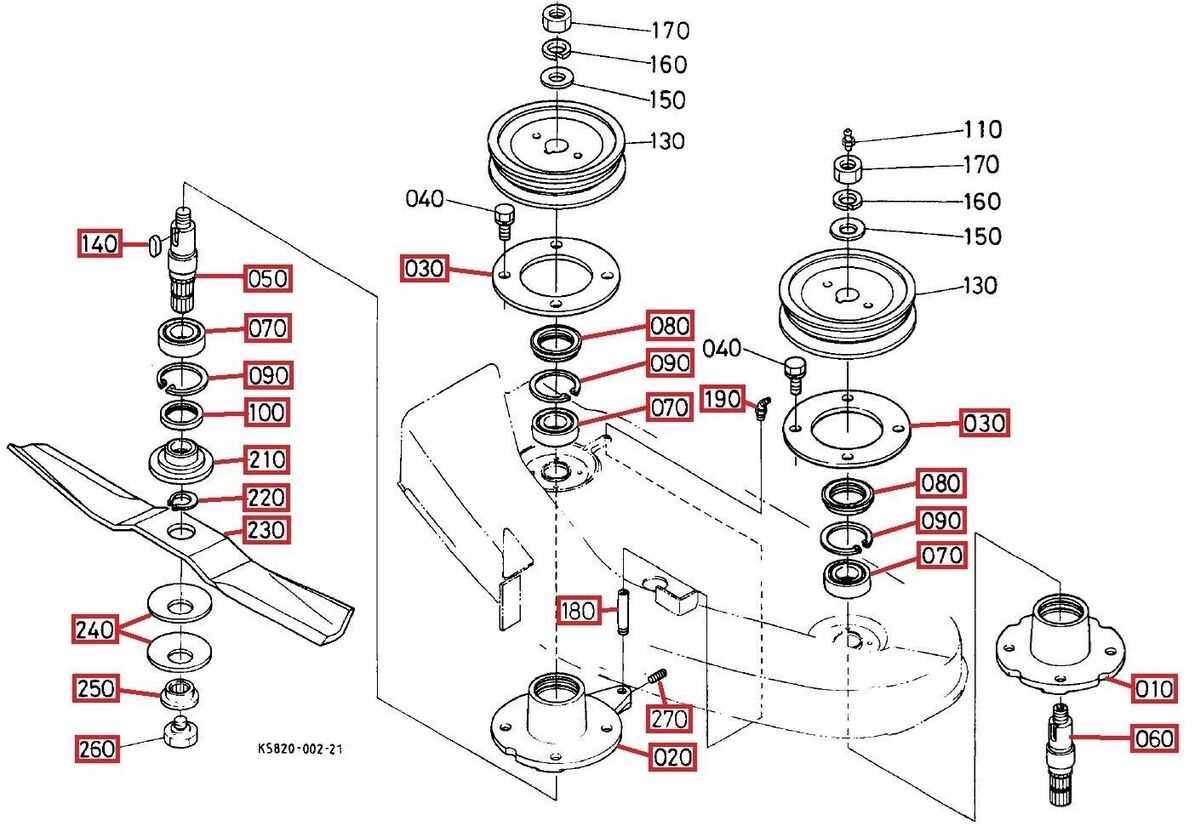

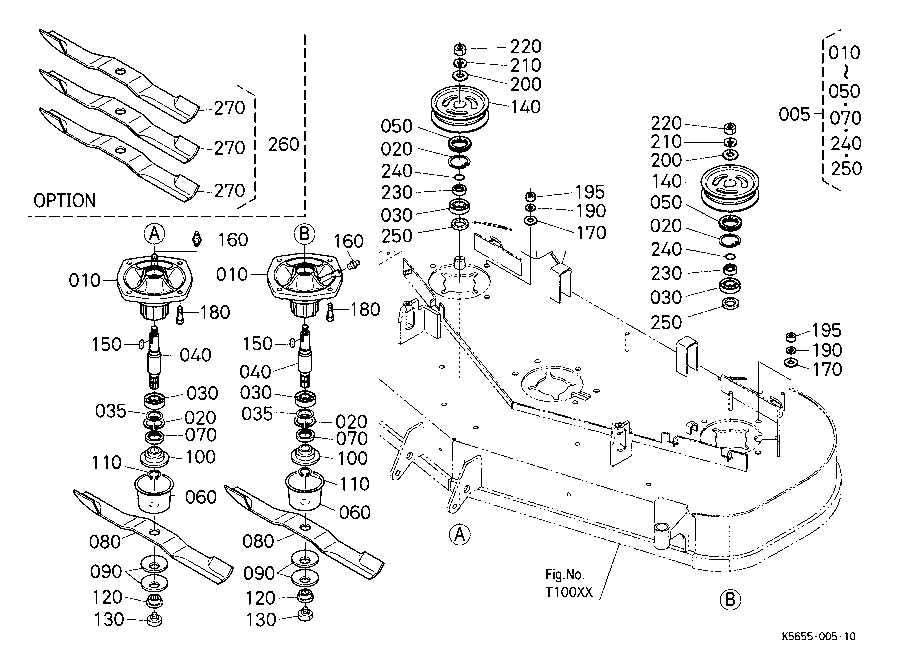

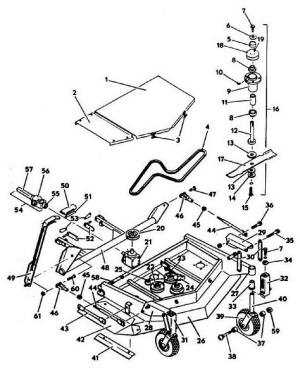

Kubota ZD331 Deck Parts Overview

Maintaining your lawn care equipment is essential for achieving optimal performance and longevity. In this section, we will explore the intricate assembly of a specific model, focusing on its essential components and how they interact. Knowledge of these elements can significantly enhance your troubleshooting and repair skills.

Every mower consists of various mechanisms that contribute to its functionality. Familiarizing yourself with these elements will empower you to make informed decisions regarding maintenance and repairs. With a clear understanding of how each piece fits together, you can ensure your equipment operates at its best.

Additionally, recognizing the significance of each component allows for efficient troubleshooting when issues arise. By referring to a comprehensive visual representation, you can quickly identify potential problems and take appropriate action. This proactive approach will ultimately save time and resources, ensuring your equipment remains in top condition.

