Comprehensive Parts Diagram for John Deere 5520

In the world of agricultural equipment, having a comprehensive grasp of the individual components is essential for effective maintenance and repair. Recognizing how each piece functions within the overall system allows operators to enhance efficiency and longevity. This section aims to shed light on the intricacies involved in identifying and managing these vital elements.

Moreover, visual aids play a crucial role in simplifying the complexities associated with machinery assembly and disassembly. They offer a clear representation of how different segments interconnect, facilitating better comprehension for both novice and experienced users. This exploration is designed to equip you with the knowledge necessary to tackle challenges that may arise.

Whether you are a seasoned professional or a newcomer in the field, understanding the layout and function of each component empowers you to make informed decisions. Ultimately, this knowledge fosters a more proficient handling of machinery, ensuring optimal performance and minimal downtime.

Overview of John Deere 5520

This section provides a comprehensive look at a popular agricultural machine known for its efficiency and reliability. Designed to meet the needs of modern farming, this vehicle combines advanced technology with robust engineering to deliver superior performance in various tasks.

Features of this model include a powerful engine, excellent maneuverability, and a user-friendly interface that enhances productivity. The machine is equipped with various attachments, allowing it to perform multiple functions, from tilling to hauling.

In addition, maintenance plays a crucial role in ensuring longevity and optimal functionality. Regular servicing and familiarity with the internal structure contribute significantly to the performance and durability of the equipment.

Overall, this agricultural machine stands out for its versatility and the ability to adapt to different farming conditions, making it an invaluable asset for any operator.

Importance of Parts Diagrams

The visual representation of components is essential in understanding machinery assembly and functionality. These illustrations serve as vital tools for maintenance, repair, and troubleshooting, enabling users to identify each element and its role within the system.

Accurate references facilitate efficient repairs, minimizing downtime and ensuring optimal performance. When technicians can easily locate and recognize specific pieces, they can quickly address issues and implement solutions.

Moreover, comprehensive visuals enhance learning, especially for those new to mechanical work. Familiarity with the layout promotes confidence, making complex tasks more approachable. In essence, such representations are invaluable for both seasoned professionals and beginners alike.

Main Components of the 5520

This section delves into the essential elements that constitute the functionality and efficiency of this agricultural machinery. Understanding these core components is crucial for operators and maintenance personnel to ensure optimal performance and longevity.

Powertrain System

- Engine: The heart of the machine, providing the necessary power for various tasks.

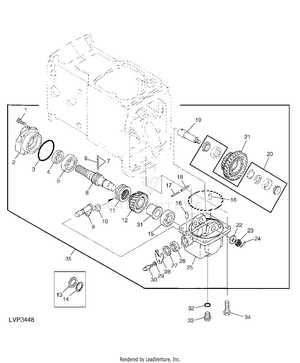

- Transmission: Facilitates smooth shifting and control over different speeds and torque levels.

- Drive Shaft: Connects the engine to the transmission, transferring power effectively.

Operational Components

- Hydraulic System: Powers implements and attachments, enabling efficient operation.

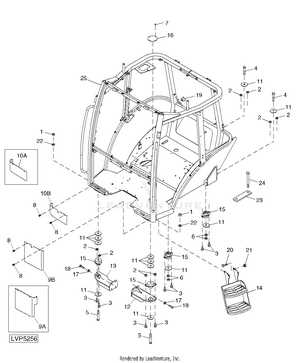

- Chassis: The structural framework that supports all components and ensures stability.

- Cab: Provides the operator with a comfortable and controlled environment for handling tasks.

Each of these components plays a vital role in ensuring that the machinery operates effectively, contributing to productivity and ease of use in agricultural settings.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed view of various elements, enabling users to identify and locate each piece accurately. By mastering the interpretation of these visuals, individuals can enhance their troubleshooting skills and streamline their repair processes.

Key Elements to Look For

When examining a visual representation, pay attention to the following elements:

| Element | Description |

|---|---|

| Labels | Identify each component with corresponding references for easier lookup. |

| Symbols | Understand the common icons used to represent various parts, as they can vary between manufacturers. |

| Connections | Note how different components interact and connect to one another within the system. |

Steps for Effective Interpretation

To effectively interpret these visuals, follow these steps: first, familiarize yourself with the layout. Next, cross-reference each label with your repair manual. Finally, take notes on any parts that may require replacement or attention during your maintenance routine.

Common Repairs for the 5520

Regular maintenance and timely repairs are essential for ensuring the longevity and efficiency of agricultural machinery. Understanding common issues can help operators address problems before they escalate, minimizing downtime and repair costs. This section explores frequent repairs needed for these machines, providing insights into solutions and preventive measures.

