Understanding the Western Plow Parts Diagram for Better Maintenance

In the realm of winter maintenance, a thorough comprehension of the various components involved is crucial for effective operation and repair. Knowledge of how these elements interconnect allows for more efficient performance and longevity of the machinery.

Familiarity with the intricate layout of these devices not only aids in troubleshooting but also enhances the overall user experience. Each segment plays a vital role in the functionality, ensuring that the task of clearing snow is carried out smoothly and effectively.

By exploring the configuration and relationship of these essential elements, operators can better maintain their equipment, thus optimizing performance during those critical winter months. Understanding the significance of each component fosters a proactive approach to equipment care and management.

Understanding Western Plow Components

Grasping the various elements involved in snow removal systems is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance, durability, and reliability during harsh winter conditions. By familiarizing yourself with these individual pieces, you can enhance your overall efficiency and prolong the lifespan of your equipment.

Key Elements of the System

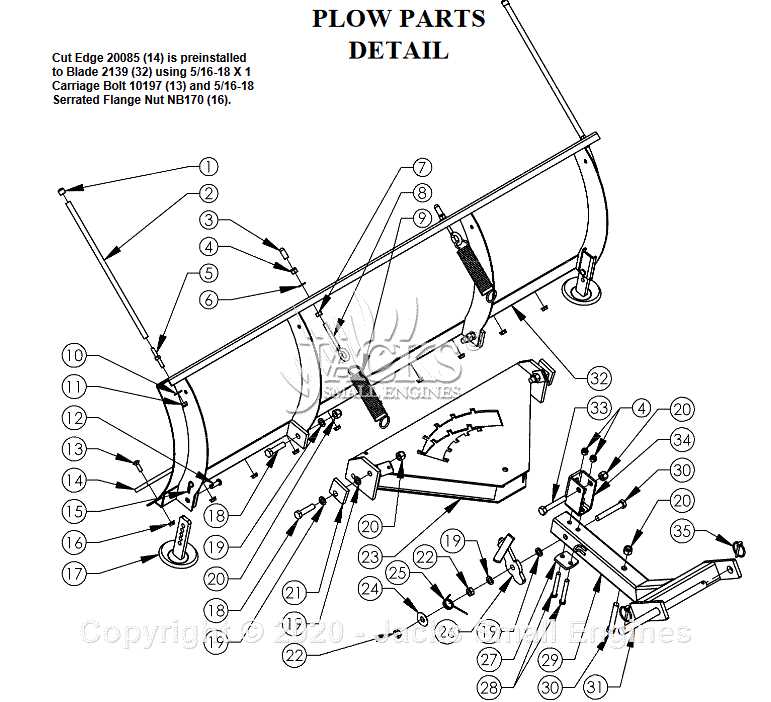

At the core of any snow clearing mechanism are the essential components that facilitate movement and control. Frames provide the necessary support, while blades are designed to push and clear accumulated snow. Understanding the function of each element allows operators to make informed decisions during usage and repairs.

Maintenance and Care

Regular inspection and maintenance of the system’s components are vital for preventing wear and tear. Lubrication of moving parts, checking for corrosion, and ensuring all fasteners are secure contribute significantly to the longevity of the equipment. By adhering to a routine care schedule, users can maintain peak performance and reduce the likelihood of breakdowns.

Essential Parts of Western Plows

Understanding the key components of snow removal equipment is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency and effectiveness during winter operations.

- Blade: The main tool for cutting through snow, its design can vary for different types of terrain.

- Frame: The sturdy structure that supports all other components, ensuring stability during use.

- Mounting System: Connects the equipment to the vehicle, allowing for easy attachment and detachment.

