Understanding the John Deere L100 Mower Deck Parts Diagram

For enthusiasts of lawn maintenance, having a thorough grasp of the essential components that make up a grass-cutting machine is vital. Knowledge of these elements not only facilitates effective repairs but also enhances overall performance and longevity of the equipment. Each segment plays a crucial role in ensuring that the machine operates smoothly and efficiently.

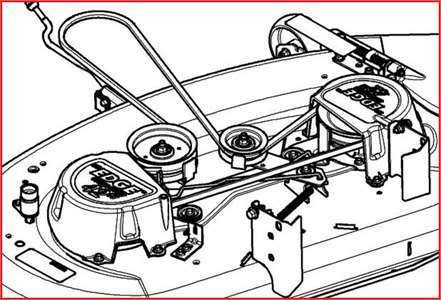

When navigating the intricacies of a cutting unit, it’s important to visualize how the various components interact with each other. From the cutting blades to the drive system, each part has its unique function that contributes to the overall effectiveness of the machine. Recognizing these elements helps users to troubleshoot issues more effectively and perform maintenance tasks with confidence.

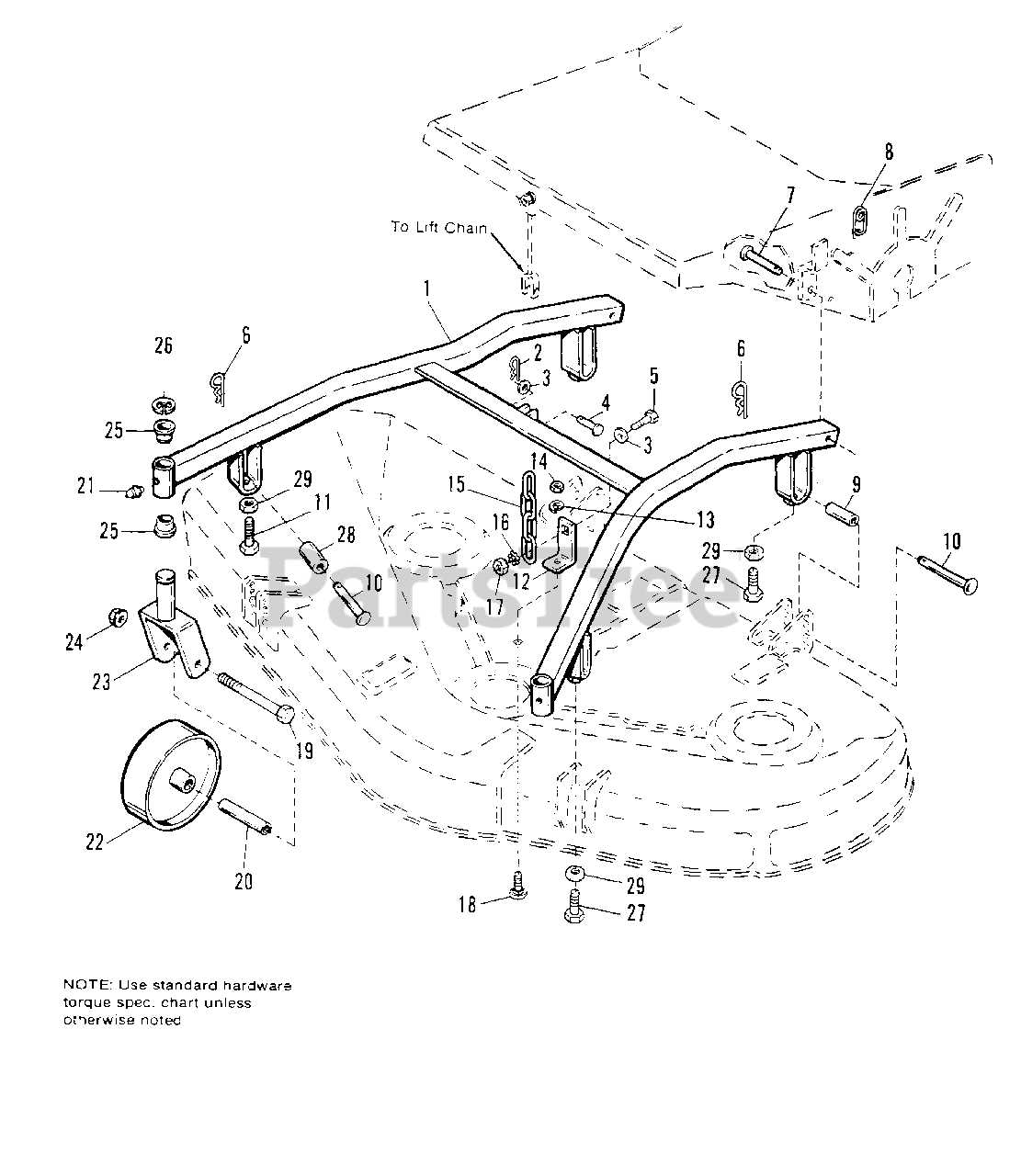

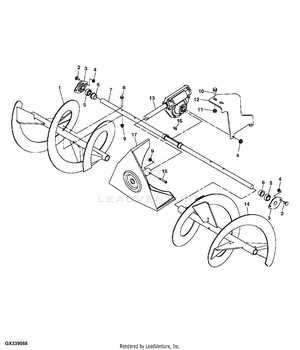

Additionally, having access to detailed representations of these components can serve as a valuable resource for both novice and experienced operators alike. Such diagrams provide clarity, making it easier to identify specific elements and understand their placement within the assembly. This understanding ultimately leads to better care practices and informed decision-making when it comes to repairs or upgrades.

Understanding the John Deere L100 Mower

This section delves into the intricacies of a popular grass-cutting machine known for its reliability and efficiency. With a blend of robust engineering and user-friendly features, it has become a favorite among homeowners seeking to maintain their lawns effortlessly. Familiarity with its components and functionality can significantly enhance performance and longevity.

One of the essential aspects to consider is how the different elements work together to achieve optimal results. Below is a table summarizing key components and their functions:

| Component | Function |

|---|---|

| Engine | Provides power for cutting and maneuvering. |

