Comprehensive Guide to John Deere 350 Crawler Parts Diagram

The intricate workings of heavy machinery often require a deep exploration of their essential elements. Proper knowledge of these components not only enhances functionality but also aids in effective maintenance and repair.

In this section, we will delve into the specific arrangements and classifications of various parts that constitute a well-known model of track-type equipment. A comprehensive overview will empower operators and enthusiasts to grasp the ultimate significance of each element.

Understanding the configuration and interaction of these components is vital for anyone looking to optimize performance and extend the lifespan of their machinery. Whether for professional use or personal projects, familiarity with these essentials lays the groundwork for success.

Understanding John Deere 350 Crawler

This section explores a renowned piece of machinery, known for its robust performance and versatility in various applications. By examining its components and overall functionality, users can appreciate its significance in the industry.

Key Features

This machinery stands out due to its powerful engine and efficient design, making it suitable for tough terrains and demanding tasks. Its construction allows for enhanced stability and maneuverability, critical for optimal performance.

Component Overview

Familiarity with the essential elements contributes to effective operation and maintenance. Below is a table outlining some of the critical components:

| Component | Description |

|---|---|

| Engine | Delivers reliable power for various tasks. |

| Tracks | Provide traction and stability on uneven surfaces. |

| Hydraulics | Facilitate movement and operation of attachments. |

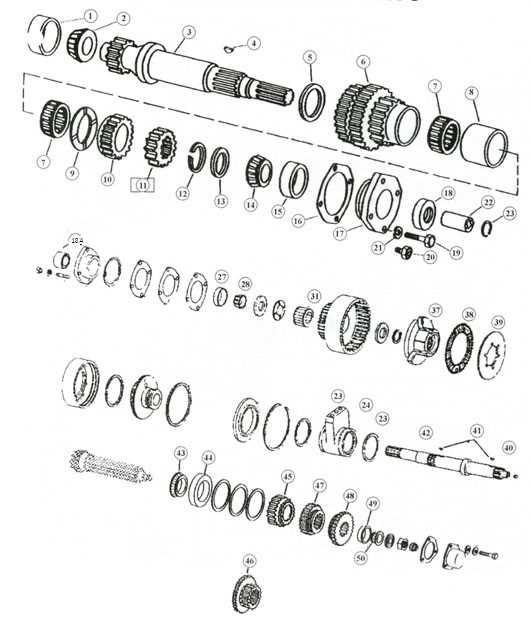

Essential Parts of the Crawler

This section focuses on the critical components that ensure the efficient operation of heavy machinery designed for rough terrains. Understanding these elements is vital for maintenance and performance optimization.

- Engine: The powerhouse that drives the entire system, providing necessary torque and horsepower.

- Transmission: Facilitates gear changes, ensuring smooth acceleration and deceleration.

- Tracks: These are crucial for traction and stability on uneven surfaces.

- Undercarriage: Supports the vehicle’s weight and absorbs shocks, enhancing durability.

- Hydraulic System: Powers various attachments and assists in movement, offering versatility.

Each of these components plays an ultimate role in achieving peak performance and longevity of the machinery.