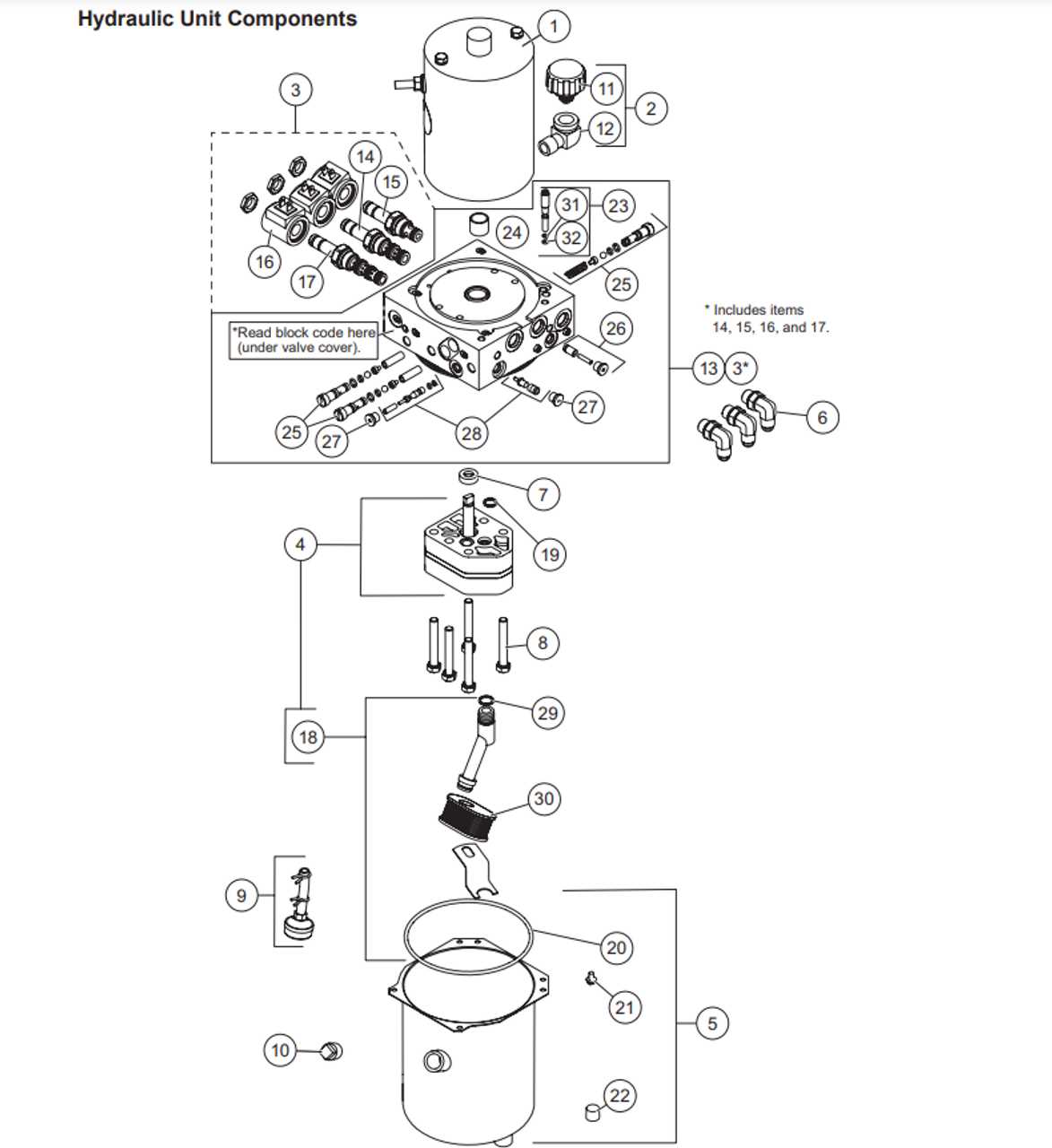

- Hydraulic System: Enables adjustments to the blade’s angle and height, providing versatility in operations.

- Skids: Help regulate the blade’s height above the ground, protecting surfaces beneath.

