Understanding the John Deere Deck Parts Diagram for Efficient Maintenance

When maintaining outdoor machinery, a comprehensive grasp of the various components is essential for optimal performance. This knowledge not only enhances efficiency but also extends the lifespan of your equipment. A clear visual representation of these elements can serve as a valuable reference during repairs and maintenance.

Visual aids can significantly simplify the process of identifying and understanding the individual elements within your lawn machinery. By examining a detailed schematic, users can easily locate specific components, ensuring they are well-informed when tackling repairs or replacements. Such clarity can ultimately save time and resources.

Delving into the specifics of these essential components allows for a deeper appreciation of their functions and interconnections. Understanding how each part contributes to overall operation will empower users to make informed decisions and enhance their machinery’s effectiveness.

Understanding John Deere Deck Components

This section explores the essential elements that contribute to the efficient operation of a mowing apparatus. Each component plays a crucial role in ensuring optimal performance and longevity, creating a seamless experience for users.

Blade Assembly: The cutting mechanism is fundamental to the functionality, providing precision in grass trimming and enhancing the overall appearance of the landscape.

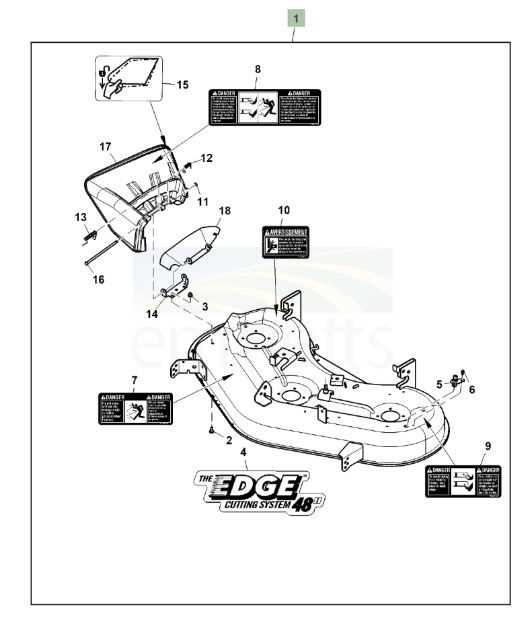

Housing: This protective casing supports and safeguards internal mechanisms, ensuring durability and reliability in various conditions.

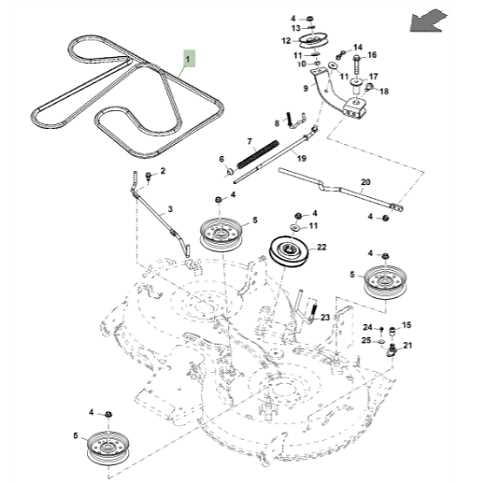

Drive System: Responsible for transferring power, this system is key to achieving the desired speed and efficiency during operation.

Adjustment Mechanisms: These allow for customized height settings, accommodating different terrains and grass types for a tailored mowing experience.

Wheels: Integral for mobility, the wheels must be robust enough to navigate various surfaces while maintaining stability.

Understanding these elements helps users make informed decisions regarding maintenance and upgrades, ultimately enhancing their mowing experience.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is essential for effective maintenance and repair. These illustrations serve as a crucial reference, ensuring that every element is correctly identified and understood. Without reliable visuals, the risk of errors increases significantly, leading to potential inefficiencies and costly mistakes.

Moreover, well-crafted visuals facilitate smoother communication between technicians and suppliers. When everyone is on the same page, it reduces misunderstandings and speeds up the procurement process, ultimately enhancing the overall efficiency of operations. In the long run, investing in accurate visual guides can save time, resources, and effort.

