Complete Guide to John Deere D110 Mower Deck Parts Diagram

In the realm of landscape maintenance, having a comprehensive grasp of the machinery involved is essential for effective operation and upkeep. The intricate design of these devices often necessitates a detailed examination of their individual elements, allowing users to identify and replace any worn or malfunctioning components with ease. This understanding not only enhances performance but also extends the lifespan of the equipment.

Visual representations play a crucial role in this educational process, providing clarity on how various sections interact within the overall system. By studying these illustrations, operators can familiarize themselves with each crucial segment, ensuring they can tackle any repairs or maintenance tasks with confidence. Additionally, such resources foster a deeper appreciation for the engineering behind these powerful tools.

Whether you are a novice gardener or a seasoned professional, acquiring knowledge about the specific constituents of your equipment can significantly impact your efficiency and effectiveness in lawn care. Recognizing each component’s function paves the way for informed decision-making and enhances your overall maintenance routine.

Understanding John Deere D110 Mower

This section aims to provide insights into a specific lawn care machine designed for efficient grass maintenance. Featuring a user-friendly design, it combines functionality with reliability, making it an essential tool for homeowners looking to achieve a well-kept landscape.

Key Features

The equipment stands out due to its powerful engine and innovative cutting system, which ensures a clean and even trim. Its ergonomic design allows for easy maneuverability, while the durable construction enhances longevity, making it suitable for various terrains.

Maintenance Tips

Regular upkeep is vital for optimal performance. This includes checking oil levels, cleaning the cutting mechanism, and inspecting the wheels for wear and tear. Adhering to a maintenance schedule will not only prolong the machine’s life but also enhance its efficiency.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use recommended oil type |

| Blade Sharpening | Every 20 hours | Check for dullness |

| Air Filter Cleaning | Every season | Ensure proper airflow |

Key Features of D110 Mowers

The machinery designed for residential landscaping boasts several impressive characteristics that enhance performance and user experience. These features contribute to efficient operation, ensuring that tasks such as grass trimming and lawn maintenance are completed with ease.

Powerful Engine Performance

Equipped with a robust engine, these machines deliver reliable power that enables smooth operation across various terrains. The combination of high torque and efficiency allows for quick maneuvering, making them ideal for medium-sized yards.

User-Friendly Design

The thoughtful design includes ergonomic controls and a comfortable seating arrangement, ensuring that operators can work for extended periods without discomfort. Additionally, easy-access components simplify maintenance tasks, allowing users to keep their equipment in optimal condition with minimal effort.

Importance of Mower Deck Components

The efficiency and performance of any cutting equipment heavily rely on the individual elements that make up its operational assembly. Each component plays a crucial role in ensuring that the machinery operates smoothly, providing an optimal experience for users. Understanding these elements is essential for effective maintenance and troubleshooting.

Key Functions of Essential Elements

- Cutting Precision: The sharpness and design of the blades determine the quality of the cut.

- Durability: Components made from high-quality materials ensure longevity and reliability during operation.

- Balance and Stability: Properly aligned parts contribute to even weight distribution, enhancing maneuverability.

Maintenance and Performance

Regular inspection of the individual components is vital for maintaining high performance. Neglecting any part can lead to decreased efficiency and potential damage. Key maintenance practices include:

- Checking for wear and tear on blades and supports.

- Ensuring that all fasteners are tight and secure.

- Cleaning components to prevent buildup of grass and debris.

In conclusion, recognizing the significance of each element within the assembly is crucial for both effective operation and longevity of the equipment.

