Comprehensive Guide to John Deere 350 Hay Rake Parts Diagram

In the realm of modern farming, understanding the intricate mechanisms of machinery is crucial for efficient operation and maintenance. The various elements that constitute these machines play a vital role in optimizing agricultural productivity. Familiarity with the configuration and function of these components ensures seamless workflows and reduces the likelihood of equipment failures.

Every piece of machinery comes with its unique assembly, which requires careful attention to detail. By exploring the layout and interconnectivity of the different sections, operators can gain valuable insights into the maintenance requirements and potential troubleshooting procedures. This knowledge empowers users to perform routine inspections and necessary repairs, enhancing the longevity of their equipment.

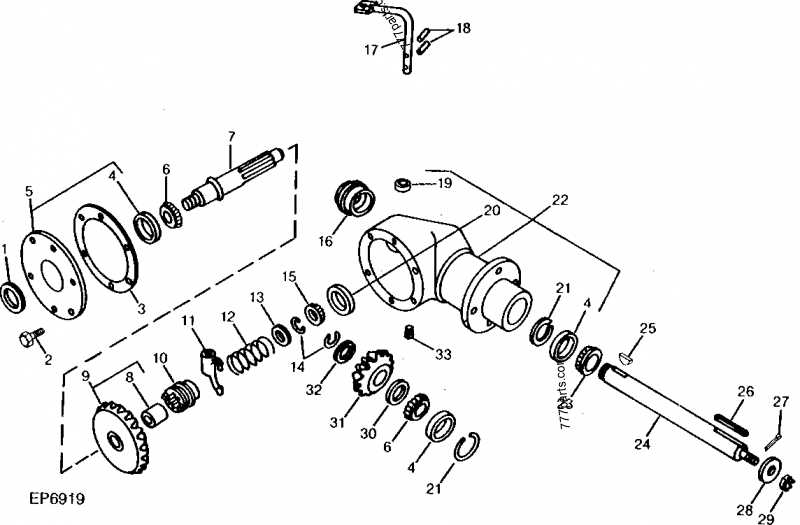

Furthermore, a clear visual representation of the machinery’s components can greatly aid in the understanding of its operation. Such diagrams serve as essential references, guiding users through the intricacies of assembly and disassembly. In the competitive field of agriculture, being well-informed about these crucial elements can lead to better resource management and improved yield outcomes.

Understanding John Deere 350 Hay Rake

This section explores the essential components and functionality of a specific agricultural implement designed for efficient crop handling. By understanding its design, users can enhance operational effectiveness and maintenance practices.

- Overview of Design: The implement features a robust framework that supports various attachments.

- Key Functionalities: It effectively gathers and organizes organic material, promoting efficient processing.

- Maintenance Considerations: Regular inspections and timely repairs are vital for longevity and performance.

In-depth knowledge of this machinery not only improves usage but also aids in troubleshooting common issues.

Key Features of the Hay Rake

This section highlights the essential characteristics that contribute to the efficiency and effectiveness of a forage gathering implement. Understanding these features can aid in selecting the right equipment for optimal performance in the field.

| Feature | Description |

|---|---|

| Durability | Constructed with robust materials to withstand harsh conditions and ensure longevity. |

| Adjustable Settings | Offers customizable settings to accommodate various types of vegetation and ground conditions. |

| Efficient Design | Engineered to minimize crop damage while maximizing the collection process. |

| Easy Maneuverability | Features a design that allows for smooth navigation in tight spaces and around obstacles. |

| Low Maintenance | Designed for easy upkeep, reducing downtime and operational costs. |

Common Parts of the 350 Model

This section provides an overview of the essential components found in the specified agricultural implement. Understanding these elements is crucial for efficient maintenance and optimal performance. Each piece plays a significant role in the overall functionality, ensuring reliable operation in various farming tasks.

Key Components

- Frame: The sturdy structure that supports the entire mechanism.

