Understanding the John Deere 7-Iron Commercial 72 Parts Diagram

The intricate machinery behind a high-performance mowing system is essential for achieving optimal results in landscaping and maintenance tasks. Understanding the various elements that contribute to its functionality allows operators to enhance efficiency and ensure longevity. This section delves into the specifics of a well-engineered cutting apparatus, focusing on the key components that work in harmony to deliver superior performance.

Each segment of this sophisticated device is designed with precision, playing a vital role in the overall operation. By familiarizing oneself with these elements, users can not only troubleshoot issues more effectively but also perform routine maintenance with greater confidence. A detailed exploration of these crucial features sheds light on how they interconnect to create a seamless mowing experience.

In addition to improving operational knowledge, recognizing the significance of each part encourages a proactive approach to care and upkeep. Whether you are a seasoned professional or a passionate hobbyist, a thorough understanding of the system’s anatomy will empower you to make informed decisions regarding repairs and enhancements, ultimately leading to a more rewarding experience in landscape management.

Understanding the John Deere 7-Iron

This section delves into the intricacies of a well-regarded mowing mechanism that has gained popularity among professionals. Its robust design and reliable performance make it a preferred choice for many. Knowing how it operates and the elements that contribute to its functionality is essential for optimal usage and maintenance.

Key Features and Benefits

The highlighted mowing unit boasts a durable construction, ensuring longevity even under rigorous conditions. Efficient cutting capabilities allow for a pristine finish on various grass types. Additionally, the design promotes ease of maneuverability, which is crucial for tackling expansive areas and intricate landscapes.

Maintenance Tips

Regular upkeep is vital for preserving the efficiency of this equipment. Ensure that components are checked frequently for wear and tear, and perform necessary adjustments to maintain peak performance. Keeping the blades sharp is particularly important, as it directly impacts the quality of the cut and overall health of the turf.

Key Features of 7-Iron Decks

The design of cutting decks plays a crucial role in achieving optimal performance for mowing equipment. These systems are engineered to enhance efficiency and durability, ensuring a consistent cut across various terrains. Understanding the key attributes of these cutting platforms can help users make informed decisions about their equipment needs.

Durability and Construction

One of the standout characteristics of these decks is their robust construction. Crafted from high-quality materials, they are designed to withstand harsh conditions and heavy use. This strength not only extends the lifespan of the mower but also minimizes the need for frequent repairs, ultimately saving time and resources.

Cutting Efficiency

These cutting platforms are designed for superior performance, featuring advanced blade configurations that optimize grass clipping. The unique design promotes even distribution of clippings, leading to a cleaner finish and healthier lawn. Additionally, the aerodynamic shape enhances airflow, which contributes to an effective cutting experience.

With features focused on both durability and efficiency, these systems are ideal for both residential and commercial applications, ensuring that users can achieve the best results with every mow.

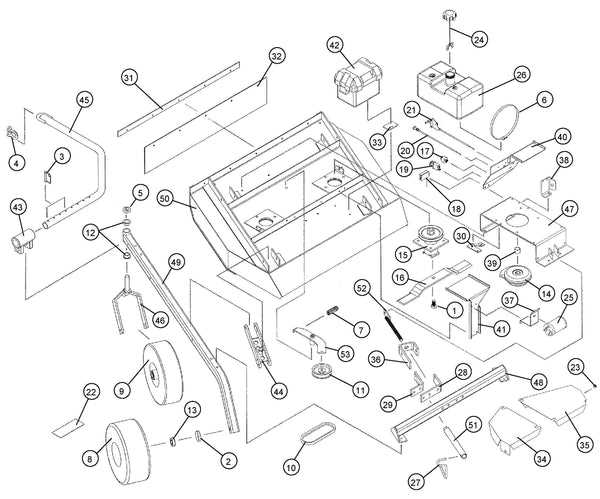

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, offering clarity and precision in identifying each element’s role and location. By examining these visual aids, technicians can enhance their efficiency and minimize errors during servicing.

Comprehension of complex systems is significantly improved through the use of these illustrations. They break down the overall structure into manageable sections, allowing users to grasp how individual pieces interact within the whole. This ultimate knowledge not only aids in troubleshooting but also fosters a deeper appreciation for the equipment’s design.

Moreover, these representations facilitate communication among team members, ensuring everyone is aligned in their understanding. This collaborative approach can lead to faster problem resolution and better overall performance of the machinery. In essence, the utilization of such visual tools is integral to successful equipment management.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as maps, guiding users through the assembly and connection of various elements within a system.

Begin by familiarizing yourself with the legend or key, which explains the symbols and notations used. This will help clarify the relationships between different pieces. Pay attention to the layout, as it often indicates the order of assembly or disassembly, revealing how components interact.

Next, look for reference numbers or labels that correspond to descriptions in accompanying documentation. This dual approach allows you to cross-check information and ensures accuracy in identifying each part.

Finally, practice makes perfect. Regularly reviewing such visuals will enhance your ability to interpret them quickly and accurately, ultimately improving your overall efficiency in tackling repairs.

Common Issues with 7-Iron Parts

In the realm of turf management, specific components often face recurring challenges that can impact performance and durability. Understanding these common problems is essential for maintenance and ensuring optimal functioning of equipment.

Frequent Malfunctions

Components can experience wear and tear over time, leading to diminished efficiency. Issues such as improper alignment, fatigue cracks, and corrosion are often reported. Regular inspection can help in identifying these problems early, minimizing costly repairs.

