Comprehensive Guide to John Deere 4300 Parts Diagrams

In the realm of heavy equipment maintenance, having a clear visual reference for each component is crucial. This allows operators and technicians to identify, replace, or repair elements with precision, ensuring optimal performance and longevity.

The ability to navigate through these visual guides not only streamlines the repair process but also enhances the overall efficiency of machinery operations. By gaining insights into the arrangement and functionality of various elements, one can address issues more effectively.

Ultimately, accessing these detailed illustrations empowers users to delve deeper into their understanding of the machinery, leading to informed decisions and improved maintenance practices. Whether for troubleshooting or routine checks, such resources are invaluable in the world of equipment management.

Understanding John Deere 4300 Models

This section explores the various configurations and features of a specific line of agricultural machinery, focusing on their operational capabilities and unique characteristics. Each model offers distinct advantages that cater to different farming needs.

Performance and Versatility: The machinery is designed to handle a variety of tasks, from tilling to hauling. Its adaptability makes it suitable for diverse farming environments.

Specifications and Features: Understanding the technical specifications can help users select the ideal model for their requirements, ensuring optimal performance in the field.

By examining the range of options available, operators can make informed decisions that enhance productivity and efficiency in their agricultural operations.

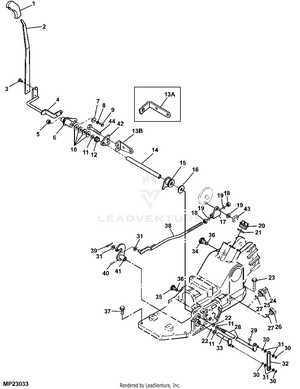

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery and equipment assembly. These illustrations provide clarity on the relationships between different elements, making it easier for technicians and users to identify necessary replacements or repairs. By utilizing such resources, one can enhance the maintenance process and improve overall efficiency.

Facilitating Maintenance

Clear visuals streamline maintenance tasks by allowing individuals to quickly locate specific pieces. This efficiency reduces downtime and minimizes the risk of errors during repairs, ensuring that machinery operates smoothly and reliably.

Enhancing Troubleshooting

These visual aids are invaluable when diagnosing issues. By analyzing the layout and connections of components, users can delve into potential problems more effectively, leading to faster resolutions and better decision-making regarding repairs or replacements.

Common Issues with John Deere 4300

When it comes to machinery maintenance, certain challenges frequently arise that can hinder performance and efficiency. Understanding these common problems can help operators identify and address issues before they escalate, ensuring smoother operation and longevity of the equipment.

Mechanical Problems

Several mechanical issues may occur, impacting functionality. Regular inspections and maintenance are crucial to avoid these complications:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Engine Misfire | Poor acceleration, rough idling | Check spark plugs, ignition system |

| Hydraulic Leaks | Visible fluid loss, decreased lifting capacity | Inspect hoses, seals, and fittings |

| Transmission Slipping | Unresponsive shifting, loss of power | Check fluid levels, inspect the clutch |

Electrical Issues

Electrical malfunctions can also arise, causing disruptions in operation. Here are some typical electrical concerns:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Battery Drain | Difficulty starting, dim lights | Test battery health, check connections |

| Faulty Sensors | Error codes, warning lights | Inspect wiring, replace malfunctioning sensors |

| Wiring Issues | Intermittent power loss, short circuits | Examine wiring harness, repair as needed |

Where to Find Diagrams Online

Locating detailed illustrations and schematics for machinery can significantly enhance repair and maintenance efforts. A variety of resources are available online, catering to different needs and preferences.

- Manufacturer Websites: Often the most reliable source, these platforms usually provide comprehensive manuals and visual aids directly related to their equipment.

- Online Marketplaces: Websites that sell machinery often include images and breakdowns of components to assist buyers in understanding what they are purchasing.

- Forums and Community Groups: Enthusiast communities often share valuable resources, including illustrations and user-generated content that can aid in troubleshooting and repairs.

- Technical Publications: Numerous websites specialize in providing manuals and schematics, often available for download or purchase.

Utilizing these resources can streamline the process of finding the necessary information to maintain and repair equipment effectively.