- Wheels: Designed for mobility, enabling easy transport across fields.

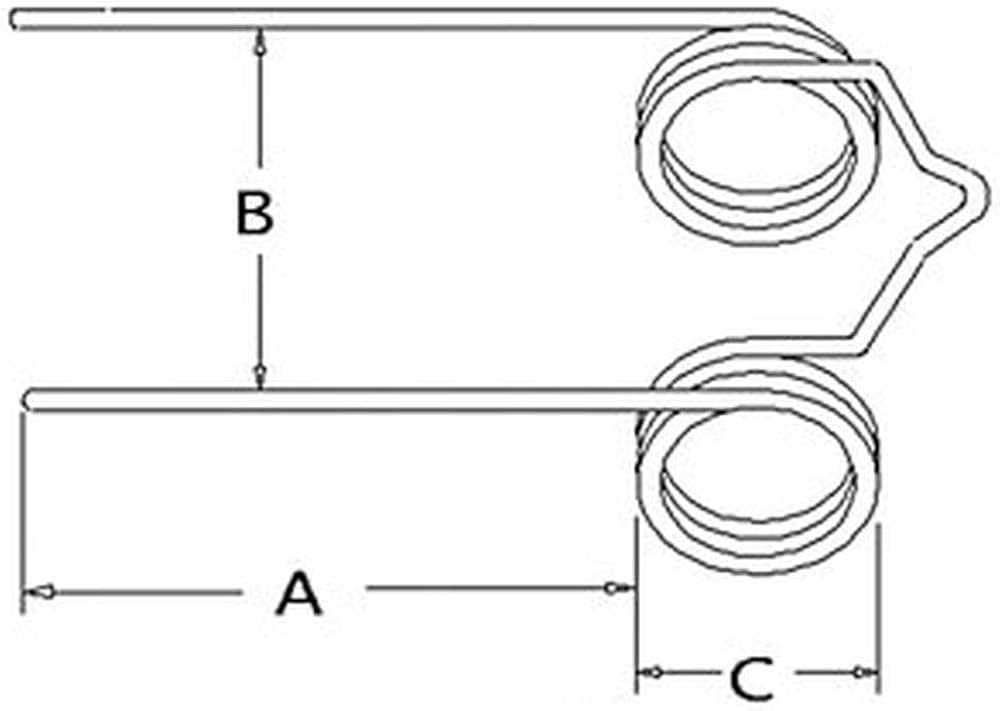

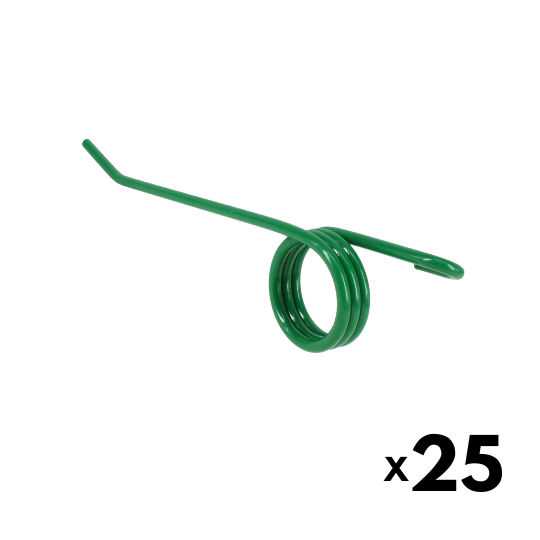

- Tines: These flexible prongs gather and distribute materials effectively.

- Gearbox: Transmits power from the tractor to the working components.

- Hitch: Connects the implement to the tractor for secure towing.

Additional Elements

- Springs: Provide tension and assist in the operation of the tines.

- Bearings: Facilitate smooth movement and reduce friction in moving parts.

- Adjustable Links: Allow customization of the working height and angle.

- Support Arms: Help maintain the stability of the implement during use.