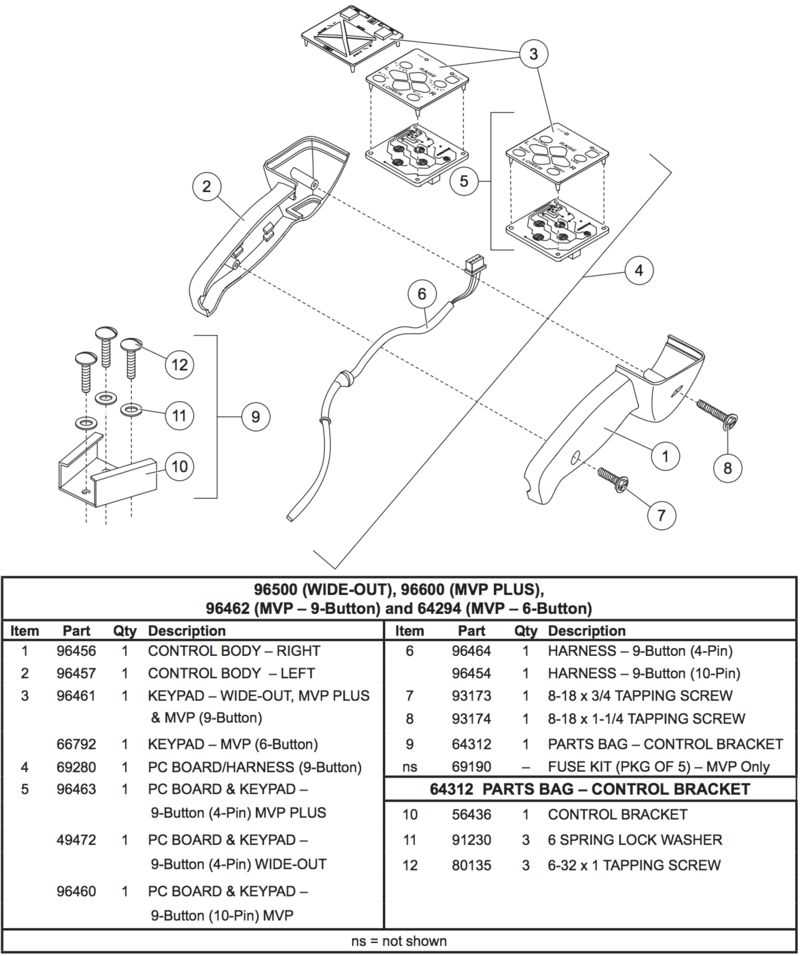

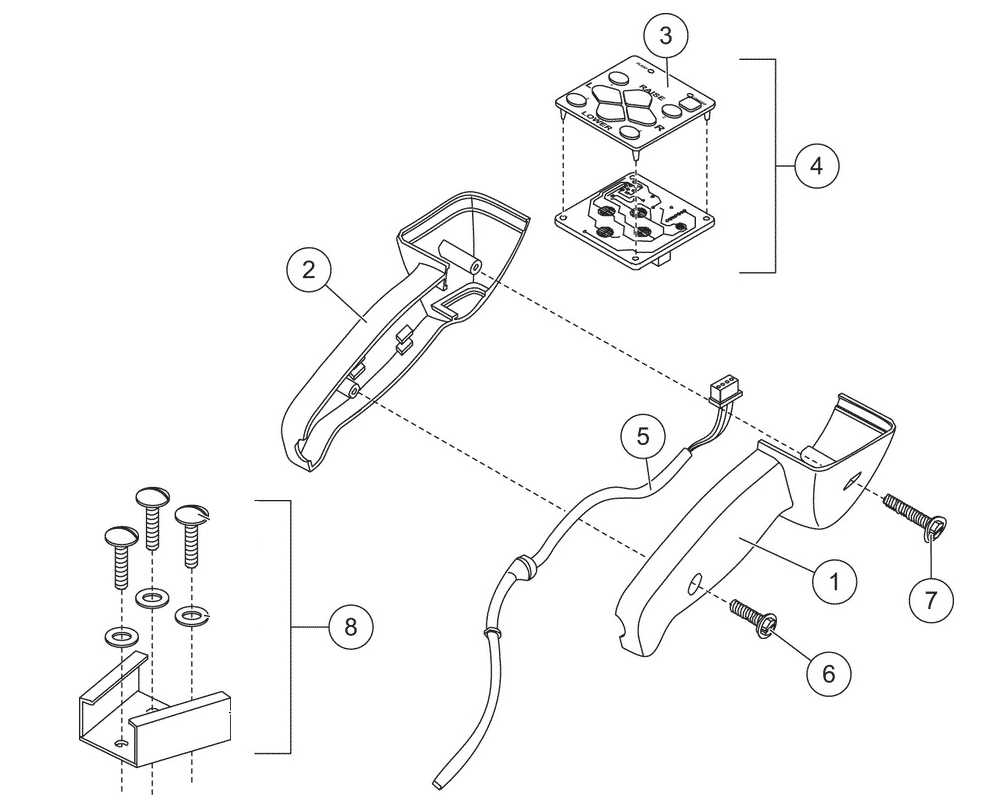

- Control Mechanism: Facilitates operation from inside the vehicle, enhancing user convenience.

By familiarizing oneself with these essential elements, operators can ensure their equipment functions smoothly and effectively during the winter season.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations serve as visual guides, enabling users to identify and locate various elements quickly. Familiarizing yourself with these visuals can enhance your ability to manage machinery efficiently.

Key Elements to Consider

- Labels: Each component is typically labeled with a unique identifier, often a number or letter. These labels correspond to a list of descriptions.

- Connections: Look for lines or arrows indicating how different pieces interact or connect with one another. This helps in understanding the assembly process.

- Scale: Be aware of the scale used in the representation, as it affects the proportions and the relative sizes of the parts.

- Legend: Many illustrations include a legend or key that explains symbols and abbreviations, which is crucial for accurate interpretation.

Steps for Effective Interpretation

- Begin by examining the overall layout, noting the arrangement of components.

- Identify and review each label to understand the role of each piece.

- Follow the connections to visualize how parts are linked or function together.

- Refer to the legend for clarification on any symbols that are unclear.

By practicing these steps, you can become proficient in deciphering these visual tools, leading to improved troubleshooting and repair skills.

Maintenance Tips for Plow Parts

Proper upkeep of your snow removal equipment is essential for ensuring optimal performance and longevity. Regular attention to various components can prevent costly repairs and enhance efficiency during operations.