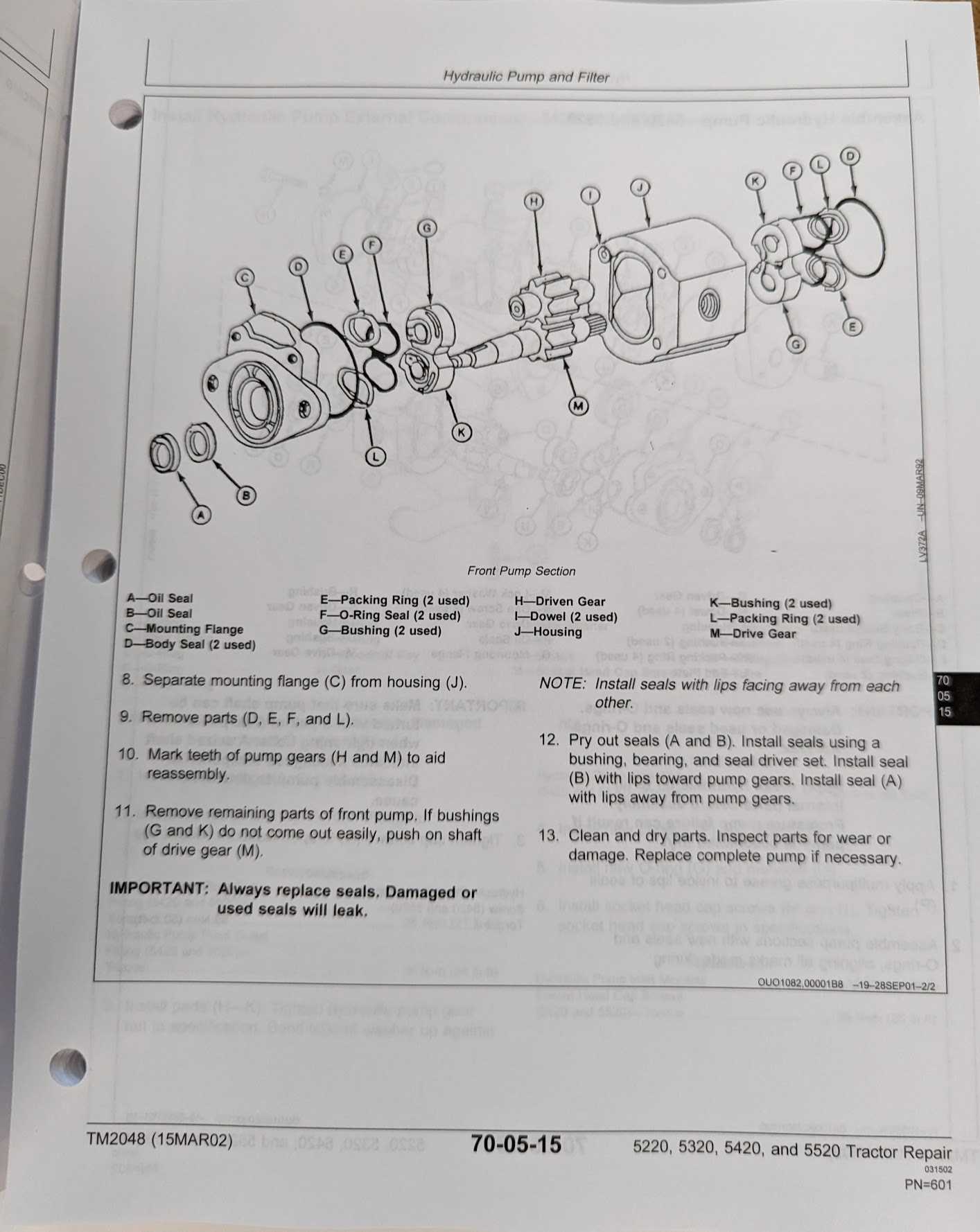

Hydraulic System Issues

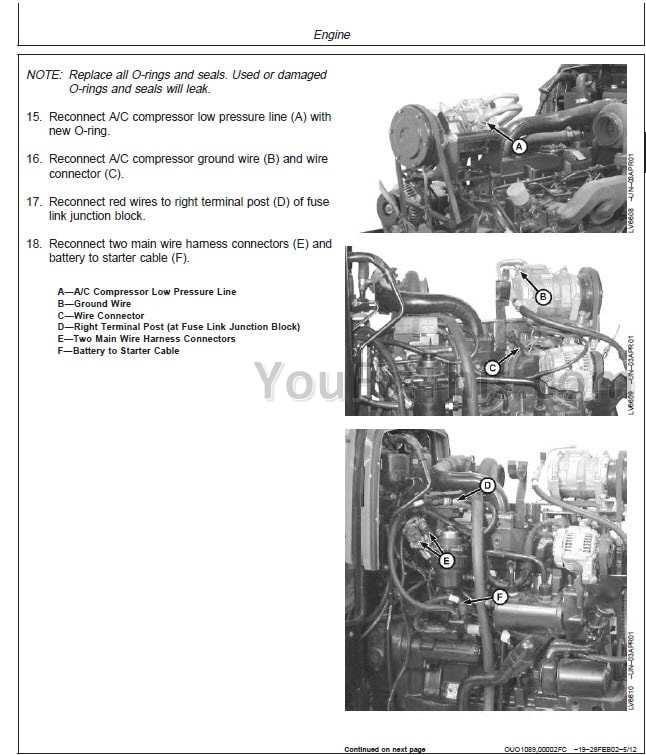

One of the most prevalent problems involves the hydraulic system. Operators may encounter leaks or reduced pressure, often stemming from worn seals or damaged hoses. Regular inspections and timely replacement of components can prevent more serious issues from arising, ensuring optimal performance during critical tasks.

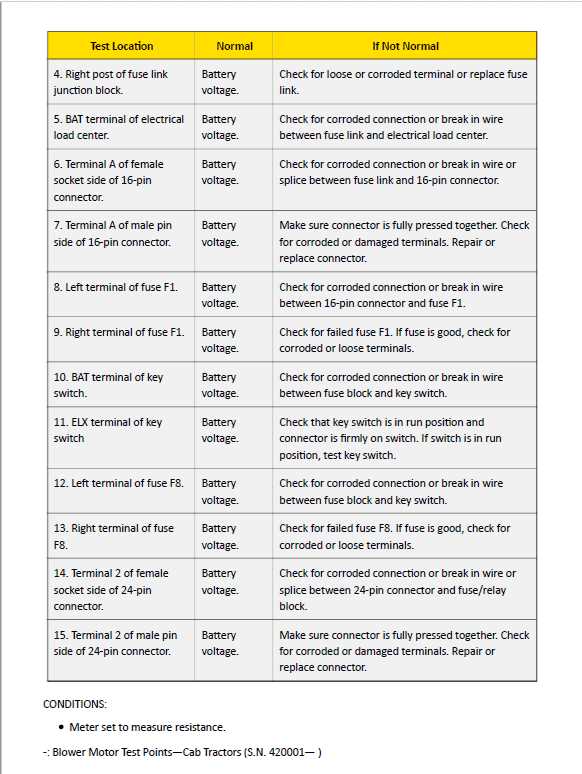

Electrical System Failures

Electrical malfunctions can lead to operational failures, including starting issues or malfunctioning lights. Common culprits include faulty wiring and corroded connections. Routine checks of the electrical system, along with cleaning and securing connections, can help maintain functionality and avoid unexpected breakdowns.

Finding Replacement Parts Easily

Locating suitable components for agricultural machinery can often be a daunting task. With numerous models and variations available, understanding where to search for quality replacements is crucial for maintaining equipment efficiency. Streamlining this process not only saves time but also ensures that you have the correct items to keep your machinery running smoothly.

Utilizing Online Resources

The internet is a valuable tool for discovering suitable replacements. Many specialized websites offer detailed catalogs and user-friendly search options, allowing you to filter results based on specific criteria. By entering your machine’s model number, you can quickly access a comprehensive list of compatible components, ensuring you find exactly what you need.

Consulting User Manuals

User manuals often contain critical information regarding compatible components and their specifications. These documents provide insights into maintenance procedures and can guide you in identifying the correct items. Keeping a digital or physical copy of the manual can enhance your ability to source appropriate replacements efficiently.

Tips for Maintenance and Care

Regular upkeep and attentive care are essential for ensuring optimal performance and longevity of agricultural machinery. By following a systematic approach to maintenance, operators can prevent costly repairs and enhance the efficiency of their equipment.

1. Schedule Routine Inspections: Establish a timeline for regular checks on key components. This proactive measure allows for early identification of wear and potential issues before they escalate.

2. Keep Clean: Regularly remove dirt, debris, and residues from the machine’s surfaces and internal parts. A clean environment minimizes the risk of corrosion and ensures smooth operation.

3. Lubrication: Ensure that all moving parts are adequately lubricated. Using the appropriate lubricants can reduce friction, enhance performance, and extend the lifespan of mechanical components.