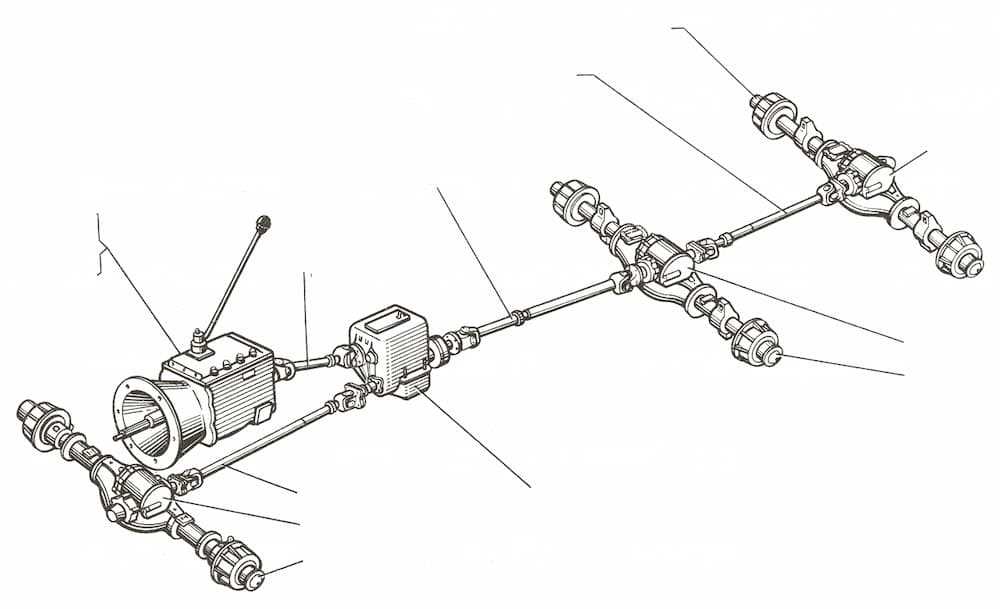

Identifying Key Components

Understanding the main elements of machinery is essential for effective maintenance and operation. By recognizing these critical parts, users can enhance performance and ensure longevity. A comprehensive overview of these components helps in troubleshooting and optimizing functionality.

Each unit comprises specific sections that contribute to its overall efficiency. Familiarity with these areas enables operators to identify wear and potential issues early. This proactive approach minimizes downtime and facilitates smoother workflows.

Key components often include the engine assembly, transmission systems, hydraulic units, and electrical setups. Knowing the function and location of each part allows for better planning when it comes to repairs or upgrades.

Regular reference to detailed schematics can significantly aid in this identification process. By delving into the intricacies of these diagrams, users can develop a more profound understanding of their machinery’s design and capabilities.

Maintenance Tips for Longevity

Proper upkeep of your machinery is essential for ensuring its durability and optimal performance. By adhering to a consistent maintenance routine, you can significantly extend the lifespan of your equipment and reduce the likelihood of costly repairs.

- Regular Inspections: Conduct frequent checks to identify any signs of wear or damage. Early detection can prevent larger issues.

- Fluid Changes: Change oils and other fluids according to the manufacturer’s recommendations to keep components lubricated and functioning smoothly.

- Filter Replacements: Regularly replace air, oil, and fuel filters to ensure efficient operation and prevent contaminants from causing damage.

- Cleaning: Keep the machine clean by removing dirt, debris, and grease, which can hinder performance and lead to corrosion.

- Proper Storage: Store equipment in a dry, sheltered location to protect it from the elements and minimize wear.

Implementing these practices will not only enhance the reliability of your machinery but also promote safety and efficiency during operation.

Replacement Parts Options Available

When it comes to maintaining agricultural machinery, ensuring the availability of high-quality components is crucial. A variety of choices are at your disposal, catering to different needs and preferences. Understanding these options will help you make informed decisions that enhance the performance and longevity of your equipment.

OEM Components are designed to meet the original specifications of the machinery. These parts guarantee compatibility and reliability, ensuring that your equipment operates as intended. They are often recommended for those who prioritize quality and want to maintain the manufacturer’s standards.

Aftermarket Alternatives offer a cost-effective solution without sacrificing performance. Many manufacturers produce these components that can be compatible with the original equipment. However, it’s essential to research and select reputable brands to ensure you are getting durable and efficient replacements.

Used Components can provide significant savings while still delivering functional reliability. Sourcing pre-owned parts from trustworthy suppliers can be a sustainable choice, as it promotes recycling and reduces waste. However, thorough inspection is vital to ensure they are in good working condition.

Custom Solutions may be necessary for specialized machinery or unique applications. Collaborating with skilled technicians can help design and fabricate parts tailored to specific requirements, ensuring optimal performance in unique scenarios.

Exploring these various options enables owners to find the best fit for their machinery maintenance needs, balancing cost, quality, and performance effectively.