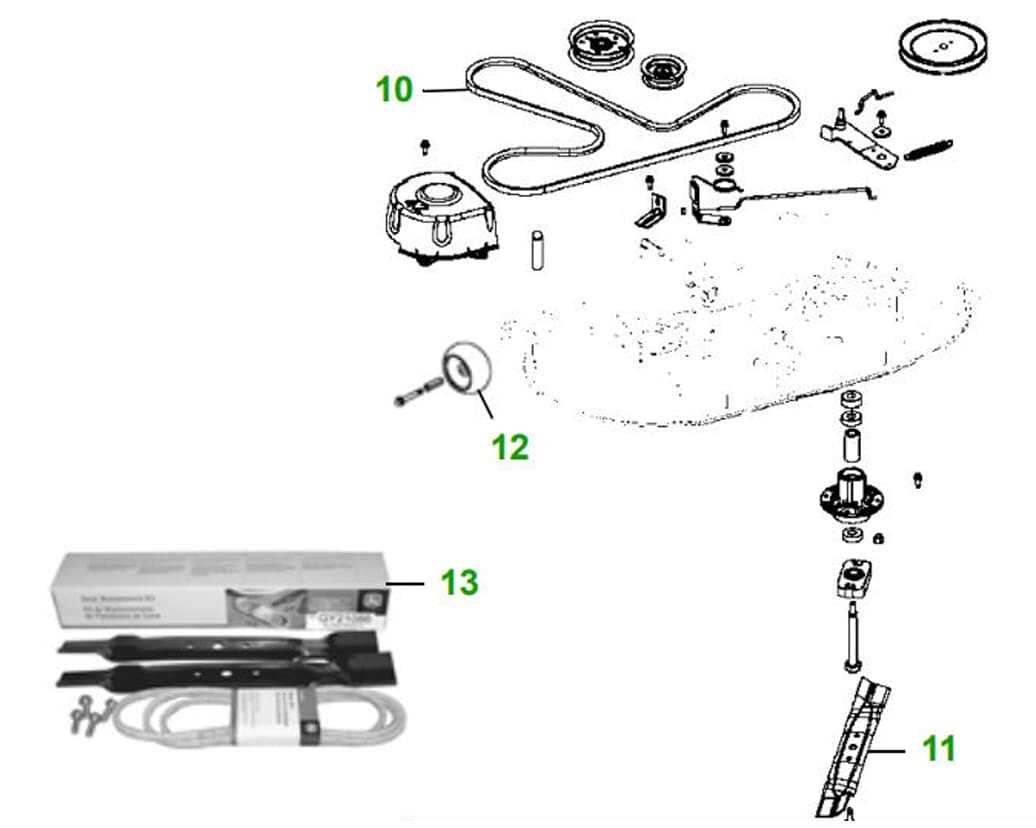

Common John Deere Deck Parts

Understanding the essential components of lawn care machinery is crucial for maintaining optimal performance. Each section plays a significant role in ensuring efficiency and longevity. Familiarizing oneself with these elements can enhance both maintenance practices and overall functionality.

Key Components

The primary elements include blades, spindles, and belts. Blades are critical for achieving a clean cut, while spindles support the rotational movement. Belts are responsible for transferring power, ensuring that the cutting mechanism operates smoothly. Regular inspection of these components can prevent breakdowns and improve cutting performance.

Maintenance Tips

To prolong the life of these components, it is essential to perform routine checks and replacements as needed. Sharpening blades, checking spindle integrity, and monitoring belt tension are vital practices. By keeping these elements in optimal condition, users can enjoy a well-maintained lawn and reliable equipment for years to come.