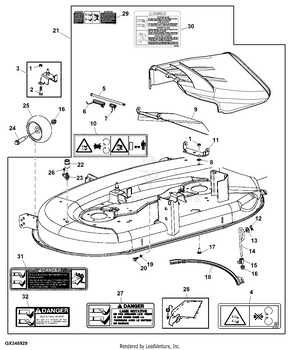

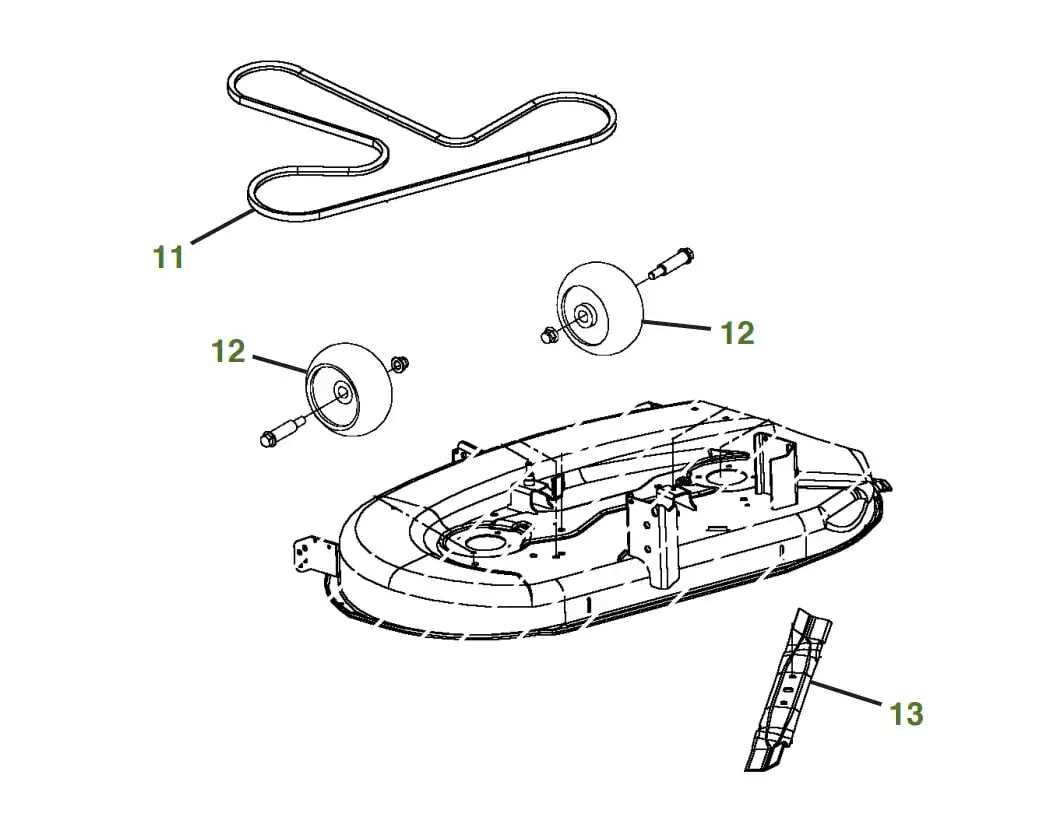

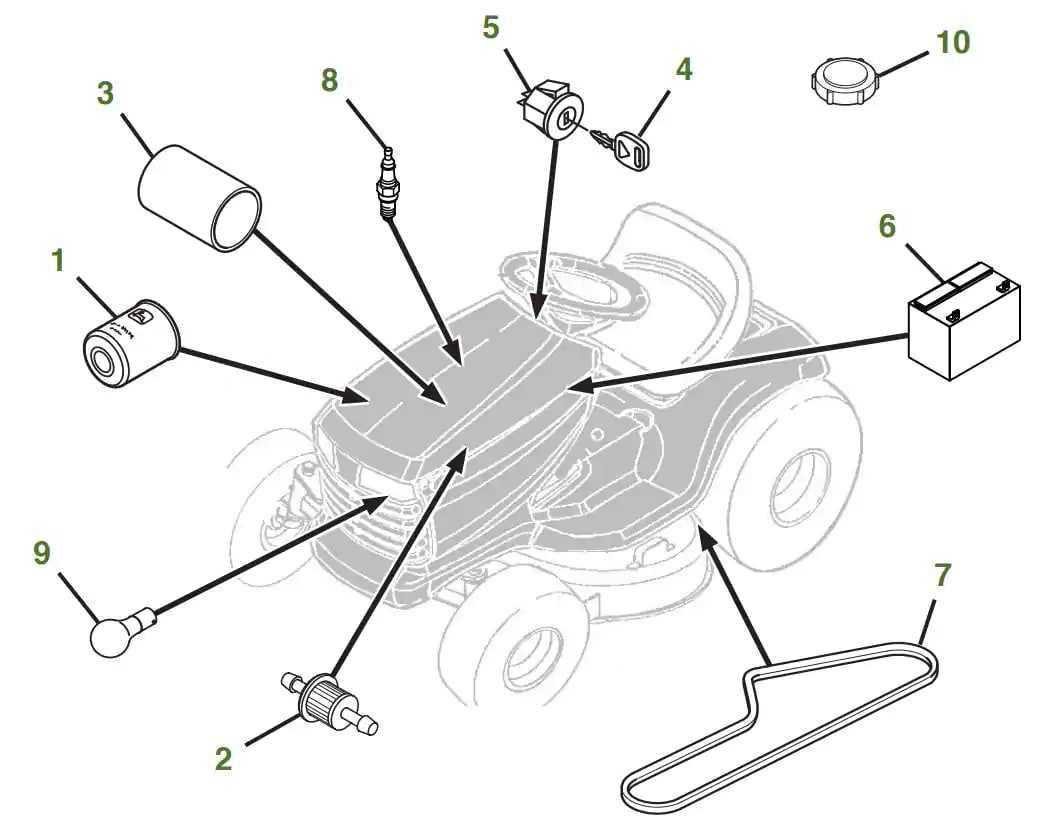

Identifying Parts in the Diagram

Understanding the components represented in a visual schematic is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and recognizing them can simplify the troubleshooting process. By familiarizing oneself with the layout and designations, users can ensure proper identification and replacement when needed.