- Lubrication Points: Ensure all moving parts function smoothly and efficiently.

Benefits of Regular Maintenance

Routine upkeep of machinery is essential for optimal performance and longevity. By consistently checking and servicing equipment, users can ensure that their tools operate efficiently and effectively, minimizing the risk of unexpected failures.

Enhanced Performance: Regular inspections can lead to improved functionality, allowing machines to operate at their peak potential. This translates to better productivity and reduced downtime.

Cost Savings: Investing time and resources in maintenance can prevent costly repairs in the future. Addressing minor issues early can save significant expenses down the line.

Increased Safety: Well-maintained equipment reduces the risk of accidents and injuries, providing a safer working environment for operators and nearby personnel.

Prolonged Lifespan: Consistent care extends the life of machinery, allowing for more extended use and better return on investment.

Ultimately, prioritizing regular maintenance is a proactive approach that yields numerous benefits, ensuring that equipment remains reliable and effective for years to come.

Identifying Worn Components

Recognizing components that have experienced wear is crucial for maintaining the efficiency and longevity of agricultural machinery. Regular inspections can help detect signs of fatigue and damage, allowing for timely replacements and minimizing operational disruptions.

Start by examining key elements for visible signs of wear, such as cracks, dents, or excessive rust. Surface irregularities can indicate a need for replacement, while components that appear overly thin may compromise functionality. Additionally, listen for unusual noises during operation, which can signal that specific parts are not functioning correctly.

It’s also important to assess the alignment and movement of moving parts. Any irregularities in motion can lead to increased strain, causing further degradation over time. Regular maintenance checks should include a detailed review of all operational elements to ensure optimal performance.

How to Access the Parts Diagram

Finding a visual reference for equipment components is essential for maintenance and repairs. This guide will help you navigate various resources to obtain a detailed illustration that outlines the various elements of your machinery.

Begin by visiting the manufacturer’s official website, where you can typically find a dedicated section for resources and manuals. Look for an area labeled ‘Support’ or ‘Customer Service’ to locate specific documentation related to your model.

Another useful option is to consult online forums or community groups focused on agricultural equipment. Experienced users often share valuable insights and links to schematics that can aid in your search.

Additionally, consider reaching out to local dealers or repair shops. They usually possess extensive knowledge and may provide you with copies of the necessary illustrations or guide you to where they can be accessed.

Lastly, online retailers that specialize in machinery components often feature breakdowns and visual aids that can assist you in understanding the configuration of your equipment.

Ordering Replacement Parts Easily

Acquiring necessary components for agricultural equipment can be a straightforward process when approached systematically. Understanding how to efficiently locate and order the required items ensures minimal downtime and optimal performance of machinery.

Steps to Streamline Your Ordering Process

Follow these essential steps to simplify your procurement journey:

| Step | Description |

|---|---|

| 1 | Identify the exact components needed by consulting your machinery’s manual or maintenance guidelines. |

| 2 | Use reputable online platforms or local suppliers that specialize in agricultural equipment to find the right items. |

| 3 | Check for availability and compare prices to ensure you get the best deal. |

| 4 | Place your order, ensuring to double-check part numbers and specifications. |

| 5 | Track your shipment to stay updated on delivery times and ensure timely receipt. |

Helpful Resources for Efficient Ordering

Utilizing specific resources can further enhance your ordering experience. Consider accessing online forums or communities where fellow operators share their insights on reliable suppliers and best practices. Additionally, manufacturers’ websites often provide detailed catalogs that can assist in identifying components quickly.

Installation Tips for New Parts

When it comes to replacing components in agricultural machinery, ensuring proper installation is crucial for optimal performance and longevity. This section provides essential guidance to help you navigate the installation process smoothly and effectively.

Preparation and Inspection

Before beginning the installation, thoroughly inspect the new components. Check for any visible damage and ensure that all necessary tools are available. Read the manufacturer’s instructions carefully to familiarize yourself with the specific requirements for your equipment.