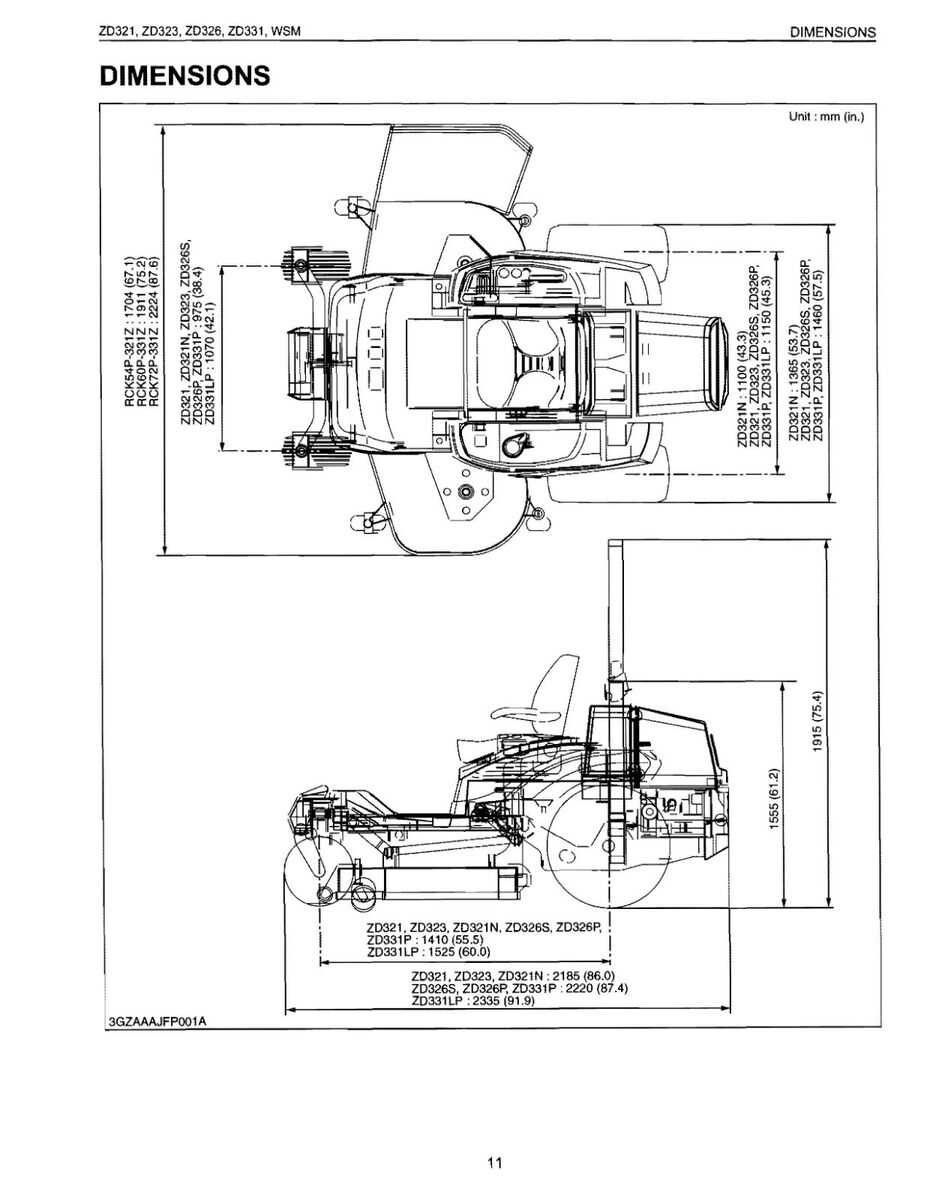

Kubota ZD331 Overview

This section provides a comprehensive introduction to a popular model in the landscape maintenance sector, focusing on its design, functionality, and user benefits. Ideal for both residential and commercial applications, this equipment is engineered for efficiency and ease of use.

Key Features

- Powerful engine performance

- Advanced maneuverability

- Durable construction for long-lasting use

- User-friendly controls for enhanced operation

Applications

- Residential lawn care

- Commercial landscaping projects

- Golf course maintenance

- Municipal parks and recreation areas

With a focus on reliability and effectiveness, this machinery stands out as a top choice for professionals seeking to optimize their maintenance tasks.

Importance of Deck Components

The functionality and performance of a lawn maintenance machine heavily rely on its individual elements. Each component plays a crucial role in ensuring that the equipment operates efficiently and effectively. Understanding the significance of these elements can enhance both maintenance practices and overall performance.

Enhanced Performance

Key elements contribute directly to the machine’s operational capability. When these components are in optimal condition, they work together to provide a smooth and effective mowing experience. Regular inspection and timely replacement of worn-out parts ensure that the machinery functions at its best, allowing for a clean and precise cut.

Safety and Reliability

Maintaining the integrity of each individual element is vital for user safety. Components that are compromised can lead to malfunction, posing risks to the operator and surrounding individuals. Reliability of the machine increases significantly when all parts are functioning correctly, reducing the likelihood of accidents and equipment failure.