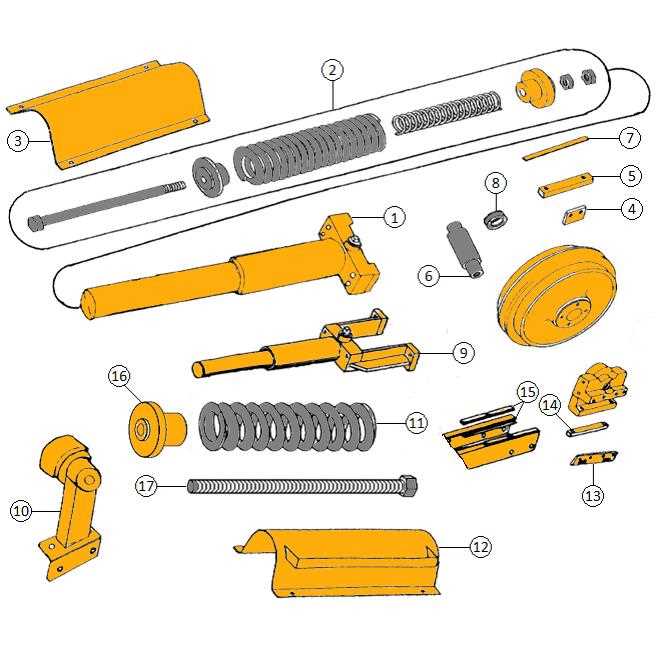

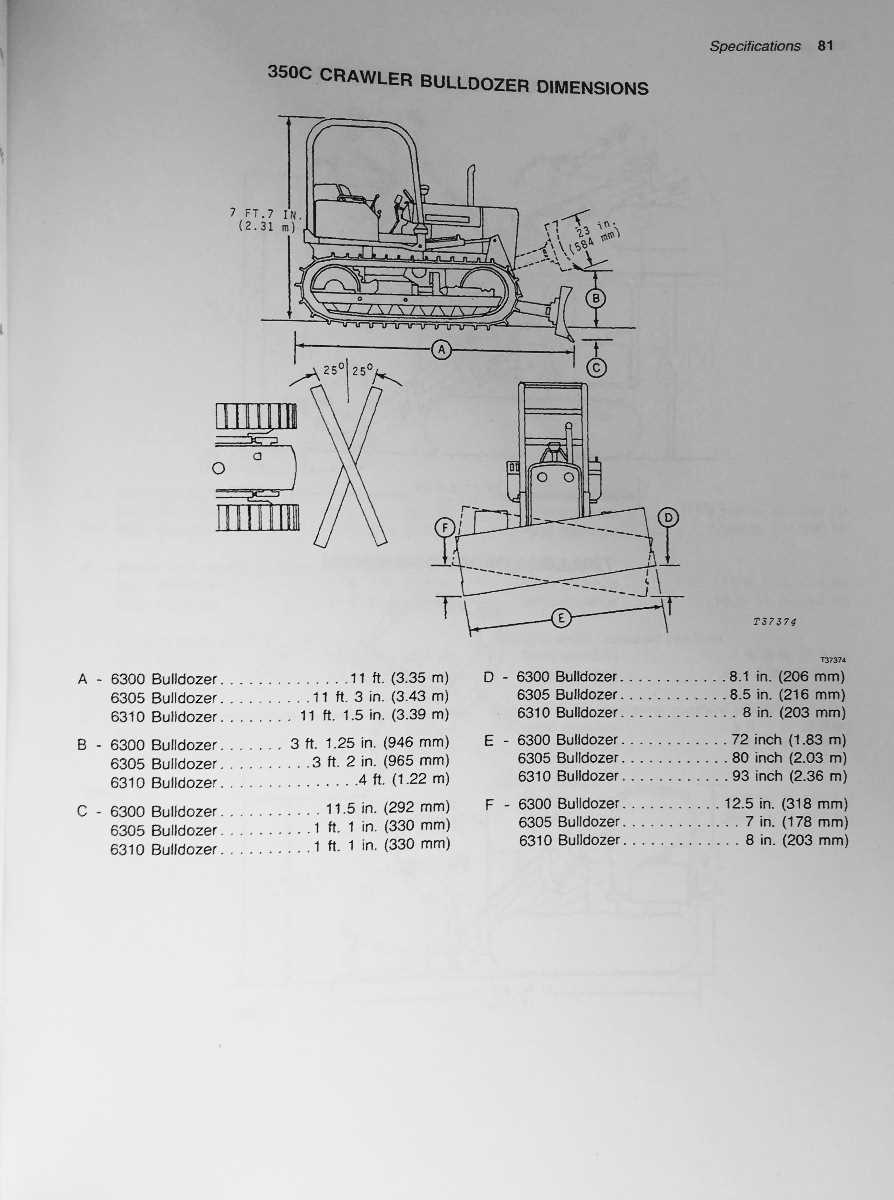

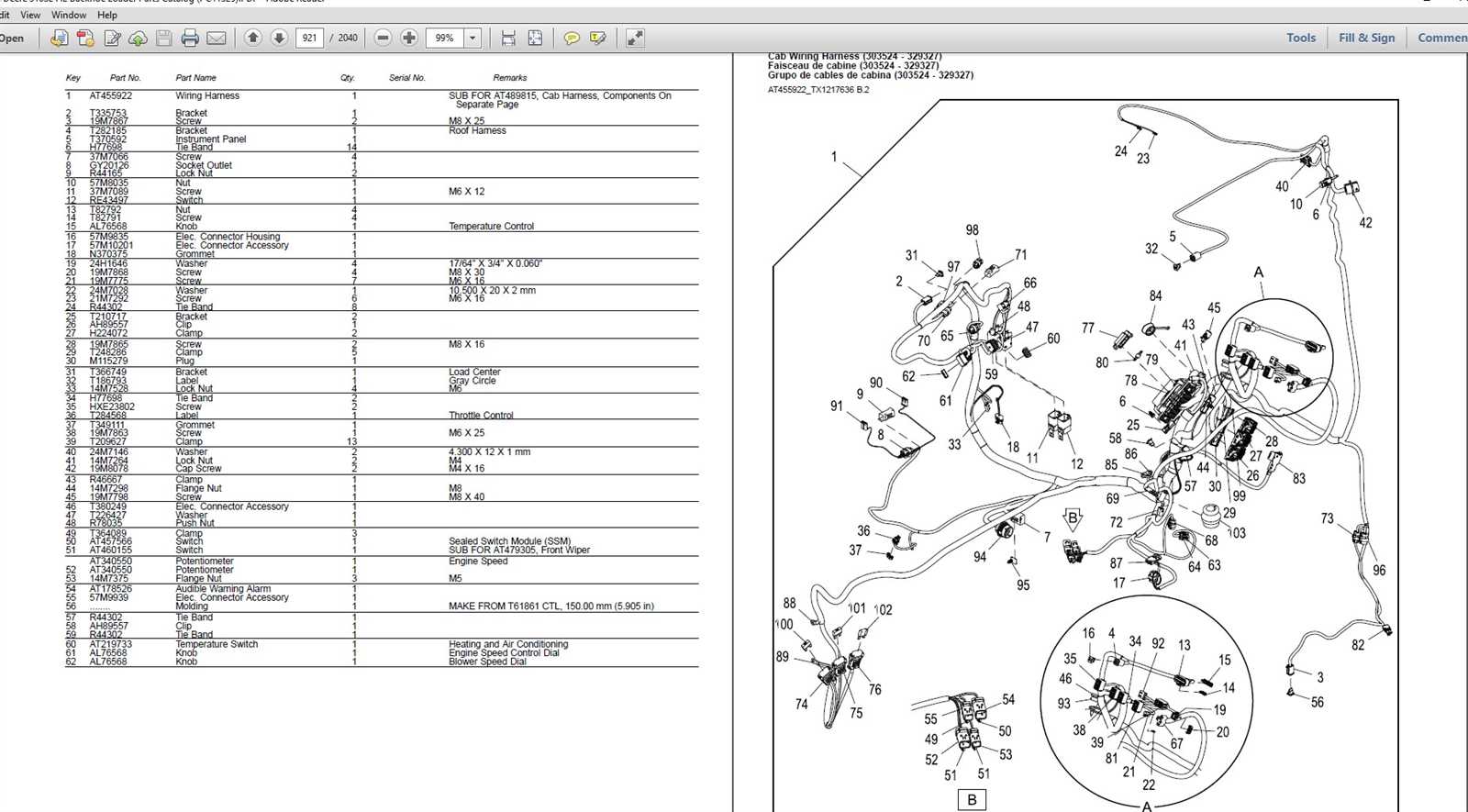

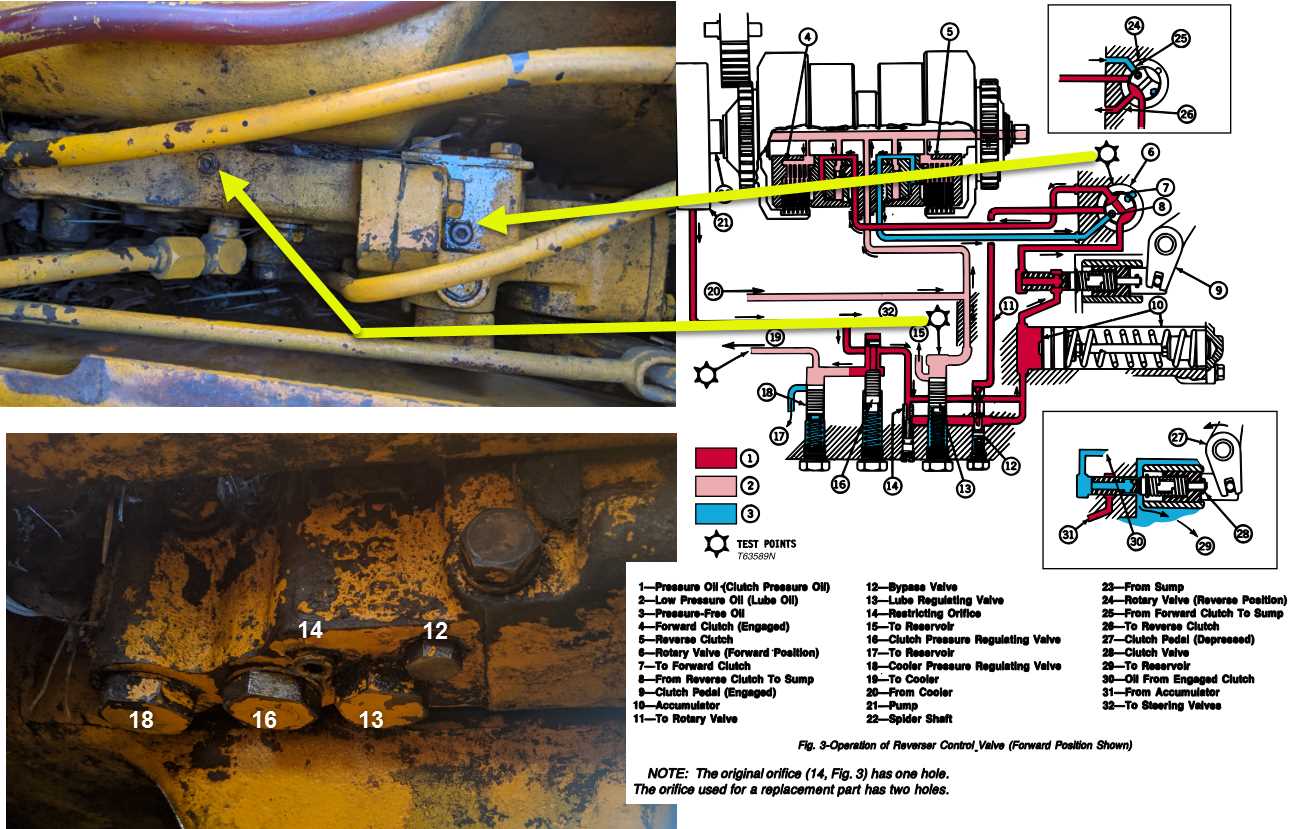

Diagram Overview for Maintenance

This section provides a comprehensive visual guide aimed at facilitating the upkeep of your machinery. Understanding the layout and functions of various components is essential for effective servicing and troubleshooting.

Importance of a Clear Visual Reference

Having a well-organized representation aids in identifying parts and understanding their interrelations. This clarity can significantly enhance maintenance efficiency, allowing for quicker repairs and optimal performance.

Key Components to Focus On

Pay special attention to the major assemblies and their corresponding functions. Regular inspection of these elements is crucial. Use this visual aid to locate wear points and potential issues before they escalate, ensuring the longevity of your equipment.