| Transmission | Facilitates movement across various terrains. |

| Cutter Assembly | Engages blades to trim grass efficiently. |

| Chassis | Offers structural support and stability. |

| Controls | Enables user to adjust settings and navigate. |

Understanding these elements allows operators to perform maintenance tasks effectively, ensuring the machine remains in peak condition. Familiarity with these features not only enhances user experience but also extends the life of the equipment.

Essential Components of the Mower Deck

The efficiency of any cutting machine relies heavily on its core elements. Understanding these fundamental components is crucial for maintaining optimal performance and ensuring longevity. Each piece plays a specific role, contributing to the overall functionality of the equipment.

Blade Assembly: The heart of the cutting mechanism, the blade assembly is responsible for achieving a clean and precise cut. Regular inspection and sharpening of the blades are essential for maintaining their effectiveness.

Spindle Housing: This component houses the spindle that connects to the blades. It supports the rotational movement, allowing the blades to operate smoothly. Proper lubrication and timely replacements can prevent wear and tear.

Grass Chute: The grass chute directs the clippings away from the cutting area. An efficient design prevents clogging and ensures a tidy finish. Regular cleaning helps maintain optimal airflow and functionality.

Deck Shell: The outer casing provides structural integrity and protection to the internal components. A durable shell withstands wear from debris and impacts, while also aiding in effective cutting performance.

Height Adjustment Mechanism: This system allows users to modify the cutting height according to specific needs. Smooth operation of this mechanism is vital for achieving the desired results while adapting to varying grass conditions.

By understanding these critical components, operators can ensure their machinery remains in top condition, leading to improved efficiency and a better cutting experience.

