Understanding the John Deere X320 48 Mower Deck Parts Diagram

Maintaining a lush and healthy outdoor space requires an understanding of the crucial mechanisms that contribute to effective grass cutting. By familiarizing oneself with the various elements involved, one can enhance the performance and longevity of their equipment. This section will explore the intricate relationships between these components and their functionality.

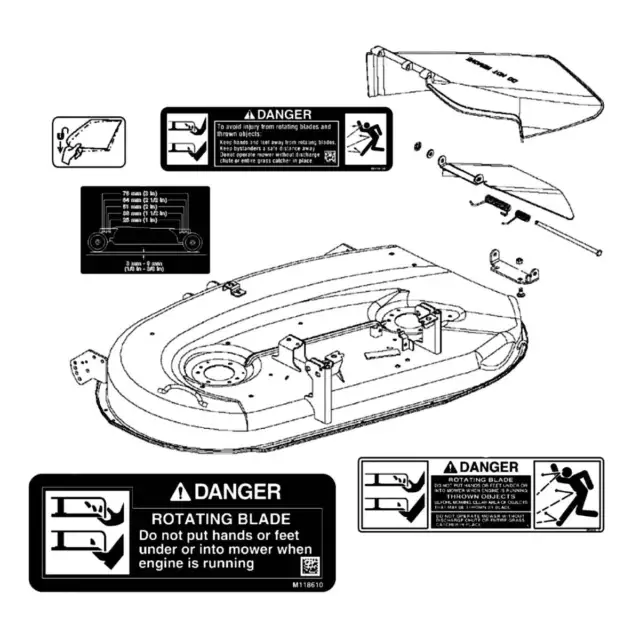

Illustrating the layout of these essential elements provides valuable insights for users aiming to optimize their maintenance efforts. Knowing how each segment fits together allows for informed decisions regarding repairs and upgrades. Such knowledge empowers operators to tackle challenges with confidence.

In addition, access to comprehensive visuals aids in the identification of components, facilitating a smoother workflow during maintenance tasks. This guidance ensures that every individual can effectively manage their equipment, leading to a more rewarding experience in lawn management.

Understanding the John Deere X320

This section explores the essential features and functionalities of a specific model in the lawn maintenance category. Its robust design and efficient operation make it a popular choice among homeowners and professionals alike. Key components work in harmony to ensure optimal performance, providing a seamless experience in managing outdoor spaces.

Performance is a crucial aspect that enhances usability, allowing users to tackle various terrains with ease. The engineering behind the machinery contributes to its durability and reliability, making it suitable for both small and large areas.

Additionally, maintenance plays a vital role in sustaining the longevity of the equipment. Understanding the core components and their functions enables owners to perform necessary upkeep, ensuring peak efficiency throughout the seasons.

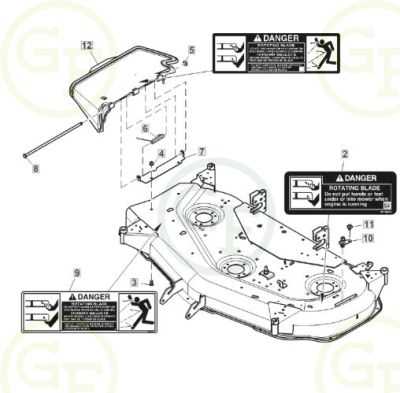

Overview of the 48-Inch Mower Deck

The 48-inch cutting platform is designed to provide an efficient and effective solution for maintaining lawns and gardens. Its robust construction and optimal blade configuration ensure a clean and even cut, making it suitable for various terrains and grass types.

Key Features

This cutting apparatus is equipped with several essential features that enhance its performance:

- Durable materials for long-lasting use

- Adjustable height settings for different grass lengths

- Streamlined design for improved maneuverability

Maintenance Tips

| Task | Frequency |

|---|---|

| Check blade sharpness | Every season |

| Clean undercarriage | After each use |

| Inspect belts and cables | Monthly |

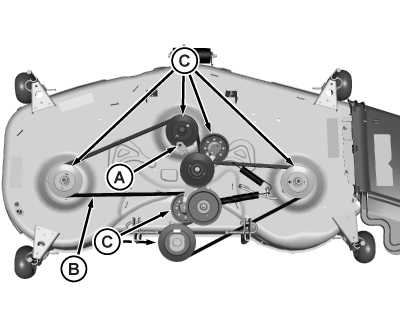

Essential Components of the Mower Deck

Understanding the fundamental elements of a cutting apparatus is crucial for maintaining optimal performance. Each component plays a significant role in ensuring efficient operation and longevity, providing a seamless experience in lawn care.