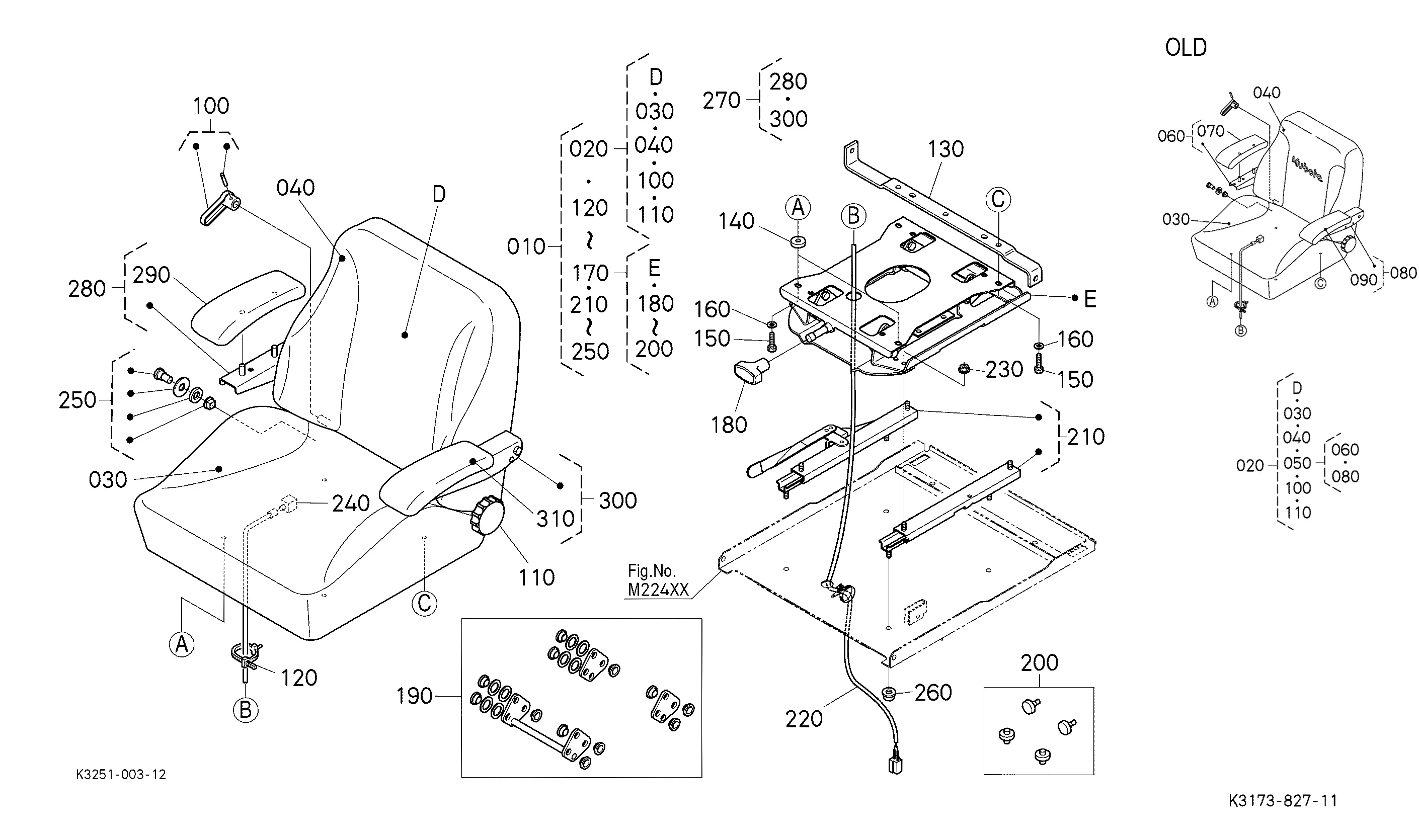

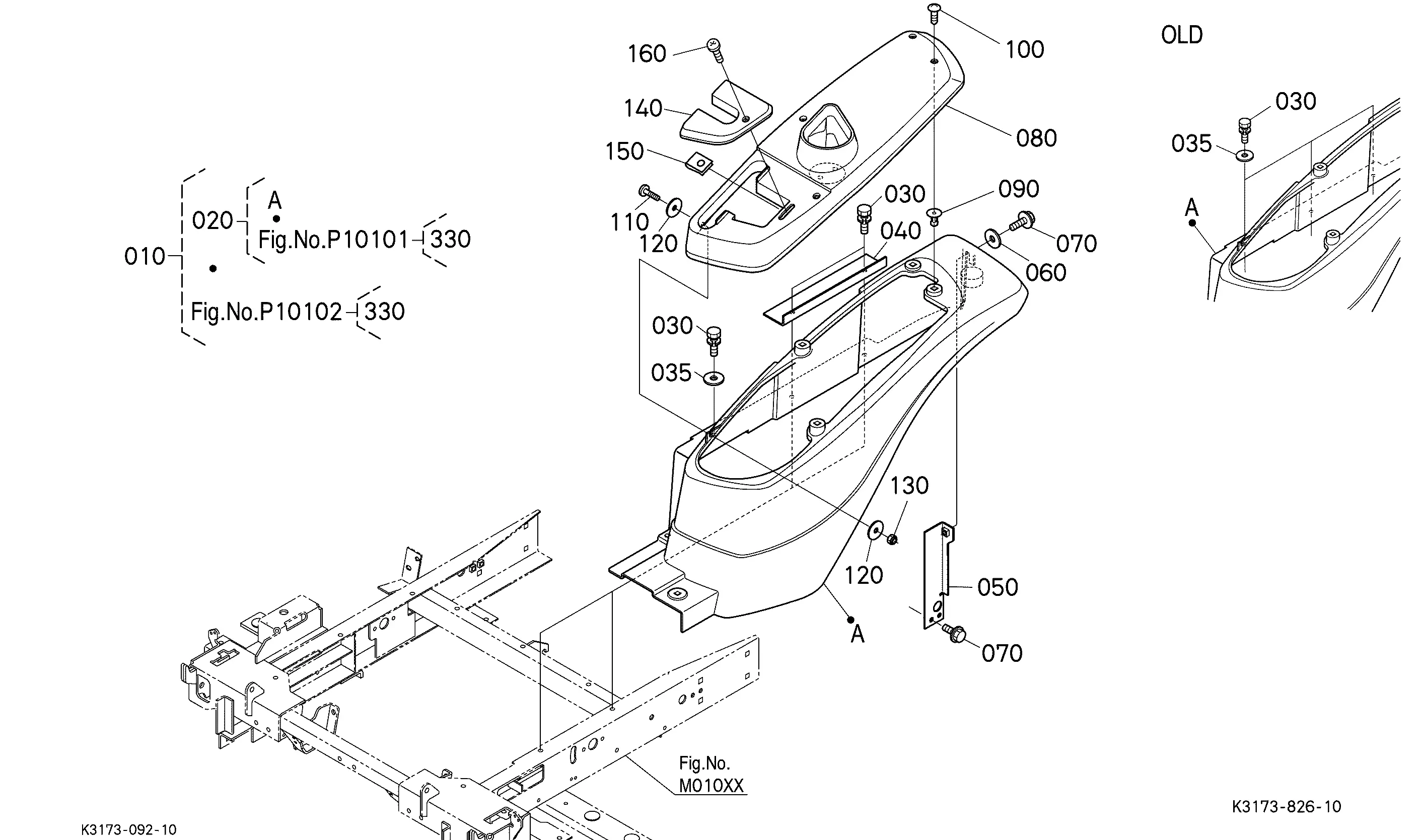

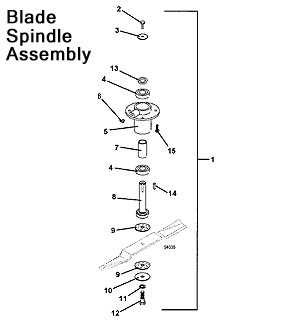

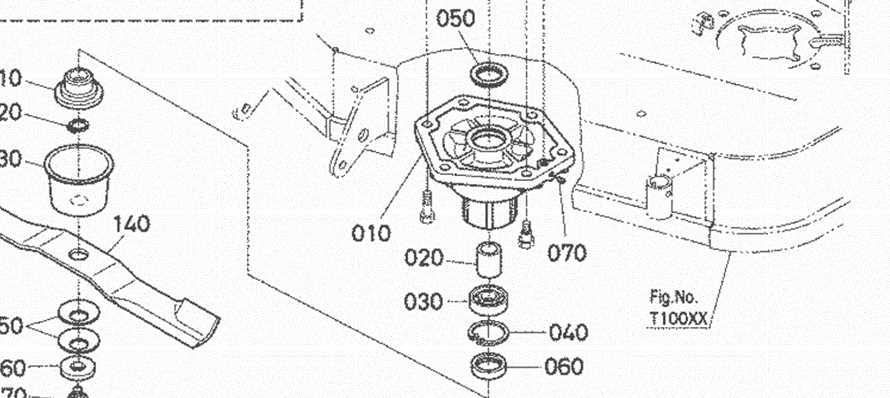

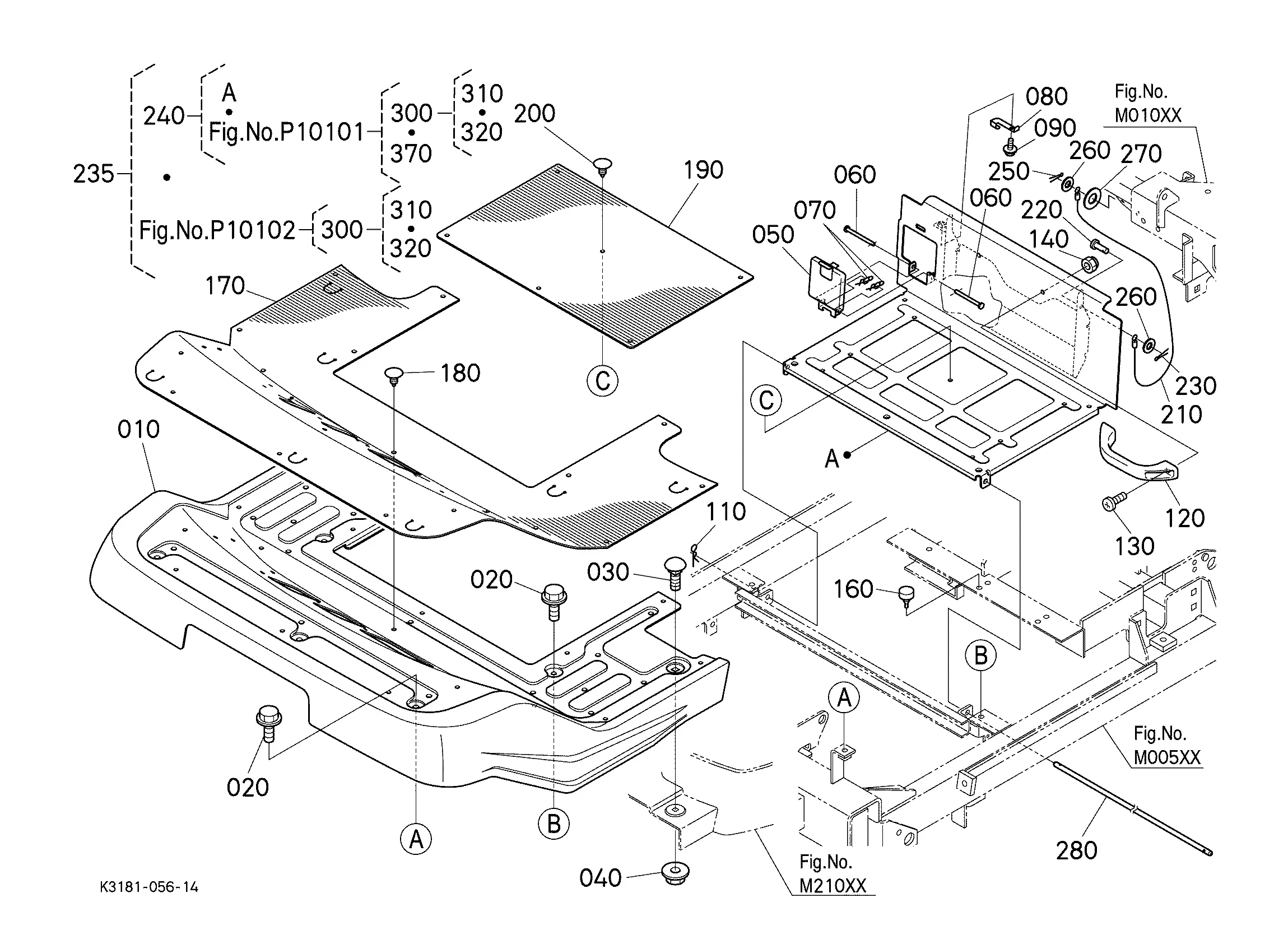