Common Issues with Mower Deck Parts

Maintaining the cutting assembly of any lawn care equipment is crucial for optimal performance. Various challenges can arise over time, affecting the efficiency and functionality of the system. Understanding these common issues can help in addressing them promptly, ensuring a well-kept lawn.

- Wear and Tear: Regular usage can lead to deterioration of components, impacting cutting efficiency.

- Misalignment: Components may shift or become misaligned, resulting in uneven cutting or additional strain on the machine.

- Corrosion: Exposure to moisture can cause rust and corrosion, compromising the integrity of metal parts.

- Dull Blades: Blades can become blunt over time, leading to ragged cuts and increased stress on the motor.

- Obstructions: Debris can accumulate in the assembly, obstructing movement and reducing performance.

By being aware of these potential issues, operators can take preventative measures and perform regular inspections, ensuring the longevity and reliability of their equipment.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular care and attention. By following a few essential maintenance practices, you can enhance performance, prevent potential issues, and extend the life of your machinery.

Regular Cleaning: Keeping the machine free from debris and grass clippings is crucial. Accumulated material can hinder performance and lead to rust or corrosion. After each use, take the time to clean the exterior and any hard-to-reach areas.

Check the Blades: Dull or damaged cutting elements can affect the quality of the job. Inspect them frequently and sharpen or replace as needed to ensure a clean cut and efficient operation.

Oil and Lubrication: Regularly check the oil levels and lubricate moving parts. Proper lubrication reduces friction, which in turn minimizes wear and tear, promoting smoother operation and enhancing performance.

Inspect Belts and Cables: Examine all belts and cables for signs of wear or damage. Replace any frayed or broken components promptly to avoid unexpected breakdowns during operation.

Seasonal Maintenance: At the start of each season, conduct a thorough inspection and servicing of your machinery. This includes changing the oil, replacing filters, and checking the battery, ensuring everything is in optimal working condition.

By adhering to these maintenance practices, you can ensure that your equipment operates at its best, providing reliable performance for years to come.

How to Identify Worn Parts

Recognizing the signs of fatigue in machinery components is essential for maintaining optimal performance and longevity. Regular inspections can help you spot issues before they escalate, ensuring your equipment operates efficiently. This section outlines effective methods for identifying elements that may need replacement or repair.

Visual Inspection: Begin with a thorough visual examination. Look for any obvious signs of wear, such as cracks, rust, or fraying. Components that show discoloration or a significant buildup of debris may also indicate excessive wear.

Functional Testing: Evaluate how each component performs under standard operating conditions. If you notice vibrations, unusual noises, or inconsistent operation, these may be symptoms of underlying problems. Pay attention to how each part interacts with the rest of the system.

Measurements: Use calipers or other measuring tools to check dimensions against manufacturer specifications. Any deviation from the norm could signal wear. Regular measurements can help you track gradual changes over time.

Comparative Analysis: If possible, compare worn components with new or less used ones. This side-by-side evaluation can highlight differences in appearance and functionality, making it easier to identify issues.

Consultation of Manuals: Refer to the equipment’s service manual for specific indicators of wear and recommended maintenance schedules. Manuals often provide critical insights into typical wear patterns for various components.

Replacing Blades: A Step-by-Step Guide

Maintaining the cutting components of your machine is essential for optimal performance. Regularly replacing the blades ensures a clean cut and enhances the longevity of your equipment. This guide provides clear instructions for safely and effectively changing the blades.

-

Gather Necessary Tools and Materials:

- New blades

- Wrench or socket set

- Screwdriver

- Safety gloves

- Protective eyewear

-

Prepare the Machine:

- Ensure the engine is turned off and cool.

- Disconnect the spark plug wire to prevent accidental starting.

- Elevate the unit safely, using jack stands if necessary.

-

Remove the Old Blades:

- Locate the securing bolts on the blades.

- Using the appropriate wrench, loosen and remove the bolts.

- Carefully detach the old blades and set them aside.