Key Elements Overview

Every cutting assembly consists of various integral components that work together. These parts are designed to enhance functionality and facilitate ease of use. Here are some of the primary elements:

| Component | Description |

|---|---|

| Blade | The primary tool responsible for cutting grass, available in different shapes and sizes. |

| Spindle | A rotating mechanism that holds and drives the cutting blades. |

| Belt | Transfers power from the engine to the spindle, enabling blade movement. |

| Housing | The protective casing that encases the blades and other components. |

| Wheel Assembly | Supports the entire structure, allowing for adjustable height and maneuverability. |

Importance of Each Component

Each part contributes uniquely to the overall functionality. Regular inspection and maintenance of these elements can prevent issues and enhance the efficiency of the apparatus. Understanding how these components interact allows for better troubleshooting and repair, ensuring a longer lifespan for the equipment.

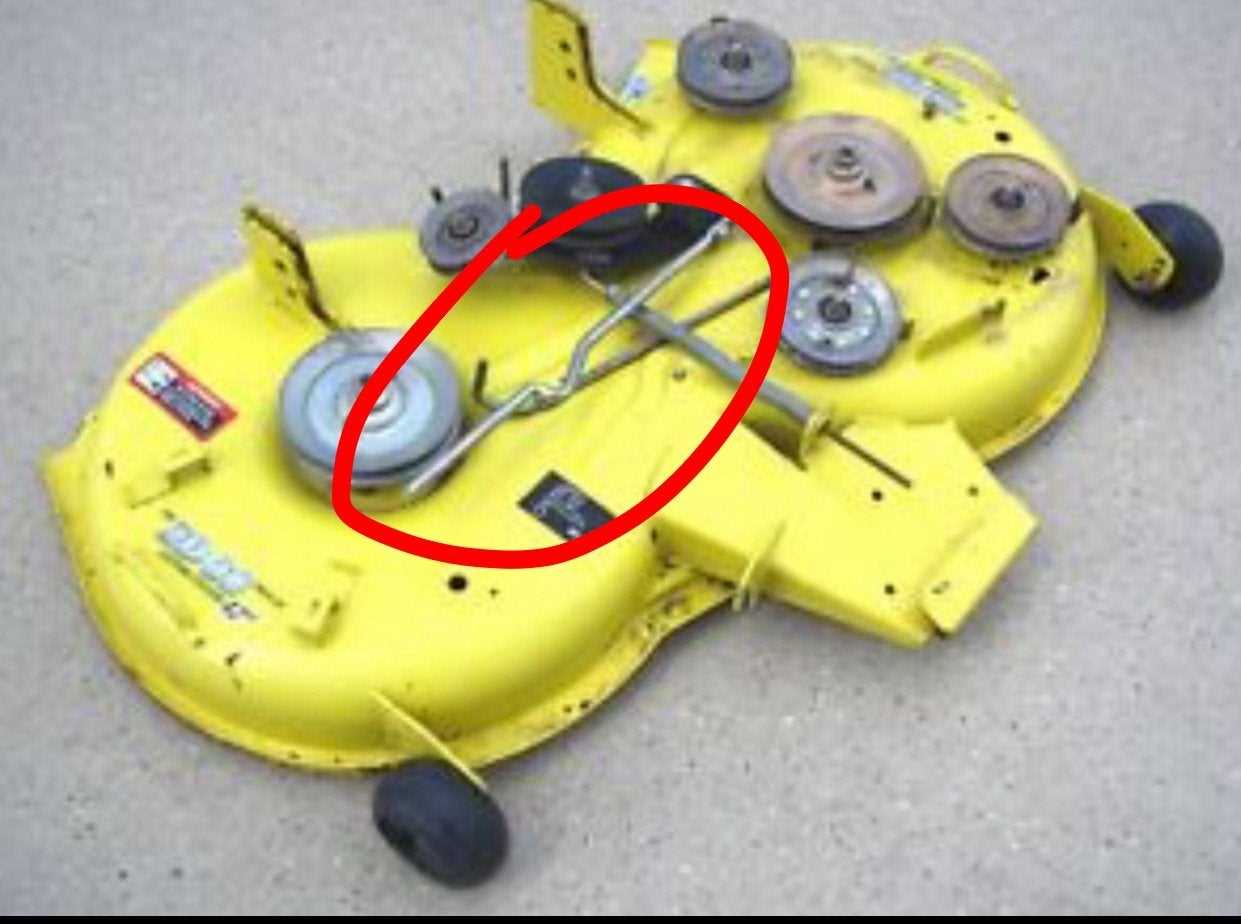

Common Issues with Mower Decks

When maintaining lawn equipment, several frequent challenges may arise that can affect performance and efficiency. Understanding these issues can help ensure proper operation and extend the life of the machinery. Regular inspection and maintenance are essential to prevent minor problems from escalating into significant repairs.

Uneven Cutting

One prevalent issue is uneven cutting, which can result from misalignment or wear of the blades. This not only affects the appearance of the lawn but can also lead to long-term damage to the grass. Ensuring that blades are sharpened regularly and that the cutting height is consistent can mitigate this problem.

Clogging and Debris Buildup

Another common concern is clogging caused by grass clippings and debris accumulation. This can hinder performance and reduce the effectiveness of the equipment. Regular cleaning and maintenance, particularly after use in damp conditions, can help maintain optimal functionality and prevent blockages.

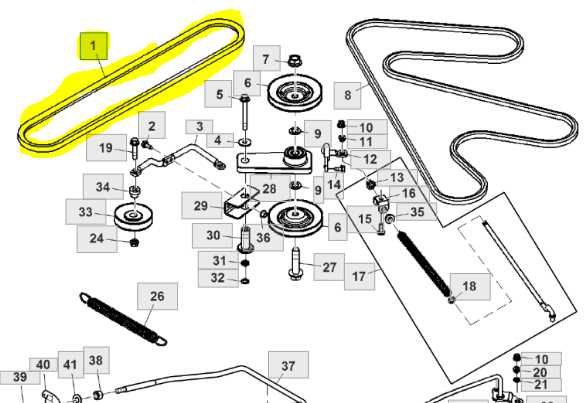

How to Read the Parts Diagram

Understanding the visual representation of components is crucial for efficient maintenance and repairs. This guide will help you navigate the intricacies of the schematic, making it easier to identify and locate necessary elements for your equipment.

Familiarize Yourself with the Symbols