Identifying Key Components Easily

Understanding the primary elements of machinery is essential for efficient maintenance and repair. Familiarity with various components allows operators and technicians to quickly address issues and ensure optimal performance. This guide focuses on methods to recognize crucial elements, enhancing both knowledge and troubleshooting skills.

Common Element Types

Identifying different types of components can significantly streamline the repair process. Here are several common categories:

| Component Type | Description |

|---|---|

| Engine | The core power source, vital for operation. |

| Transmission | Responsible for power distribution and gear shifting. |

| Hydraulic System | Facilitates movement and operation of attachments. |

| Chassis | The framework that supports the entire structure. |

Tips for Identification

To enhance your ability to identify these components, consider utilizing visual aids and manuals. Regularly consulting these resources not only boosts confidence but also improves overall maintenance efficiency.

Common Issues with 350 Crawler Parts

When it comes to heavy machinery, certain challenges frequently arise with components that can hinder performance and efficiency. Understanding these common problems can help operators maintain their equipment effectively and prolong its lifespan.

- Wear and Tear: Regular usage leads to natural degradation of key elements, which can result in decreased functionality.

- Hydraulic Leaks: Fluid leaks can compromise hydraulic systems, leading to reduced power and responsiveness.

- Electrical Failures: Malfunctions in wiring and connections may cause operational interruptions, impacting overall performance.

- Track Issues: Problems with the undercarriage can cause uneven wear and affect stability during operation.

- Engine Performance: Lack of maintenance can lead to engine troubles, affecting power and efficiency.

Addressing these issues promptly through regular inspections and maintenance is essential to ensure reliable operation and avoid costly repairs.

Where to Source Replacement Parts

Finding quality components for machinery maintenance is crucial for optimal performance and longevity. Several reliable sources exist for acquiring these essential items, catering to a variety of needs and budgets.

Authorized Dealers often provide the most reliable options, ensuring compatibility and quality assurance. These establishments typically stock a wide range of items tailored specifically for particular models.

Online Marketplaces offer a convenient platform for sourcing components. Websites dedicated to heavy equipment allow users to compare prices and availability, making it easier to find the right fit.

Local Salvage Yards can also be a treasure trove of functional parts at lower prices. Inspecting items personally allows for thorough evaluation before purchase.

Aftermarket Suppliers present another viable avenue. These vendors manufacture alternatives that can provide similar functionality at a reduced cost, though caution is advised regarding quality and fit.

By exploring these various sources, operators can effectively locate the necessary items to keep their machinery running smoothly.

Benefits of Accurate Diagrams

Precision illustrations play a vital role in enhancing understanding and efficiency within technical fields. They provide a clear visual representation of complex systems, aiding users in identifying components and their relationships. This clarity not only streamlines maintenance but also minimizes errors during repairs.

Enhanced Understanding

Detailed visual representations foster a deeper comprehension of machinery. Users can quickly grasp how various elements interact, leading to more effective troubleshooting and servicing.

Improved Efficiency

Utilizing precise illustrations significantly reduces the time spent on repairs. Technicians can swiftly locate the necessary components and execute tasks with confidence, thus maximizing productivity.

| Benefit | Description |

|---|---|

| Clarity | Visuals simplify complex structures. |

| Speed | Quick identification of parts enhances workflow. |

| Accuracy | Minimized errors lead to reliable outcomes. |

DIY Repairs Using the Diagram

Undertaking maintenance on heavy machinery can be a rewarding experience, allowing operators to gain a deeper understanding of their equipment while saving on repair costs. Utilizing a detailed illustration of components can significantly enhance the repair process.

Here are some steps to effectively use the visual guide for your repairs:

- Identify the Issue: Start by determining what needs fixing. Listen for unusual sounds or observe performance issues.

- Consult the Illustration: Refer to the provided visual representation to locate the specific components related to the issue.

- Gather Necessary Tools: Ensure you have all required tools and replacement pieces before starting the repair.

- Follow the Steps: Adhere to the sequential instructions depicted in the guide for disassembly and reassembly.

- Test the Repair: Once repairs are complete, conduct a thorough test to confirm that everything functions correctly.