| Component | Description |

|---|---|

| Blade | The cutting element that interacts with the grass. |

| Spindle | Holds the blade in place and allows for rotation. |

| Chassis | The main frame that supports other components. |

| Lift Lever | Used to raise and lower the cutting element. |

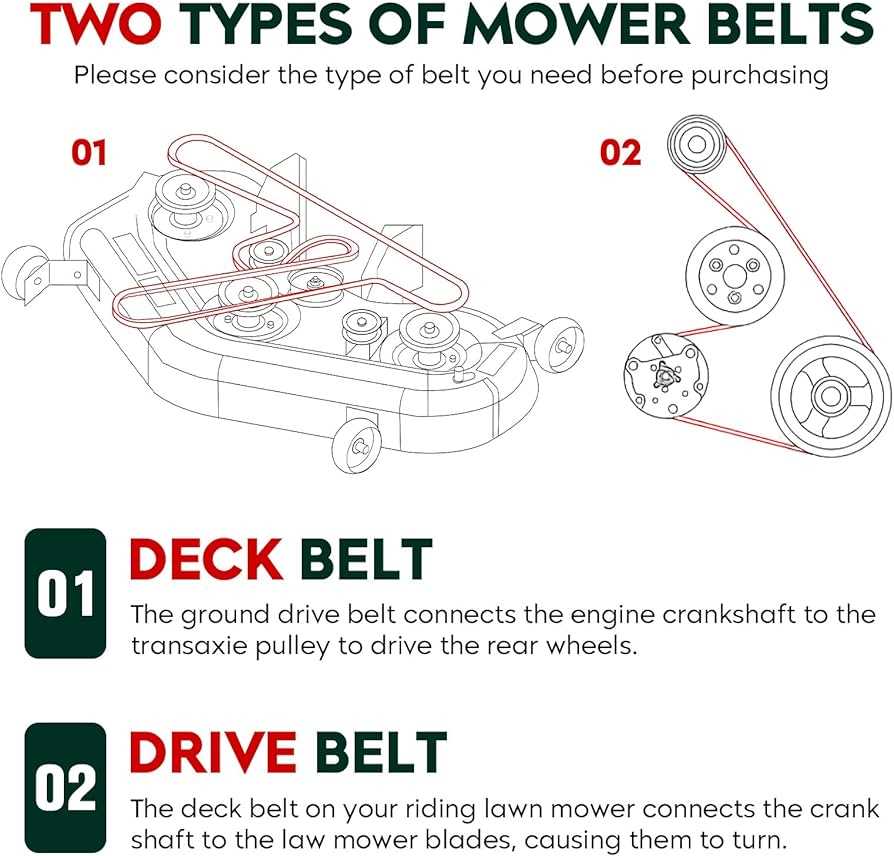

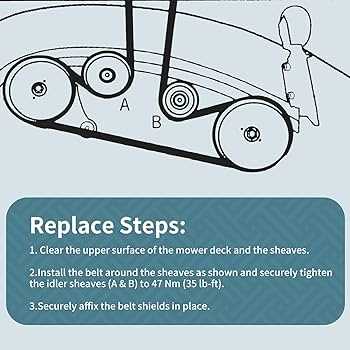

| Drive Belt | Transfers power from the engine to the cutting mechanism. |

Referencing the schematic can aid in visualizing the connection between various components, enhancing the ability to perform necessary repairs. This knowledge not only streamlines the maintenance process but also extends the lifespan of the equipment.

Common Issues with Mower Decks

Maintaining a healthy cutting system is crucial for achieving a well-manicured lawn. Various problems can arise that hinder performance, leading to uneven cuts and increased wear. Understanding these common issues can help ensure longevity and effectiveness.

- Clogging: Grass clippings and debris can accumulate, obstructing the cutting mechanism. Regular cleaning is essential.

- Blade Dullness: Over time, cutting edges can lose sharpness, resulting in ragged cuts. Frequent sharpening or replacement is recommended.

- Misalignment: Components may shift out of position, causing uneven cutting heights. Regular adjustments can rectify this.

- Wear and Tear: Frequent use can lead to degradation of parts. Inspecting and replacing worn components can prevent further issues.

- Rust and Corrosion: Exposure to moisture can lead to oxidation. Proper storage and cleaning can mitigate this problem.

Being aware of these common challenges allows for proactive maintenance, ensuring optimal performance and a beautiful lawn year-round.

Replacement Parts for D110 Deck

Maintaining optimal performance requires timely replacement of components. Understanding the necessary elements for efficient operation is crucial for longevity and effectiveness. Below are essential replacements that ensure smooth functionality.

- Blades: Sharp and durable blades are essential for a clean cut. Regular replacement helps maintain lawn health.

- Spindles: These support the blades and facilitate rotation. Worn spindles can lead to uneven cutting.

- Belts: Drive belts transfer power from the engine to the cutting mechanism. Inspecting and replacing worn belts is vital for performance.

