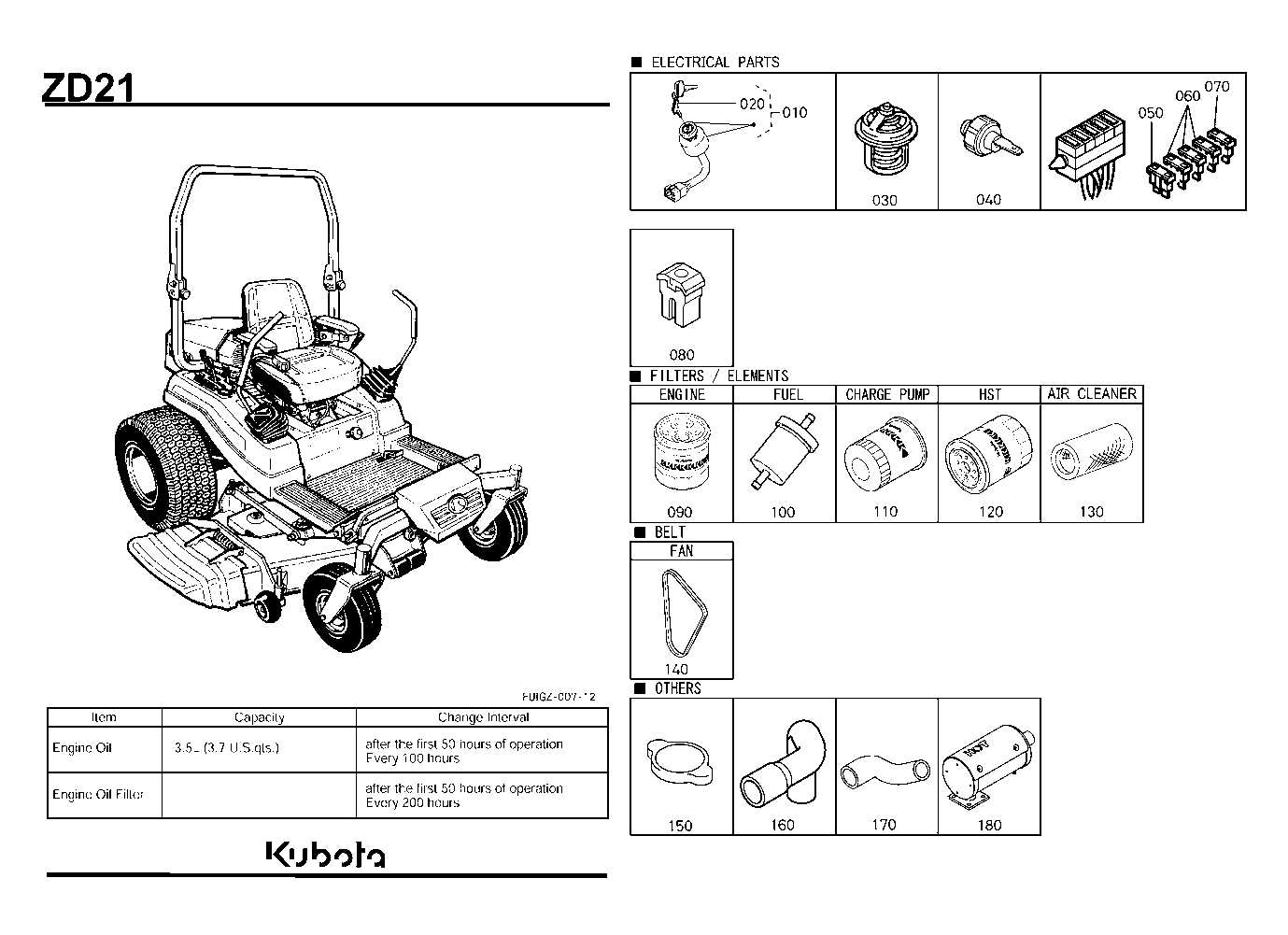

Kubota ZD21 Mower Deck Parts Diagram for Easy Maintenance and Repair

When it comes to outdoor maintenance equipment, it is essential to have a clear understanding of its various elements. The proper functioning of these devices depends on how well the individual components work together. By familiarizing yourself with each part, you can ensure more efficient care and timely repairs, extending the lifespan of your equipment.

Diagrams and schematics play a crucial role in helping you grasp the structure of these machines. They provide a detailed visual representation, making it easier to identify specific elements. Whether you’re conducting routine maintenance or addressing an unexpected issue, having a clear view of the mechanism aids in precise adjustments and replacements.

Exploring the structure and understanding how everything fits together allows you to take proactive steps in maintaining your equipment. Knowing the layout of each section will enable you to perform tasks efficiently and with confidence, avoiding unnecessary complications.

Kubota ZD21 Mower Deck Overview

This section provides a detailed exploration of a key component that plays a vital role in maintaining lawns efficiently. Known for its durability and performance, this feature offers reliable operation and a seamless experience during use, ensuring precise grass cutting over large areas. Its design focuses on delivering consistency, regardless of terrain or grass type.

