Parts Diagram for John Deere 566 Baler

In the world of agricultural machinery, comprehending the intricate components of equipment designed for harvesting is essential. These machines play a vital role in the efficient collection and processing of forage, ensuring that farmers can maximize their productivity. A thorough grasp of how each element interacts within the system is crucial for optimal performance and maintenance.

Every unit consists of various segments, each with a specific function that contributes to the overall operation. Recognizing the layout and connections between these elements allows for better troubleshooting and repair. By exploring the organization of these components, users can enhance their understanding and efficiency, leading to improved results in their agricultural practices.

Additionally, familiarizing oneself with these parts can aid in effective maintenance routines. Proper care and timely replacement of worn elements can significantly extend the lifespan of the machinery. This knowledge empowers operators to keep their equipment running smoothly, ultimately leading to a more successful harvesting season.

This section provides a comprehensive overview of the essential components and configurations found in a specific agricultural machinery model. By exploring the various elements involved, readers will gain valuable insights into the structure and functionality of this device, enhancing their understanding of its operation and maintenance.

1. Introduction to Agricultural Machinery

An overview of the significance of equipment in farming and its role in enhancing productivity.

2. The Importance of Component Knowledge

Understanding individual parts is crucial for effective operation and troubleshooting of machinery.

3. Overview of the Machine’s Functionality

A description of how the equipment operates and its purpose within farming operations.

4. Key Elements of the Mechanism

Highlighting the main components that contribute to the machine’s efficiency.

5. Types of Mechanisms Used

A discussion on various mechanical systems utilized in the equipment.

6. Maintenance Requirements

Essential upkeep practices to ensure longevity and optimal performance of the machinery.

7. Common Issues and Troubleshooting

Identifying frequent problems and offering solutions to rectify them effectively.

8. Upgrades and Modifications

Exploring possible enhancements that can improve performance or adapt to new farming needs.

9. Safety Considerations

Emphasizing the importance of safety protocols when operating and maintaining the machine.

10. Conclusion on Component Significance

A summary of how understanding the machinery’s structure contributes to successful farming practices.

11. Resources for Further Learning

Providing references and guides for readers seeking more information.

12. Final Thoughts on Agricultural Equipment

Encouraging readers to appreciate the intricacies of agricultural machinery and their vital role in modern farming.

| Heading | Description | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Introduction to Agricultural Machinery | Overview of equipment significance in farming. | |||||||||||||||||||||

| 2. The Importance of Component Knowledge | Crucial understanding for operation and troubleshooting. | |||||||||||||||||||||

| 3. Overview of the Machine’s Functionality | Description of how the equipment operates. | |||||||||||||||||||||

4. Key Elements of the Mechani

Key Components of the BalerThe efficient operation of a harvesting machine relies on several critical elements, each contributing to its overall functionality. Understanding these essential components is vital for maintaining optimal performance and ensuring longevity. These components work in harmony to process material effectively. Below is a detailed overview of the key elements that comprise this machinery.

Functionality of the Baling MechanismThe efficiency of the baling apparatus is pivotal for the seamless operation of agricultural processes. This mechanism is designed to compact and bundle various types of materials, such as hay or straw, into manageable forms. By employing a series of components that work in unison, it ensures the creation of uniform bales that are easy to handle and transport. Central to this functionality is the innovative design that facilitates the movement of raw material through the system. As the feed is drawn in, it undergoes a process of compression, where specialized elements exert pressure to mold the material into a desired shape. This process not only enhances storage capabilities but also optimizes the efficiency of subsequent handling and distribution. Furthermore, the use of advanced mechanisms allows for adjustments in size and density, catering to various operational requirements. This versatility is essential for farmers who need to adapt their methods based on the specific characteristics of the material being processed. Overall, the effective operation of this system contributes significantly to the productivity and success of agricultural endeavors. Maintenance Tips for LongevityEnsuring the durability and efficiency of agricultural machinery requires regular upkeep and attention. Implementing a systematic maintenance routine not only enhances performance but also extends the lifespan of the equipment. By focusing on key practices, operators can prevent unexpected breakdowns and costly repairs. Regular InspectionsConduct frequent evaluations of the machinery to identify wear and tear. Pay close attention to components that experience significant stress during operation. Early detection of issues can lead to timely repairs, reducing the risk of extensive damage. Lubrication and CleaningProper lubrication of moving parts is essential for optimal function. Use high-quality lubricants to minimize friction and prevent overheating. Additionally, keep the equipment clean to avoid the accumulation of debris, which can hinder performance and lead to mechanical failures. Common Issues with Baler PartsWhen operating agricultural machinery, various complications may arise that hinder efficiency and performance. Understanding these frequent challenges can help in maintaining optimal functionality and extending the lifespan of the equipment. This section explores the common problems encountered with components, providing insights into their causes and potential solutions. Worn or Damaged ComponentsOne of the most prevalent issues involves the deterioration of critical components over time. Frequent use can lead to wear and tear, resulting in reduced performance and efficiency. Regular inspections can help identify these problems early, allowing for timely replacements or repairs to prevent further damage. Misalignment and Adjustment IssuesImproper alignment of machinery parts can lead to operational inefficiencies and increased strain on the system. Regular maintenance and adjustments are essential to ensure all components work harmoniously. Failure to address misalignment can result in mechanical failures and costly repairs down the line. How to Read Parts Diagrams