Regular Inspections

Conducting routine checks can help identify wear and tear before they escalate. Here are some key areas to focus on:

- Check for rust or corrosion on metal surfaces.

- Inspect hydraulic hoses for leaks or cracks.

- Ensure all bolts and fasteners are securely tightened.

Lubrication and Cleaning

Keeping equipment clean and well-lubricated is crucial for smooth operation. Follow these steps:

- Clean off debris after each use to prevent buildup.

- Apply lubricant to moving parts regularly to reduce friction.

- Use appropriate cleaning agents that do not damage surfaces.

By following these maintenance tips, you can extend the life of your snow management tools and ensure they perform reliably during winter months.

Common Issues with Plow Equipment

Maintaining effective equipment for snow management can often present various challenges that operators encounter regularly. Understanding these common difficulties is essential for ensuring optimal performance and longevity of the machinery.

Mechanical Failures

One of the primary concerns involves mechanical breakdowns, which can occur due to wear and tear or lack of proper maintenance. Regular inspections and timely replacements of worn components are crucial to prevent sudden failures that can disrupt operations.

Hydraulic Problems

Hydraulic systems are vital for the functionality of snow-clearing equipment. Leaks or pressure loss can lead to diminished performance, causing inefficient operation. Ensuring that hoses and connections are intact, as well as checking fluid levels, can mitigate these issues.

Proactive maintenance and awareness of these challenges will enhance the reliability and efficiency of your snow management tools, ultimately leading to smoother operations during harsh winter conditions.