Main Features and Benefits

Built with strength and precision, this mechanism is engineered to provide smooth, even cuts. Its design allows for easy adjustments, enabling the user to maintain optimal cutting height. With robust construction, it stands up to regular use and resists wear, making it a dependable tool for frequent tasks.

Performance and Durability

The system’s performance is enhanced by its ability to handle varying conditions with minimal effort. Whether working on flat surfaces or uneven terrain, it delivers reliable results. Its long-lasting nature is further supported by quality materials, ensuring that it remains a key player in maintaining healthy and attractive outdoor spaces over time.

Essential Components of a Mower Deck

The structure responsible for cutting grass efficiently consists of several key elements working together. Each part plays a vital role in ensuring smooth operation and optimal performance. Understanding the main components is crucial for maintaining functionality and achieving the best results.

Blades and Their Role

The blades are arguably the most critical part of the cutting system. Their sharpness and durability directly affect the quality of the cut. Regular maintenance and sharpening ensure a clean, even cut, preventing strain on the entire system. Well-maintained blades also contribute to the machine’s overall efficiency.

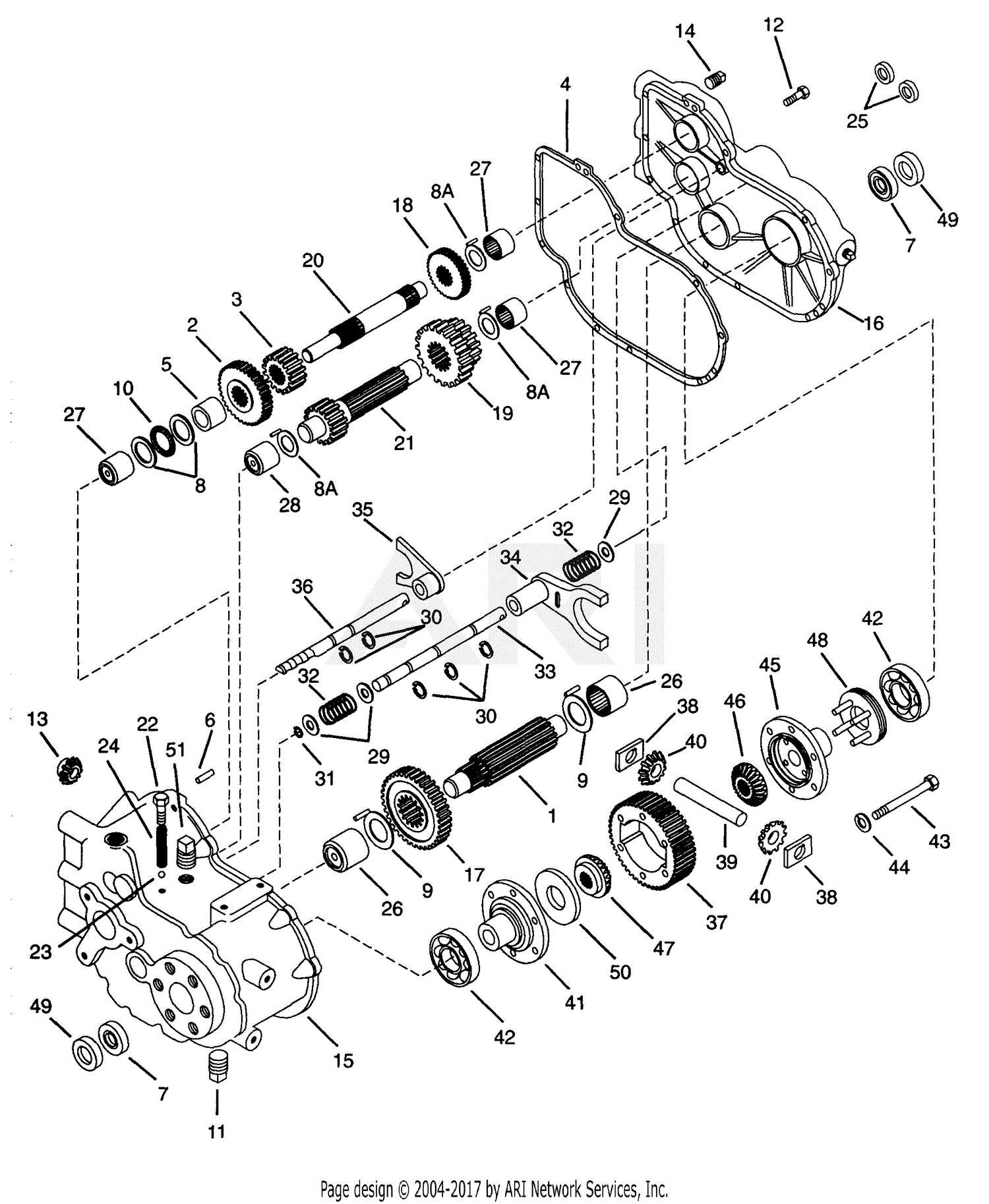

Spindle and Pulley System

The rotating mechanism, often referred to as the spindle, drives the movement of the cutting elements. Attached to the spindle are pulleys that manage the tension and speed, ensuring smooth operation. Proper lubrication and timely replacement of these components prevent breakdowns and extend the life of the equipment.