4. Monitor Fluid Levels: Regularly check and maintain fluid levels, including oil, coolant, and hydraulic fluids. Proper fluid maintenance is critical for the efficient functioning of all systems.

5. Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance schedules and part replacements. This ensures that the equipment operates as intended and remains within warranty requirements.

6. Store Properly: When not in use, ensure that the machinery is stored in a sheltered environment to protect it from harsh weather conditions. Proper storage prevents damage and prolongs the life of the equipment.

By implementing these maintenance strategies, operators can ensure their machinery remains reliable and effective for all agricultural tasks.

Comparing OEM vs. Aftermarket Parts

The choice between original manufacturer components and alternative options is a significant consideration for many users. Each category presents unique advantages and potential drawbacks, influencing overall performance, durability, and cost-effectiveness.

Benefits of OEM Components

- Precision fit and compatibility with the original equipment.

- Guaranteed quality and reliability, often backed by warranties.

- Support from the manufacturer in case of issues.

Advantages of Aftermarket Alternatives

- Typically lower prices, offering cost savings.

- Wide variety of options and features that may enhance performance.

- Availability from multiple suppliers, increasing accessibility.

Ultimately, the decision should be based on specific needs, budget considerations, and the importance of reliability in operation.

Tools Needed for Repairs

Successful maintenance and repairs require a range of essential tools to ensure efficiency and effectiveness. Utilizing the right equipment not only simplifies the process but also enhances safety and precision. Below are the key items needed for optimal repair work.

Essential Hand Tools

- Wrenches

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and standard)

- Torque wrench

Power Tools

- Drill

- Angle grinder

- Impact wrench

- Jigsaw

- Rotary tool

Having these tools readily available will streamline the repair process and contribute to a successful outcome.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in modern machinery, enabling efficient power transmission and enhanced functionality. By utilizing fluid dynamics, these systems facilitate the movement and control of various components, allowing for precise operations across different applications.

The fundamental principles governing hydraulic systems include:

- Fluid Power: The use of incompressible fluids to transfer energy and perform work.

- Pressure: The force exerted by the fluid within the system, essential for movement and operation.

- Flow Rate: The volume of fluid passing through the system over time, influencing speed and efficiency.

Key components of hydraulic systems typically consist of:

- Pumps: Devices that generate fluid flow and pressure.

- Actuators: Mechanisms that convert hydraulic energy into mechanical motion.

- Valves: Control elements that regulate fluid flow and pressure within the system.

- Reservoirs: Storage units for hydraulic fluid, ensuring a consistent supply.

- Filters: Components that remove contaminants, maintaining fluid integrity.

Understanding these elements is essential for troubleshooting and optimizing system performance, ensuring reliable operation and longevity of machinery.

Electrical System Overview

The electrical system of agricultural machinery plays a crucial role in ensuring the proper functioning of various components. It encompasses everything from power generation to distribution, allowing for efficient operation of essential systems such as lighting, ignition, and control interfaces.

Key Components

This system includes several vital elements that contribute to its overall effectiveness. The major components are the battery, alternator, wiring harness, and various sensors that monitor and manage functionality.

| Component | Description |

|---|---|

| Battery | Stores electrical energy and provides power for starting the engine. |

| Alternator | Generates electricity while the engine runs, recharging the battery. |

| Wiring Harness | Connects electrical components, facilitating the flow of current. |

| Sensors | Monitor various parameters and ensure optimal performance. |

System Functionality

The electrical system operates by converting mechanical energy into electrical energy, enabling various functions that enhance operational efficiency. Proper maintenance and understanding of this system are essential for reliable performance in the field.

Resources for Further Information

For those seeking comprehensive knowledge about machinery components and their assembly, various reliable sources can provide essential insights and guidance. Whether you are a technician, a hobbyist, or a farmer, having access to detailed resources will enhance your understanding and ability to maintain equipment effectively.

- Manufacturer Websites: Official sites often offer manuals, FAQs, and service guides that are crucial for accurate information.

- Online Forums: Community-driven platforms allow users to share experiences, troubleshooting tips, and advice related to specific machinery.

- Instructional Videos: Video tutorials on platforms like YouTube can visually guide users through repairs and maintenance procedures.

- Parts Retailers: Many retailers provide detailed catalogs and schematics to assist in identifying and ordering components.

- Local Dealerships: Authorized dealerships often have knowledgeable staff who can provide expert advice and access to genuine components.

Utilizing these resources will ensure that you have a well-rounded understanding of your machinery, enabling effective maintenance and operation.