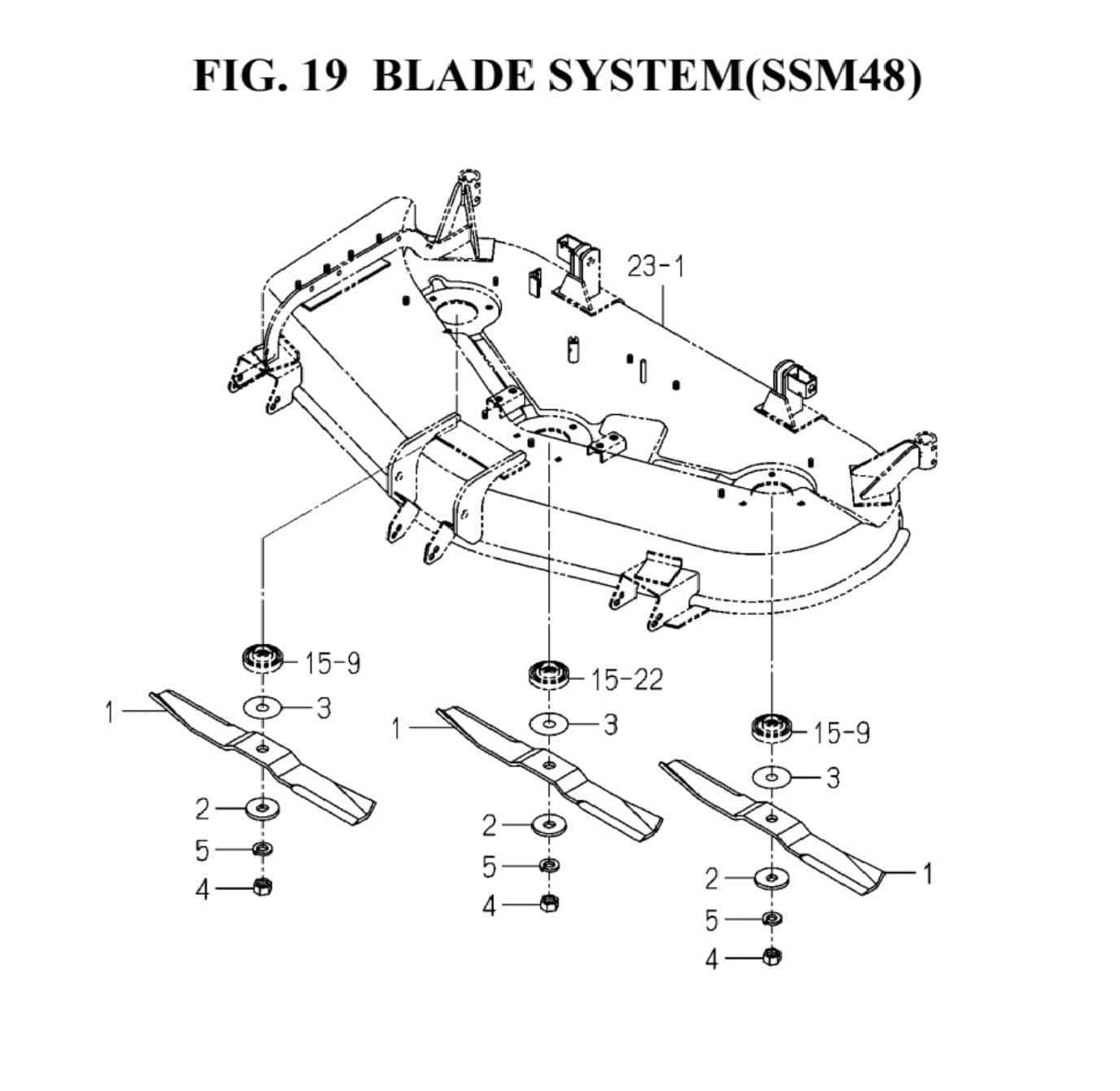

How to Read a Parts Diagram

Understanding a schematic representation is essential for effective maintenance and repair tasks. This visual guide provides a clear overview of various components and their interconnections, enabling users to identify and locate specific elements quickly.

To effectively interpret such a guide, follow these key steps:

- Familiarize Yourself with Symbols:

- Study the legend to understand different notations.

- Note any unique icons that represent specific items.

- Identify Key Sections:

- Look for labeled areas that group related components.

- Recognize larger assemblies that may contain multiple parts.

- Trace Connections:

- Follow lines that indicate how items interact or connect.

- Pay attention to arrows that show the direction of movement or flow.

- Cross-Reference with Lists:

- Use accompanying reference materials to match items with descriptions.

- Check for part numbers to ensure accuracy when ordering replacements.