Choosing the Right Replacement Parts

Selecting suitable components for your machinery is crucial for maintaining efficiency and performance. When it comes to replacing essential elements, understanding the specifications and compatibility is key. Each component plays a vital role in the overall functionality, and choosing the right one can prevent unnecessary downtime and costly repairs.

Assessing Compatibility

Before making a purchase, it’s important to ensure that the new item aligns with your equipment’s model and specifications. Reference the manufacturer’s guidelines to confirm that the replacements are suitable. Compatibility not only affects performance but also longevity, as mismatched components can lead to further issues.

Quality Considerations

Investing in high-quality replacements can save you time and money in the long run. Look for reputable brands that offer durable materials and reliable performance. Always check reviews and ratings to gauge the experiences of other users. This diligence will help you make informed decisions, enhancing the efficiency of your machinery.

Tools Needed for Plow Repairs

When it comes to maintaining and fixing your equipment, having the right instruments is essential. Proper tools not only ensure efficiency but also enhance safety during repairs. Below is a list of necessary items to keep on hand for effective maintenance.

- Wrenches: A variety of sizes will help in loosening or tightening fasteners.

- Sockets and Ratchets: These are crucial for accessing hard-to-reach bolts.

- Screwdrivers: Both flat-head and Phillips types are necessary for different screw types.

- Pliers: Useful for gripping and bending components as needed.

- Jack and Stands: Essential for lifting the equipment safely for underneath work.

In addition to these basic tools, consider the following specialized items:

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues.

- Grease Gun: Keeps moving parts lubricated and functioning smoothly.

- Cutting Tools: Necessary for replacing damaged sections or components.

- Measuring Tape: For precise measurements during repairs.

Having these tools readily available will not only streamline the repair process but also contribute to the longevity and reliability of your equipment.

Installation Guide for Plow Parts

This section provides a comprehensive overview of the steps necessary for the effective installation of various components used in snow removal equipment. Proper assembly ensures optimal performance and longevity, enabling efficient operation during winter conditions.

- Gather Necessary Tools and Components

- Wrenches

- Screwdrivers

- Socket set

- Safety gear

- Prepare the Equipment

- Ensure the vehicle is parked on a flat surface.

- Disconnect the power source if applicable.

- Clean the mounting area of any debris.

- Attach the Main Frame

- Align the frame with the mounting brackets.

- Secure the frame using bolts and washers.

- Tighten all connections according to manufacturer specifications.

- Install Auxiliary Components

- Attach any additional elements like hydraulic cylinders or lights.

- Ensure all connections are snug and properly aligned.

- Connect Electrical Wiring

- Follow the wiring diagram for correct connections.

- Use heat-shrink tubing to protect exposed wires.

- Test connections for proper functionality.

- Final Inspection

- Check all bolts and fasteners for tightness.

- Inspect for any signs of wear or damage.

- Perform a test operation to ensure everything functions correctly.

Following these guidelines will help in achieving a successful setup, enabling reliable performance in harsh winter environments. Regular maintenance and checks after installation are recommended to prolong the lifespan of the equipment.

Differences Between Plow Models

Understanding the variations among different models is essential for selecting the right equipment for specific tasks. Each type comes with unique features, designed to cater to various operational needs and environmental conditions. These distinctions can significantly affect performance, efficiency, and overall user experience.

Design Variations: Different models showcase diverse designs, influencing their maneuverability and ease of use. For instance, some units are built for compactness, allowing for better navigation in tight spaces, while others emphasize durability and strength for heavy-duty tasks.

Material Composition: The materials used in construction can vary greatly. Some versions utilize high-strength alloys to withstand harsh conditions, while others may incorporate lighter materials for increased agility. This choice affects longevity and maintenance requirements.

Adjustability Features: Many models offer distinct adjustability options, enabling operators to customize their equipment according to specific needs. This can include height adjustments, angle modifications, and even hydraulic capabilities, allowing for greater versatility in operations.