Engaging in this hands-on approach not only fosters a sense of accomplishment but also builds skills that can be invaluable for future projects.

Upgrading vs. Replacing Components

When considering enhancements for machinery, a critical decision revolves around whether to upgrade existing elements or to replace them entirely. Each approach has its merits and drawbacks, influencing both performance and cost-effectiveness.

Upgrading components often allows for improved functionality without the need for complete overhaul. This path can lead to:

- Cost savings, as upgrades can be less expensive than full replacements.

- Minimized downtime, allowing for quicker enhancements.

- Retention of familiar systems, which can ease the transition for operators.

Conversely, replacing components may be necessary under certain circumstances. Key reasons for full replacement include:

- Severe wear and tear that compromises safety.

- Incompatibility issues with newer technologies.

- Desire for the latest features that upgrades cannot provide.

Ultimately, the decision hinges on a careful assessment of the machinery’s condition, budget constraints, and operational needs.

Expert Tips for Long-lasting Performance

To ensure optimal functionality and durability of your machinery, it’s essential to implement several best practices. These recommendations will help enhance the longevity of your equipment while maintaining peak performance levels.

Regular Maintenance

Consistent upkeep is crucial. Schedule routine inspections to identify wear and tear before they escalate into major issues.

Quality Components

Utilizing high-grade materials and replacements can significantly influence the operational life. Always opt for reliable suppliers to ensure quality.

| Tip | Description |

|---|---|

| Routine Checks | Conduct inspections frequently to catch problems early. |

| Proper Lubrication | Keep all moving parts well-lubricated to minimize friction. |

| Environment Control | Avoid exposure to harsh conditions whenever possible. |

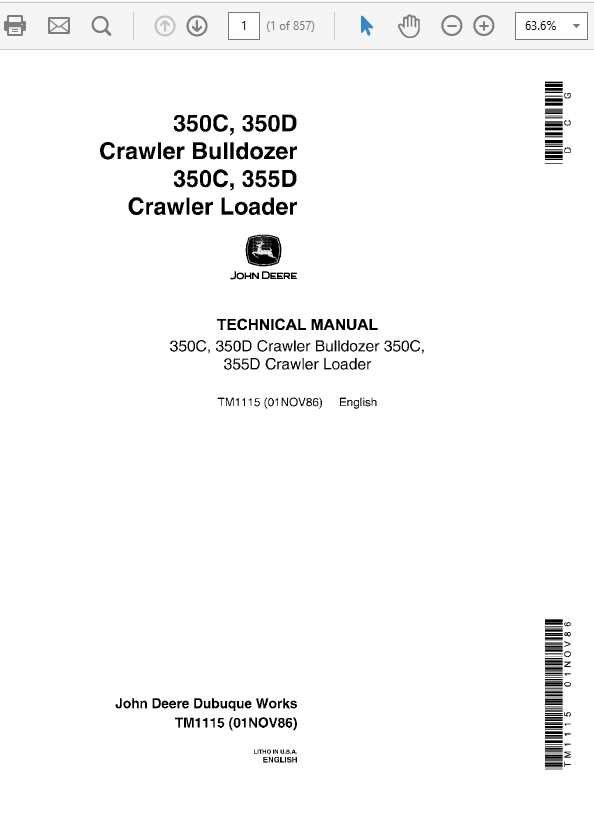

Resources for Further Learning

Expanding your knowledge about machinery and their components can greatly enhance your understanding and maintenance skills. Various resources are available to assist enthusiasts and professionals alike in gaining deeper insights into equipment functionality, repair techniques, and part identification.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms where users share experiences, troubleshooting tips, and advice on machinery. | Visit Forum |

| Technical Manuals | Official guides that provide detailed information on specifications, maintenance schedules, and repair instructions. | View Manuals |

| YouTube Tutorials | Video content covering practical demonstrations, repairs, and tips for equipment care. | Explore Tutorials |

| Workshops | Hands-on training sessions that offer real-time learning experiences with experts in the field. | Find Workshops |