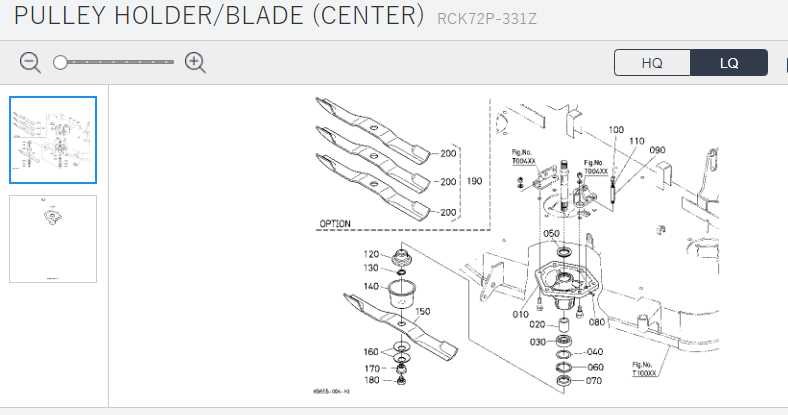

Identifying Key Parts in Diagrams

Understanding the components illustrated in visual representations is essential for effective maintenance and repair. By recognizing the main elements, users can navigate complex layouts with greater ease, enabling them to address issues more efficiently and ensure proper functioning of the equipment.

