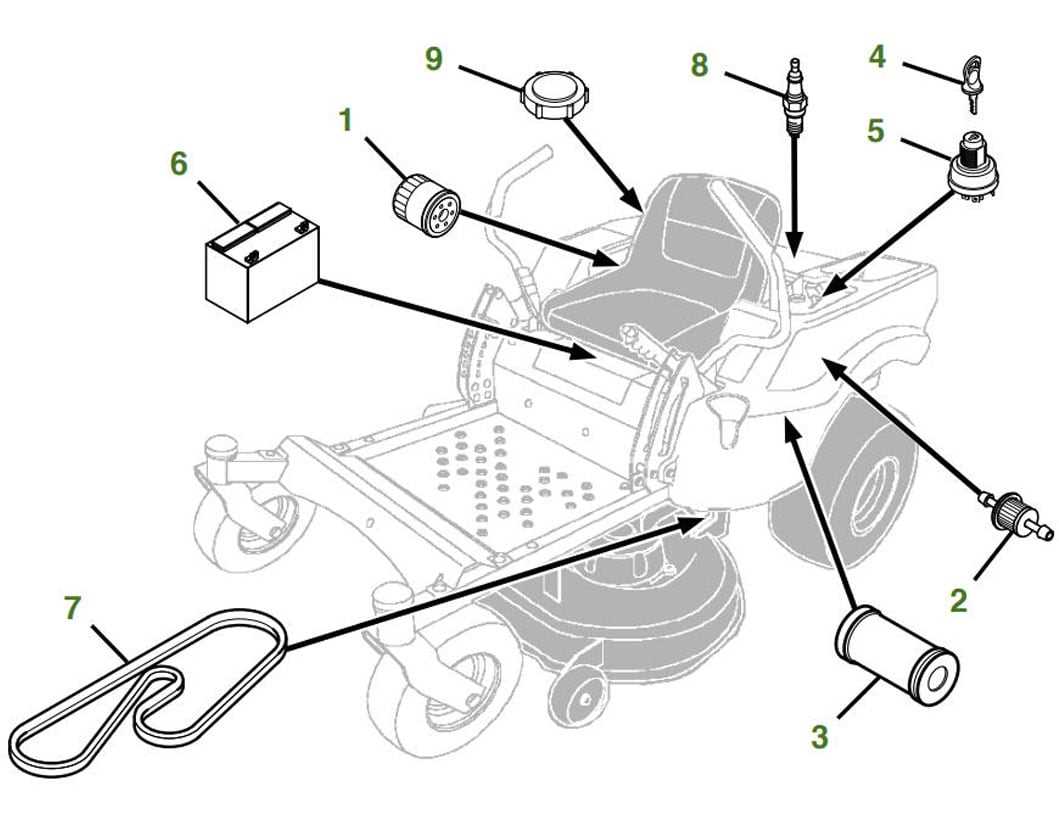

Tools Required for Maintenance

Proper upkeep of your equipment ensures longevity and optimal performance. A well-equipped workspace is essential for effective maintenance, allowing for easy access to the necessary tools and ensuring tasks can be completed efficiently.

- Wrench Set

- Screwdrivers (Flathead and Phillips)

- Socket Set

- Pliers

- Torque Wrench

In addition to these basic tools, consider the following items for specialized tasks:

- Grease Gun

- Blade Sharpener

- Fuel Can

- Cleaning Brushes

- Protective Gear

Having the right equipment on hand can significantly enhance the maintenance experience and contribute to the ultimate functionality of your machinery.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment effectively. By following these structured steps, you can ensure that each component is addressed properly, leading to optimal functionality and longevity.

Preparation and Tools

Before beginning, gather all necessary tools and ensure you have a clean workspace. Familiarize yourself with the various components to streamline the repair process.

Inspection and Replacement

Carefully inspect each element for wear or damage. Replace any faulty items with high-quality substitutes to enhance performance. Remember to refer to your specific model for precise compatibility.

Comparing Different Mower Deck Models

When evaluating various cutting platforms, it’s essential to consider the unique features and specifications that distinguish each model. Understanding these differences can guide users in selecting the most suitable option for their needs.

- Design Variations: Models often differ in construction and shape, impacting performance and maneuverability.

- Material Quality: The durability of components varies, influencing longevity and maintenance requirements.

- Cutting Width: Different widths can affect efficiency and suitability for various terrains.

- Adjustability: Some platforms offer customizable height settings, enhancing versatility.

By delving into these aspects, users can make an informed decision about which cutting solution best meets their specific demands.

Where to Find Genuine Parts

Locating authentic components for your outdoor equipment is essential for optimal performance and longevity. Reliable sources not only ensure quality but also provide peace of mind regarding the integrity of your machinery.

Authorized Dealers: Visiting an official distributor guarantees access to original items, complete with warranties and expert support.

Online Retailers: Numerous e-commerce platforms specialize in high-quality components. Always verify seller ratings and product authenticity to avoid counterfeits.

Manufacturer’s Website: Directly checking the manufacturer’s site can lead you to a plethora of resources, including listings of certified sellers and potential discounts.

Local Repair Shops: Many local services not only perform repairs but also stock genuine replacements. Establishing a relationship with these professionals can provide valuable recommendations.

Investing time to find reputable sources will ultimately enhance the efficiency and reliability of your equipment.

Tips for Efficient Mowing

Achieving a well-manicured lawn requires more than just cutting grass. Implementing effective techniques can significantly enhance the overall quality of your outdoor space. By optimizing your approach, you can save time, energy, and resources while ensuring a lush, healthy landscape.

Timing and Frequency

The timing of your grass cutting plays a crucial role in maintaining its health and appearance. Mowing during the cooler parts of the day, such as early morning or late afternoon, helps reduce stress on the grass. Additionally, adjusting the frequency of cutting based on growth patterns ensures that the lawn remains vibrant without becoming overgrown.

Proper Equipment Maintenance

Regular maintenance of your cutting equipment is essential for optimal performance. Keeping blades sharp ensures clean cuts, reducing the risk of disease. Furthermore, inspecting your tools for wear and tear can prevent issues that may lead to inefficient operation. Below is a quick checklist for maintaining your equipment:

| Task | Frequency |

|---|---|

| Sharpen blades | Every 20-25 hours of use |

| Check oil levels | Before each use |

| Clean equipment | After each use |

| Inspect belts and cables | Monthly |

By following these guidelines, you can enhance the efficiency of your lawn care routine, ensuring a beautiful and thriving outdoor environment.

Owner Reviews and Recommendations

Feedback from users provides invaluable insights into the performance and reliability of various equipment. By examining these reviews, potential buyers can make informed decisions based on real-life experiences. This section summarizes the thoughts and suggestions of owners who have utilized these tools extensively.

Many users emphasize the importance of quality when selecting components for their machinery. Here are some common points mentioned in reviews:

- Durability: Owners appreciate parts that withstand regular use and harsh conditions.

- Ease of Installation: Many highlight the benefit of components that are simple to install, reducing downtime.

- Performance: Users often report improvements in functionality after upgrading specific items.

- Customer Support: Positive experiences with customer service can greatly influence satisfaction levels.

Recommendations often focus on specific brands or models that have proven reliable over time. Here are some popular suggestions:

- Consider opting for components known for their long-lasting performance.

- Look for user-friendly installation guides or videos to ease the process.

- Research customer service ratings to ensure support is available when needed.

- Check online forums for firsthand experiences and advice from fellow owners.

By taking into account these reviews and recommendations, prospective buyers can enhance their decision-making process and ensure they choose high-quality equipment that meets their needs.