Maintenance Tips

Routine care is vital for extending the lifespan of equipment. Lubrication, cleaning, and timely replacement of worn elements can prevent many common issues. It is advisable to refer to maintenance manuals for specific recommendations tailored to each component.

| Issue | Description | Solution |

|---|---|---|

| Corrosion | Rust formation on metal surfaces due to exposure. | Regular cleaning and application of protective coatings. |

| Misalignment | Components not correctly positioned, leading to uneven wear. | Adjustment and realignment as per manufacturer guidelines. |

| Fatigue Cracks | Cracks develop from repeated stress over time. | Regular inspections and replacement of affected parts. |

Replacement Parts for 72-Inch Deck

Maintaining a well-functioning cutting platform is essential for optimal performance and longevity. When components wear out or become damaged, timely replacement ensures that the machinery operates smoothly and efficiently. Understanding the necessary elements for a 72-inch cutting system can greatly enhance its productivity and durability.

Common Components to Consider

- Blades

- Spindles

- Belts

- Deck Shell

- Idler Pulleys

Each of these components plays a vital role in the overall function of the deck. Regular inspection and prompt replacement of any worn or damaged parts can prevent more significant issues down the line.

Finding Quality Replacements

- Identify the specific part needed for replacement.

- Check for compatibility with the existing system.

- Purchase from reputable suppliers to ensure quality.

- Consider OEM options for the best fit and performance.

By prioritizing high-quality replacements, users can extend the life of their equipment and maintain peak performance throughout its operational life.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of your machinery, saving you time and money in the long run. By following a structured approach to upkeep, you can prevent potential issues and maintain peak functionality.

Regular Cleaning

Keeping your equipment clean is essential for preventing wear and tear. Debris and dirt accumulation can lead to corrosion and malfunction. After each use, take the time to remove any grass clippings, dust, or mud. Use appropriate cleaning tools to ensure every component is free from buildup.

Scheduled Inspections

Conducting routine checks on vital parts will help you identify problems early. Focus on areas such as blades, belts, and filters. Replace worn components promptly to avoid more significant repairs later. An annual professional inspection can also provide insights that may not be apparent during regular checks.

Choosing the Right Blades

Selecting the appropriate cutting implements is crucial for achieving optimal performance in turf maintenance. The right tools not only enhance the efficiency of mowing but also ensure a healthier lawn by providing a clean cut. Understanding the various options available can greatly impact the results of your landscaping efforts.

Types of Blades

There are several types of cutting implements designed for different tasks. Standard blades are ideal for routine mowing, while mulching blades provide finer clippings that decompose quickly, enriching the soil. For tough, overgrown areas, high-lift blades may be necessary, as they excel in lifting grass and expelling clippings more effectively.

Material Considerations

The composition of the blades also plays a significant role in their performance and longevity. Steel blades are popular for their durability, but coated options can offer increased resistance to rust and wear. When selecting blades, consider both the material and the specific requirements of your mowing environment to ensure you achieve the best possible results.

Tools Needed for Repairs

Proper maintenance and repair of outdoor equipment require a specific set of tools to ensure efficiency and effectiveness. Having the right instruments at hand can significantly simplify the repair process, minimizing downtime and enhancing performance.

Before starting any maintenance task, it’s essential to gather the following tools:

- Wrenches: Various sizes for tightening and loosening bolts.

- Screwdrivers: Both flathead and Phillips types for different screw heads.

- Socket set: For quicker access to nuts and bolts in tight spaces.

- Pliers: Useful for gripping and twisting wires or small parts.

- Torque wrench: To ensure fasteners are tightened to the correct specifications.

- Wire cutters: For cutting and stripping wires as needed.

- Oil can: Essential for lubricating moving parts.

- Measuring tape: To measure components accurately during repairs.

Having these essential tools readily available not only streamlines the repair process but also ensures that tasks are performed correctly and safely. Regular checks of tool conditions can further enhance your repair efficiency.

Where to Buy Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Whether you’re looking for original items or high-quality alternatives, knowing where to source them is essential for any operator.

Online Retailers

Many websites specialize in offering a wide range of components. These platforms often provide detailed descriptions and customer reviews, allowing you to make informed decisions. Look for sites that guarantee authenticity and have a robust return policy to ensure satisfaction.

Local Dealerships

Visiting nearby distributors can be beneficial, as they typically stock genuine items. Engaging with knowledgeable staff can also help you identify the best options for your specific needs. Additionally, local businesses may offer personalized services, including installation advice.

Understanding Warranty Coverage

Warranty coverage plays a crucial role in the ownership experience of any machinery or equipment. It provides peace of mind, ensuring that any manufacturing defects or issues encountered during the stipulated period are addressed without incurring additional costs. This section explores the key elements of warranty policies, helping users make informed decisions regarding their investments.

Key Components of Warranty Policies

- Duration: Warranty periods can vary significantly, often ranging from one year to several years. Understanding the specific time frame helps in planning maintenance and potential repairs.

- Coverage Limits: Not all issues are covered under a warranty. Familiarize yourself with what is included, such as parts replacement, labor, and specific conditions that may void the warranty.

- Transferability: Some warranties can be transferred to new owners, which may increase the resale value of the equipment. Check if this option is available.

- Service Requirements: Certain warranties stipulate regular maintenance or inspections. Adhering to these requirements is essential to maintain coverage.

Maximizing Warranty Benefits

- Documentation: Keep all purchase and service records organized. These documents are vital in the event of a claim.

- Regular Maintenance: Follow the manufacturer’s recommendations for upkeep. Regular servicing can prevent issues and ensure compliance with warranty terms.

- Contact Information: Maintain up-to-date contact details for the manufacturer or dealer to facilitate prompt service and support when needed.