- Mounting Hardware: Bolts, nuts, and washers ensure secure attachment. Replacing these components prevents vibration and damage.

- Wheels: Smooth-rolling wheels enhance maneuverability. Regularly check for wear and replace as necessary.

Acquiring high-quality replacements not only improves functionality but also extends the lifespan of the equipment. Ensure you choose the right specifications for seamless integration.

Maintenance Tips for Mower Decks

Keeping your cutting equipment in optimal condition is essential for achieving a clean and efficient lawn care experience. Regular upkeep not only extends the life of the machine but also ensures that it operates at peak performance. Here are some valuable maintenance practices to consider.

Regular Cleaning

Cleaning the exterior and underside of the equipment is crucial. Grass clippings, dirt, and debris can accumulate, leading to rust and reduced efficiency.

- After each use, remove clippings and debris with a brush or hose.

- Avoid using high-pressure water, as it can damage electrical components.

- Inspect for any signs of wear or damage while cleaning.

Sharpening Blades

Sharp blades are essential for a clean cut, which promotes healthy grass growth. Dull blades can tear the grass, leading to disease.

- Check blade sharpness regularly, ideally after every 10 hours of use.

- Remove the blades and sharpen them using a file or sharpening tool.

- Ensure blades are balanced after sharpening to prevent vibrations during operation.

By following these tips, you can maintain the performance and longevity of your cutting equipment, ensuring it remains effective season after season.

Tools Needed for Repairs

When tackling maintenance and repair tasks on outdoor equipment, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures safety and precision in every step of the repair.

Here is a list of essential tools that you may need:

- Wrenches: Adjustable and socket wrenches for loosening and tightening bolts.

- Screwdrivers: Both flat-head and Phillips types to handle various screws.

- Pliers: Needle-nose and regular pliers for gripping and bending tasks.

- Ratchet Set: For quick adjustments and tight spaces.

- Torque Wrench: To ensure bolts are tightened to the correct specifications.

In addition to these basics, you might find the following items helpful:

- Wire Cutters: For electrical repairs and modifications.