Performance Metrics: Variances in power and efficiency are also notable. Some configurations are designed for high-performance tasks, delivering faster operation and better results under challenging circumstances. In contrast, others prioritize energy efficiency, making them suitable for more routine applications.

Recognizing these differences is crucial for users aiming to maximize productivity and ensure their equipment meets the demands of their environment.

Seasonal Maintenance for Snow Plows

Proper upkeep throughout the year is essential for ensuring optimal performance and longevity of your snow-clearing equipment. Regular check-ups and timely interventions can prevent costly repairs and enhance efficiency during the winter months.

Key Areas to Focus On

When preparing your machinery for the cold season, concentrate on several critical components that significantly affect operation. Addressing these areas will help maintain effectiveness and safety.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Blade | Inspect for damage and sharpen edges | Before winter season |

| Hydraulic System | Check fluid levels and look for leaks | Monthly |

| Electrical System | Test connections and ensure battery is charged | Before winter season |

| Frame | Examine for rust or structural issues | Monthly |

Post-Season Care

After the winter season concludes, it’s important to perform a thorough inspection and maintenance of your equipment. Cleaning off any accumulated debris and checking for wear and tear can significantly enhance the lifespan of your machinery. Regularly scheduled maintenance not only improves functionality but also ensures safety for operators.

Safety Considerations During Repairs

When engaging in maintenance or restoration activities, ensuring personal safety and the protection of others is paramount. Proper precautions can prevent accidents and injuries, making the work environment more secure. Familiarity with essential safety protocols can greatly enhance the repair process.

Preparation and Personal Protective Equipment

Before beginning any repair tasks, assess the workspace and gather necessary tools. Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves, goggles, and sturdy footwear to shield against potential hazards. Additionally, ensure the area is well-ventilated to avoid inhaling harmful fumes from lubricants or cleaning agents.

Handling Tools and Equipment

Using tools correctly is vital for safety. Always follow the manufacturer’s instructions and conduct regular inspections of equipment for wear and tear. If a tool is damaged, it should be replaced immediately to avoid malfunctions. Moreover, maintain a clean workspace to minimize the risk of trips and falls, keeping all items organized and securely stored.

Upgrading Your Plow System

Enhancing your snow removal equipment can significantly improve efficiency and performance during winter months. By investing in advanced components and technology, you can ensure your setup meets the demands of harsh conditions and provides reliable service.

Consider the following options when upgrading your equipment:

- Improved Blade Materials: Switch to high-grade steel or composite materials for enhanced durability and performance.

- Advanced Hydraulic Systems: Opt for hydraulic upgrades that offer faster response times and better control.

- Enhanced Mounting Systems: Explore options that allow for quicker attachment and detachment, reducing downtime.

- Incorporating Technology: Utilize GPS and sensors for precision tracking and more effective operation.

- Upgraded Lighting: Install high-intensity LED lights for improved visibility during nighttime operations.

Evaluating the specific needs of your equipment will help you prioritize which upgrades will yield the best results. Regular maintenance and timely enhancements can prolong the lifespan of your system and ensure optimal performance when you need it most.

Where to Find Parts Diagrams Online

Locating detailed illustrations for machinery components can be essential for maintenance and repairs. Numerous resources are available on the internet, catering to both professionals and DIY enthusiasts. Understanding where to look can save time and enhance your repair experience.

Official Manufacturer Websites

One of the most reliable sources for accurate illustrations is the official website of the equipment manufacturer. These sites often provide comprehensive resources, including technical manuals and visual breakdowns, ensuring that users access the most up-to-date information.

Online Retailers and Specialty Stores

In addition to manufacturer sites, numerous online retailers specialize in equipment parts and accessories. These platforms often feature visual guides to assist customers in identifying and selecting the right components for their needs.

| Resource Type | Examples |

|---|---|

| Manufacturer Websites | John Deere, Case IH, Bobcat |

| Online Retailers | Agricultural Supply Co., Equipment Parts Warehouse |

| Community Forums | Reddit, TractorByNet |