Importance of Accurate Identification

Correctly identifying each element allows for precise troubleshooting and enhances the overall comprehension of the machinery. When individuals are familiar with the various components, they can quickly determine which parts require attention or replacement, leading to minimized downtime and improved performance.

Utilizing Visual Guides

Visual aids serve as invaluable tools for both novice and experienced operators. By referring to these guides, users can reinforce their understanding of the machine’s configuration, leading to more informed decision-making when undertaking repairs or routine maintenance tasks.

Maintenance Tips for Kubota Deck

Proper care is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only enhances performance but also helps prevent costly repairs.

Here are some key maintenance tips:

- Regular Cleaning: Remove debris and grass clippings to avoid buildup that can lead to corrosion.

- Inspect Blades: Check for wear and sharpness. Dull blades should be sharpened for optimal cutting.

- Check Belts: Look for signs of wear or fraying and replace if necessary to maintain proper functionality.

- Grease Fittings: Lubricate moving parts to reduce friction and prevent premature wear.

- Fluid Levels: Regularly check and top off oil and hydraulic fluids to ensure smooth operation.

By following these guidelines, you can maintain the efficiency and reliability of your equipment for years to come.

Common Issues with Deck Parts

Maintenance of cutting components can lead to various complications that affect overall performance. Understanding these challenges is essential for ensuring smooth operation and longevity of the equipment.

Frequent Problems

- Worn Blades: Over time, blades may become dull or damaged, resulting in uneven cuts and reduced efficiency.

- Alignment Issues: Misalignment can cause excessive wear on the components and lead to inefficient operation.

- Debris Build-Up: Grass and other debris can accumulate, obstructing movement and affecting functionality.

Signs of Wear

- Inconsistent Cutting: An indicator that blades may need sharpening or replacement.

- Excessive Vibration: This could signal misalignment or damage to the cutting mechanism.

- Noisy Operation: Unusual sounds often suggest a need for inspection and possible adjustments.

Replacement Procedures for Deck Components

Maintaining the functionality of your machinery requires regular updates and replacements of various elements. This section outlines the essential steps for replacing specific components to ensure optimal performance and longevity.

Preparation Steps

Before beginning the replacement process, gather the necessary tools and components. It is important to consult the manufacturer’s guidelines to understand the specific requirements for each part. Make sure the equipment is turned off and properly secured to prevent accidents during maintenance.

Replacement Process

Start by carefully removing the existing component. Use appropriate tools to avoid damaging surrounding areas. Once the old part is detached, compare it with the new replacement to ensure compatibility. After confirming a proper fit, install the new element, making sure all connections are secure. Finally, conduct a thorough inspection to verify that everything is in place and functioning correctly.

Regular maintenance is crucial for the longevity of your equipment. Following these procedures can help maintain efficiency and prevent future issues.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These specialized items are crafted to meet precise specifications, enhancing reliability and efficiency while reducing the likelihood of breakdowns.

Quality Assurance

Authentic components undergo rigorous testing and adhere to strict quality standards. This guarantees superior durability and functionality compared to generic alternatives, ultimately resulting in fewer repairs and extended service life.

Compatibility and Fit

Using original components ensures perfect compatibility with your equipment. This seamless integration helps maintain the integrity of the machinery and avoids potential issues caused by improper fitting.

| Feature | Genuine Components | Generic Alternatives |

|---|---|---|

| Durability | High | Variable |

| Performance | Optimal | Subpar |

| Warranty | Included | Limited |

Comparing Aftermarket and OEM Parts

The decision between selecting original equipment manufacturer components and their aftermarket counterparts is crucial for many machinery owners. Each option presents distinct advantages and potential drawbacks that can significantly impact performance, longevity, and overall satisfaction.

Quality and Reliability

OEM components are typically designed and tested by the original manufacturer, ensuring a high standard of quality and compatibility with the equipment. This often translates to enhanced reliability and peace of mind for users. Conversely, aftermarket alternatives may vary widely in quality. While some can offer comparable performance, others might not meet the same stringent standards, potentially leading to premature failure.

Cost Considerations

One of the primary factors influencing the choice is cost. Aftermarket options often come at a lower price point, making them appealing to budget-conscious consumers. However, it’s essential to weigh this against the potential need for more frequent replacements or repairs that could arise from inferior quality. In contrast, investing in OEM components may result in higher upfront costs but can lead to greater value in the long run due to their durability.