DIY Repair vs. Professional Help

When it comes to fixing machinery, there are two primary routes individuals can take: tackling the repairs themselves or seeking assistance from a skilled technician. Each option carries its own advantages and challenges, influencing both the cost and time required for the task. Understanding these factors is crucial for making an informed decision.

Advantages of DIY Repair

- Cost Savings: Handling repairs independently can significantly reduce expenses, as you won’t need to pay for labor.

- Skill Development: Engaging in hands-on work can enhance your mechanical skills and knowledge.

- Flexibility: You can work on your own schedule, allowing for greater convenience.

- Satisfaction: Successfully completing a repair can provide a sense of accomplishment.

Benefits of Professional Assistance

- Expertise: Professionals bring specialized knowledge and experience, ensuring high-quality repairs.

- Time Efficiency: Skilled technicians can often complete repairs more quickly than a novice.

- Warranty Protection: Work done by professionals may come with guarantees, providing peace of mind.

- Complex Issues: Some repairs require advanced tools and skills that may be beyond the average DIYer.

Ultimately, the choice between DIY repairs and hiring a professional depends on the complexity of the issue, your comfort level with mechanical work, and your available resources. Weighing the pros and cons will help determine the best approach for your specific situation.

Cost Considerations for Parts

Understanding the financial implications of component acquisition is crucial for effective maintenance and repair planning. Different factors influence expenses, including quality, availability, and supplier pricing. Evaluating these elements can help in making informed decisions, ultimately leading to cost-efficient operations.

Factors Influencing Costs

Several key factors play a role in determining the overall expense of components:

| Factor | Description |

|---|---|

| Quality | Higher quality items may come at a premium but can enhance longevity. |

| Supplier | Different vendors may offer varied pricing for similar items. |

| Availability | Items in stock can reduce waiting times and potential operational delays. |

Budgeting for Repairs

Creating a budget that includes potential component costs helps in financial planning. Allocating funds for both anticipated and unexpected repairs ensures that resources are available when needed. This proactive approach ultimately contributes to smoother operations and minimizes downtime.

Upgrading Your John Deere Equipment

Enhancing your machinery can significantly improve efficiency and performance. Whether you’re looking to boost power, increase durability, or add new features, understanding the options available is crucial. Regularly updating components not only extends the life of your equipment but also ensures it operates at its peak potential.

Consider evaluating the current capabilities of your machine and identifying areas for improvement. From advanced attachments to upgraded systems, the right enhancements can transform how you work. Researching compatible upgrades will allow you to make informed decisions that align with your operational goals.

Always prioritize quality when selecting new components. Investing in reliable upgrades can minimize downtime and reduce long-term costs. Additionally, consulting with experts or fellow operators can provide valuable insights into effective enhancements tailored to your specific needs.

Customer Reviews on Parts Quality

This section explores the feedback from users regarding the quality of components associated with agricultural machinery. Many individuals have shared their experiences, highlighting the durability, performance, and reliability of various replacements. These insights help potential buyers make informed decisions based on real-world usage.

Overall, reviews frequently emphasize the robustness of these components, with numerous users noting that they stand up well under demanding conditions. A common theme is the value for money, as many find that high-quality alternatives outperform cheaper options in the long run. Satisfaction levels often correlate with the ease of installation and compatibility with existing machinery.

Additionally, customers appreciate responsive support from suppliers when issues arise, which contributes to their overall positive experience. The collective feedback underscores the importance of choosing reliable replacements to ensure optimal functioning and longevity of equipment.

FAQs About John Deere 4300 Parts

This section addresses common inquiries regarding components and maintenance for a specific agricultural vehicle. Understanding the most frequent questions can help users make informed decisions about repairs and replacements.

What should I consider when purchasing components?

When seeking to acquire replacement elements, it is essential to verify compatibility with your specific model. Additionally, checking for quality and warranty options can ensure longevity and performance. Always consult with a knowledgeable supplier to clarify any doubts.

How do I identify the right component for my vehicle?

Identifying the correct item can be accomplished by referencing the vehicle’s manual, which typically includes detailed specifications and part numbers. Utilizing online resources and forums can also provide valuable insights from other users who have experienced similar needs.

Regular maintenance is key to prolonging the lifespan of your equipment. Ensuring timely replacements can prevent larger issues down the line, saving time and costs associated with extensive repairs.

Always seek professional assistance if you’re uncertain about installations or troubleshooting. Proper guidance can enhance safety and efficiency when working with machinery.