By following these steps, users can confidently navigate through any schematic, enhancing their ability to troubleshoot and replace components effectively.

Identifying Worn or Damaged Parts

Recognizing components that have deteriorated or suffered damage is crucial for maintaining the efficiency and longevity of equipment. Timely identification helps prevent further issues and ensures optimal performance during operation.

Common Signs of Wear

Several indicators can suggest that a component may need attention. These include unusual noises, decreased efficiency, and visible signs of degradation such as cracks or excessive wear.

Inspection Checklist

| Indicator | Description |

|---|---|

| Unusual Noises | Grinding, squeaking, or rattling sounds during operation. |

| Visible Cracks | Signs of fractures or splits on the surface of components. |

| Decreased Efficiency | Lower performance or power output than usual. |

| Excessive Wear | Noticeable thinning or erosion of material on moving parts. |

Maintenance Tips for Deck Components

Proper upkeep of essential components is crucial for optimal performance and longevity of your equipment. Regular attention to these elements not only enhances functionality but also ensures safety during operation. Here are some key practices to maintain these vital pieces effectively.

1. Regular Inspection: Conduct frequent checks to identify any signs of wear or damage. Look for cracks, rust, or loose connections that may affect performance.

2. Cleanliness: Keep all surfaces free from debris, grass clippings, and dirt. This prevents buildup that can lead to corrosion or operational issues.

3. Lubrication: Apply appropriate lubricants to moving parts as specified in the user manual. This reduces friction and prolongs the life of the components.

4. Tightening Fasteners: Periodically inspect and tighten screws, bolts, and nuts. Vibrations during use can loosen these fasteners over time, leading to potential failures.

5. Seasonal Maintenance: Before seasonal changes, conduct a thorough check-up. Prepare your machinery for winter storage or ensure it’s ready for summer tasks.

6. Professional Servicing: Consider consulting a qualified technician for a comprehensive evaluation. Professional insights can help in identifying issues not easily noticeable.

By following these maintenance tips, you can ensure the reliability and efficiency of your equipment for years to come.

Replacement Parts Availability and Sources

Accessing the necessary components for machinery maintenance is crucial for optimal performance and longevity. Understanding where to find reliable replacements can significantly enhance the upkeep process and minimize downtime. Various avenues exist for sourcing these essential elements, each offering distinct benefits and considerations.

Primary Sources for Components

- Authorized Dealers: These outlets provide genuine items, ensuring compatibility and reliability. They often have a comprehensive inventory and knowledgeable staff to assist with specific needs.

- Online Retailers: Numerous e-commerce platforms specialize in machinery components. They typically offer competitive pricing and a wide range of options.

- Local Repair Shops: Establishments that focus on repairs may have spare components readily available or can assist in ordering the right items.

- Aftermarket Suppliers: Many manufacturers produce compatible alternatives that can be more cost-effective. Researching quality and reviews is essential when opting for these alternatives.

Considerations When Sourcing

- Quality Assurance: Ensure that the components meet industry standards to avoid performance issues.

- Compatibility: Verify that the selected items are suitable for your specific machinery model.

- Warranty and Support: Check for guarantees on the components, which can provide peace of mind in case of defects.

- Cost vs. Value: Balance price with quality; the cheapest option is not always the best in the long run.

Step-by-Step Assembly Instructions

Assembling machinery components can be a straightforward task when approached methodically. This guide aims to provide clear, concise steps to ensure that each piece fits together seamlessly, enhancing the functionality of your equipment.

1. Gather Your Tools: Before starting, make sure you have all necessary tools at hand. Common items include wrenches, screwdrivers, and safety gloves. Having everything ready will streamline the process.

2. Review the Components: Lay out all pieces in an organized manner. Familiarize yourself with each component’s shape and function. This will help prevent confusion during assembly.

3. Start with the Base: Begin by securing the foundation of the assembly. Ensure that all mounting holes are aligned and fasteners are tight but not over-tightened to avoid damage.

4. Attach Additional Elements: Progressively add each subsequent part according to the manual’s guidelines. Always check for compatibility and proper orientation of each element.