Finding Replacement Parts Online

Locating suitable components for machinery can be a challenging yet rewarding endeavor. With the vast array of online resources available, enthusiasts and professionals alike can access a wide selection of options tailored to their specific needs. By leveraging various platforms, users can ensure they find the right items to maintain or restore their equipment efficiently.

Utilizing Specialized Websites

Many websites cater specifically to machinery enthusiasts, offering detailed catalogs and diagrams that facilitate the search for appropriate components. These platforms often provide user-friendly navigation and comprehensive information, making it easier to identify and acquire the necessary items for repair or enhancement.

Engaging with Online Communities

Participating in forums and social media groups focused on machinery can also be invaluable. Experienced users often share insights, recommendations, and sources for obtaining the desired components, fostering a supportive environment for all involved. Such interactions can lead to discovering lesser-known suppliers and unique solutions tailored to individual requirements.

Understanding Deck Assembly Process

The process of assembling a cutting platform involves several critical steps that ensure functionality and efficiency. Each component plays a vital role in achieving optimal performance, requiring careful attention to detail during installation. A thorough grasp of this process can significantly enhance the overall operation and longevity of the equipment.

First, begin by gathering all necessary components and tools, ensuring that everything is within reach. This preparatory step lays the foundation for a smooth assembly experience.

Next, refer to the assembly guidelines to identify the proper sequence of installation. Understanding the arrangement of components will help avoid confusion and potential errors, leading to a more cohesive setup.

Additionally, pay close attention to the alignment and securing of each part. Proper fastening prevents future complications and enhances stability during operation. Regular checks throughout the process are essential to maintain quality and ensure a successful assembly.

In conclusion, mastering the assembly of the cutting platform not only improves efficiency but also contributes to the durability of the machinery. A well-executed setup is key to achieving outstanding results in the field.

Safety Precautions During Repairs

Ensuring a secure environment during maintenance activities is essential for both personal safety and effective functioning of the equipment. Adopting proper measures minimizes the risk of accidents and injuries, allowing for a smoother repair process.

- Always wear appropriate protective gear, including gloves, goggles, and steel-toed boots.

- Disconnect the power source before starting any repair work to prevent accidental activation.

- Use tools that are in good condition and specifically designed for the task at hand.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace organized to prevent tripping hazards and ensure easy access to tools.

Following these safety guidelines not only protects individuals but also enhances the efficiency of the repair process. Regularly reviewing and adhering to these precautions is vital in maintaining a safe working environment.

Tools Required for Deck Maintenance

Proper upkeep of your equipment’s surface is essential for optimal performance and longevity. Ensuring that you have the right instruments on hand can significantly enhance the efficiency of your maintenance tasks. Below is a list of essential tools that facilitate thorough care and servicing.

First, a reliable set of wrenches and sockets will allow for the adjustment and securing of various components. A torque wrench is particularly important to ensure that fasteners are tightened to the manufacturer’s specifications. Additionally, screwdrivers in various sizes are necessary for handling different types of screws.

Furthermore, having a high-quality cleaning solution and scrub brush is vital for removing debris and buildup, promoting a clean and functional surface. A protective cover is also recommended to shield against environmental elements when the machinery is not in use.

Finally, safety gear, such as gloves and goggles, should always be worn to protect yourself during maintenance tasks. By equipping yourself with these tools, you can ensure your equipment remains in excellent condition.

FAQs about ZD331 Deck Parts

This section addresses common inquiries regarding components related to the specified model, providing clarity and understanding for users seeking information about their maintenance and functionality.

What should I consider when replacing components? It’s essential to ensure compatibility with your specific model. Always refer to your user manual for guidance on selecting the correct replacements.

How can I identify worn-out components? Look for signs of damage such as unusual noises, vibrations, or uneven cutting. Regular inspections can help in early detection.

Where can I purchase quality components? Reliable suppliers include authorized dealers and reputable online platforms. Always check for authenticity to avoid counterfeit items.

Are there any maintenance tips for longevity? Regular cleaning, timely replacements, and following the manufacturer’s recommendations can significantly extend the life of your equipment.

What should I do if I encounter issues during installation? Consult the installation guide and consider reaching out to customer support for assistance. Online forums can also be a helpful resource for troubleshooting advice.