John Deere LT133 Mower Deck Parts Guide

For those who maintain expansive lawns and green spaces, ensuring that the cutting device operates smoothly is crucial. When various elements of the equipment are well-coordinated, the overall performance improves, leading to a more efficient and hassle-free experience. Familiarity with the key aspects of such devices can greatly simplify the process of maintaining their functionality over time.

Each section of the equipment plays a vital role, from the mechanisms that guide the cutting tool to the supports that keep everything stable. Recognizing the intricate connections between these parts allows for better handling and repair when necessary. A clear understanding of this helps users achieve optimal results during regular use and upkeep.

Proper care and maintenance of these elements not only extends the life of the device but also ensures safety during operation. Identifying the specific elements and their interactions can help avoid unnecessary breakdowns, making the entire maintenance process more straightforward and effective.

Key Components and Features Overview

The model in focus is equipped with a variety of essential elements that ensure efficient and smooth functionality. Understanding the different aspects and mechanisms involved helps in maintaining optimal performance and durability. This overview will guide you through the primary mechanical components, offering insights into their role in the overall operation.

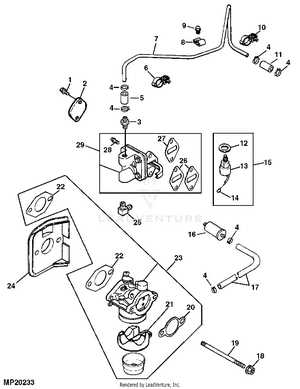

Engine System: The heart of this equipment, the power source, drives all essential functions, delivering the necessary energy to tackle various outdoor tasks. Its construction emphasizes reliability and ease of maintenance, allowing for consistent output over extended periods.

Drive Assembly: The propulsion mechanism plays a crucial role in maneuverability and stability during use. Built to adapt to varying terrains, it ensures a balanced and controlled movement, making the equipment suitable for different working conditions. This assembly is key to maintaining smooth and consistent operations.

Blades and Cutting Mechanism: This feature ensures efficient handling of tasks, providing a clean and precise outcome. Engineered for durability, the cutting system is designed to withstand regular use, ensuring long-term effectiveness. Proper care

Mower Deck Maintenance Tips

Proper care and regular upkeep of the cutting platform are crucial to ensure efficient performance and extend its lifespan. A well-maintained cutting mechanism not only delivers better results but also minimizes the chances of unexpected issues during use. Regular checks and a few simple adjustments can make a significant difference.

Cleaning and Debris Removal

Clearing accumulated grass and debris from the underside is essential to maintain optimal cutting efficiency. Follow these steps for a thorough cleaning:

- After each use, turn off the engine and ensure the blade has completely stopped before cleaning.

- Use a brush or scraper to remove grass clippings and dirt buildup from the cutting surface.

- Consider using a hose for a more thorough wash, ensuring no water enters sensitive components.

Blade Sharpness and Adjustment

Keeping the cutting blades in good condition ensures a clean cut and reduces strain on the machine. Here are some key tips for maintaining blade sharpness:

- Inspect the blades periodically for dullness or damage. Sharpen them if needed.

- Ensure

Essential Components of the Cutting Deck

The mechanism beneath the equipment plays a crucial role in achieving precise trimming of grass and maintaining a well-groomed lawn. It contains several key elements that work together to ensure smooth and efficient operation. Understanding these parts can help in maintaining the machinery for optimal performance.

- Blades: These sharpened metal pieces are the primary tools for slicing through grass. Properly balanced and sharpened blades ensure an even cut.