5. Double-Check Connections: Once everything is assembled, go over each connection. Ensure that all bolts and screws are properly tightened and that there are no loose components.

6. Conduct a Functionality Test: After assembly, perform a test run to confirm that everything operates as intended. Look for any unusual noises or movements, which could indicate misalignment.

By following these straightforward instructions, you can successfully assemble your machinery, ensuring it operates efficiently and reliably.

Tools Needed for Deck Repairs

When it comes to maintaining outdoor machinery, having the right tools is essential for ensuring efficient and effective repairs. A well-equipped workspace not only simplifies the process but also enhances safety and precision. Below is a list of necessary implements to facilitate repair tasks.

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for various fasteners.

- Hammer: A sturdy hammer can assist in aligning components and driving in pins.

- Pliers: Needle-nose and regular pliers are helpful for gripping and twisting wires.

- Safety Gear: Gloves and goggles are vital for protecting hands and eyes during repairs.

Each tool serves a specific purpose, contributing to a smooth and effective repair experience. Ensuring these items are on hand can save time and prevent frustration.

- Inspect tools regularly to ensure they are in good working condition.

- Organize your workspace for easy access to all necessary items.

With the proper equipment and preparation, you can tackle repairs confidently and efficiently.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when conducting maintenance on machinery. Adhering to specific safety measures minimizes risks and promotes a secure atmosphere for repairs.

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure the machine is turned off and disconnected from any power source before starting any work.

- Utilize tools correctly and check them for damage before use.

Proper organization and planning can further enhance safety:

- Read the manufacturer’s guidelines thoroughly before beginning repairs.

- Keep your workspace tidy to prevent accidents and injuries.

- Have a first-aid kit accessible in case of emergencies.

By following these precautions, individuals can significantly reduce hazards during maintenance tasks.

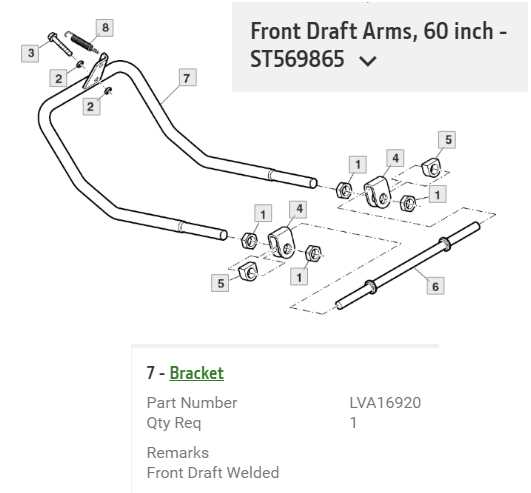

Comparing Models and Their Diagrams

Understanding the variations among different models is essential for effective maintenance and operation. Each model presents its unique configuration, which can impact performance and usability. Analyzing visual representations of these configurations can aid in identifying compatible components and enhancing the overall functionality.

When examining different variations, consider the following factors:

- Design Layout: Each variant may have a distinct layout that affects how parts are arranged and interact with each other.

- Component Specifications: Different models can utilize specific components tailored to their design, leading to variations in efficiency and compatibility.

- Maintenance Requirements: Some configurations might necessitate unique maintenance practices, which can be crucial for longevity.

- Performance Features: Certain models may offer enhanced features that can improve overall performance depending on their design.

By carefully comparing these aspects across various models, users can make informed decisions that optimize performance and ensure that the right components are utilized.

Frequently Asked Questions About Deck Parts

This section addresses common inquiries related to components associated with lawn equipment. Understanding these elements is crucial for proper maintenance and functionality, ensuring that your machinery operates efficiently and effectively.

What should I do if a component is damaged?

If you notice any damage, it is essential to inspect the part closely. Depending on the severity, you may need to replace or repair it to maintain optimal performance.

How can I find the right components for my equipment?

To identify suitable components, refer to the manufacturer’s specifications or consult with a knowledgeable dealer. Accurate identification will prevent compatibility issues.

| Question | Answer |

|---|---|

| How often should I check my equipment? | Regular inspections are recommended at least once a season. |

| Can I use aftermarket components? | Aftermarket options may be available, but ensure they meet quality standards. |