- Safety Gear: Gloves and goggles to protect yourself during the repair process.

- Lubricants: To maintain moving parts and prevent wear.

- Cleaning Supplies: Brushes and rags for maintaining a tidy workspace.

Having these tools readily available will make any repair task more manageable and will help you achieve optimal results. Make sure to inspect your toolkit regularly and replace any worn or damaged tools as necessary.

How to Use the Diagram Effectively

Utilizing a visual representation of components can greatly enhance your understanding and maintenance of equipment. This guide will provide you with strategies to maximize the benefits of such a reference, ensuring you can identify and manage each segment with confidence.

Begin with Familiarization: Take time to study the visual aid thoroughly. Understand the layout and how each component is interconnected. This foundational knowledge will be invaluable when troubleshooting or performing repairs.

Identify Key Elements: Focus on specific areas that are crucial for operation and maintenance. Mark or highlight these sections in your reference to quickly locate them during practical tasks. This will streamline your workflow and minimize downtime.

Use for Ordering and Replacement: When parts need replacement, refer to the visual guide to ensure you are ordering the correct items. Having a clear view of what each component looks like and its corresponding label will prevent mistakes and save time.

Incorporate with Manuals: Enhance your understanding by cross-referencing with the user manual. The combination of a visual reference and textual instructions can provide a comprehensive view of maintenance requirements and procedures.

Practice Regular Reviews: Regularly revisit the visual aid to keep your knowledge fresh. This practice not only reinforces your understanding but also helps you recognize potential issues before they escalate.

By applying these strategies, you can effectively utilize the visual representation of components to improve your maintenance practices and extend the life of your equipment.

Safety Precautions When Working

Ensuring safety while performing maintenance or repairs is essential to prevent accidents and injuries. Adhering to recommended guidelines not only protects the individual but also enhances the longevity of the equipment. Awareness of potential hazards is crucial for a secure working environment.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear is vital for minimizing risks associated with sharp components and moving parts. Additionally, consider wearing ear protection to guard against loud noises that could lead to hearing damage.

Before starting any maintenance tasks, make sure to disconnect the power source. This simple step can prevent accidental starts and ensure a safe working space. Familiarize yourself with the machinery’s features and functions to effectively handle any issues that may arise.

Keep the work area clean and organized to avoid tripping hazards. Removing clutter not only creates a safer environment but also allows for easier access to tools and parts. Always store tools in designated places after use to prevent misplacement and potential accidents.

Lastly, consult the user manual for specific safety recommendations related to the equipment. Following the manufacturer’s guidelines ensures that you are aware of any unique precautions necessary for the specific model you are working on.

Where to Buy Replacement Parts

Finding quality components for your outdoor equipment is crucial for maintaining performance and longevity. Various options are available for sourcing reliable replacements, ensuring your machine operates smoothly for years to come.

Online Retailers

The internet offers a plethora of platforms where you can purchase the necessary components. These sites typically provide detailed specifications and customer reviews, making it easier to select the right item for your needs.

Local Dealers

Visiting a nearby dealership can also be a great option. Many dealerships stock a range of components and can provide personalized advice based on your specific equipment. Additionally, they may offer installation services if needed.

| Source Type | Advantages |

|---|---|

| Online Retailers | Wide selection, convenient shopping, customer reviews |

| Local Dealers | Personalized advice, immediate availability, potential installation services |

Online Resources for D110 Owners

For individuals who own this popular outdoor equipment, numerous online platforms offer valuable information and support. These resources can assist in troubleshooting, maintenance, and upgrades, ensuring that the equipment operates efficiently and lasts for years. From forums to instructional videos, there’s a wealth of content available to enhance the ownership experience.

Community Forums and Discussion Boards

Engaging with fellow enthusiasts on community forums is a great way to share experiences and solutions. These platforms allow owners to ask questions, exchange tips, and find answers from those who have faced similar challenges. Many members provide insights based on personal experiences, creating a rich repository of knowledge.

Instructional Videos and Guides

Video tutorials have become an essential resource for learning maintenance techniques and repair processes. Platforms like YouTube host a variety of channels dedicated to outdoor equipment care, where owners can find step-by-step guides. These visual aids can significantly simplify complex tasks, making it easier to keep machinery in top condition.