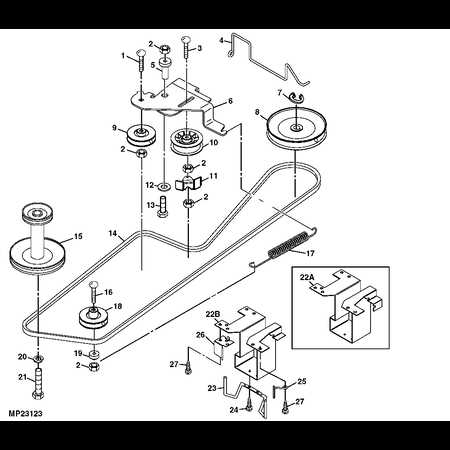

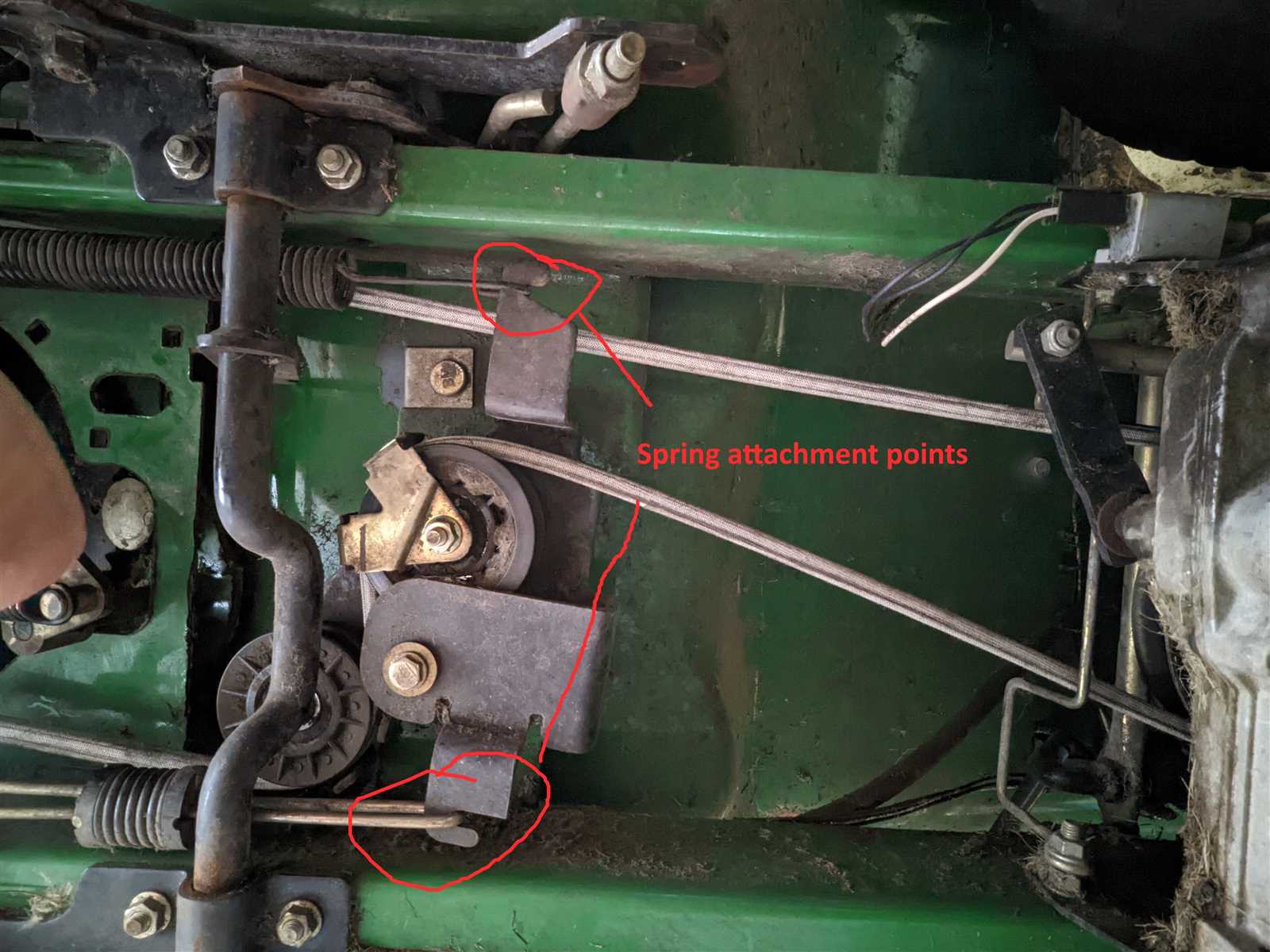

- Belt System: A set of durable belts that transfer power, allowing the blades to rotate and function smoothly. Regular inspection ensures their longevity.

- Spindles: These are central to the blade assembly, providing support and rotation. They help in maintaining the right cutting height and angle.

- Discharge Chute: A channel that directs the trimmed grass away from the machine, preventing blockages and ensuring a cleaner cut.

- Pulleys:

Guide to Replacing Blades and Belts

Maintaining the cutting and drive mechanisms is crucial for ensuring consistent performance and extending the lifespan of your equipment. Regular replacement of cutting edges and drive components keeps the machine operating smoothly and efficiently.

Step Description 1 Disconnect the power source and ensure the device is on a stable surface to prevent any movement during maintenance. 2 Remove the protective cover or shield to access the drive bands and cutting edges. Use appropriate tools to loosen the fasteners. 3 Carefully detach the old cutting edges by unfastening the bolts or screws. Inspect the new edges for sharpness and balance before installation. 4 Take out the worn drive band, checking for signs of wear or damage Identifying Common Deck Issues

Recognizing typical challenges with outdoor cutting equipment can help ensure smooth and efficient performance. Understanding the potential issues that may arise during operation allows for timely adjustments, maintaining peak functionality throughout the season.