-

Install the New Blades:

- Position the new blades in place, ensuring they align correctly.

- Secure them using the original bolts, tightening them firmly.

-

Finalize and Test:

- Reconnect the spark plug wire.

- Lower the equipment back to the ground.

- Start the engine and test the operation to ensure everything runs smoothly.

Regularly checking and replacing the cutting components will maintain efficiency and performance. Follow these steps to keep your equipment in top condition.

Importance of Proper Deck Alignment

Ensuring correct positioning of the cutting apparatus is crucial for optimal performance and longevity of the equipment. Misalignment can lead to uneven cutting, resulting in an unsightly lawn and potential damage to the machinery itself. Proper adjustment not only enhances efficiency but also contributes to a healthier grass growth by promoting an even cut.

One significant benefit of accurate alignment is the reduction of wear and tear on the blades and other components. When the cutting mechanism is properly calibrated, it minimizes unnecessary strain, which can extend the lifespan of the equipment and decrease maintenance costs. Additionally, a well-aligned system ensures that the grass is cut uniformly, promoting a more attractive landscape.

Furthermore, regular checks and adjustments are essential for maintaining performance standards. Over time, vibrations and usage can cause shifts in alignment, making periodic evaluations vital. By investing time in this maintenance task, operators can avoid costly repairs and ensure a consistently high-quality finish in their work.

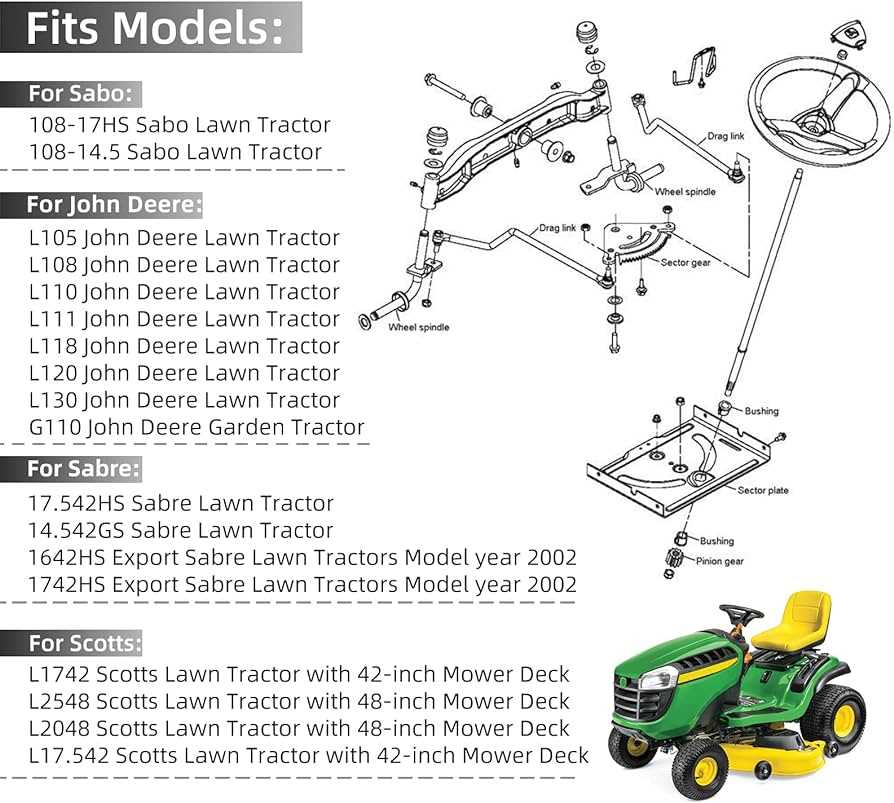

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous resources are available, ranging from online retailers to local stores, ensuring that you can maintain your machinery efficiently. By exploring these options, you can secure the necessary items to keep your equipment in optimal condition.