Conclusion: Each component, from the blades to the rotating system, must be in good working order to guarantee efficient performance. Regular inspections and timely maintenance are key to long-lasting, trouble-free operation.

Understanding Blade Functionality in the ZD21

The efficiency and quality of grass cutting depend heavily on the performance of the cutting mechanism. A well-designed blade ensures that grass is sliced cleanly, contributing to the overall appearance of the lawn. It is essential to understand how the cutting edges operate and how their shape, material, and maintenance impact their effectiveness. In this section, we will explore the key features and functions of these essential components.

Blade Design and Shape

The design of the cutting edges plays a critical role in achieving a precise cut. Factors such as the curve, length, and sharpness of the edges are optimized to slice through vegetation efficiently. The shape of the blade also influences airflow, which assists in lifting grass and directing clippings to the appropriate discharge area. This balance between cutting and air movement ensures an even and clean result.

Material and Durability

Blades are crafted from durable materials that can withstand frequent use and harsh conditions. However, regular maintenance is required to preserve their effectiveness. Sharpening and inspecting the edges for damage or wear are crucial for maintaining high performance

Belt System: Role and Maintenance Tips

The belt-driven mechanism plays a crucial part in ensuring the seamless operation of various outdoor machines. Proper alignment and consistent tension are essential to transferring power efficiently, reducing strain on other components, and prolonging the overall life of the system. Regular inspections and timely adjustments can help prevent costly repairs and extend the equipment’s lifespan.

Common Issues in Belt Systems

Over time, belts may stretch, fray, or become misaligned. This can lead to slippage, uneven performance, or even complete failure of the mechanism. Monitoring for signs of wear, such as visible cracks or changes in tension, helps address potential problems early. Replacing a damaged belt promptly is key to avoiding further complications.

Maintenance Tips for Longevity

To maintain optimal function, ensure regular cleaning of the system to remove debris that could interfere with smooth operation. Proper tension adjustment should also be checked periodically. Additionally, lubricating the moving parts connected to the belt system helps reduce friction and wear, contributing to a longer operational life.

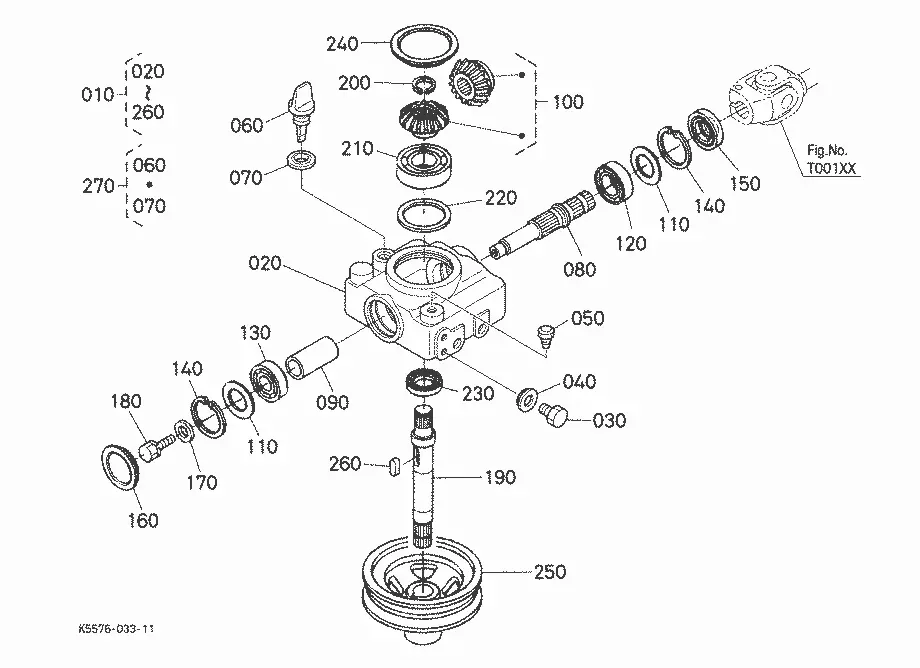

Identifying Deck Spindle and Its PurposeThe spindle is a crucial component in the cutting mechanism, responsible for ensuring smooth operation and consistent performance. Understanding its role is essential for anyone looking to maintain or enhance the efficiency of their cutting equipment. The spindle not only connects various moving parts but also ensures they work together seamlessly. Main Functions of the SpindleThe primary role of the spindle is to transfer power from the engine to the cutting blades, ensuring they spin at the necessary speed for a clean and even cut. Its design allows for stable rotation, reducing vibration and ensuring that the blades move in perfect alignment. Proper spindle maintenance is critical to avoid wear and tear that can lead to performance issues. Spindle ComponentsThe spindle assembly consists of several elements, each playing a vital role in the overall functionality. Below is a breakdown of key components commonly found in spindle assemblies: |

|---|