Frequent Imbalance Problems

One common concern is when the cutting unit experiences imbalance. This can be due to uneven wear or minor damages that alter its alignment. An unbalanced unit might lead to irregular results, causing unnecessary strain on the machine’s components.

Unusual Sounds and Vibrations

Another indication of possible problems is the presence of strange noises or excessive shaking during operation. These can signal that components are loose or misaligned, requiring immediate attention to prevent further wear and potential failures.

Issue Possible Cause Solution Uneven Cutting Worn edges or incorrect positioning Inspect and adjust the setup Vibration Loose fasteners or alignment issues Tighten Optimizing Performance of the Mower Deck

Enhancing the efficiency of the cutting system is crucial for achieving superior results in lawn maintenance. Proper maintenance and timely adjustments can significantly influence the quality of the outcome. Here are some essential practices to consider for maximizing effectiveness.

- Regular Inspection: Frequently check the cutting mechanism for any signs of wear or damage. Addressing issues early can prevent further complications.

- Sharp Blades: Keeping the cutting blades well-sharpened ensures clean cuts, promoting healthier grass growth. Dull blades can tear the grass, leading to potential diseases.

- Height Adjustment: Adjusting the cutting height based on the type of grass and the season can improve results. Different grass types thrive at specific heights.

- Debris Removal: After each use, remove grass clippings and debris from the cutting area. Accumulation can hinder performance and lead to rusting.

Implementing these practices not only improves the functionality of the cutting system but also prolongs its lifespan, ensuring a well-maintained lawn throughout the seasons.

Cleaning and Lubricating Moving Parts

Maintaining the functionality of machinery involves regular cleaning and lubrication of its moving components. Proper care ensures optimal performance and extends the lifespan of the equipment.

To effectively clean and lubricate the moving elements, follow these steps:

- Ensure the equipment is turned off and disconnected from any power source.

- Use a soft brush or cloth to remove dirt, debris, and grass clippings from the components.

- Inspect the parts for any signs of wear or damage that may require replacement.

For lubrication:

- Select an appropriate lubricant, ensuring it is suitable for the specific type of machinery.

- Apply the lubricant to all pivot points and moving surfaces, ensuring an even coat.

- Wipe away any excess lubricant to prevent accumulation of dirt.

Regularly scheduled maintenance will contribute significantly to the efficiency and reliability of your equipment, minimizing potential issues during operation.

Adjusting Deck Height for Even Cuts

Achieving a uniform cut on your lawn requires careful attention to the height settings of your cutting mechanism. Proper adjustment ensures that grass is trimmed evenly, promoting healthier growth and enhancing the overall appearance of your outdoor space. It is essential to find the right balance to accommodate various grass types and environmental conditions.

To adjust the cutting height effectively, follow these simple steps:

Step Action 1 Park the equipment on a flat, level surface to ensure accurate measurements. 2 Locate the adjustment mechanism, which may be a lever or knob, typically found near the cutting unit. 3 Set the desired height based on the grass type, considering factors like growth rate and season. 4 Once adjustments are made, check the height from multiple points across the cutting area to ensure consistency. 5 Test the cutting performance by operating the equipment in a small area and adjust if necessary. By following these guidelines, you can achieve an even and professional-looking cut, enhancing the aesthetic of your lawn and contributing to its overall health.