The first step in interpreting the illustration is to become acquainted with the symbols used. Each symbol typically represents a specific component, and recognizing these can significantly enhance your ability to locate parts swiftly. Pay attention to any accompanying legends or keys that clarify what each symbol signifies.

Follow the Flow of the Layout

Next, observe how the components are arranged within the layout. Many schematics are designed to follow a logical sequence, often indicating how parts interact with one another. By following this flow, you can gain insight into the assembly and disassembly process, ultimately making your repairs more efficient.

Identifying Replacement Parts Easily

Finding the right components for your machinery can be a straightforward task if approached systematically. By understanding the essential elements and utilizing the right resources, you can streamline the identification process.

- Start by consulting the user manual for a comprehensive overview of necessary components.

- Use online resources or forums where other users share their experiences and recommendations.

- Consider taking photographs of existing components for visual reference when searching for replacements.

Additionally, maintaining an organized inventory of your equipment can help track which elements may need replacement in the future.

- List all parts that require attention.

- Research each item using the model number.

- Compare prices and options before making a purchase.

By employing these strategies, you can effectively navigate the process of locating suitable replacements with confidence.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your machinery operates efficiently and lasts longer. Proper maintenance not only enhances performance but also reduces the likelihood of costly repairs. By following some straightforward guidelines, you can keep your equipment running at its best.

1. Cleanliness is Key: Keep the components free from debris and dirt. Regular cleaning prevents build-up that can hinder functionality and leads to premature wear.

2. Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction and helps maintain smooth operation, extending the life of your machinery.

3. Regular Inspections: Conduct frequent checks on critical components. Identifying wear and tear early can prevent major issues down the line.

4. Proper Storage: Store your equipment in a dry, sheltered area to protect it from the elements. This helps avoid rust and other environmental damage.

5. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and recommendations provided by the manufacturer for optimal results.