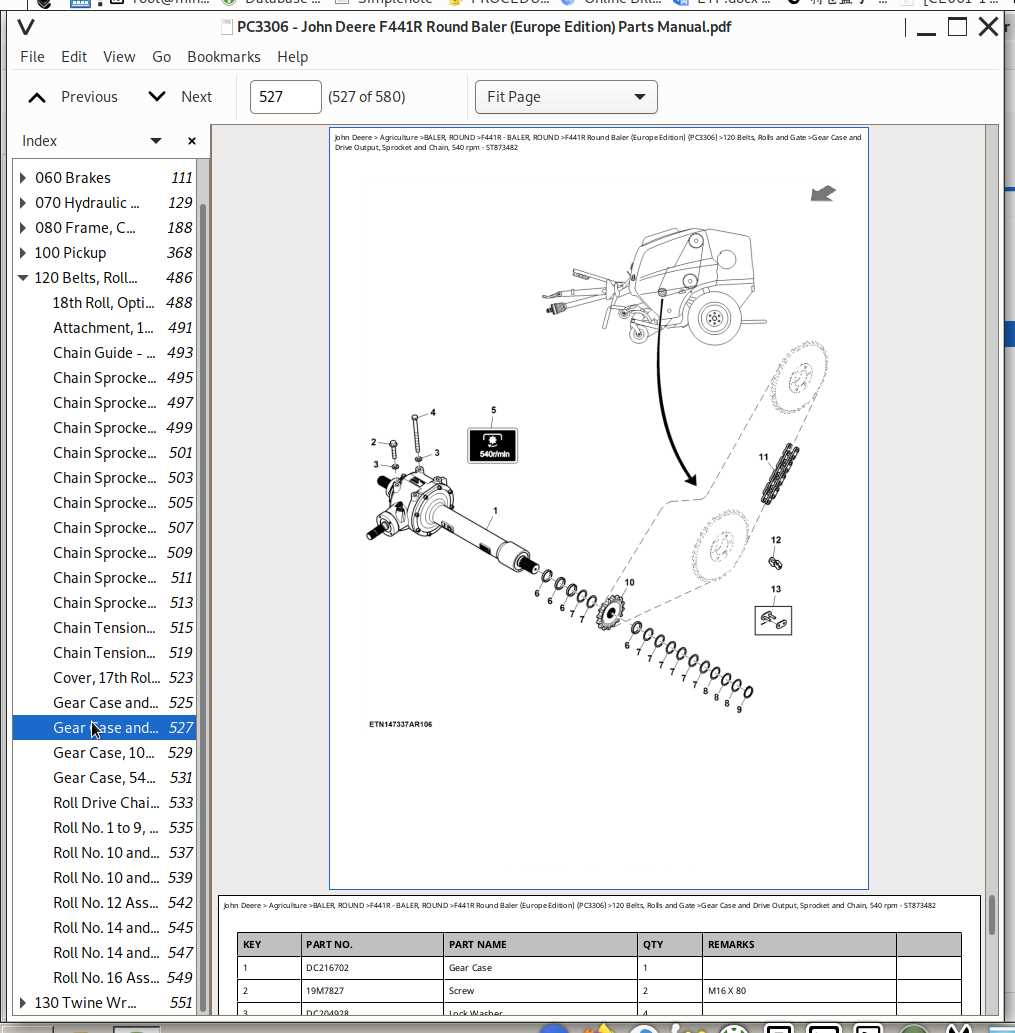

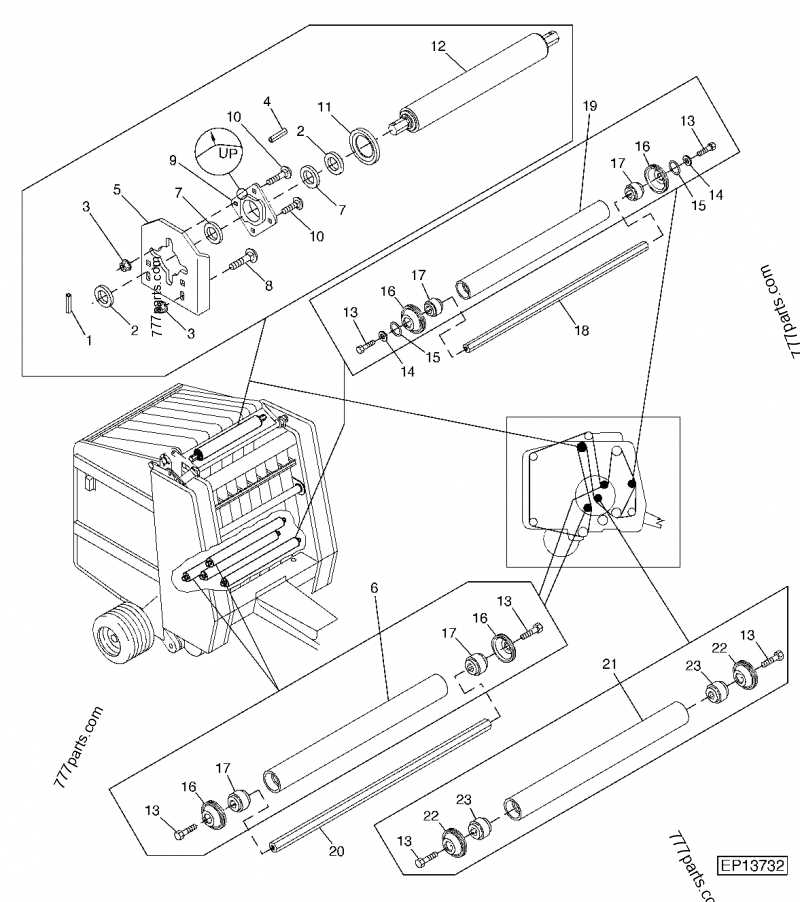

Understanding visual representations of components is crucial for efficient maintenance and repair tasks. These illustrations provide a comprehensive view of the assembly, highlighting the relationship between various elements and their specific functions. Mastering the interpretation of these visuals can significantly enhance your ability to troubleshoot and perform necessary adjustments effectively. Identifying Key ElementsStart by familiarizing yourself with the symbols and labels used within the illustration. Each symbol typically corresponds to a specific component or mechanism, while labels provide additional context. Pay attention to any accompanying numbers or letters, as these often refer to parts lists that further detail the items depicted. Understanding Assembly Order

Another critical aspect is recognizing the sequence in which components are assembled. The layout often reflects the order of installation, allowing you to visualize how each piece fits into the larger system. This knowledge is invaluable when it comes to disassembly and reassembly, ensuring a smooth workflow during maintenance tasks. Replacing Worn-Out Components

Maintenance is essential for the longevity and efficiency of agricultural machinery. Over time, certain elements of equipment may become damaged or degraded due to regular use. Identifying and replacing these worn-out components ensures optimal performance and prevents further complications down the line. Identifying Signs of WearRegular inspection is crucial to detect signs of wear early. Look for unusual noises, decreased functionality, or visible damage on the machinery. Components such as belts, bearings, and chains are often the first to show signs of stress. Noticing these indicators promptly can save time and resources in the long run. Steps for ReplacementWhen replacing outdated components, it is important to follow a systematic approach:

Following these steps not only enhances the efficiency of the machinery but also contributes to its overall lifespan. Importance of Regular InspectionsConducting routine evaluations of agricultural machinery is crucial for ensuring optimal performance and longevity. Regular checks not only help identify potential issues early but also contribute to the overall efficiency of operations. By prioritizing these assessments, operators can maintain high productivity levels and reduce unexpected downtimes. Consistent inspections provide numerous advantages, including:

Incorporating a routine inspection schedule into maintenance practices fosters a proactive approach to equipment care. Operators should establish a checklist to follow during evaluations, ensuring that all critical components are reviewed. By embracing this habit, users can ensure their machinery remains in peak condition throughout its lifespan. Essential Tools for RepairsWhen undertaking maintenance and repairs on agricultural machinery, having the right tools is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit not only facilitates the repair process but also helps in diagnosing issues quickly. From basic hand tools to specialized equipment, each item serves a unique purpose in the restoration and upkeep of these vital machines. Some of the most common tools include wrenches, sockets, and screwdrivers, which are essential for loosening and tightening various components. Additionally, pliers and cutting tools are useful for gripping and trimming materials. It is also advisable to have measuring devices, such as calipers and tape measures, to ensure precise adjustments. For more complex repairs, hydraulic jacks and lifting equipment provide the necessary support to access difficult areas safely. Ordering Genuine Replacement PartsAcquiring authentic components for your machinery is essential for maintaining optimal performance and longevity. Ensuring that you use the right elements not only enhances functionality but also guarantees safety during operation. This section delves into the importance of sourcing genuine items and provides guidance on how to obtain them effectively. Benefits of Authentic ComponentsUtilizing original components offers numerous advantages. First and foremost, they are designed specifically for your equipment, ensuring a perfect fit and seamless integration. Additionally, genuine items often come with warranties, providing peace of mind and financial protection. Investing in authentic replacements helps avoid issues that can arise from using substandard alternatives, such as reduced efficiency and increased wear and tear. Where to PurchaseTo acquire original components, it is advisable to reach out to authorized distributors or manufacturers. They provide comprehensive catalogs and can assist in identifying the exact items you need. Online platforms also offer convenience, with options to browse and order components directly. Always ensure that the supplier is reputable to guarantee the authenticity of the items. Comparison with Other Baler ModelsWhen evaluating different equipment designed for the efficient collection and compression of agricultural materials, it is essential to understand how various models stack up against one another. Each machine offers distinct features and functionalities that cater to specific needs, making it crucial for operators to compare them carefully. Key Features to ConsiderWhen examining the differences among various models, several characteristics should be prioritized:

Performance InsightsOperators often report variations in performance based on the machine’s design and engineering. Understanding these performance metrics can help in making informed decisions:

By considering these factors, operators can select the model that best meets their operational requirements and enhances productivity. Safety Guidelines for OperationEnsuring a secure environment during the operation of heavy machinery is paramount. Adhering to safety protocols minimizes the risk of accidents and injuries, fostering a productive work atmosphere. Operators must be vigilant and well-informed about the operational features and potential hazards associated with the equipment they handle. Pre-Operation ChecksBefore commencing any work, a thorough inspection of the machinery is essential. This includes checking for mechanical issues, ensuring all safety devices are functional, and confirming that the area is clear of obstacles. Operators should familiarize themselves with the user manual and safety instructions specific to the equipment in use. Proper Usage PracticesDuring operation, it is crucial to maintain focus and follow established procedures. Operators should avoid distractions, wear appropriate protective gear, and ensure that bystanders are at a safe distance. Regular breaks should be taken to prevent fatigue, which can lead to lapses in attention and increase the likelihood of mishaps.

Resources for Baler OwnersOwning and operating a hay compression machine requires access to reliable information and resources. Whether you are seeking maintenance tips, troubleshooting guides, or technical specifications, having the right materials at your fingertips can enhance performance and longevity. This section provides valuable insights into various resources available for individuals who utilize these agricultural implements. Online Forums and CommunitiesEngaging with fellow operators can offer practical advice and shared experiences. Consider joining online platforms where you can ask questions, share insights, and connect with others. Some popular options include:

Manufacturer Websites and DocumentationOfficial websites of equipment manufacturers often provide a wealth of information. Here are some features you can typically find:

Utilizing these resources can greatly assist in maintaining and optimizing your machinery for better performance and efficiency. |