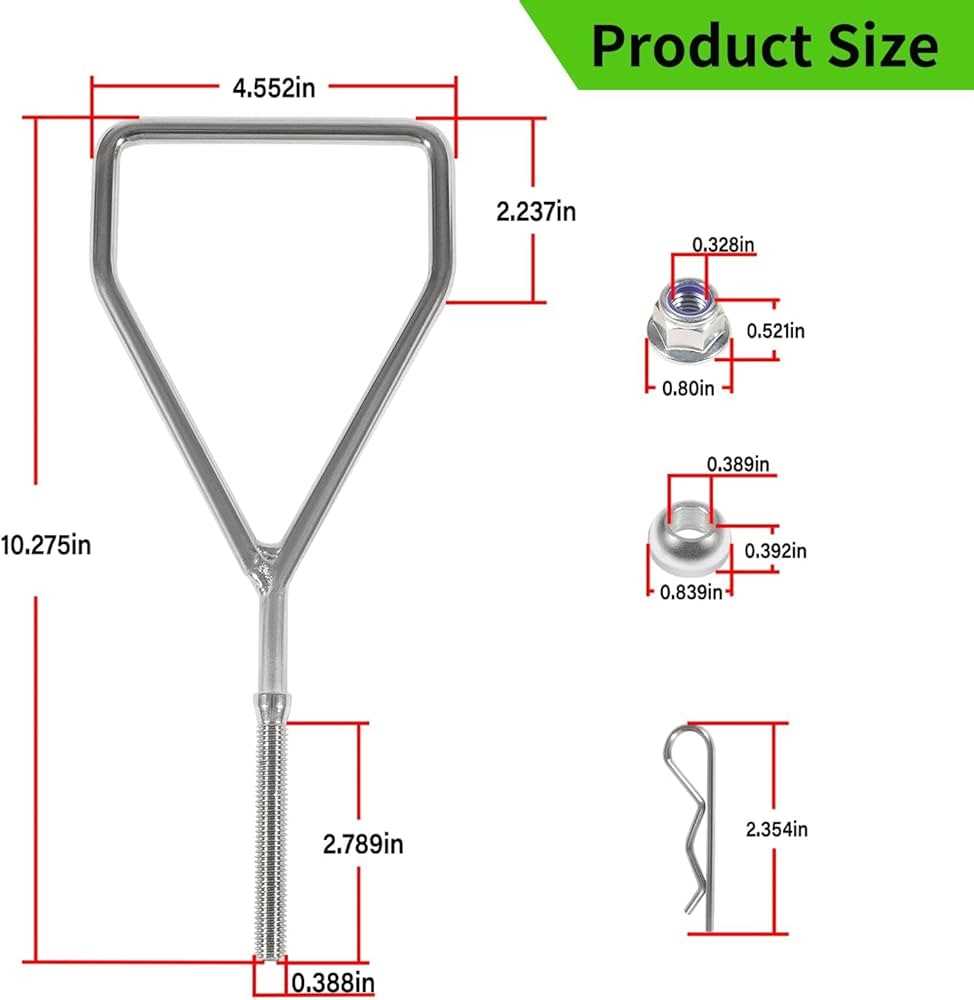

Choosing Compatible Replacement Parts

Selecting appropriate components for your outdoor equipment is essential to ensure optimal performance and longevity. The right substitutes not only enhance functionality but also promote efficiency during operation. Understanding compatibility is crucial, as it impacts both assembly and overall effectiveness.

When considering alternatives, it’s important to evaluate specifications and compatibility with existing machinery. Here are some factors to keep in mind:

Factor Description Specifications Ensure that the dimensions and capacities of the components align with your equipment’s requirements. Material Quality Select components made from durable materials to enhance longevity and resistance to wear. Brand Compatibility Opt for parts from reputable manufacturers known for producing reliable and efficient components. Reviews and Recommendations Consult user feedback and expert recommendations to gauge the reliability of potential replacements. By paying attention to these aspects, you can ensure a smooth transition to replacement components that uphold the performance and durability of your equipment.

Understanding the Drive System

The functionality of a grass-cutting machine heavily relies on its propulsion mechanism. This essential component is responsible for transferring power from the engine to the blades, ensuring efficient operation and optimal performance. By grasping how this system operates, users can enhance their machine’s longevity and performance.

Key Components of the Drive Mechanism

The drive system consists of several crucial elements that work in harmony. Understanding each part helps in maintaining and troubleshooting any issues that may arise:

- Engine: The heart of the device, responsible for generating power.

- Transmission: This component transmits power to the wheels and blades, enabling movement.

- Belt System: A series of belts facilitate the connection between the engine and transmission, allowing for smooth power transfer.

- Wheels: The wheels provide mobility, allowing the device to navigate various terrains.

- Blades: The cutting mechanism, which is directly powered by the engine through the drive system.

Maintenance Tips for Optimal Performance

Regular upkeep of the drive system can significantly impact its efficiency. Here are some recommended practices:

- Inspect the belts for wear and replace them as necessary.

- Ensure that all connections are secure to prevent slippage.

- Check the oil levels of the engine to maintain smooth operation.

- Clean any debris that may hinder the functioning of the drive components.

- Consult the manual for specific guidelines regarding maintenance schedules.

Safety Guidelines for Deck Repairs

Ensuring a safe working environment during maintenance tasks is crucial to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of the repair process. It is essential to follow specific protocols to minimize risks while handling equipment and performing repairs.

Before commencing any repair work, always wear appropriate personal protective equipment, such as gloves, safety goggles, and sturdy footwear. These items can safeguard against sharp objects, debris, and potential impacts. Additionally, ensure that the machinery is turned off and disconnected from the power source to avoid accidental starts during repairs.

It is also advisable to work in a well-ventilated area, especially if using tools that may generate fumes or dust. Maintaining a clean workspace can help reduce the risk of slips, trips, and falls. Be mindful of your surroundings and keep all tools and materials organized to avoid unnecessary hazards.

Furthermore, consult the user manual for specific safety instructions related to the equipment being repaired. Familiarizing yourself with the machinery’s operation and maintenance guidelines can provide valuable insights and enhance your safety while working.