Implementing these strategies will ensure your equipment delivers the ultimate performance and reliability throughout its lifespan.

Tools Needed for Mower Deck Repairs

Proper maintenance and repairs of lawn equipment require specific instruments to ensure efficiency and safety. Having the right tools on hand not only simplifies the process but also enhances the quality of the work performed.

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening bolts and nuts. |

| Wrench Set | Essential for adjusting and securing components. |

| Screwdriver Set | Used for various fastening tasks. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Cleaning Brush | For removing debris and buildup. |

Step-by-Step Repair Process

Undertaking a repair task requires careful planning and execution to ensure optimal results. This guide outlines a systematic approach to address issues effectively, making the process straightforward and manageable.

Begin by gathering all necessary tools and equipment. A well-organized workspace enhances efficiency and safety. Ensure you have the right manual or reference material for specific guidance on the model you are working with.

Next, perform a thorough inspection of the unit. Identify any damaged or worn components that need attention. Document your findings, as this will help streamline the repair process and keep track of parts that require replacement.

Once you have pinpointed the issues, disassemble the relevant sections carefully. Use appropriate tools to avoid causing further damage. Keep track of all screws and small components to facilitate reassembly.

After disassembly, clean all parts to remove debris and buildup. This step is crucial for maintaining optimal functionality. Examine each piece for signs of wear and replace any that are compromised.

With the new or repaired components ready, begin the reassembly process. Follow the reverse order of disassembly, ensuring each part is secured properly. Double-check your work to prevent loose components during operation.

Finally, conduct a test run to verify that everything operates as intended. Monitor for any unusual noises or performance issues. If problems persist, revisit your steps to identify any overlooked aspects.

Upgrades for Enhanced Mowing Efficiency

Improving performance during lawn maintenance can significantly impact the quality of your work and save valuable time. By focusing on specific enhancements, you can ensure that your equipment operates at its best, providing a smoother and more effective cutting experience.

- Blade Upgrades: Consider investing in high-performance blades that offer superior cutting efficiency and longevity. Options like mulching blades can improve grass decomposition and enhance the nutrient cycle.

- Engine Performance: Upgrading to a more powerful engine can lead to better torque and speed. Regular maintenance, such as air filter and oil changes, also plays a crucial role in maintaining optimal performance.

- Drive System Enhancements: A robust transmission system can improve speed control and maneuverability. Consider options that allow for smoother shifts and better traction on varying terrains.

- Suspension Improvements: Upgrading the suspension can enhance stability and comfort, particularly on uneven surfaces. This helps maintain a consistent cutting height and reduces operator fatigue.

- Smart Technology Integration: Incorporating GPS and smart sensors can optimize mowing patterns, making the process more efficient. These technologies can also help in tracking performance metrics and maintenance needs.

By implementing these enhancements, you can maximize efficiency and achieve a pristine lawn with less effort and time.

Where to Purchase Replacement Parts

Finding quality components for your outdoor equipment can significantly enhance its performance and longevity. Whether you’re in need of specific items for maintenance or repairs, there are several reliable sources available. It’s essential to consider both online retailers and local suppliers to ensure you have access to the best options.

Online marketplaces often offer a vast selection, making it easy to compare prices and availability. Websites specializing in outdoor machinery provide detailed descriptions and customer reviews, helping you make informed choices. Alternatively, visiting local hardware or specialty shops can yield immediate results and personalized assistance, ensuring you get the right fit for your machine.

Consider checking manufacturer websites for official recommendations, as they often list authorized dealers and distributors. This ensures you are purchasing high-quality replacements that meet the original specifications. Joining online forums or community groups can also provide valuable insights and recommendations from fellow enthusiasts.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components, helping users navigate their maintenance and repair needs effectively. Understanding the essentials can simplify the process of finding and replacing necessary items.

| Question | Answer |

|---|---|

| How do I identify the correct component for my machine? | Check the model number and refer to the specific reference guide for accurate identification. |

| Where can I purchase replacement items? | Authorized dealers, online retailers, and local hardware stores are good sources for authentic replacements. |

| What should I do if a component is out of stock? | Consider ordering directly from the manufacturer or explore alternative suppliers for availability. |

| Are there compatible alternatives for specific components? | Yes, aftermarket options may exist, but verify compatibility to ensure optimal performance. |