Online Retailers: The internet is a treasure trove of options for sourcing components. Websites specializing in outdoor equipment often have extensive catalogs that feature various items. Searching by model or specific needs can yield quick results, making it easier to find what you’re looking for.

Local Dealers: Visiting nearby dealerships can be beneficial as well. These establishments typically stock a range of components and can provide expert advice on what you may need. Additionally, they may offer the convenience of same-day purchases, eliminating shipping delays.

Second-Hand Options: Consider exploring second-hand markets, such as auctions or online classifieds. Often, you can find gently used components at reduced prices, which can be a great way to save money while obtaining quality items.

Forums and Communities: Engaging with online forums or community groups dedicated to machinery can also provide valuable insights. Members often share tips on where to find components and may even sell or trade items themselves.

By utilizing these avenues, you can ensure that your equipment remains functional and efficient for years to come.

Using the Parts Diagram Effectively

Understanding how to navigate a schematic can greatly enhance your repair and maintenance experience. By familiarizing yourself with the visual representation of components, you can quickly identify necessary elements and streamline your tasks.

Here are some tips for maximizing the utility of the schematic:

- Study the Legend: Most diagrams include a legend that explains symbols and color codes. Familiarize yourself with these to ensure accurate interpretation.

- Identify Key Components: Focus on the main elements relevant to your project. This will help you concentrate on what needs attention.

- Cross-reference with Manuals: Use the schematic in conjunction with your user manual for comprehensive understanding. This will provide context and additional details.

- Make Notes: As you examine the illustration, jot down any specific parts you need to order or replace. This will help prevent oversights.

- Consult Online Resources: Look for forums or websites where other users discuss similar issues. This can provide insights and tips that are not found in official materials.

By effectively utilizing a schematic, you can enhance your repair process, save time, and ensure that your maintenance efforts are successful.

Tools Required for Deck Repair

Effective maintenance and repair of outdoor equipment require the right set of tools. Having the proper instruments not only facilitates the repair process but also ensures that the task is completed safely and efficiently. Below is a list of essential tools that will assist in repairing the cutting mechanism.

- Socket Set: A comprehensive socket set is crucial for loosening and tightening various fasteners.

- Wrenches: Both open-end and adjustable wrenches are necessary for gripping and turning nuts and bolts.

- Torque Wrench: This tool ensures that all bolts are tightened to the manufacturer’s specifications.

- Screwdrivers: A variety of screwdrivers (flathead and Phillips) are needed for different types of screws.

- Blades: Replacement blades may be required for optimal performance and cutting efficiency.

- Pliers: Needle-nose and slip-joint pliers can help with gripping and maneuvering small components.

- Cleaning Supplies: Brushes and cloths are essential for removing debris and maintaining cleanliness.

- Safety Gear: Protective gloves and goggles should always be worn to ensure safety during repairs.

Having these tools readily available will streamline the repair process and help achieve the best results.

Upgrading Your Mower: What to Consider

Enhancing your grass-cutting equipment can significantly improve its performance and longevity. Whether you’re looking to boost efficiency, enhance functionality, or simply refresh your machine, there are several factors to keep in mind before proceeding with upgrades.

- Assess Your Needs: Determine the specific tasks you need your equipment to handle. Consider factors like the size of your lawn, terrain type, and desired cutting height.

- Research Compatible Components: Not all upgrades are universal. Ensure that the components you wish to add are compatible with your existing machinery.

- Budget Considerations: Establish a clear budget for your upgrades. Weigh the benefits against costs to make informed decisions.

- Quality and Durability: Invest in high-quality components that will withstand wear and tear. Look for trusted brands and materials.

- Installation and Maintenance: Consider whether you will install upgrades yourself or hire a professional. Also, think about how maintenance may change with new components.

- Consult Reviews and Recommendations: Research feedback from other users who have made similar upgrades. Their experiences can provide valuable insights.

By carefully evaluating these aspects, you can ensure that your enhancements lead to improved performance and satisfaction in your outdoor tasks.