Proper Alignment and Fastening

During installation, pay close attention to alignment of the new components. Misalignment can lead to premature wear and inefficiency. Ensure that all fasteners are tightened according to the recommended torque specifications, as under-tightening or over-tightening can create further complications.

Common Repairs and Solutions

Maintaining agricultural equipment is crucial for optimal performance and longevity. Regular inspections can help identify common issues before they escalate into significant problems. Below are some frequent repairs and effective solutions to keep your machinery running smoothly.

Frequent Issues

- Worn-out components

- Alignment problems

- Hydraulic leaks

- Electrical failures

Repair Solutions

- Replace worn parts with high-quality replacements to ensure durability.

- Regularly check and adjust alignments to avoid excessive wear.

- Inspect hydraulic systems and tighten connections to fix leaks.

- Test electrical systems and replace faulty wiring or components as needed.

Safety Precautions When Operating

Ensuring safety during equipment operation is crucial to prevent accidents and injuries. Adhering to established guidelines and maintaining vigilance can create a secure environment for both the operator and bystanders.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes gloves, goggles, and sturdy footwear to shield against potential hazards while handling machinery.

Pre-Operational Checks

Conducting thorough inspections before use is vital. Check for loose parts, leaks, and ensure all safety features are functional to minimize risks during operation.

Performance Enhancements for the Rake

Optimizing the efficiency of agricultural implements can lead to significant improvements in productivity and ease of use. By focusing on specific modifications and upgrades, operators can achieve superior results in their fieldwork.

- Upgraded Teeth: Consider using stronger materials for the tines to enhance durability and performance.

- Improved Wheel Design: Larger or more robust wheels can provide better traction and reduce soil compaction.

- Enhanced Adjustment Features: Implementing more precise adjustment options can allow for tailored settings based on varying conditions.

Additionally, routine maintenance plays a crucial role in maintaining optimal functionality:

- Regular Lubrication: Ensure all moving parts are properly lubricated to minimize friction and wear.

- Inspection of Components: Frequently check for wear and tear on key components to avoid breakdowns.

- Alignment Checks: Keeping the equipment aligned ensures uniform operation and reduces strain.

By incorporating these enhancements and maintenance practices, users can achieve the ultimate in performance from their implements.

Comparing Other John Deere Models

This section explores the features and specifications of various agricultural equipment from the same manufacturer, highlighting the differences and similarities across models. By examining these alternatives, users can make informed decisions tailored to their specific needs.

Key Features Comparison

| Model | Weight | Working Width | Power Requirement |

|---|---|---|---|

| Model A | 1,200 lbs | 10 ft | 30 HP |

| Model B | 1,500 lbs | 12 ft | 35 HP |

| Model C | 1,800 lbs | 14 ft | 40 HP |

Performance Insights

Different models excel in various conditions, making it essential to evaluate performance based on terrain and intended use. This analysis allows operators to select equipment that provides the ultimate efficiency and productivity.

Resources for Further Information

When seeking to enhance your understanding of agricultural equipment and its components, a variety of valuable resources are available. These can provide insights into maintenance, troubleshooting, and effective usage of machinery, ensuring optimal performance and longevity. Accessing the right materials can significantly improve your familiarity with these essential tools.

Online Manuals and Guides

Numerous websites offer downloadable manuals and detailed guides. These documents often include schematics, operational instructions, and maintenance tips, making them indispensable for both novice and experienced operators. Online forums and community groups can also be excellent sources of shared knowledge and practical advice.

Parts Suppliers and Retailers

Many suppliers provide extensive catalogs featuring a wide array of components and accessories. These catalogs often include diagrams that illustrate the layout and function of each part, facilitating easier identification and ordering. Consulting with reputable retailers can also offer additional support in sourcing specific items or advice on compatible alternatives.